Patents

Literature

34results about How to "Does not affect water flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

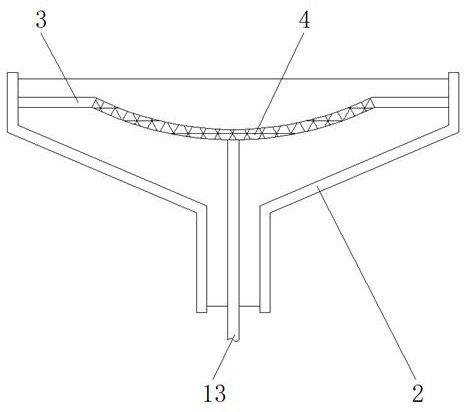

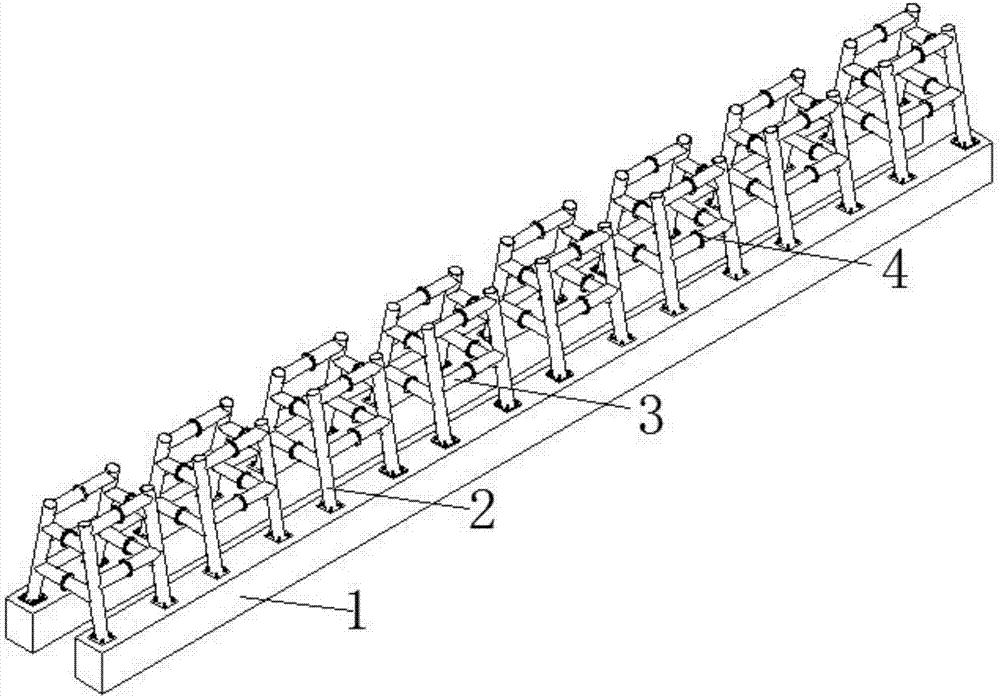

Ship propeller protection net

InactiveCN102267553AEnsure driving safetyBlock the impactPropulsive elementsForeign matterSafety net

The invention discloses a marine propeller protection net, which comprises a net cover arranged on the periphery of the propeller and connected with the bottom of the hull; The protective net at the bottom of the propeller, the protective net at the bottom of the propeller and the rear protective net of the propeller are connected to each other and are respectively connected to the bottom of the hull; the present invention arranges a net cover around the propeller of the ship, which does not affect the effect of the water flow and the propeller, and can block the impact of foreign objects The propeller, and debris such as weeds or fishing nets are not easy to touch the propeller, and it is not easy to wrap around the propeller, which ensures the life of the propeller and the safety of the ship.

Owner:金海

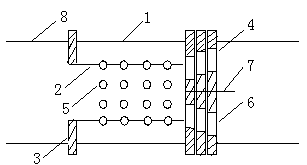

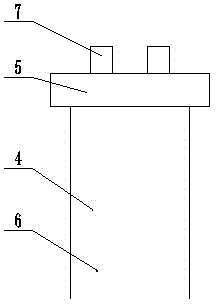

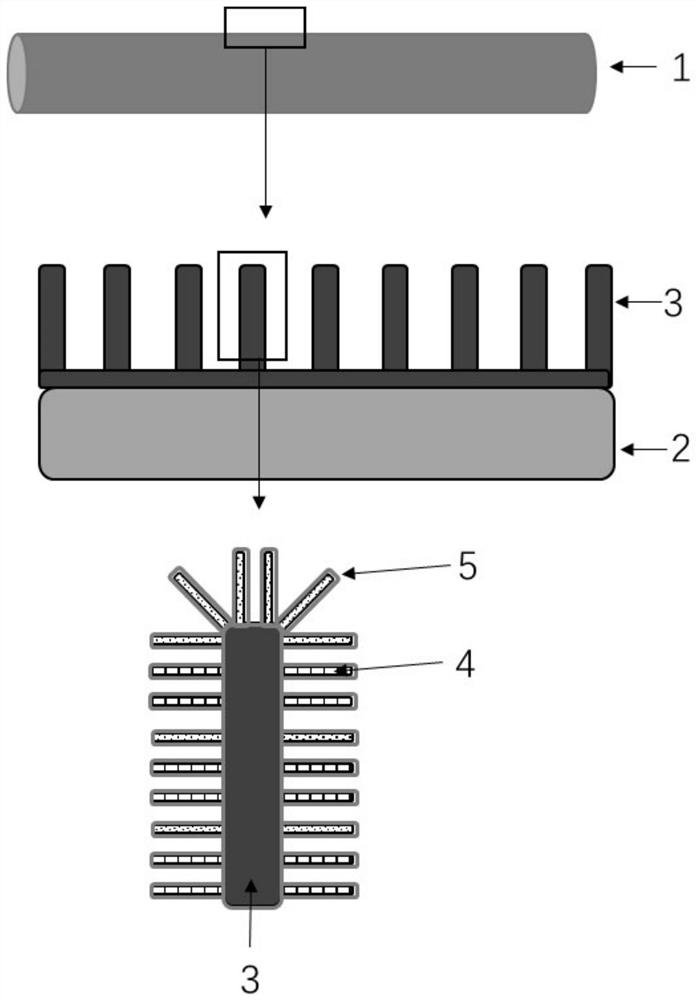

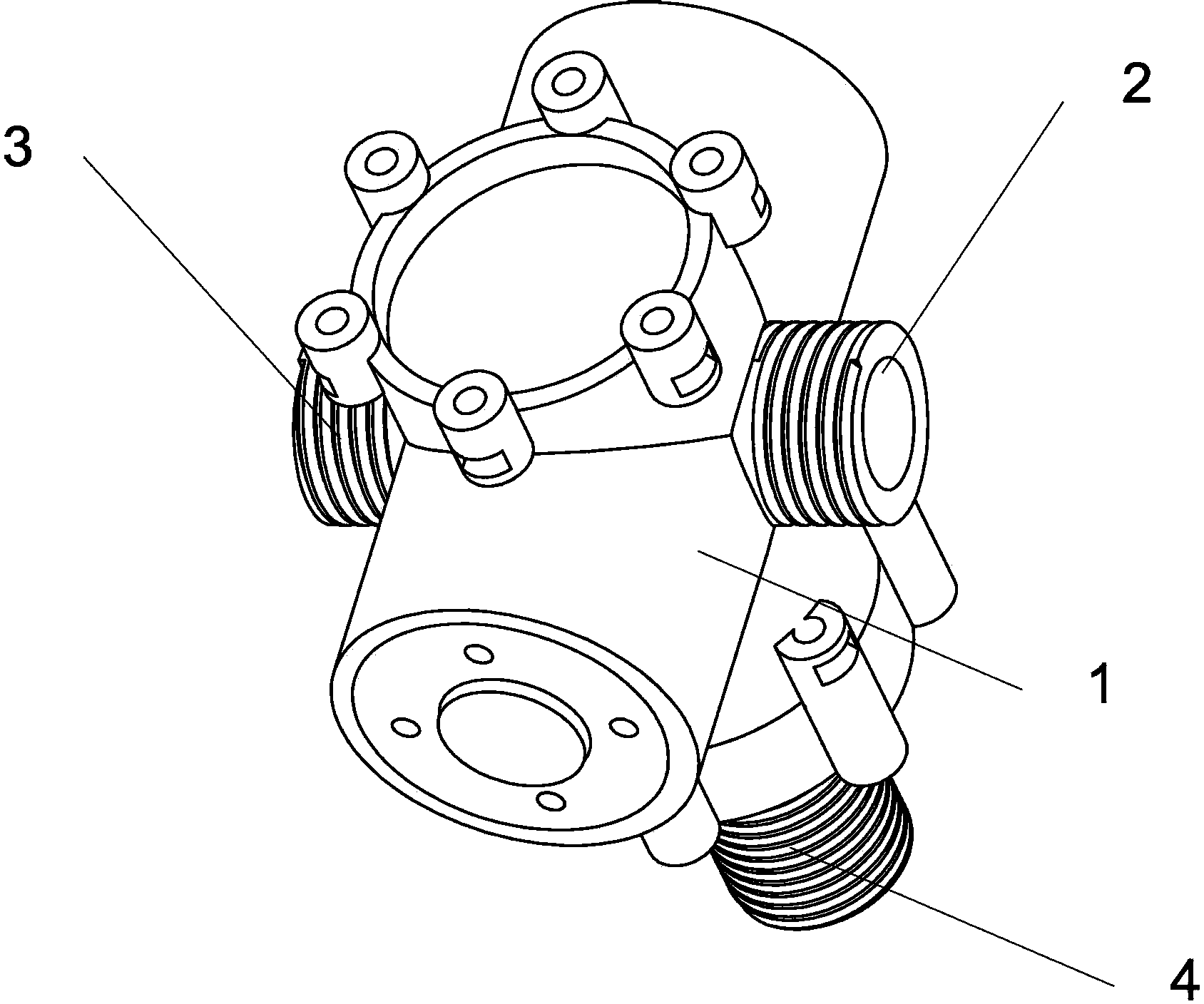

Hole plate mixed spiral flow pipeline energy dissipating device

InactiveCN102705626ALarge adjustment rangeOvercoming Vibration DeficienciesPipe elementsRotational axisEngineering

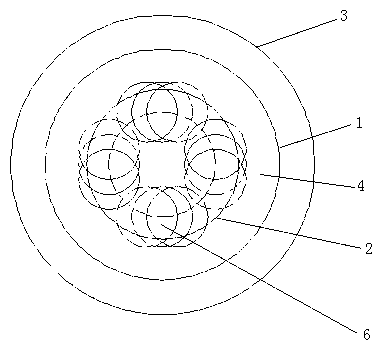

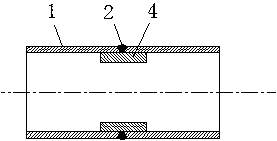

The invention relates to a hole plate mixed spiral flow pipeline energy dissipating device which belongs to the technical field of pipeline water transmission and is characterized in that the hole plate mixed spiral flow pipeline energy dissipating device is in a screen mesh type. The hole plate mixed spiral flow pipeline energy dissipating device consists of an outer pipe 1, an inner pipe 2, a flange 3, a hole plate 4, inclined holes 5, non-inclined holes 6 and a rotating shaft 7, wherein the outer pipe 1 is concentrically connected with the inner pipe 2 through the flange 3, the inclined holes 5 are symmetrically and uniformly formed around the inner pipe 2 in accordance with inclination angles, the inner pipe 2 is connected with the first hole plate 4, the hole plates 4 are connected through the rotating shaft 7 which coincides with the central axis of the outer pipe 1, and each non-inclined hole 6 is formed on each hole plate 4 in the axis direction. According to the hole plate mixed spiral flow pipeline energy dissipating device, the adjusting range of pipeline energy dissipation is greatly increased in a condition that the water transmission flow is not affected, so that the axial and circumferential force balance of the energy dissipating device is realized, the defect of pipe vibration in the process of energy dissipation is completely overcome, the safety and stability of a water transmission system are guaranteed, and the service life is prolonged.

Owner:TAIYUAN UNIV OF TECH

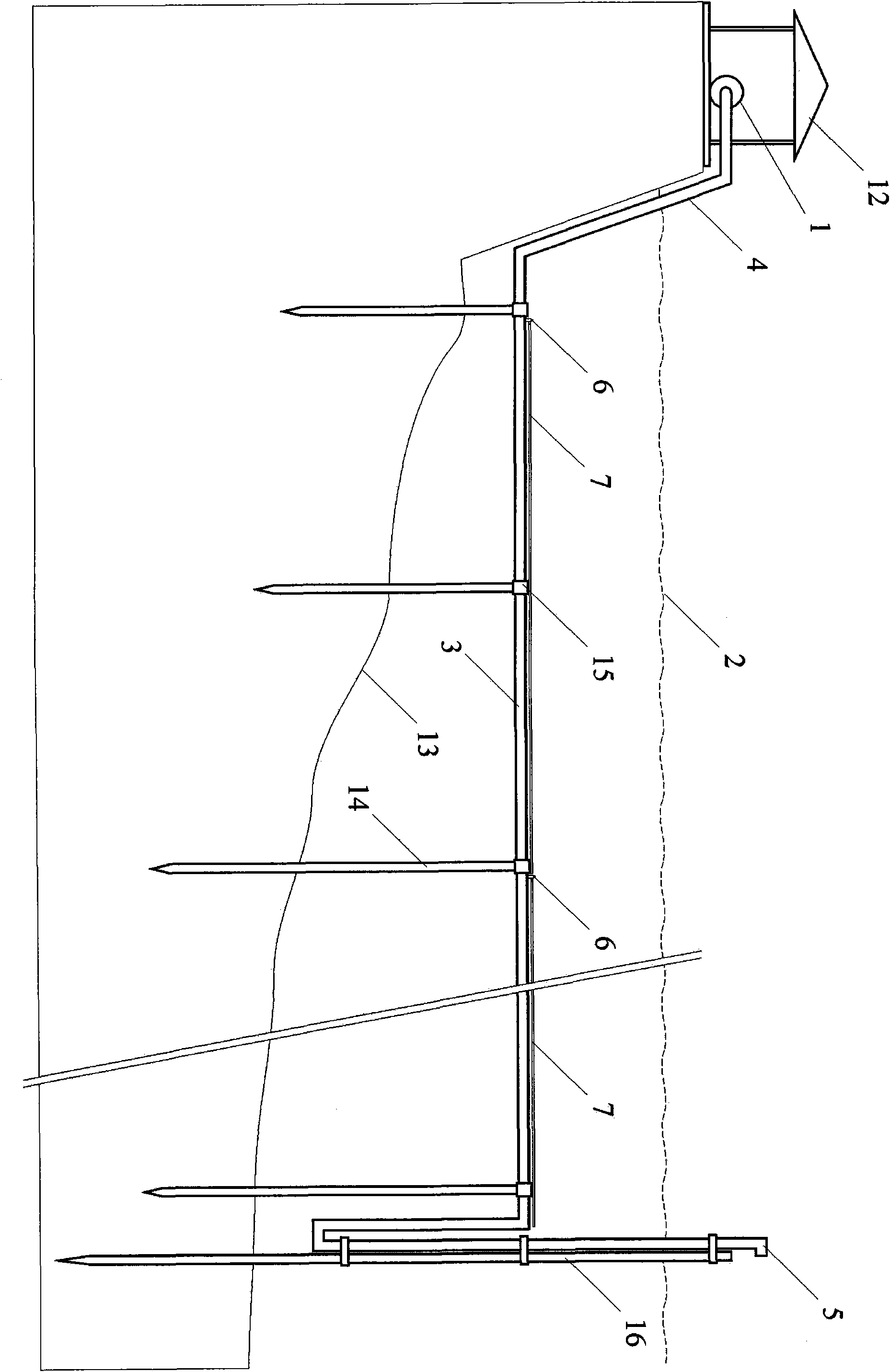

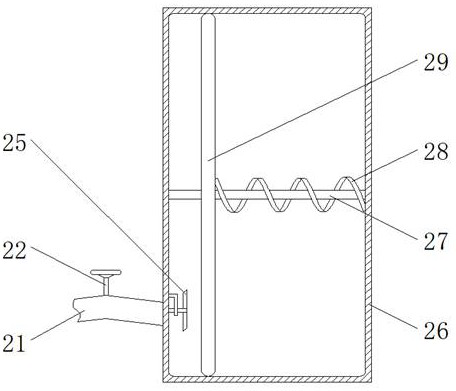

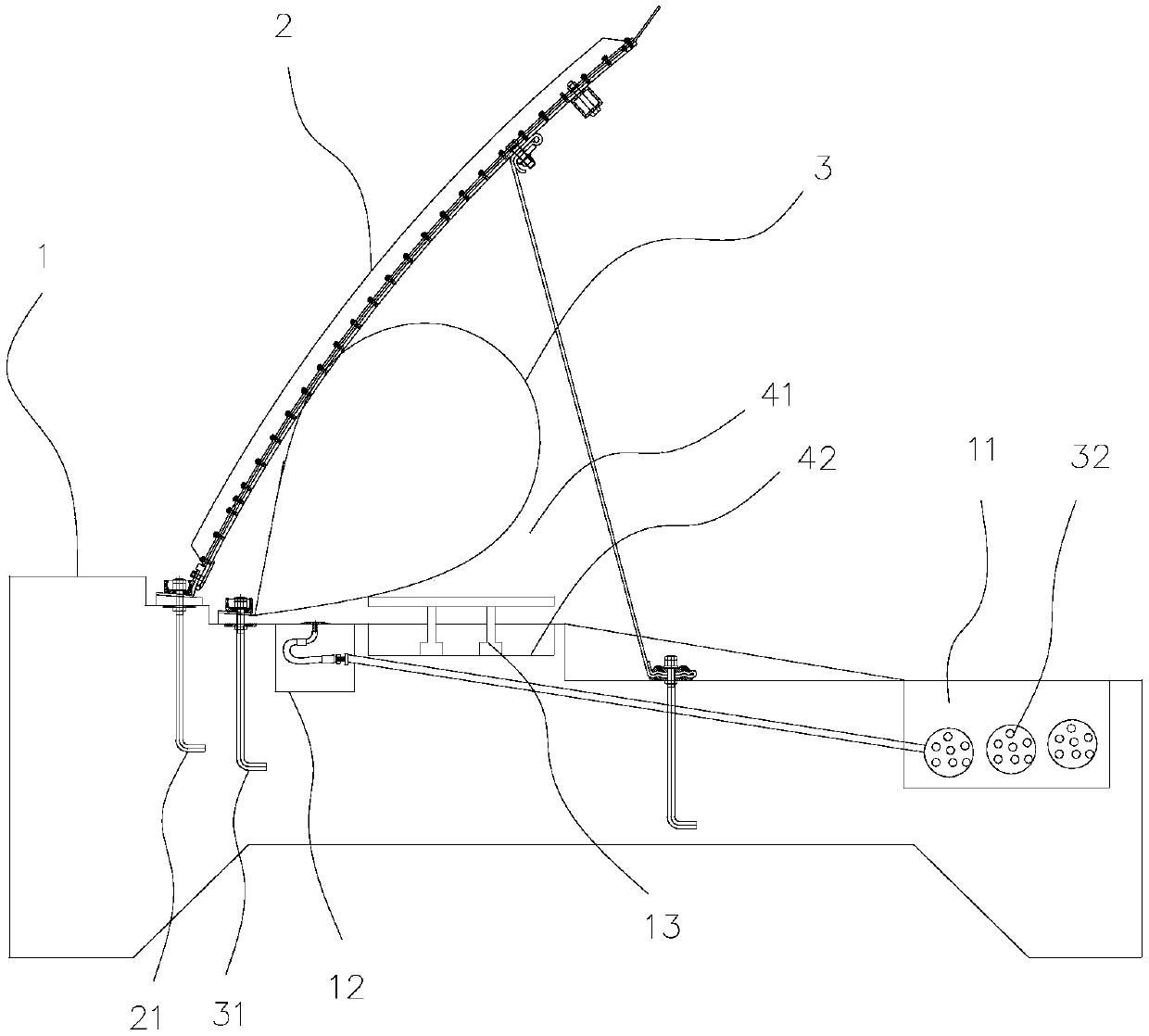

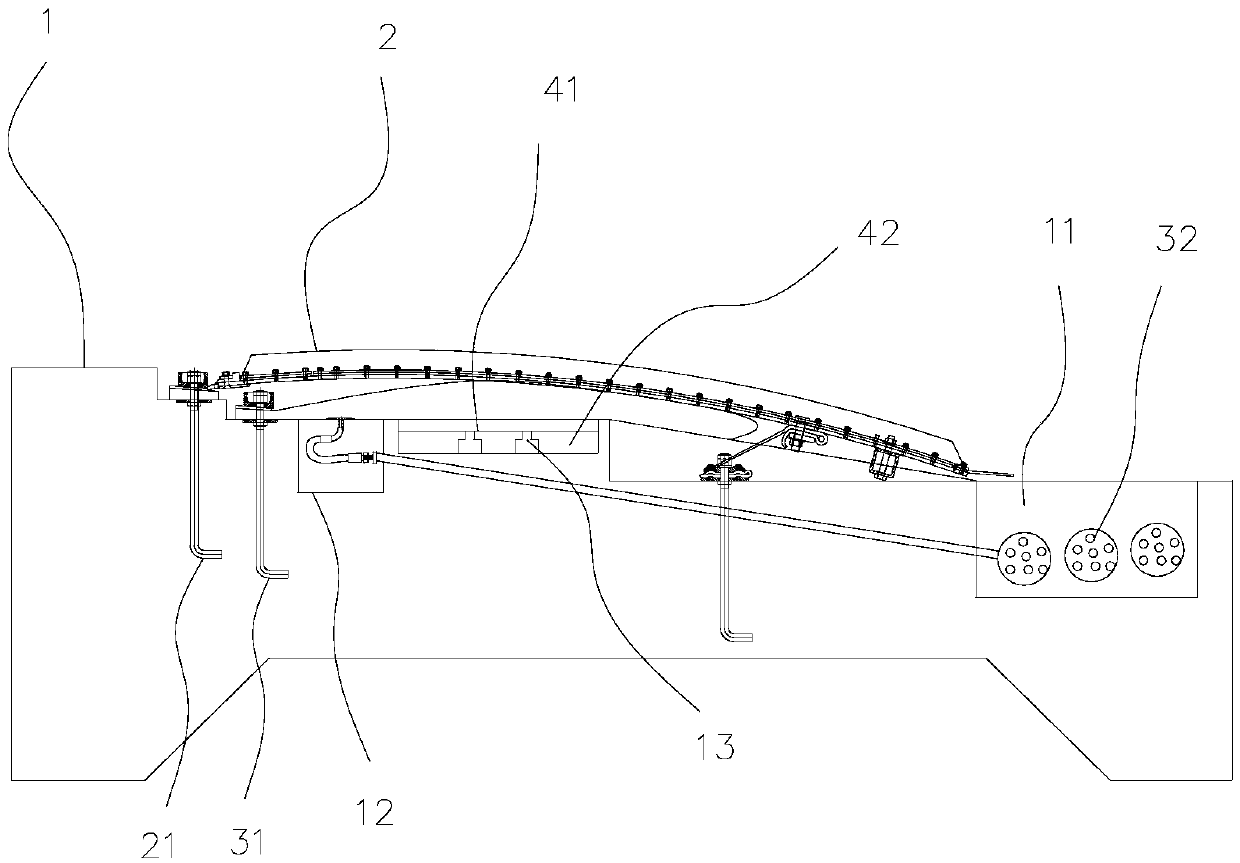

Aquatic air curtain intercepting method and device

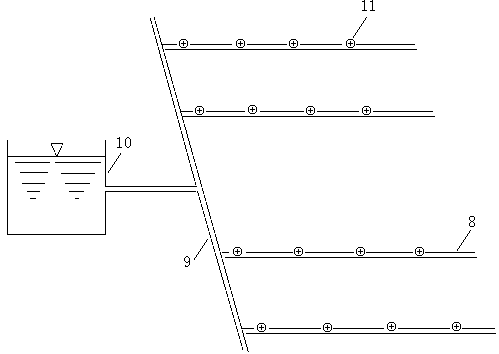

InactiveCN101967814ADoes not affect water trafficDoes not affect water flowWater cleaningWater qualityWater reservoir

The invention discloses a method and a device for intercepting floating pollutants in a low-flow water body by using aquatic air curtain. The aquatic air curtain device consisting of a fan, a gas pipeline, a U-shaped drainage tail pipe, a branched pipe interface, a micropore aeration branched pipe and the like is horizontally arranged at the depth of about 1.5 meters under the water surface in a water bottom fixed mode or a water surface suspension mode, and vertical rising curtain gas-water flow is formed in the water body by strip micropore aeration to cut off wind-generated laminar flow of the surface of the water body and intercept floating blue algae and garbage sundries carried by the wind-generated laminar flow on the windward or upstream side. An 'invisible' water body floating pollutant intercepting defense line can be built by using the technology and is used for intercepting, guiding and enriching the pollutants such as floating algae, greasy dirt, garbage sundries, weeds and the like in the low-flow water bodies of inland lakes, reservoirs, ponds and the like, in particular intercepting the floating pollutants such as water intakes of urban waterworks. The building expense of the 1km aquatic air curtain intercepting facility is less than 1 million yuan, the running power is less than 20kw, and the aquatic air curtain intercepting facility can be started and closed at any time as required, is not affected by wind waves and ships, does not affect water flow, water quality, water body landscape and ecology, and has over 10 years of service life.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

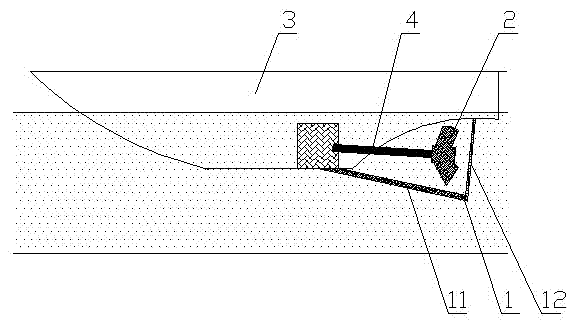

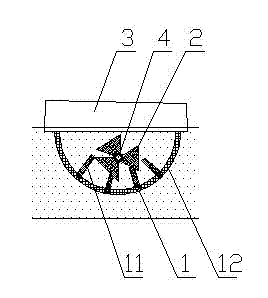

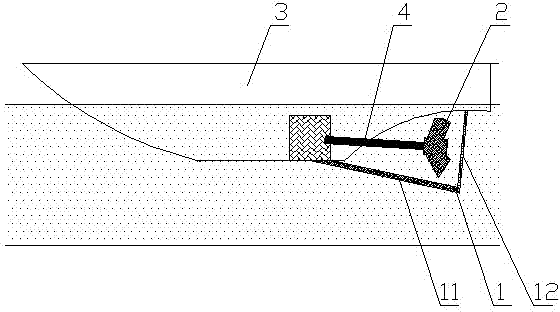

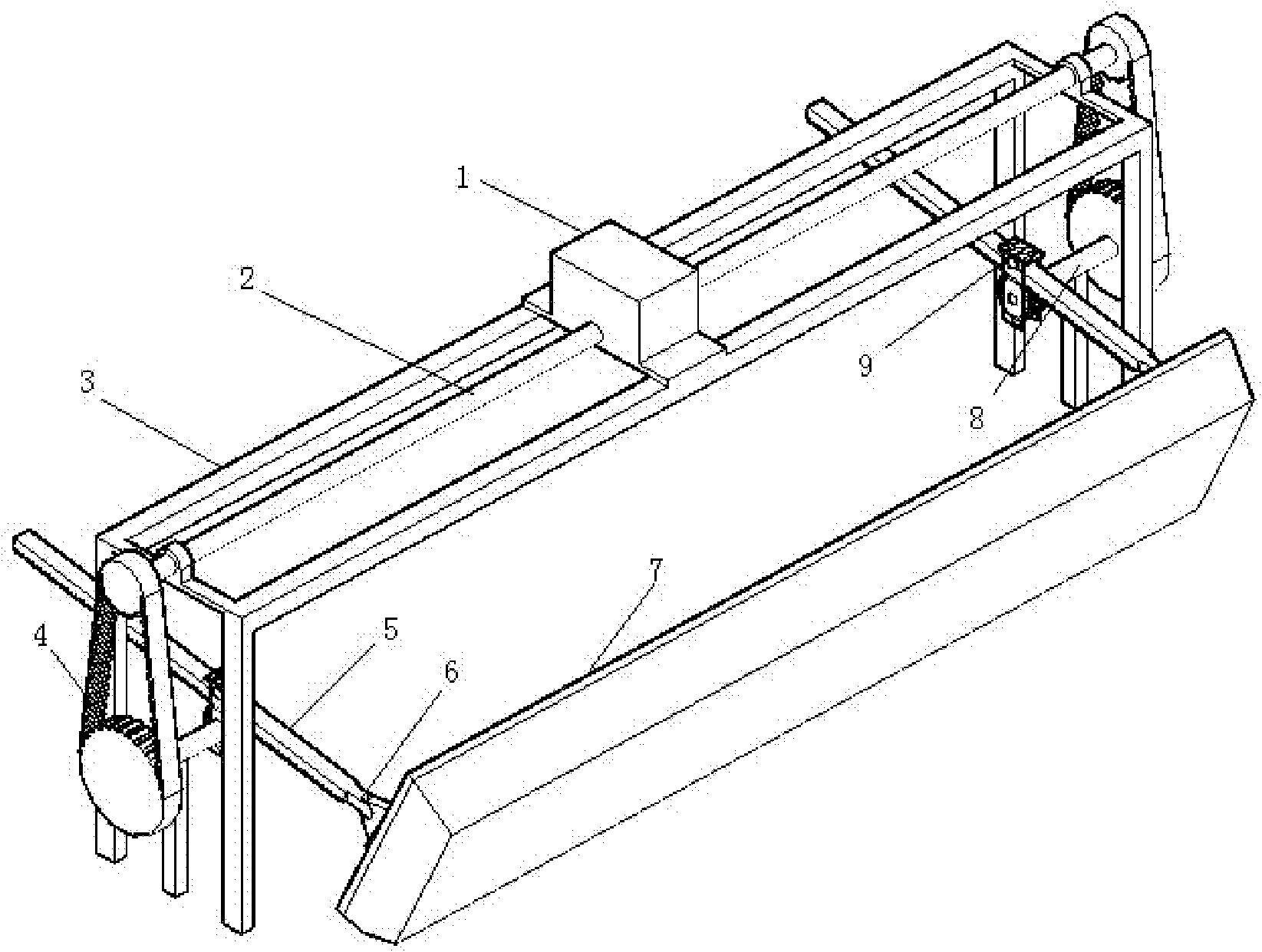

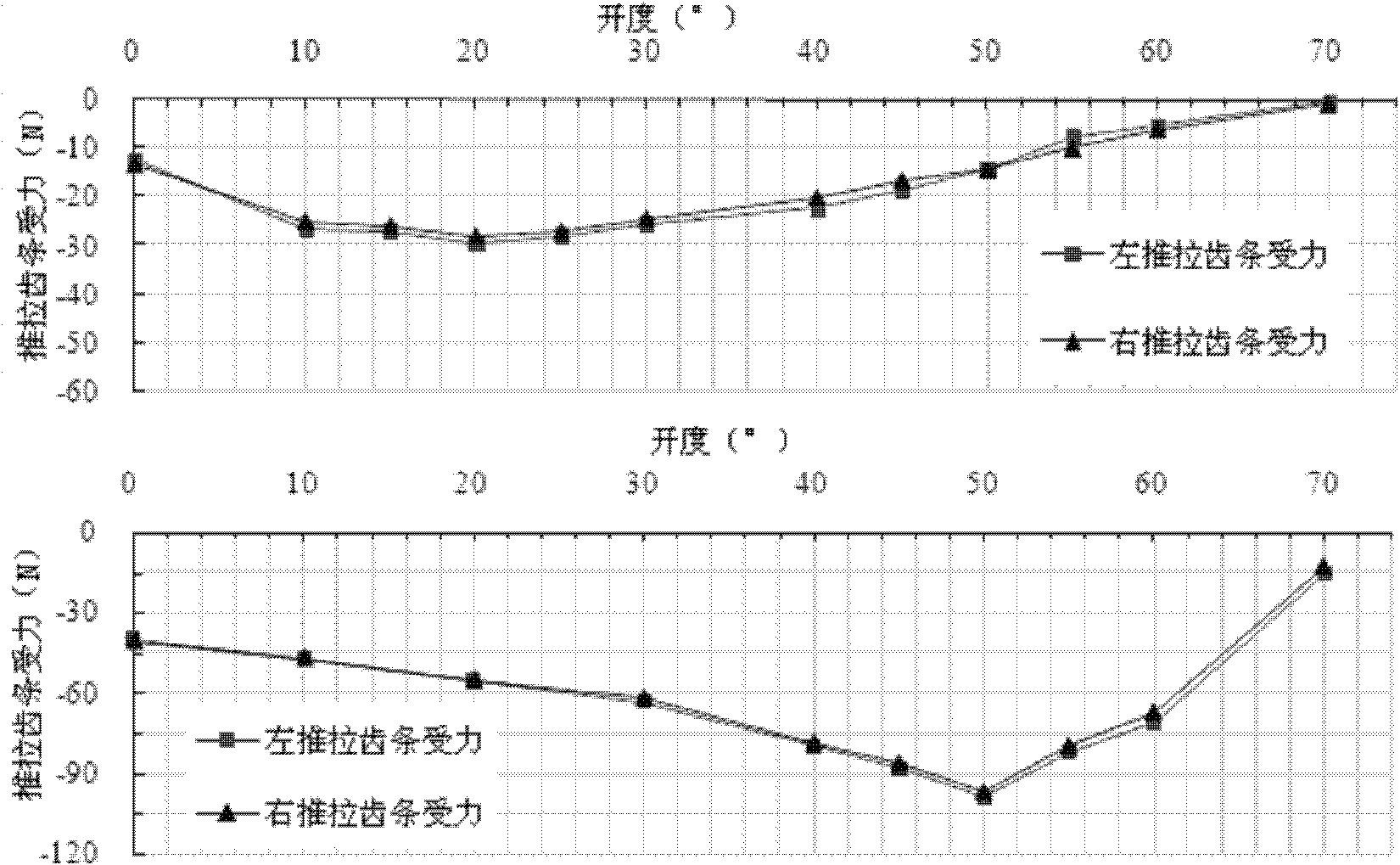

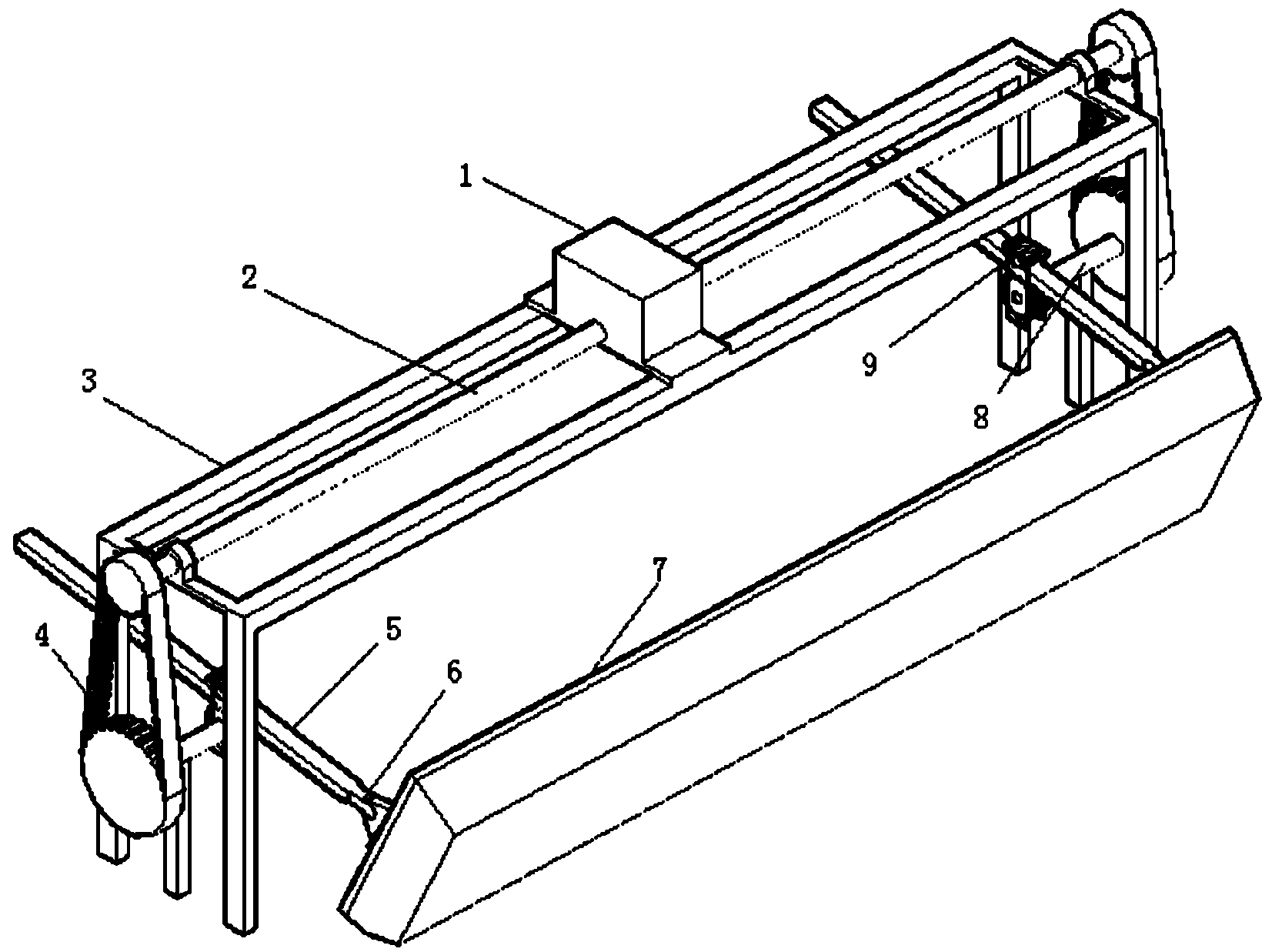

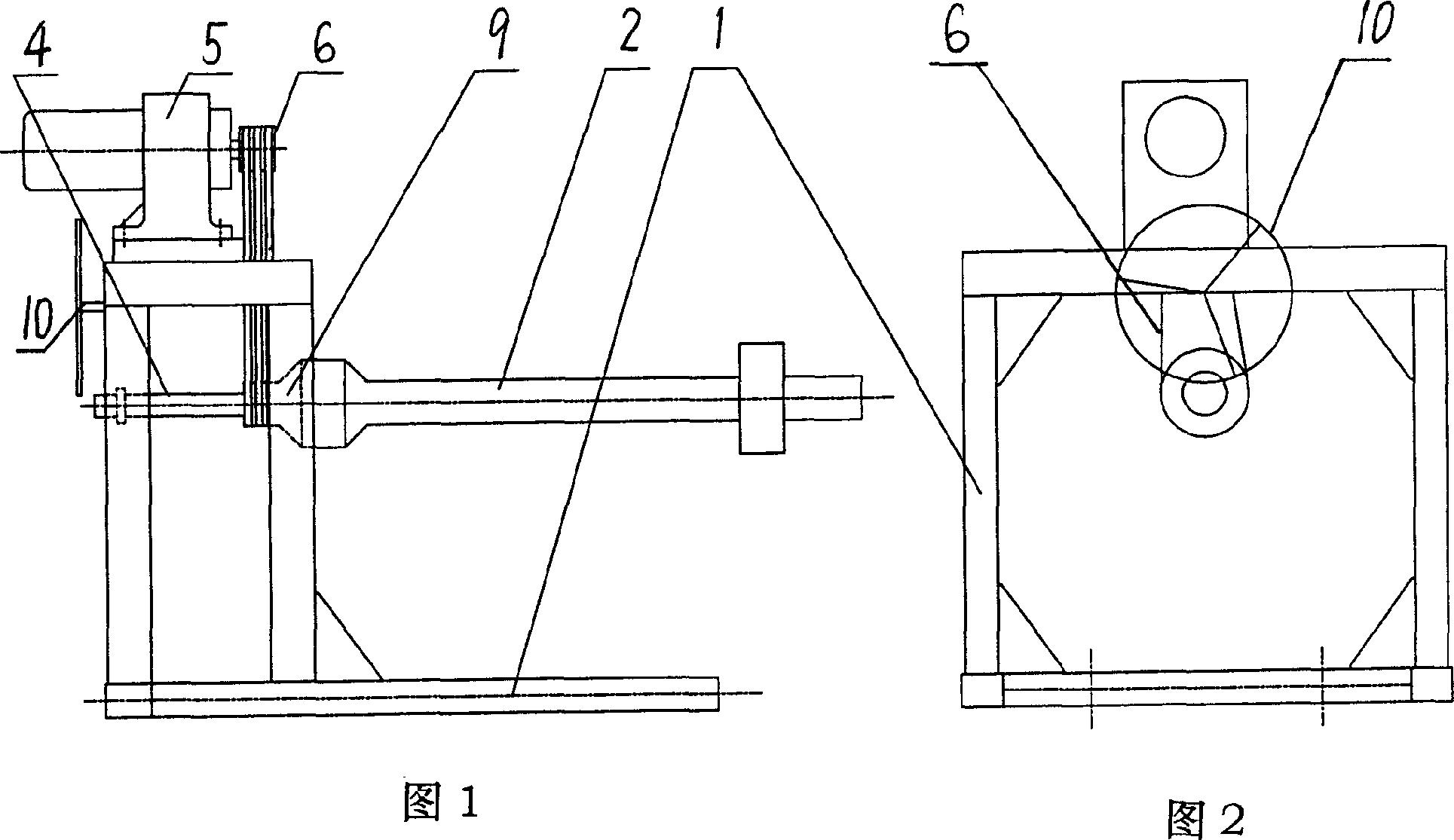

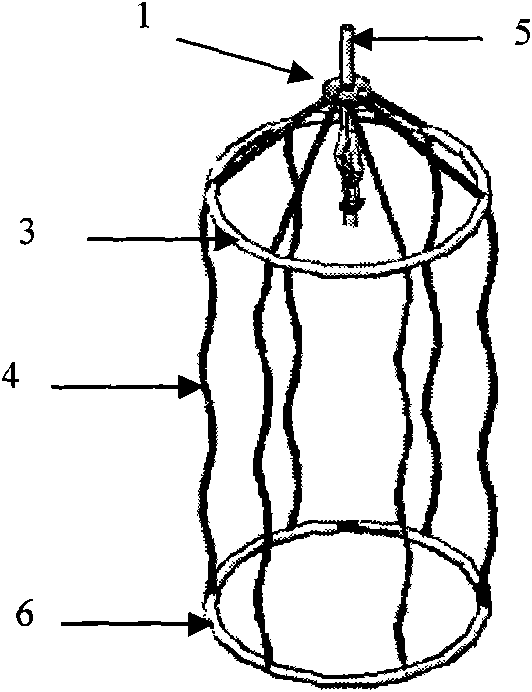

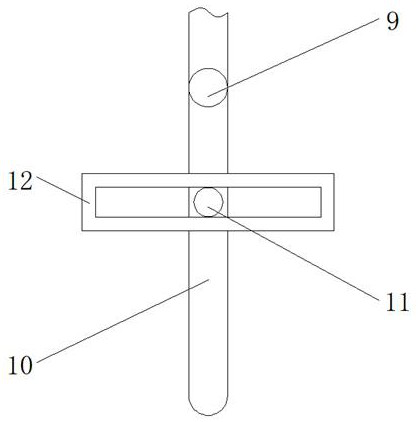

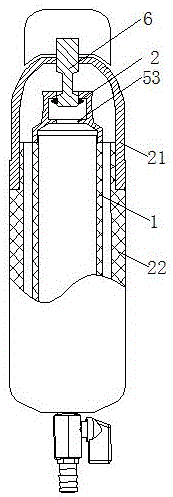

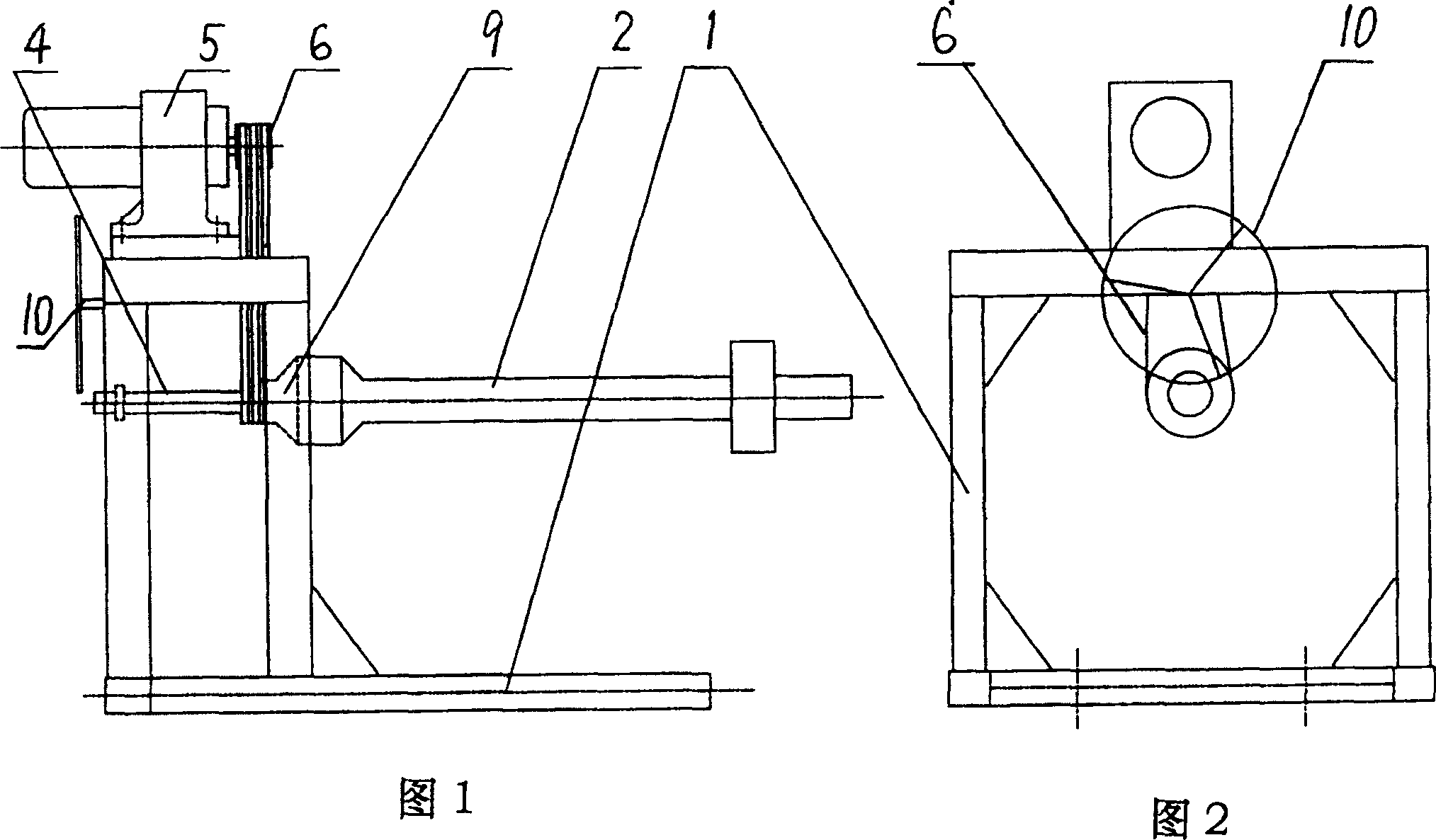

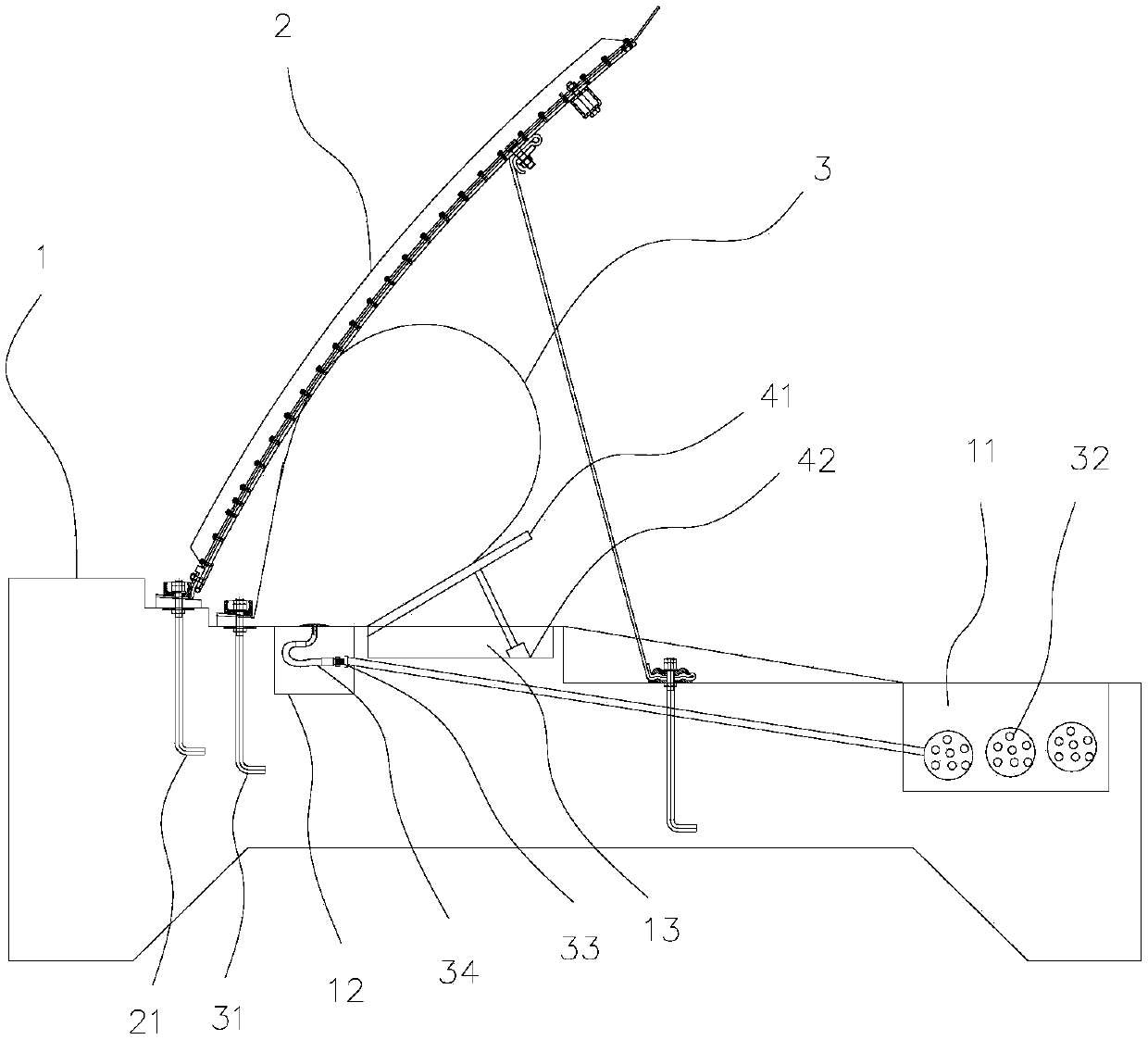

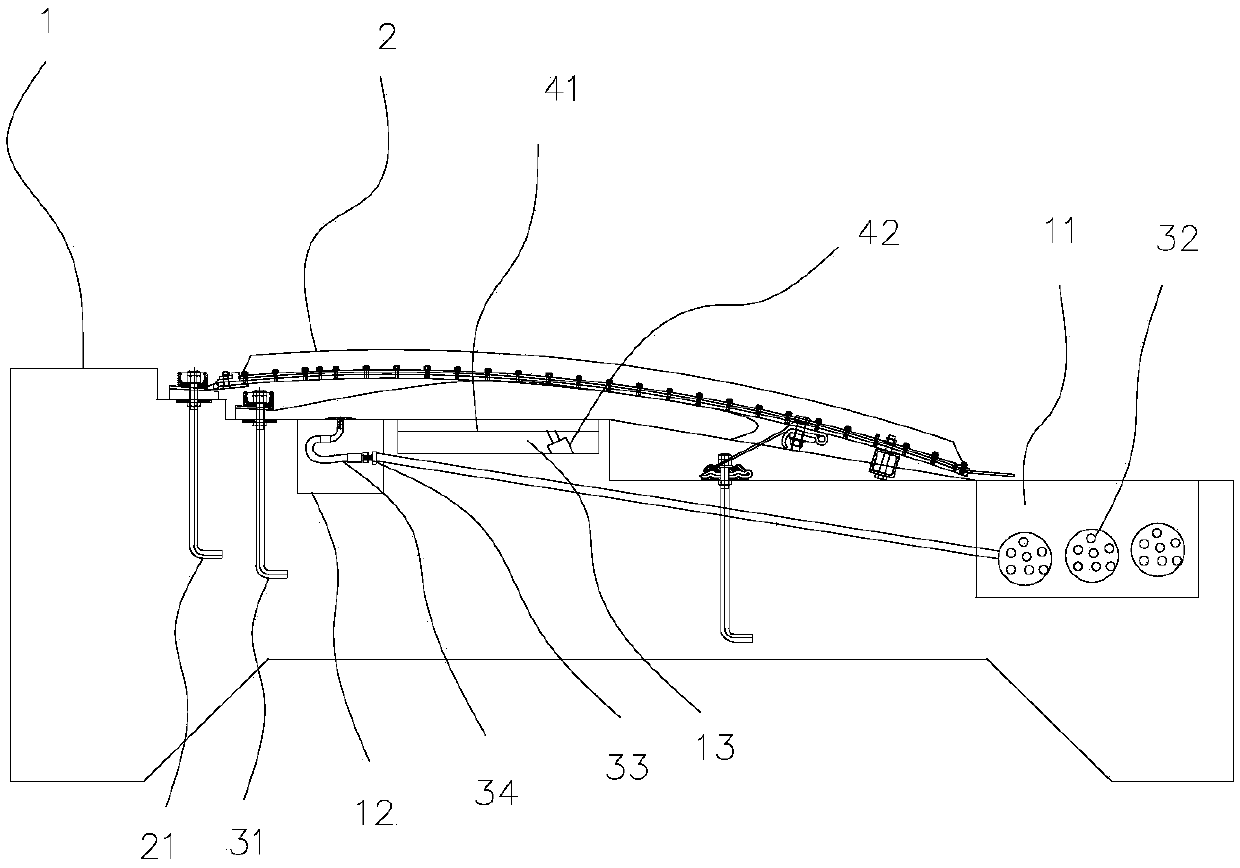

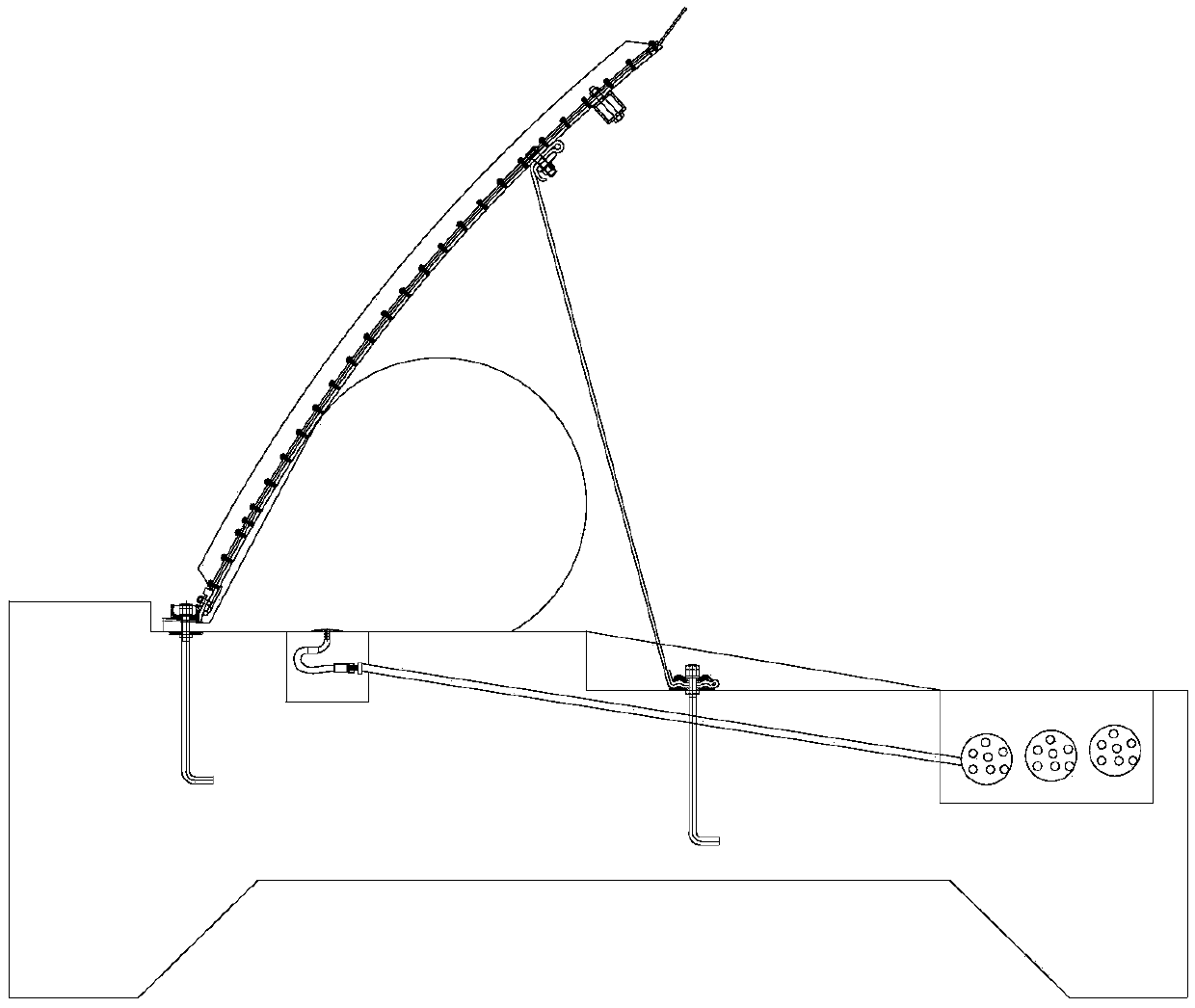

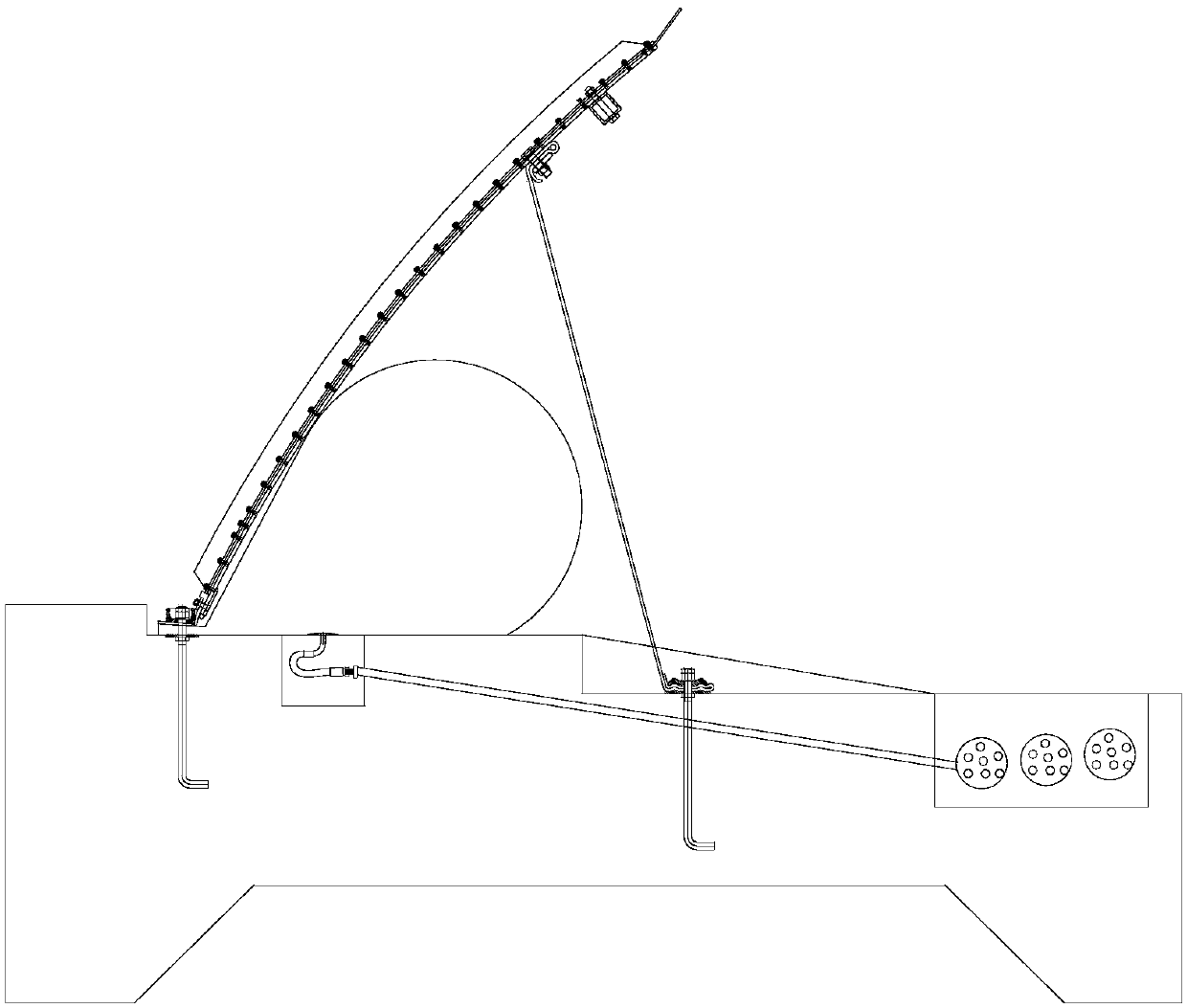

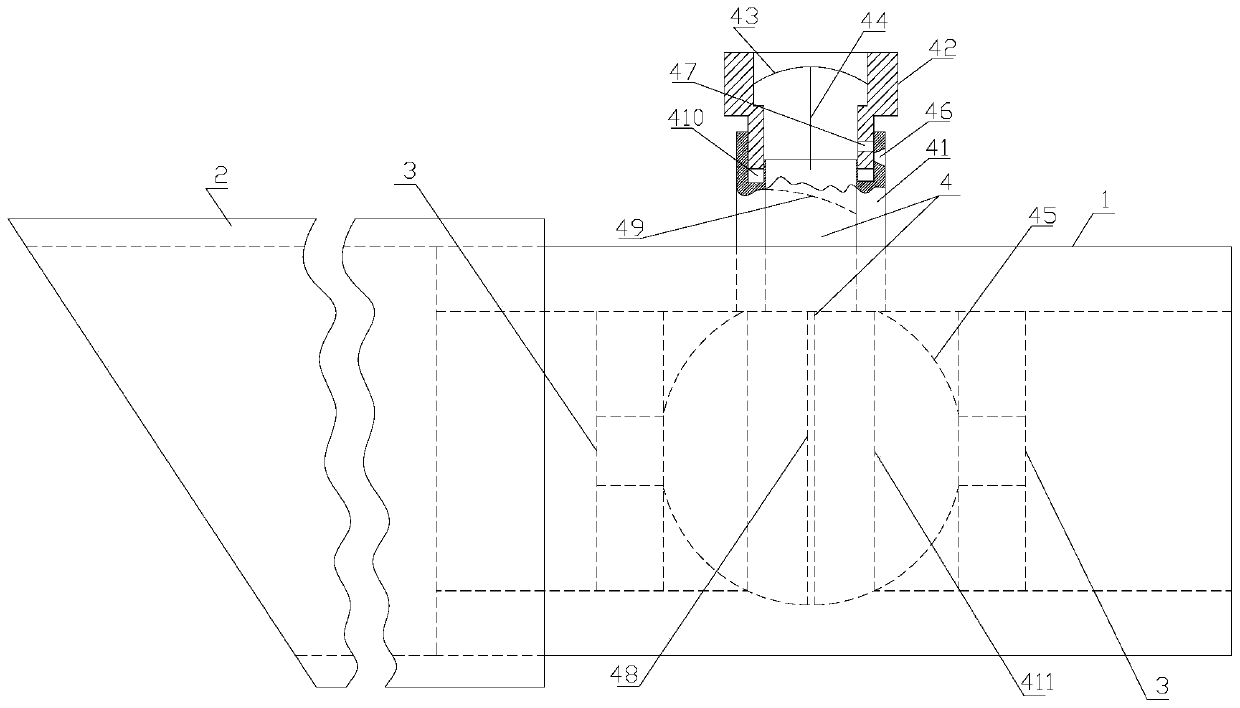

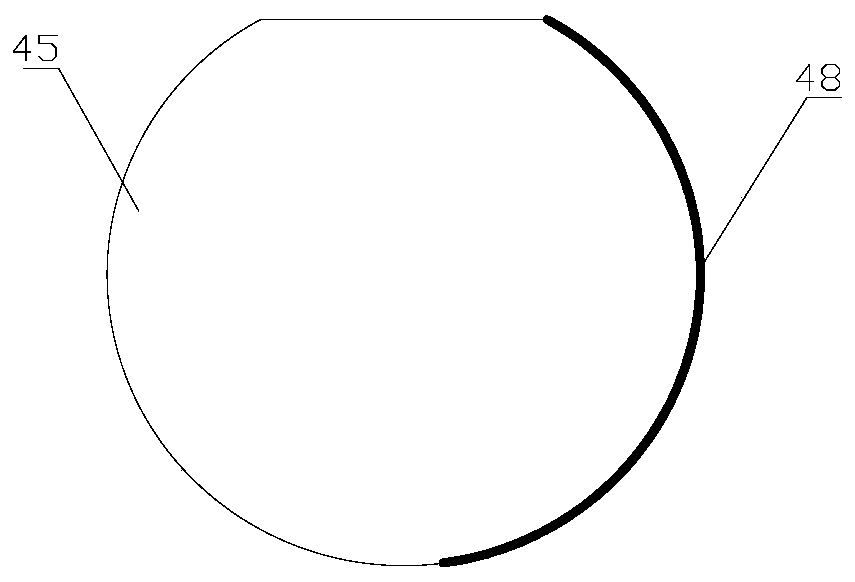

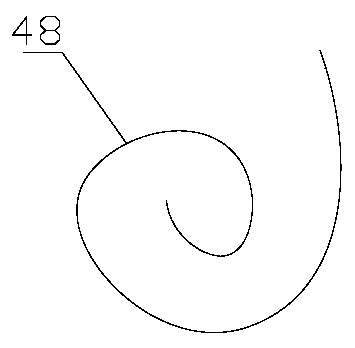

Synchronous opening/closing device for horizontal gate in hydraulic model test

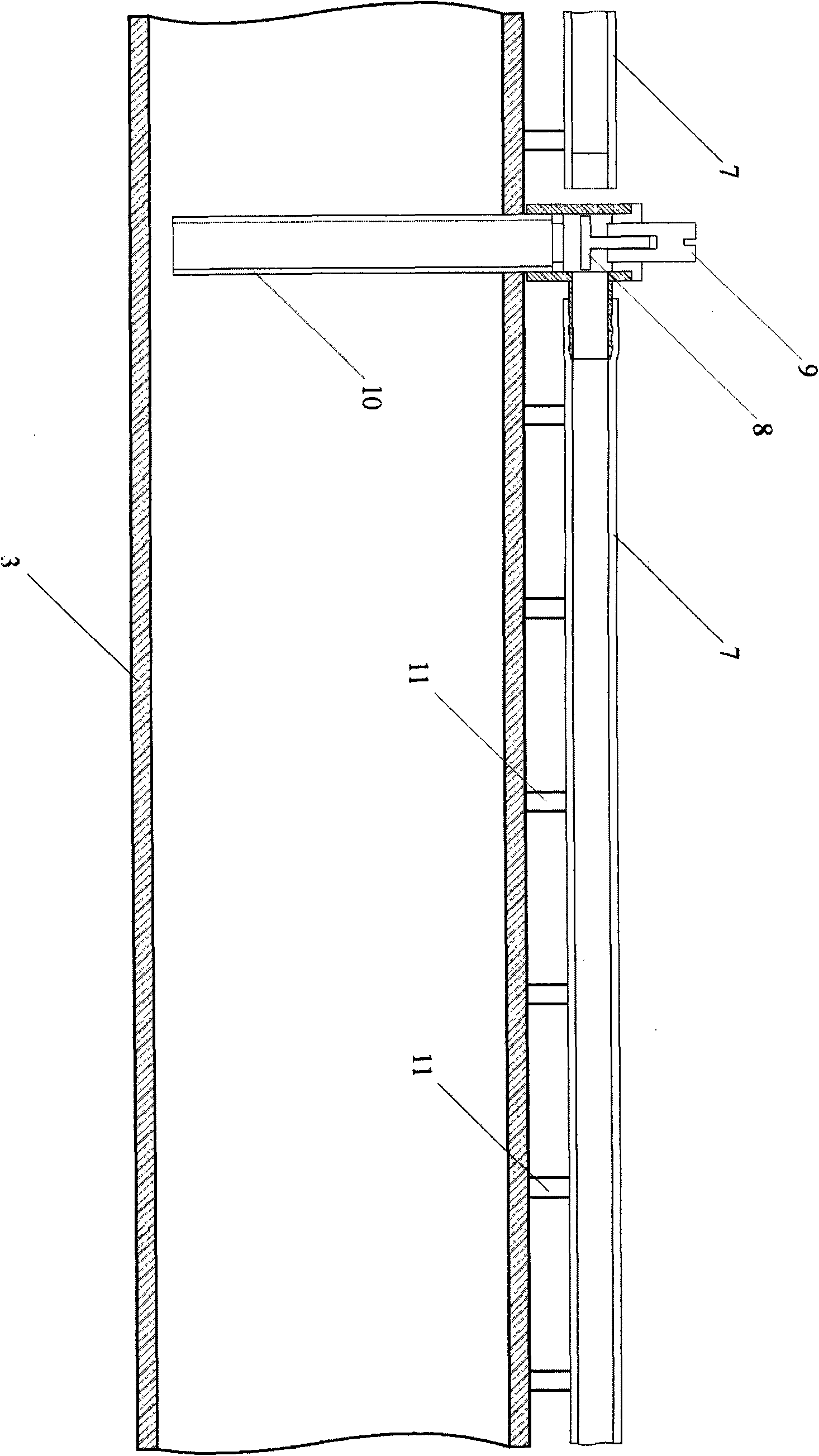

InactiveCN102493389AEasy to realize synchronous opening and closingRealize synchronous opening and closingHydraulic modelsDrive shaftPush pull

The invention discloses a synchronous opening / closing device for a horizontal gate in a hydraulic model test. The device comprises a bracket, a speed regulation motor, a gear box, a main transmission shaft and two push-pull mechanisms with the same structure, wherein the two push-pull mechanisms are located at the two end parts of the main transmission shaft respectively; each push-pull mechanism comprises a push-pull rack, a support seat, a gear, a rotation shaft and a toothed belt transmission mechanism; the push-pull rack is articulated with one side of the gate, and is in sliding connection in the support seat; the support seat is fixed on the bracket; the gear is meshed with the push-pull rack and fixedly mounted on the rotation shaft; and the rotation shaft is supported on the bracket through a bearing and connected with the end parts of the main transmission shaft through the toothed belt transmission mechanism. In the invention, one main transmission shaft drives two push-pull mechanisms with the same structure to open / close the gate from the two sides of the gate; in the basically same practical situation, the synchronous opening and closing of the gate are realized relatively easily; and the synchronization accuracy is relatively high without influencing the water flow state.

Owner:TIANJIN UNIV

Seawater desalination composite membrane based on graphene oxide and preparation method thereof

ActiveCN107188569AGood dispersionNot easy to fall offSemi-permeable membranesCeramicwareFiltrationMicrometer

Relating to the technical field of membrane separation, the invention provides a seawater desalination composite membrane based on graphene oxide and a preparation method thereof. The seawater desalination composite membrane comprises a micropore ceramic layer, a graphene oxide layer and a silicon dioxide gaseous phase layer along the filtration direction in order. The micropore ceramic layer has an average filtration pore size of 1-10 micrometers, the graphene oxide layer has an average filtration pore size of 1-5 nanometers, and the silicon dioxide gaseous phase layer has an average filtration pore size of more than 20 micrometers. The seawater desalination composite membrane provided by the invention adopts graphene oxide as the main filtration medium, the filtered desalinated water has a high desalination rate, and the seawater desalination composite membrane has the advantages of strong surface pollution resistance, difficult blockage, and long service life.

Owner:中穗华生态科技(上海)有限公司

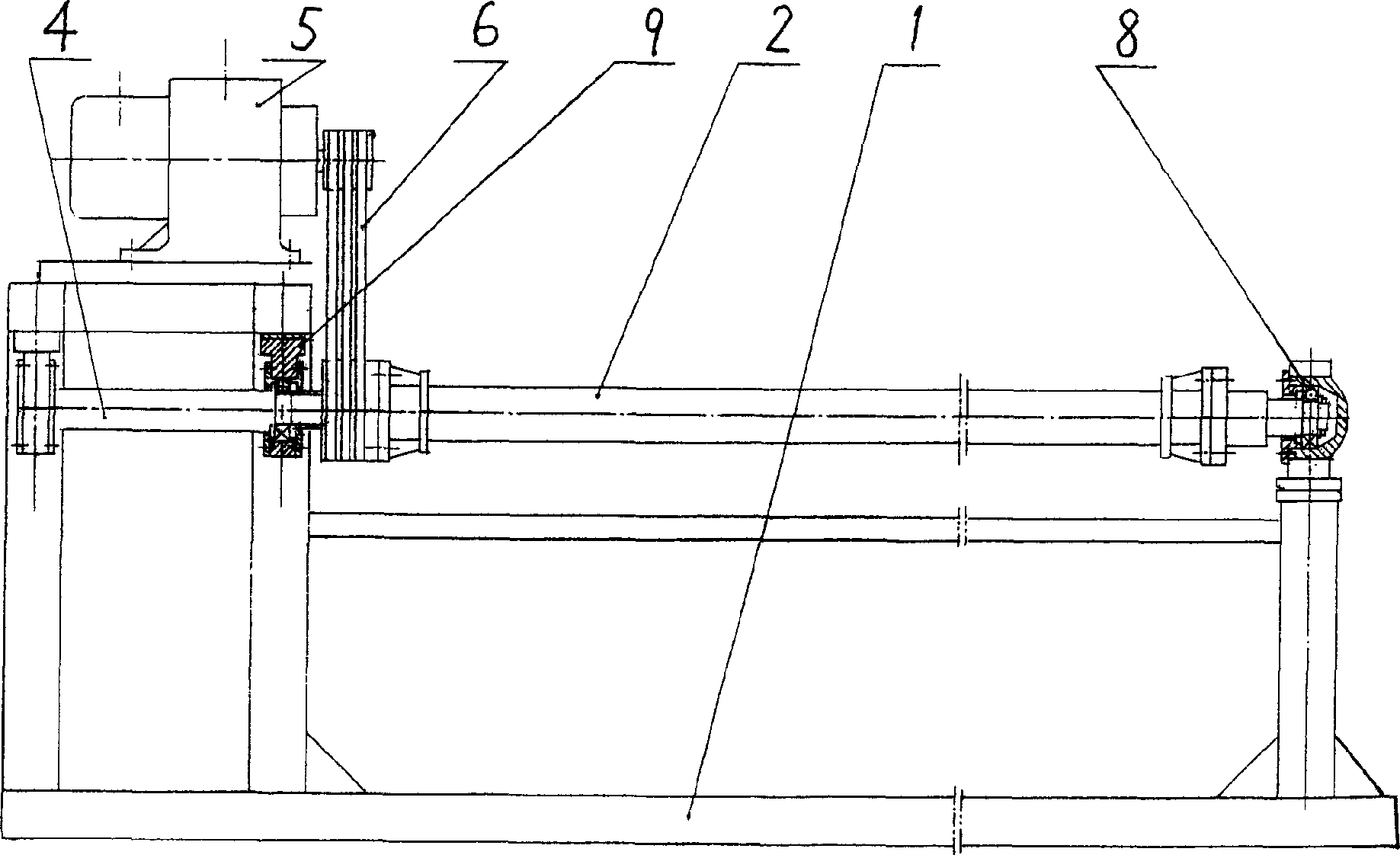

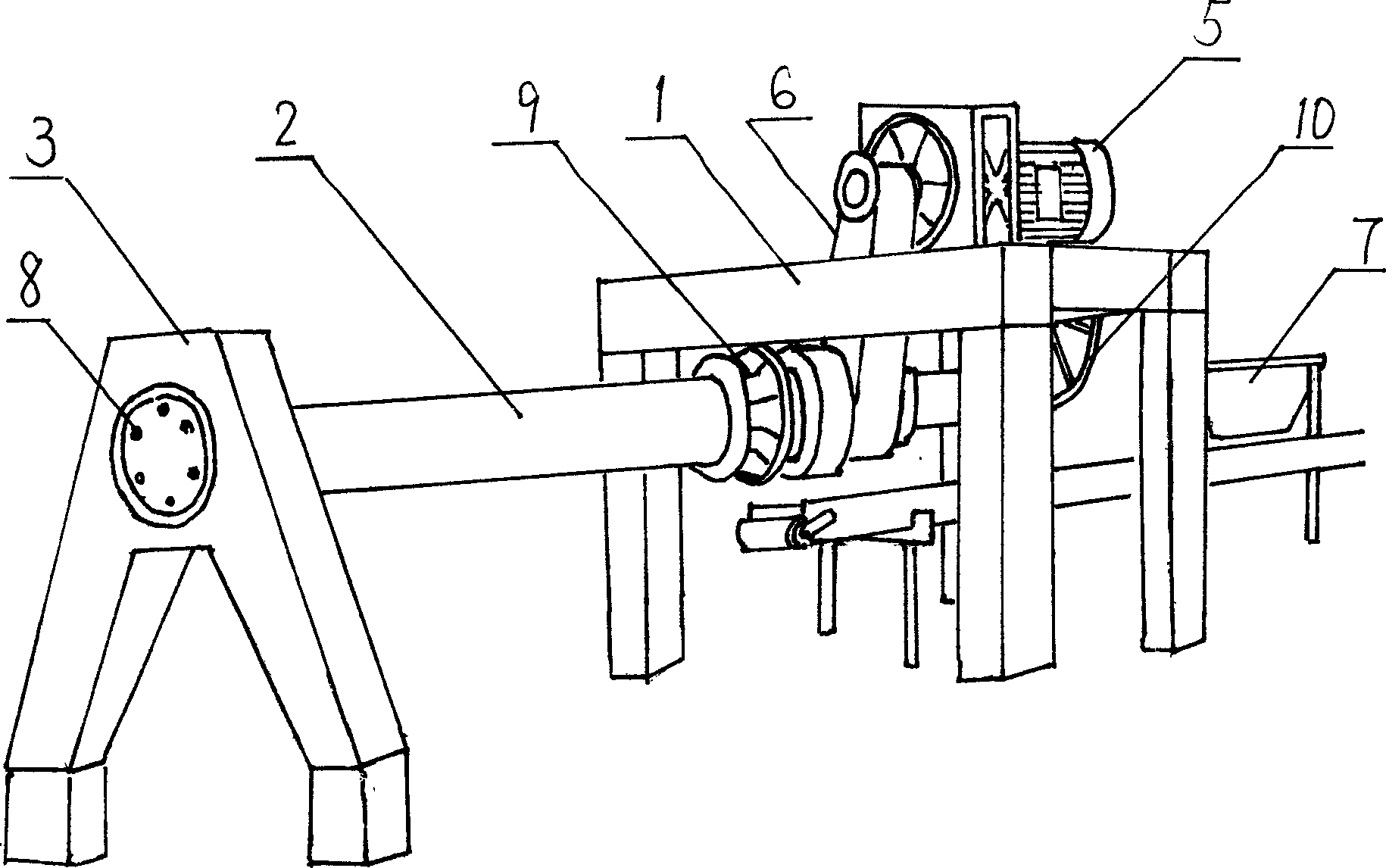

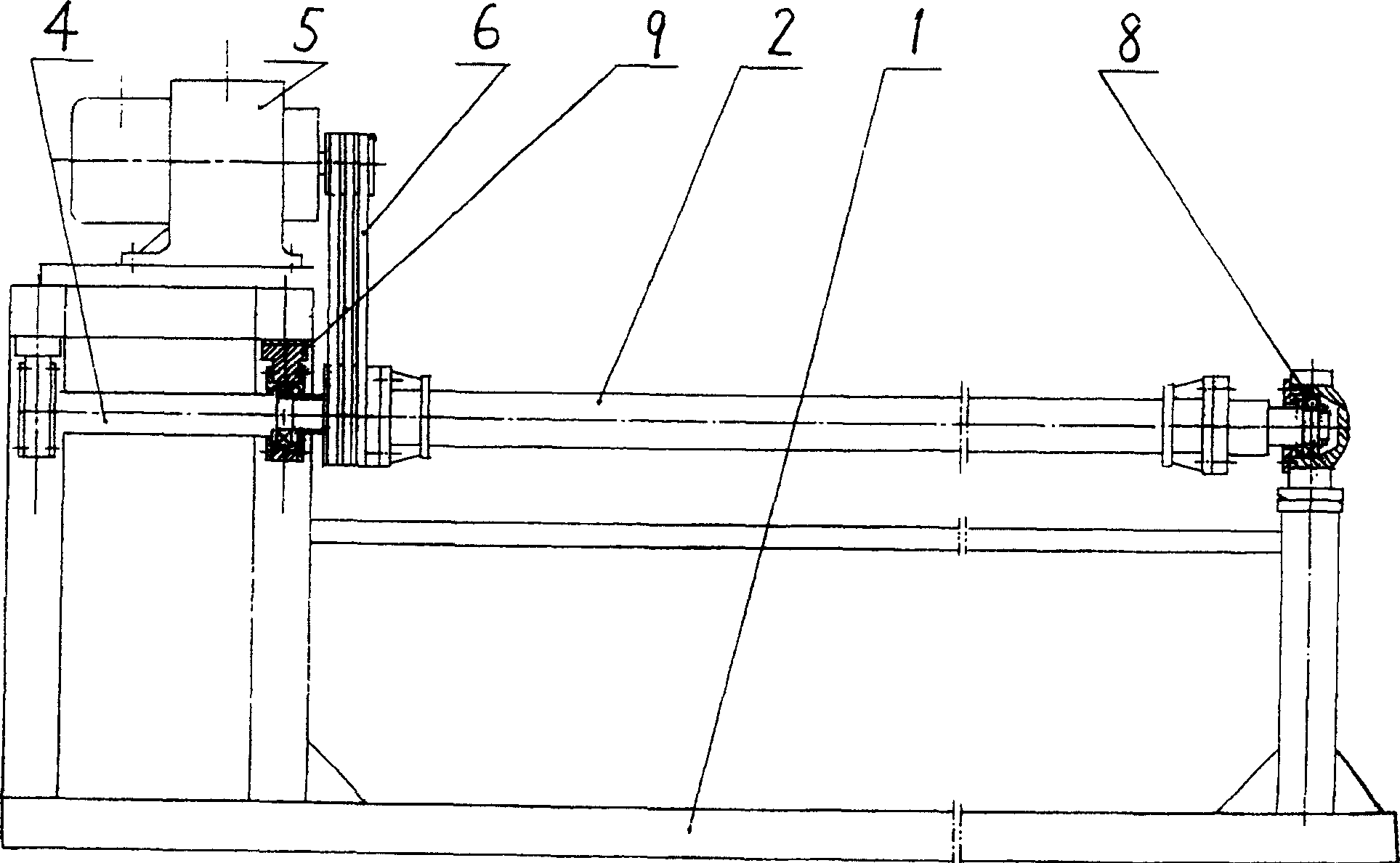

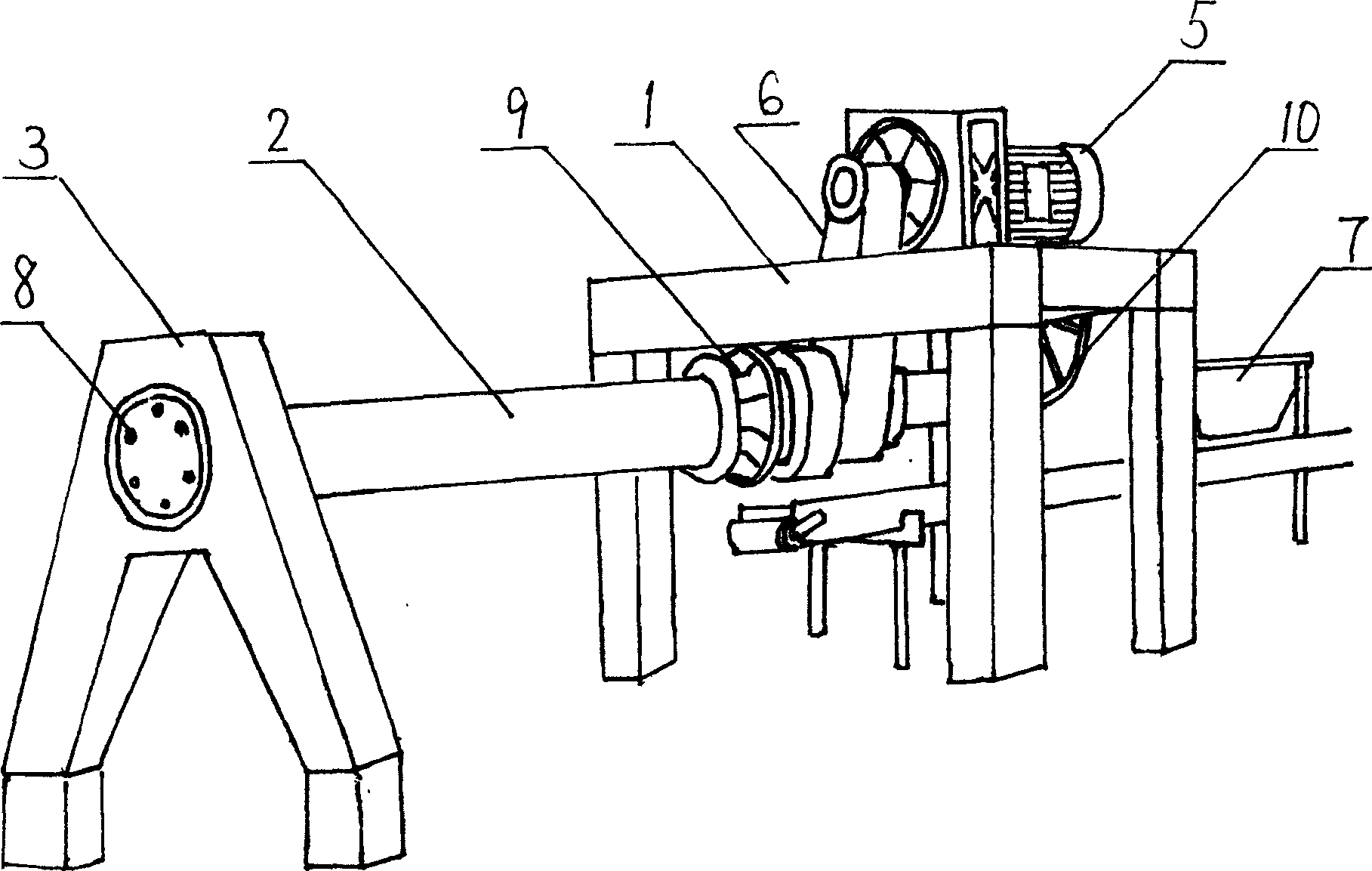

Pipe making method for suspension roller type spigot and socket muoth steel bar concrete pipe

InactiveCN1586852ASimple structureAchieve strengthShaping reinforcementsReinforced concreteHigh intensity

The reinforced concrete pipe making machine consists of mainly frame, suspension roller shaft fixed to the frame, gate head supported in the front of the suspension roller shaft, main shaft connected to the back end of the suspension roller shaft, driving mechanism connected to the main shaft, material feeding mechanism and pipe mold. The bearing in the front end of the suspension roller shaft is supported in the gate head bearing seat, the main shaft bearing is in the frame bearing seat, the jack fixed in the back end of the main shaft on the frame has head perpendicular to the main shaft axis, and the main shaft and the suspension roller shaft have angle to the horizontal plane of 0-3 deg. The pipe mold has flanged edges on two ends connected separately with spigot mold and socket mold separately. The present invention is suitable for producing high strength reinforced concrete pipe with spigot mold and socket.

Owner:黄博

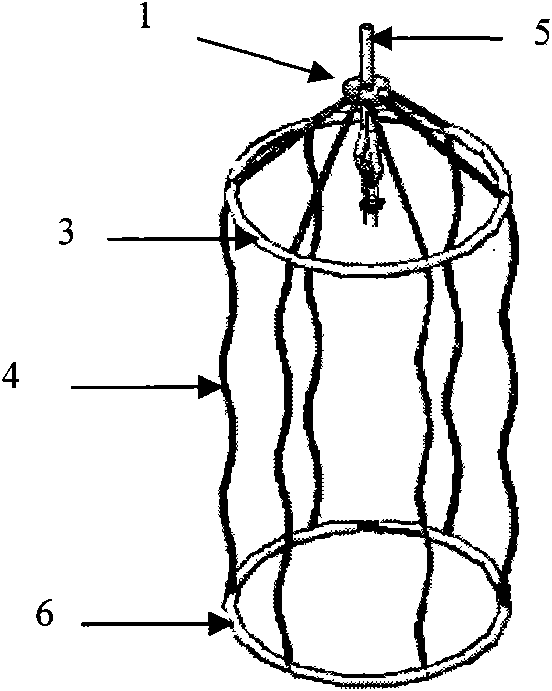

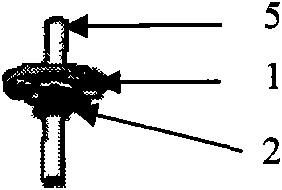

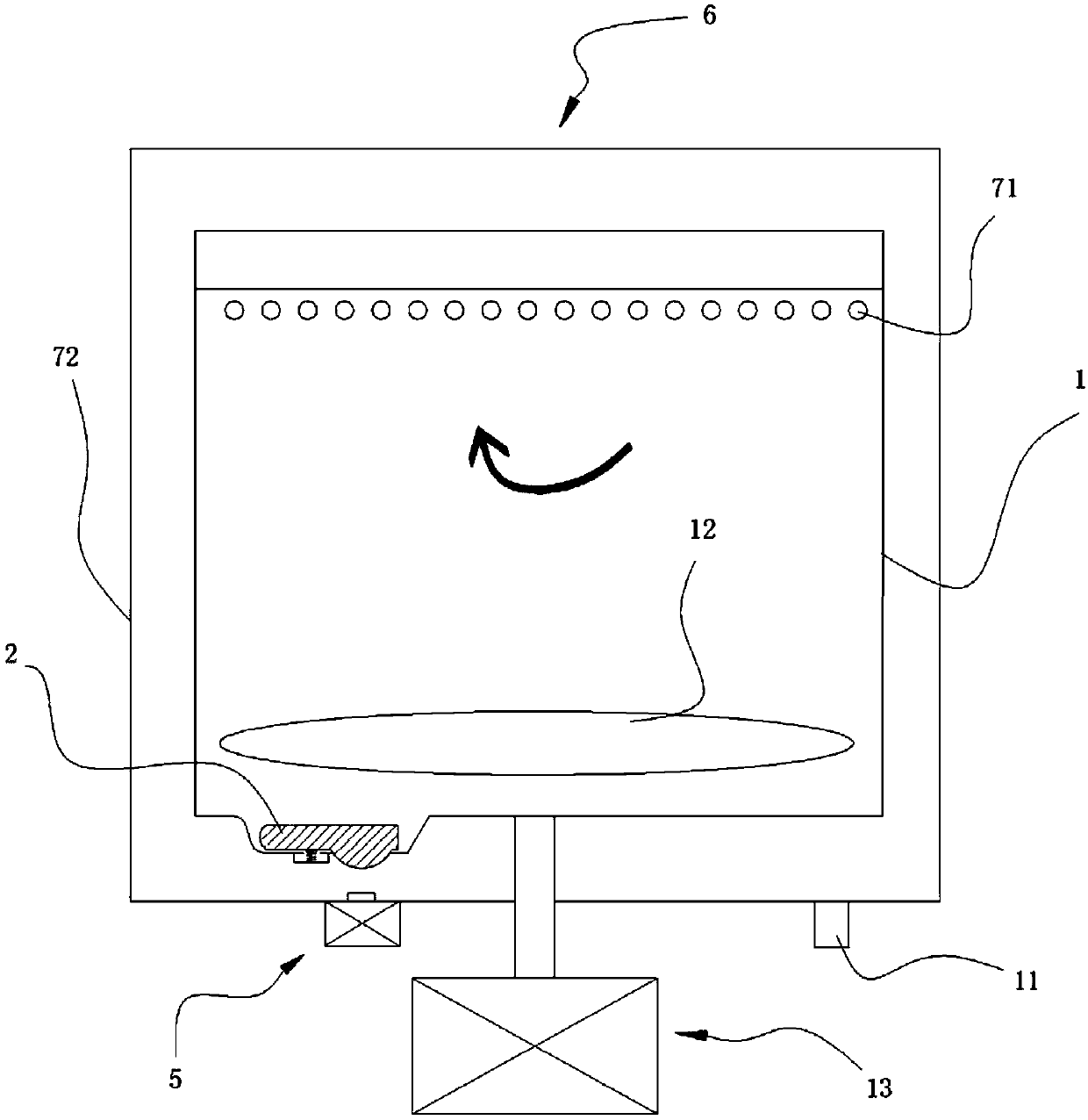

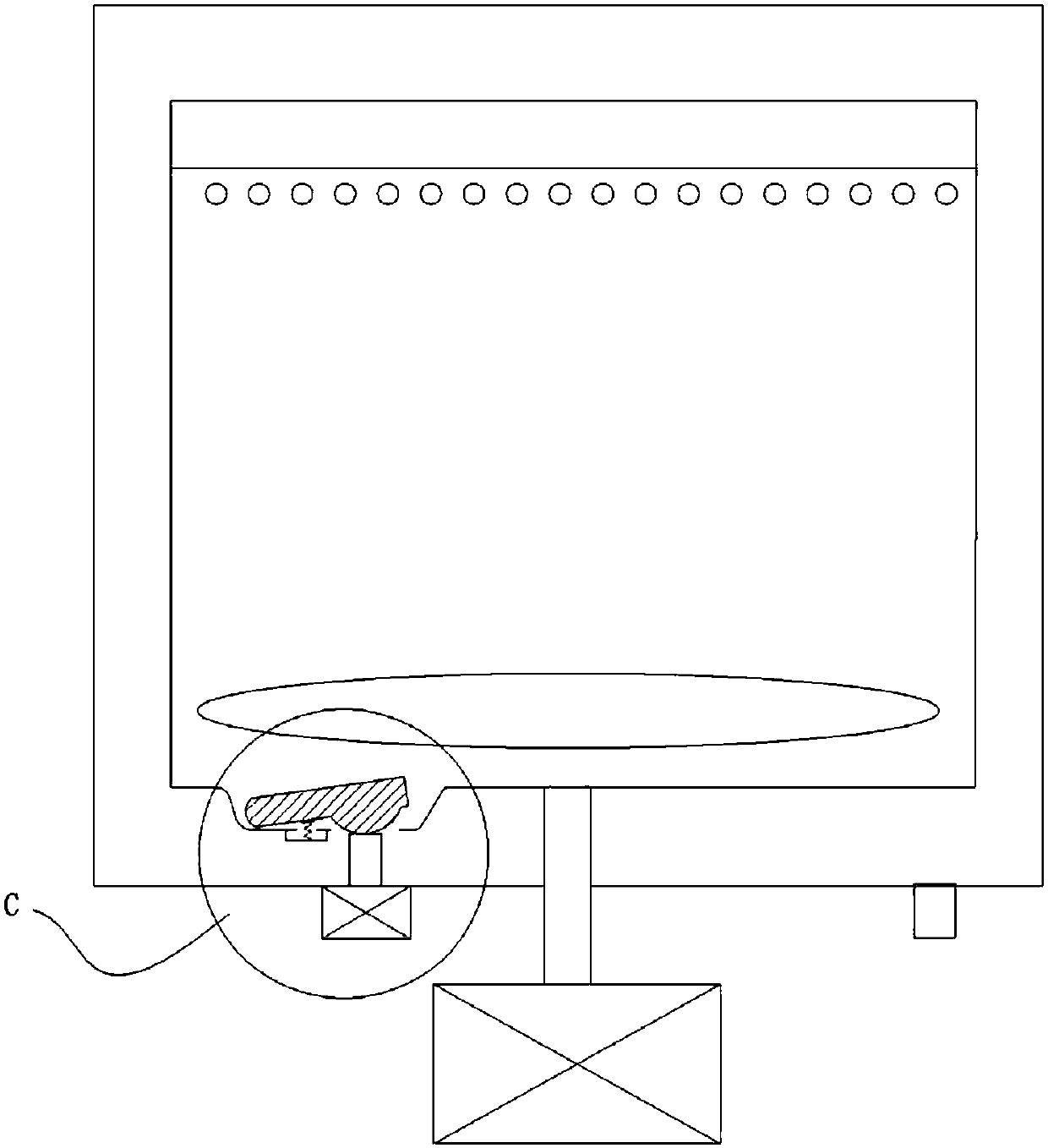

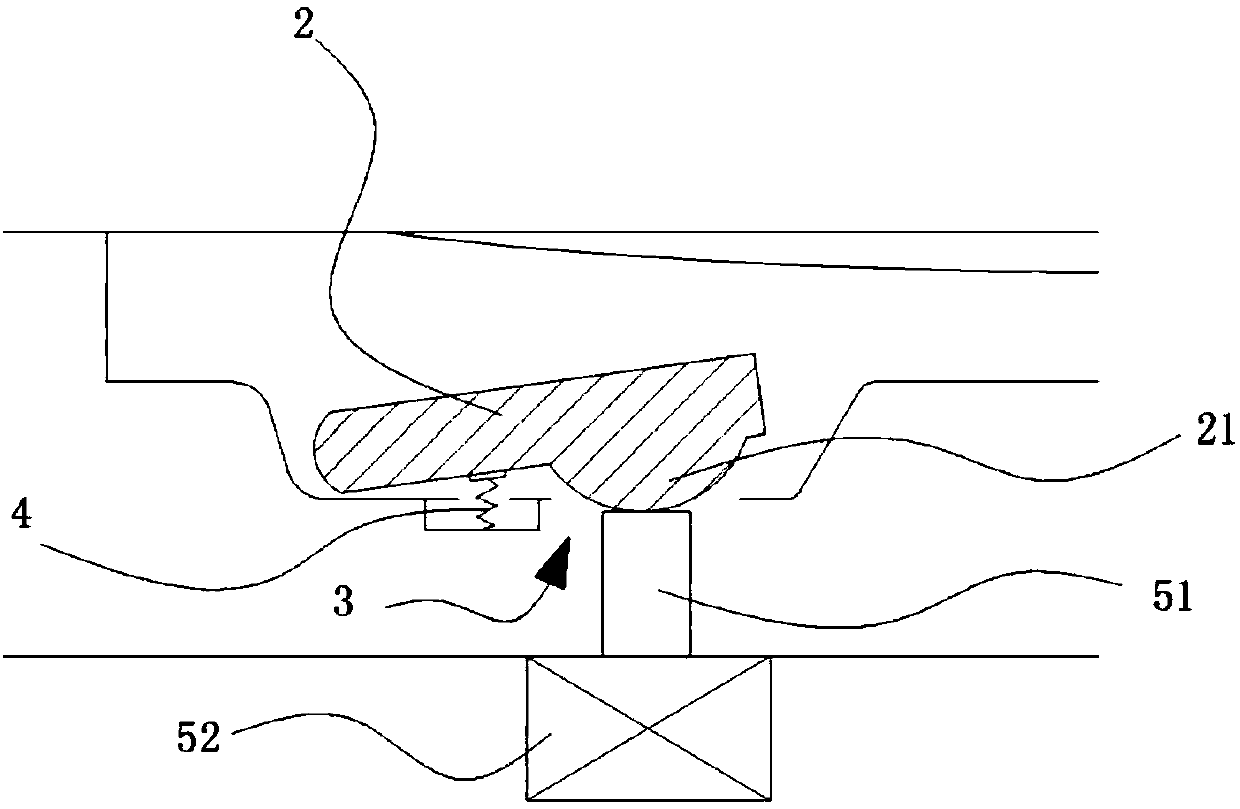

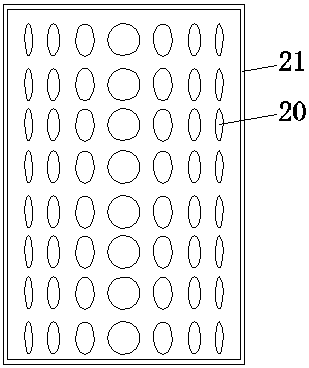

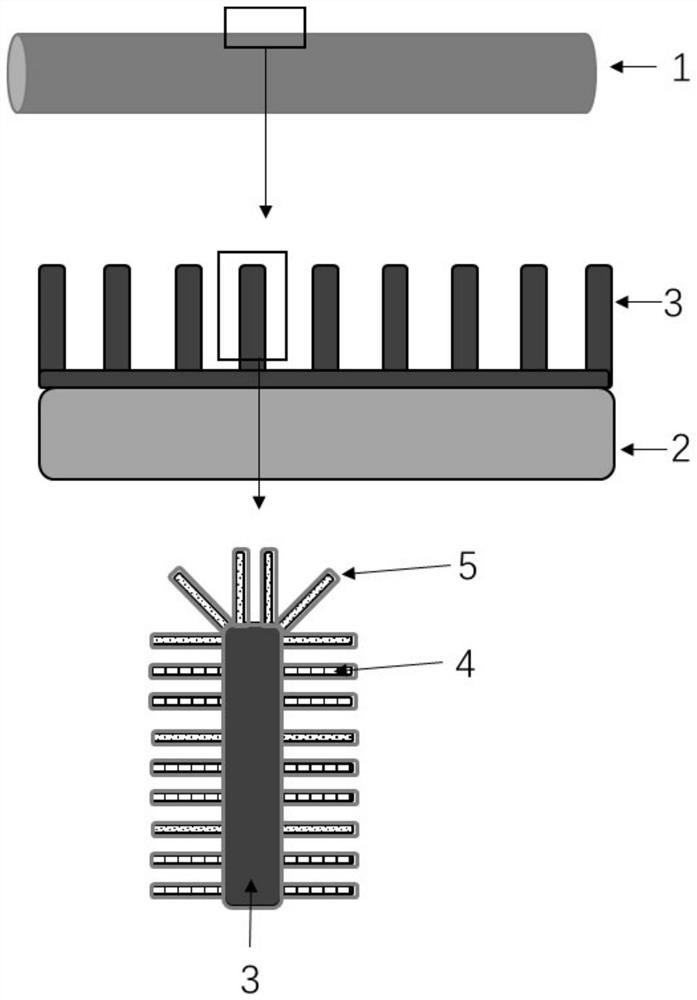

Scallop breeding cage with automatic underwater surface cleaner

InactiveCN102578002AEfficient removalDoes not affect water flowClimate change adaptationPisciculture and aquariaEngineeringOrganism

The invention relates to a scallop breeding cage with an automatic underwater surface cleaner, which is composed of a PVC (polyvinyl chloride) rotary disk, a stainless steel clamp, two or more circular hoops and a plurality of polyethylene ropes. The surface of the PVC rotary disk is provided with hollow round holes, and the ropes for suspending the breeding cage pass through the round hole at the center of the PVC rotary disk. The stainless steel clamp is fixed to the bottom of the PVC rotary disk. The circular hoops are respectively made of PVC and stainless steel, the circular hoops are slightly larger than a partition disk inside the breeding cage in diameter, the circular hoops are arranged in parallel from top to bottom, the circular hoops are connected together through the polyethylene ropes, and the polyethylene ropes are evenly wound on the periphery of each circular hoop and sequentially tied to the circular hoops. An assembled device is sleeved on the breeding cage and driven by ocean currents and waves to automatically circle round the cage, and the polyethylene ropes continuously rub the outside surface of the breeding cage to effectively reduce fouling organisms in attachment.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI +1

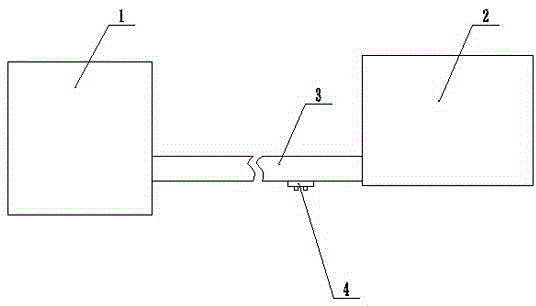

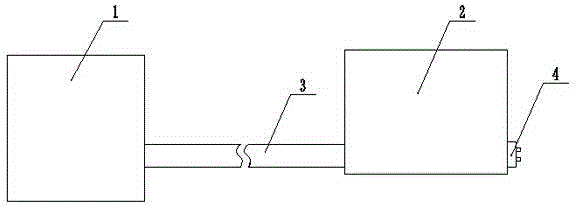

Engine preheating device

InactiveCN104314727AFast and stable ignitionSolve the problem of difficult startupMachines/enginesEngine startersCombustion chamberWater cycling

The invention belongs to the technical field of engine preheating and particularly relates to a device for preheating an engine before a car is started. The device comprises a water tank and the engine. The water tank provides cooling water for the engine. The water tank is connected with the engine through a cooling water pipe, and a water circulating passage is formed. A preheater is connected to a position, close to the engine, of the cooling water pipe. The preheater is mounted in the cooling water pipe. The preheater is an electric heater. The device has the advantages that the device is added to a car water circulating system in the prior art, the problem that the car is difficult to start in cold regions in winter is solved, the engine is preheated before the car is started, hot water rises and cold water falls after heating, automatic circulation of water in the circulating pipeline is achieved, water in the water pipe can be preheated fast to provide temperature of the combustion chamber of the engine, the engine can be ignited fast and stably, smoke discharge concentration is lowered after temperature rising, and the device is reliable, time saving, labor saving, economical and environmental friendly.

Owner:魏建元

Concentrated desalting device and desalting method for industrial high-salinity wastewater treatment

InactiveCN113105048AImprove desalination efficiencyAvoid cloggingTreatment involving filtrationMultistage water/sewage treatmentDesalinationProcess engineering

The invention discloses a concentrated desalting device for industrial high-salinity wastewater treatment and a desalting method.The concentrated desalting device comprises a treatment tank, a motor, a heating element, a discharge port and a valve, a liquid inlet is fixed to the top of the treatment tank, a steam outlet pipe is fixed to one side of the treatment tank, and an output shaft of the motor is rotationally connected with a movable cylinder; and a stirring rod is fixed to the end of a connecting shaft, a sleeve block is arranged on the outer side of a fixed block in a sleeving mode, a transmission shaft is connected to the end of a movable cylinder, a heating element is installed in a first valve plate in an embedded mode, and a discharging opening is formed in the lower corner of the treatment tank. According to the concentrated desalting device and desalting method for treating the industrial high-salinity wastewater, the wastewater can be kept in a flowing state all the time in the desalting process of the industrial high-salinity wastewater, and other fixed substances contained in the wastewater can be treated, so that the desalting efficiency is improved; and and meanwhile, salt adhering to the interior of the pipeline can be cleaned, and the blocking phenomenon is avoided.

Owner:刘建光

Clothing treatment equipment

PendingCN110409111ASmall sizeEasy dischargeOther washing machinesWashing machine with receptaclesPulp and paper industryClosed state

The invention discloses clothing treatment equipment. The clothing treatment equipment comprises a rotating barrel, a drainage hole and a plugging mechanism, wherein the rotating barrel can rotate inthe axial direction of the equipment, the drainage hole is formed in the lowest position of the bottom of the rotating barrel and the plugging mechanism is arranged at the lowest position to open or close the drainage hole, and the plugging mechanism covers the drainage hole and can rotate along with the rotating barrel when in a closed state. According to the clothing treatment equipment, a structure equivalent to an outer barrel is omitted, all washing water is contained in the rotating barrel, and the consumption of washing water is reduced. In addition, the problem of how to discharge water from the rotating barrel in the washing / dewatering process is effectively solved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

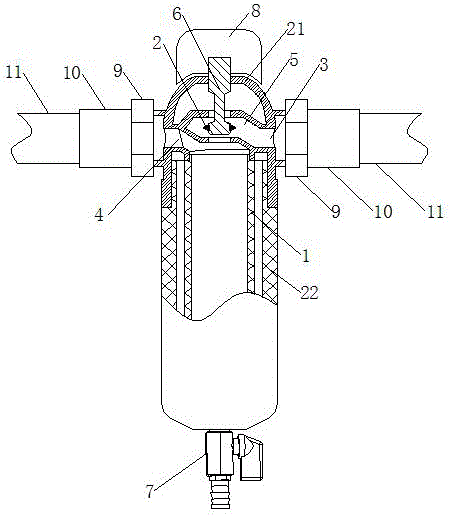

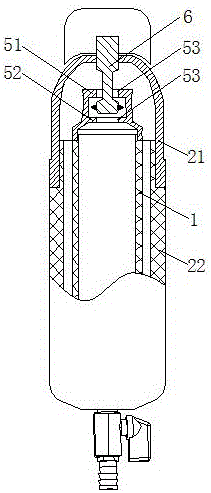

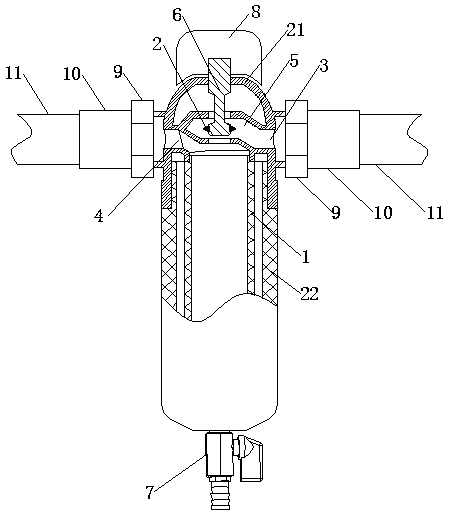

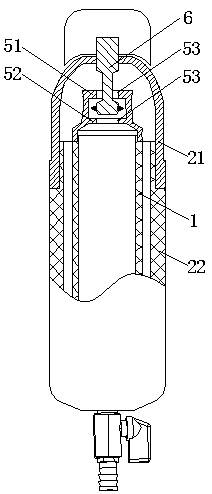

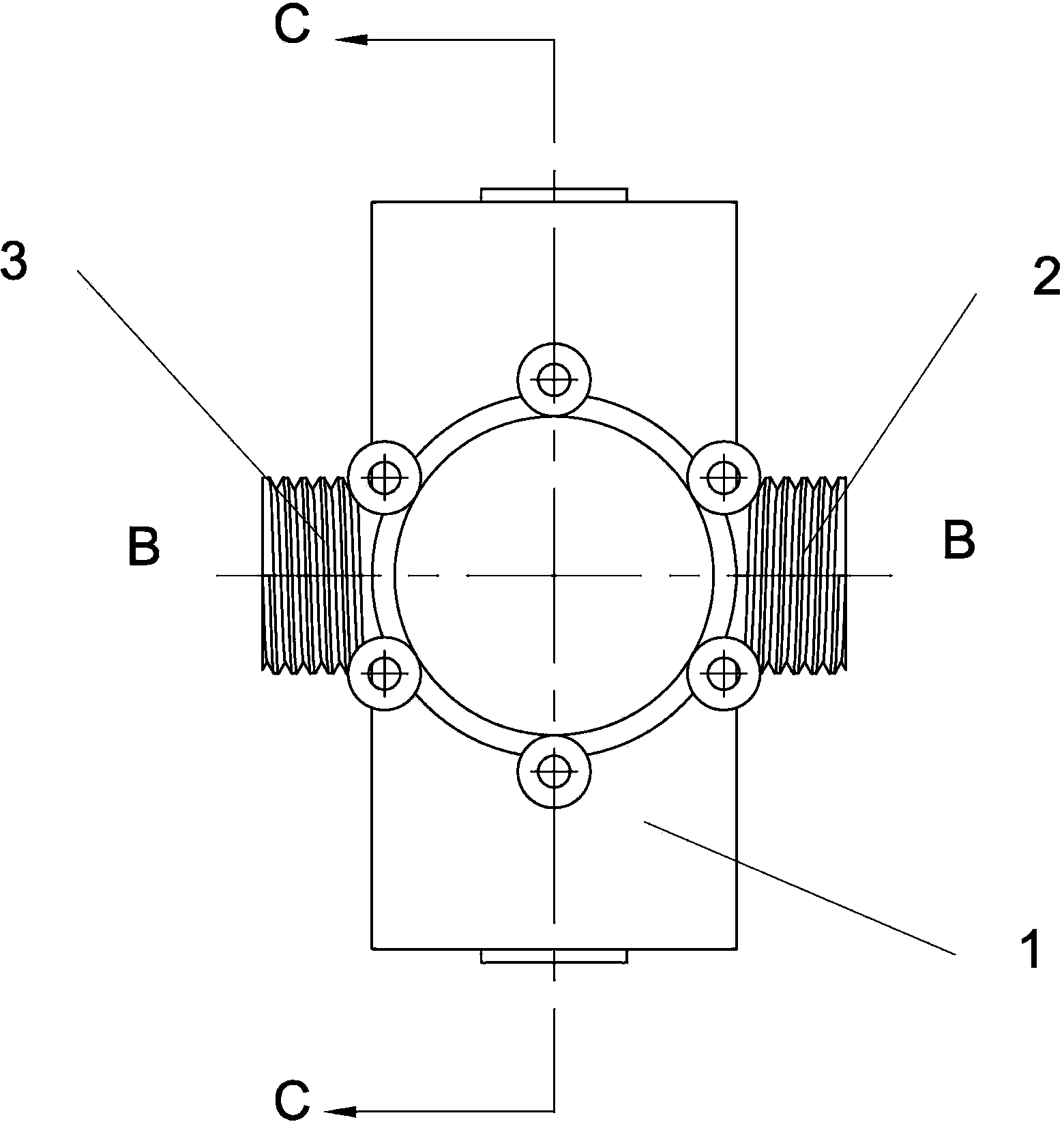

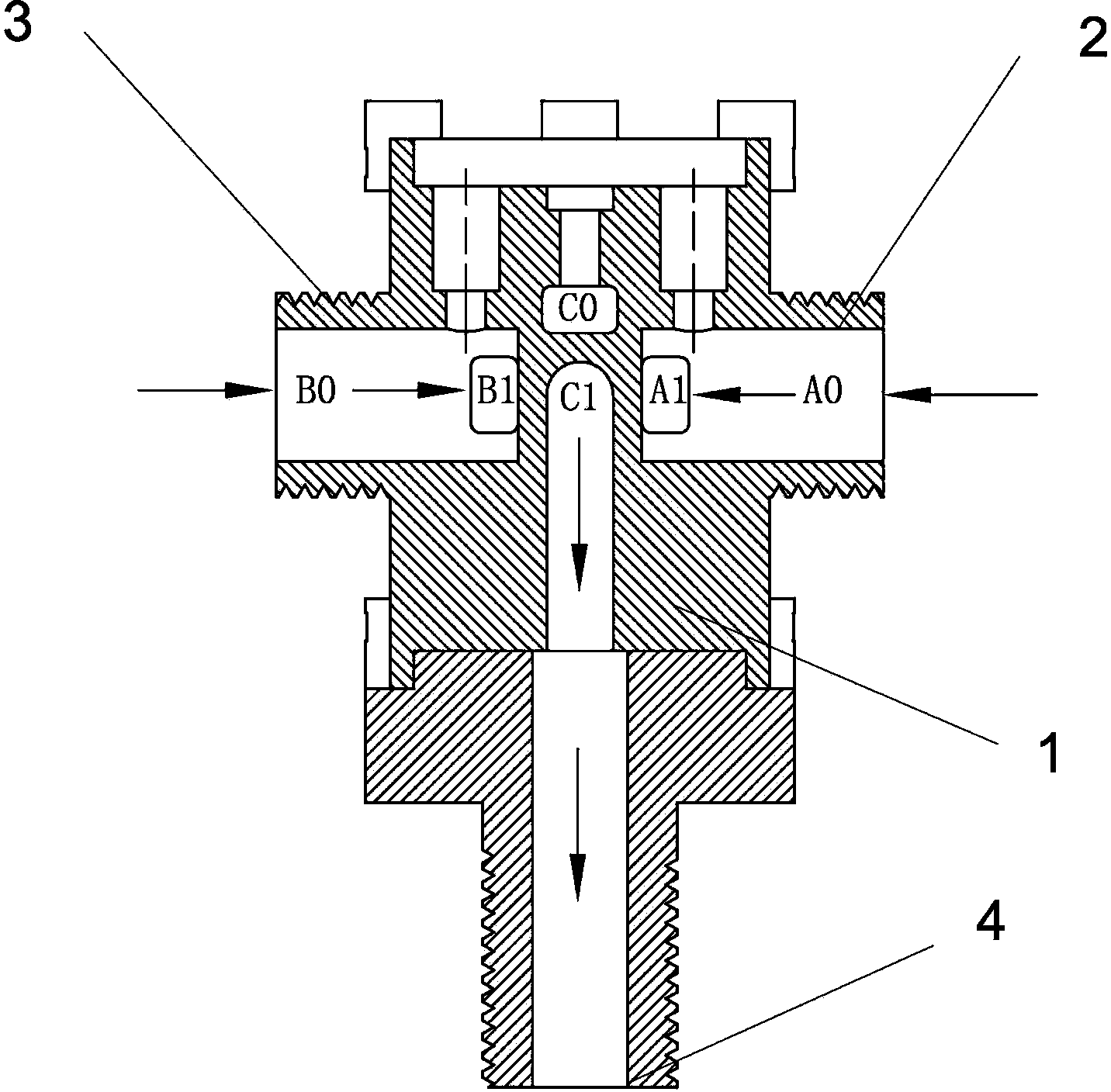

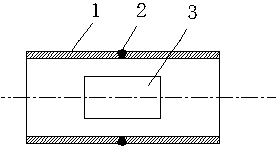

Reverse washing prefilter

ActiveCN106422461AExtended service lifeEasy to operateStationary filtering element filtersEngineeringMechanical engineering

The invention discloses a reverse washing prefilter which comprises a filter element and a shell arranged outside the filter element. The shell comprises an upper shell and a lower shell which are hermetically and integrally connected, a water inlet and a water outlet are formed in the upper shell, a water inlet cavity is formed in the upper shell, the water inlet is communicated with the inside of the water inlet cavity, the water outlet is communicated with the inside of the filter element, the upper shell comprises an upper sealing part and a lower sealing part which are positioned on the upper portion and the lower portion of the water inlet cavity respectively, water through openings are formed in the upper sealing part and the lower sealing part, a conversion rod is inserted into the water inlet cavity, the upper portion of the conversion rod sequentially penetrates the water through opening of the upper sealing part and the top of the upper shell, a sealing gasket for hermetically matching with the water through openings is arranged at the conversion rod between the upper sealing part and the lower sealing part, and a drainage valve is arranged at the bottom of the lower shell. According to the reverse washing prefilter, reverse washing operations are simple, and the filter element does not need to be disassembled, washed or replaced by professional staff.

Owner:NANJING FANSKI IND

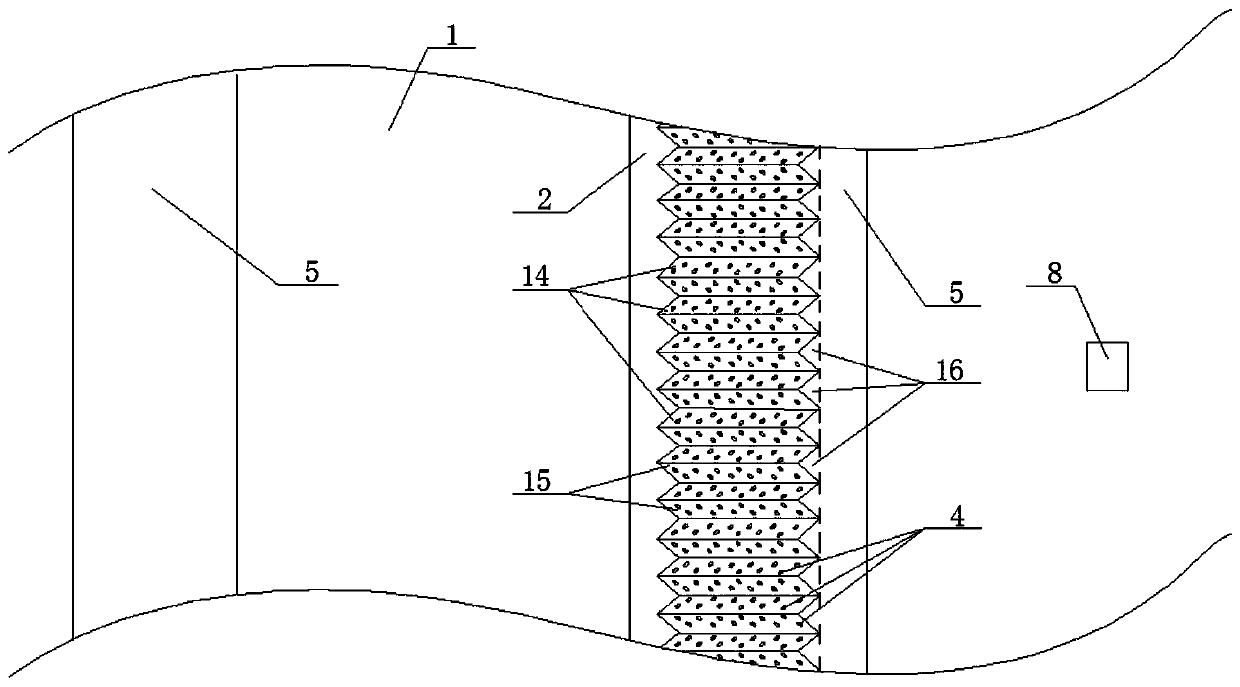

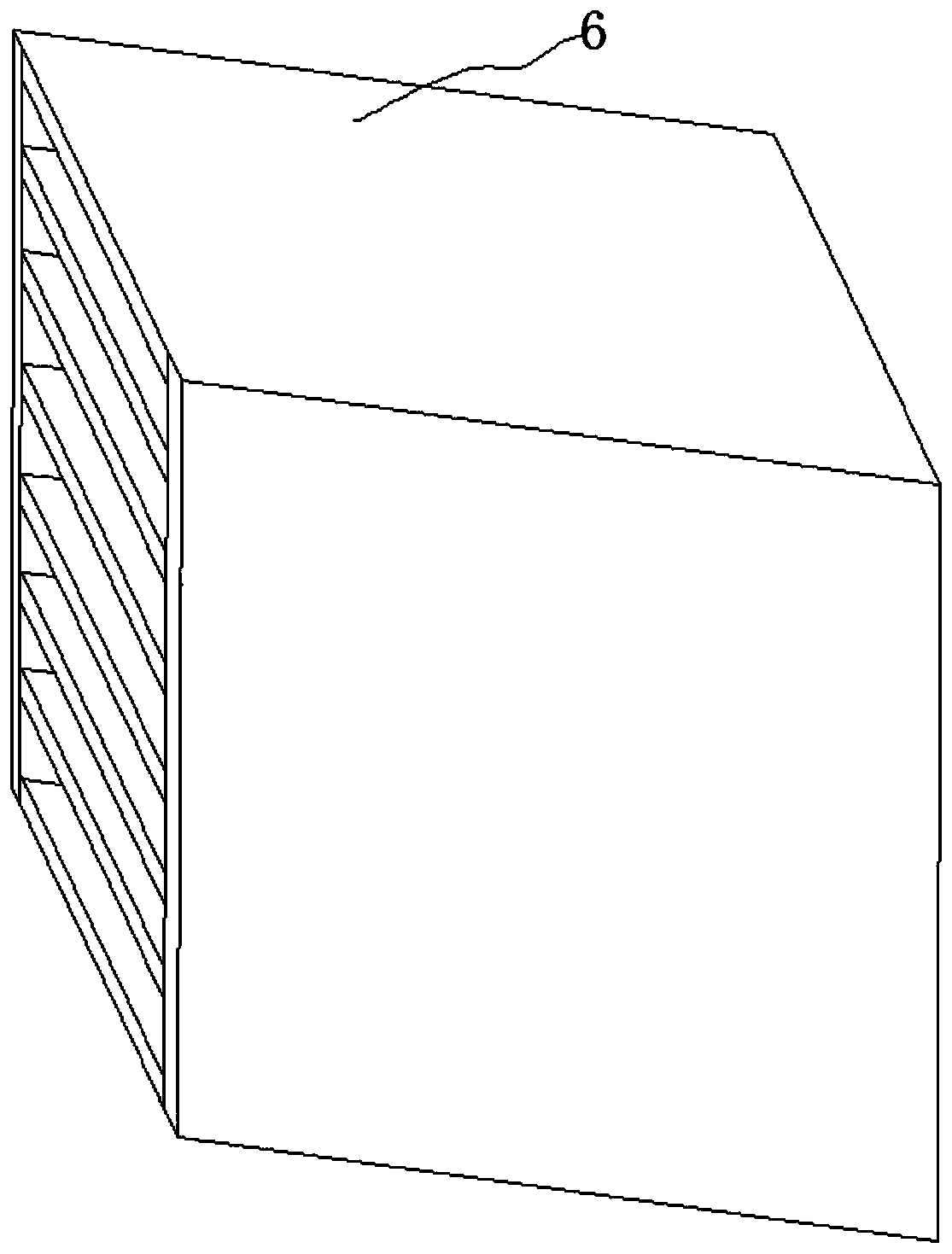

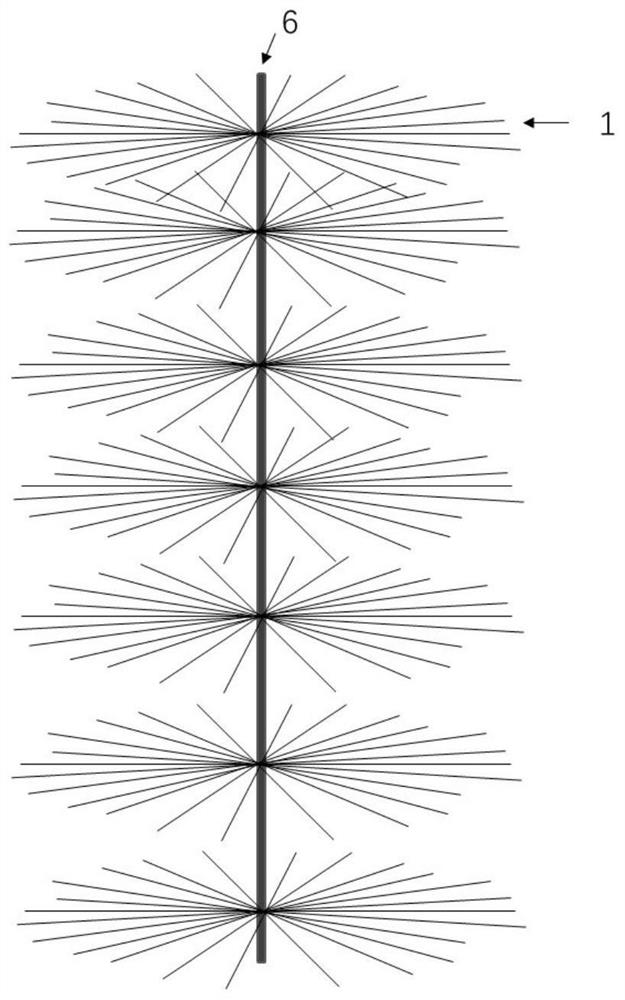

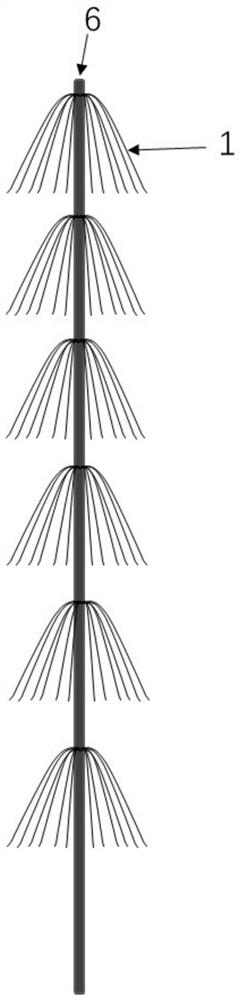

Steel water stone separation blocking dam and mounting method thereof

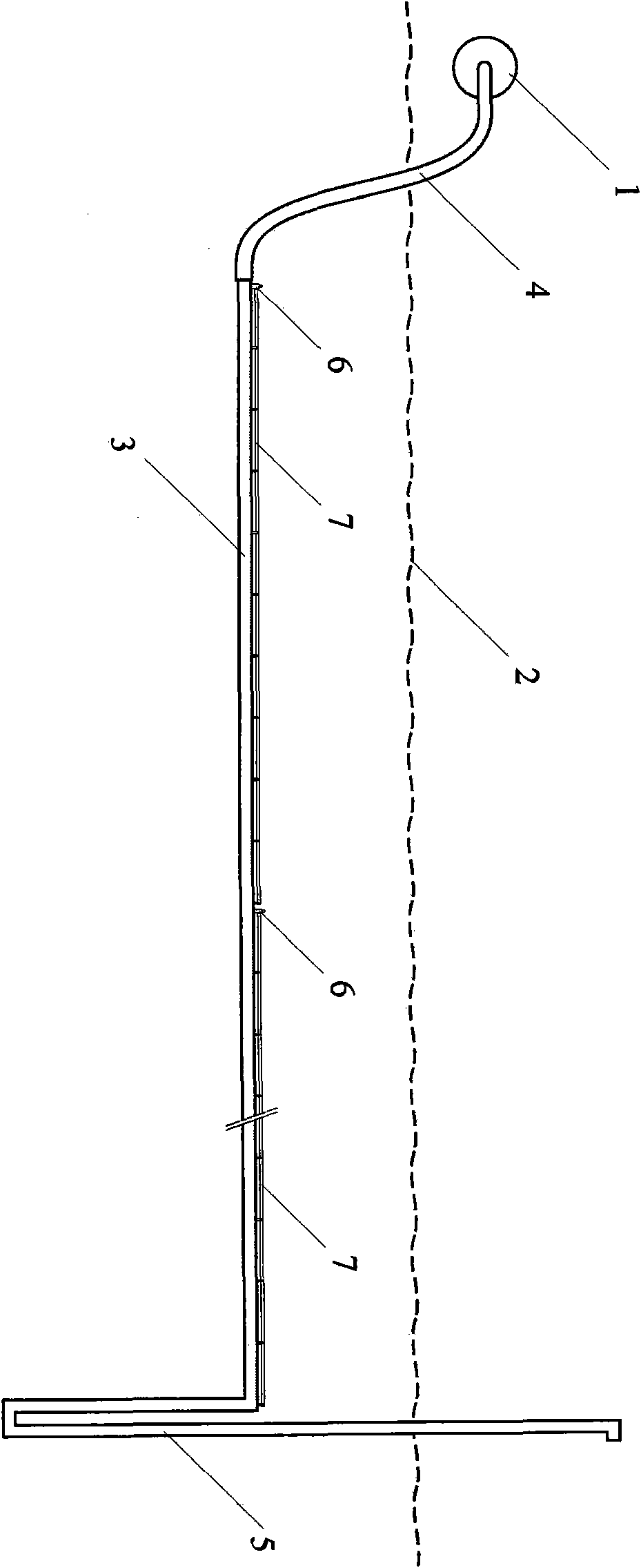

PendingCN106869081AFree passageEasy installation and constructionDamsProtective foundationCrushed stoneWater flow

The invention discloses a steel water stone separation blocking dam and a mounting method thereof. The dam comprises a concrete foundation and a blocking dam body structure arranged on the concrete foundation; the blocking dam body structure comprises two blocking dam body steel pipe sets, each blocking dam body steel pipe set comprises at least two blocking dam body steel pipes arranged on one plane in parallel, the two blocking dam body steel pipe sets are symmetrically fixed to the concrete foundation, every two adjacent blocking dam body steel pipes are connected through a fixing pipe, a horizontal base bottom plate is welded to the lower end of each blocking dam body steel pipe, and the base bottom plate and the concrete foundation are fixedly connected through foot margin anchor rods. A steel structure is adopted to serve as a blocking dam body, mounting construction is convenient, good water permeability is achieved, river water and gravel are separated, massive rocks and large broken stone are intercepted, water and sand can freely pass, the water flow is not affected, and cleaning is facilitated.

Owner:CHENGDU XINTU TECH +1

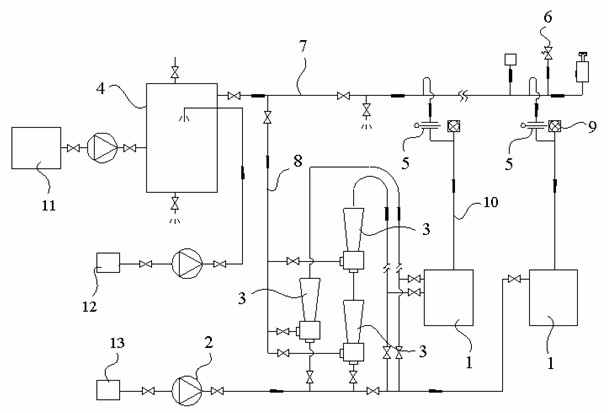

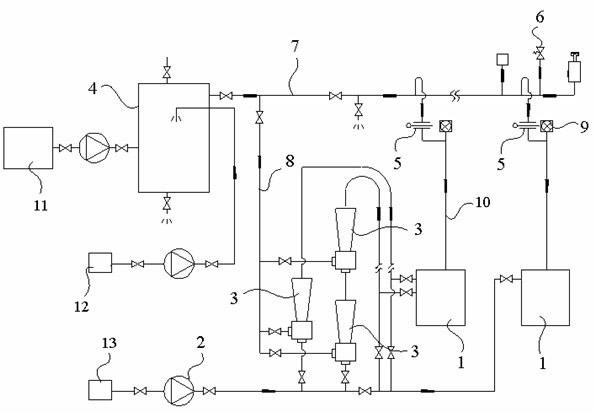

Oceangoing vessel ballast water processing method

InactiveCN102502906ALow oxygenEasy maintenanceWater/sewage treatment by flotationSocial benefitsEconomic benefits

The invention discloses an oceangoing vessel ballast water processing method. According to the method, air over the ballast water in ballast water chambers is evacuated by an inert gas, the ballast water in the ballast chambers is pumped out of the ballast chamber, the ballast water is subjected to blow-off mixing by the inert gas to generate a physical reaction, a soluble inert gas is merged into the ballast water when oxygen in the ballast water is sucked out, and the processed ballast water is discharged into the ballast water chambers. A device of the method comprises the ballast chambers, ballast pumps, Venturi ejectors and an inert gas generator. The ballast water processing method of the invention, which is a physical method, needs no extra chemical agents or relevant dosing devices; the physical reaction can be directly generated in the Venturi ejectors, and no filter devices are needed before the reaction generation, so time-cost regular cleaning is not needed, the water flow is not influenced, the discharge time is reduced, and the chambers are protected from oxidation corrosion, thereby the reliability of the ballast water processing effect is guaranteed; and the method of the invention, which has a very good practicality, can generate very good economic benefits and social benefits.

Owner:YANGZHOU DAYANG SHIPBUILDING

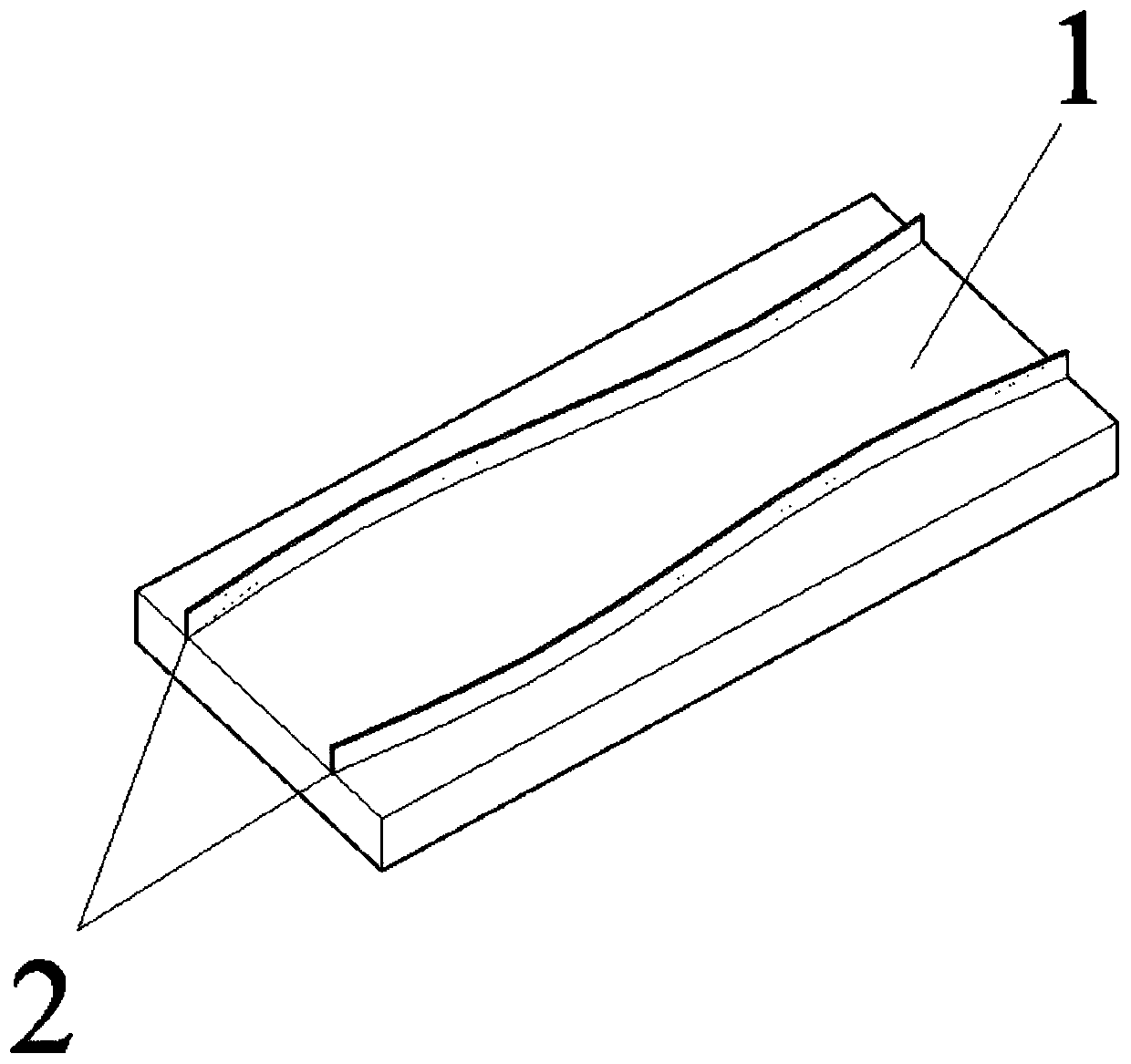

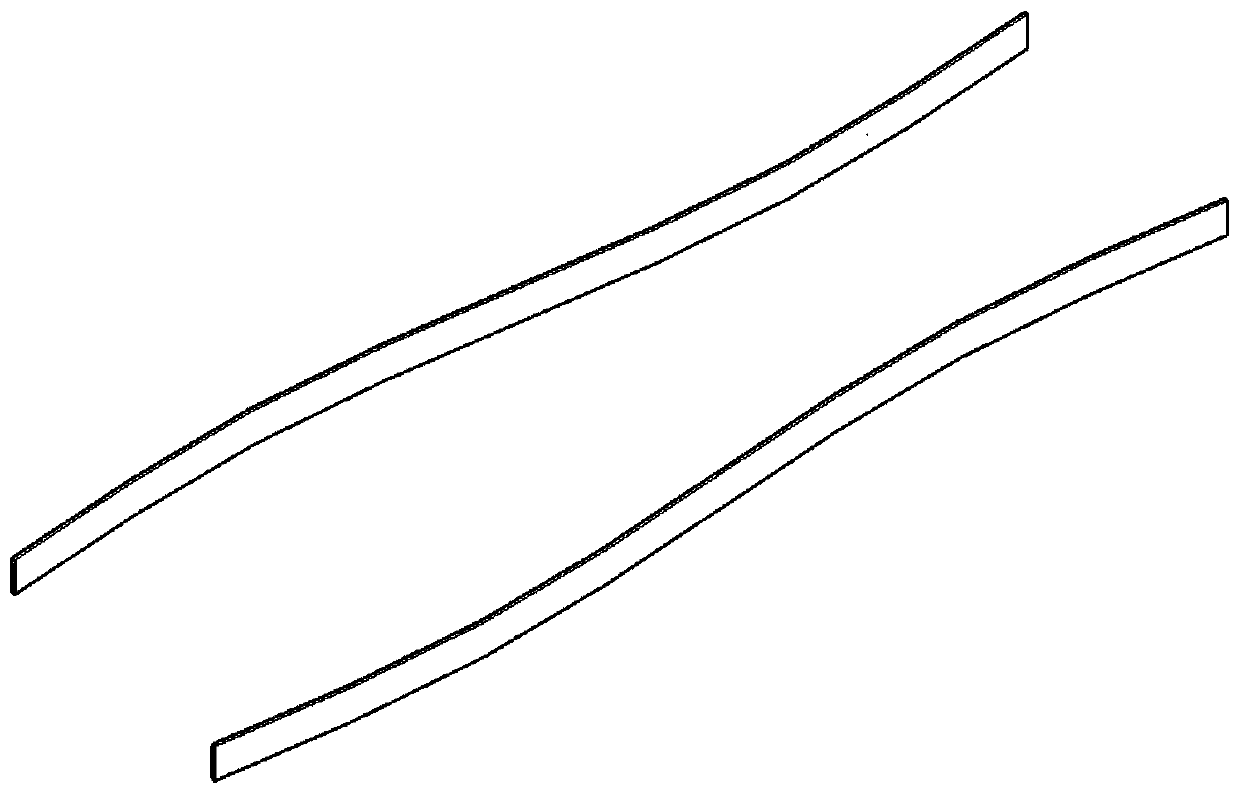

Novel bulkhead gate device capable of eliminating gate front vortex

The invention belongs to the field of water conservancy and hydropower and relates to a novel bulkhead gate device capable of eliminating a gate front vortex. Two curved barriers which are as high asa gate and are tightly attached to the surface of the gate are vertically arranged on the upstream face of the gate, and the curve request of the curved barriers is made. In the arrangement mode, thedouble-curve vortex eliminating barriers can achieve the vortex eliminating effect under the conditions of different immersing water depths and different gate opening degrees, the structure is simple,arrangement is convenient, overhauling and maintenance are easy, the flow regime of the water flow in front of the gate and the gate flow passing capacity cannot be affected, no new harmful vortex isintroduced, and no extra surface swirl nor surface indentation vortex is generated. Therefore, the phenomena that due to the existence of the gate front vortex, the flow passing capacity is reduced,water flow turbulent fluctuation is intensified, water building vibration is caused, the flow regime of the water flow is deteriorated, and cavitation and cavitation erosion are caused are reduced, and engineering safe operation is guaranteed.

Owner:DALIAN UNIV OF TECH

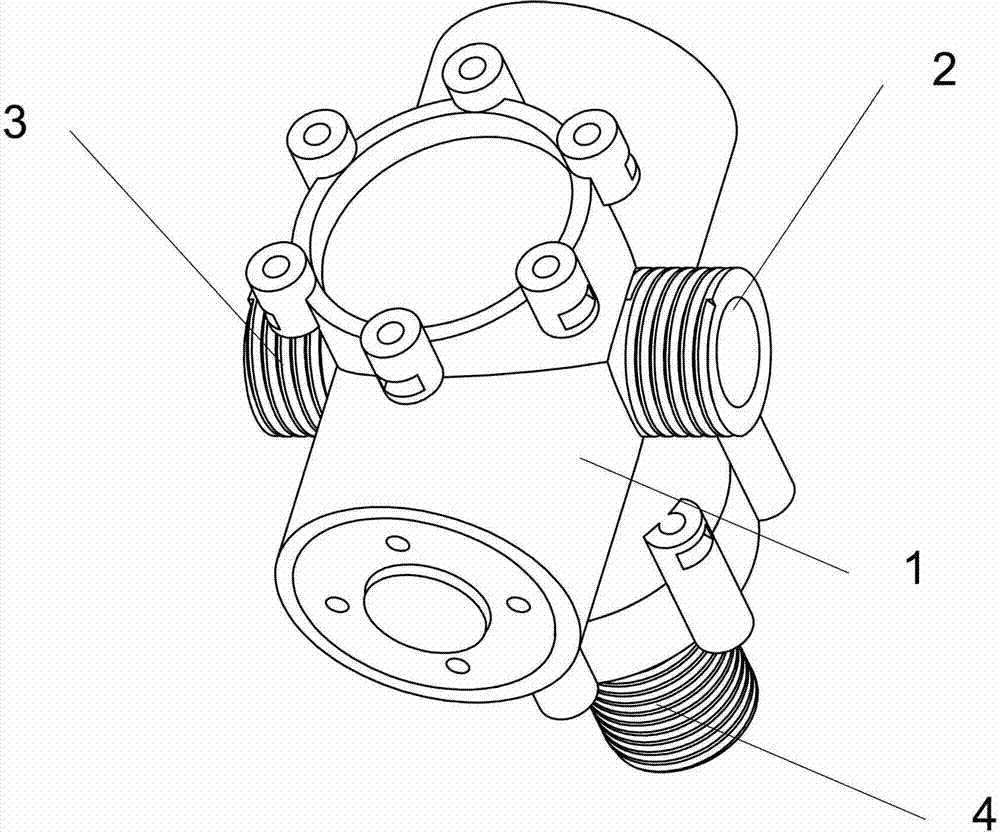

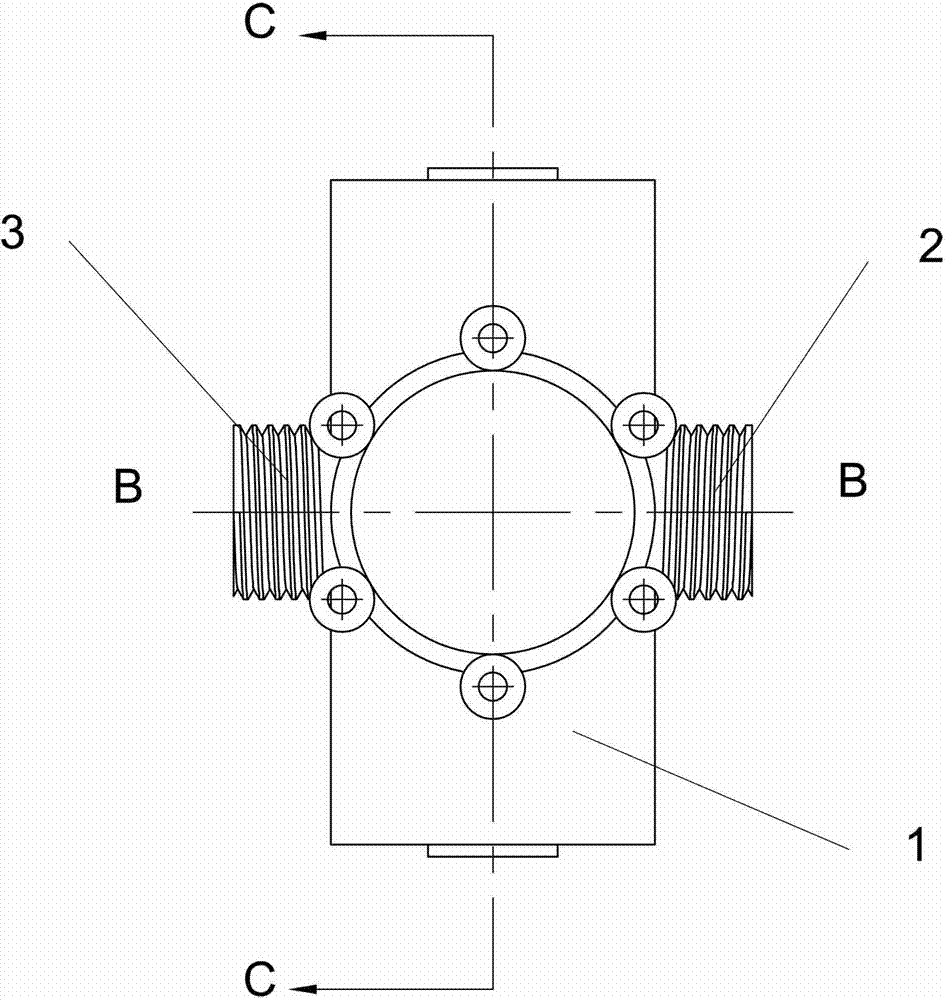

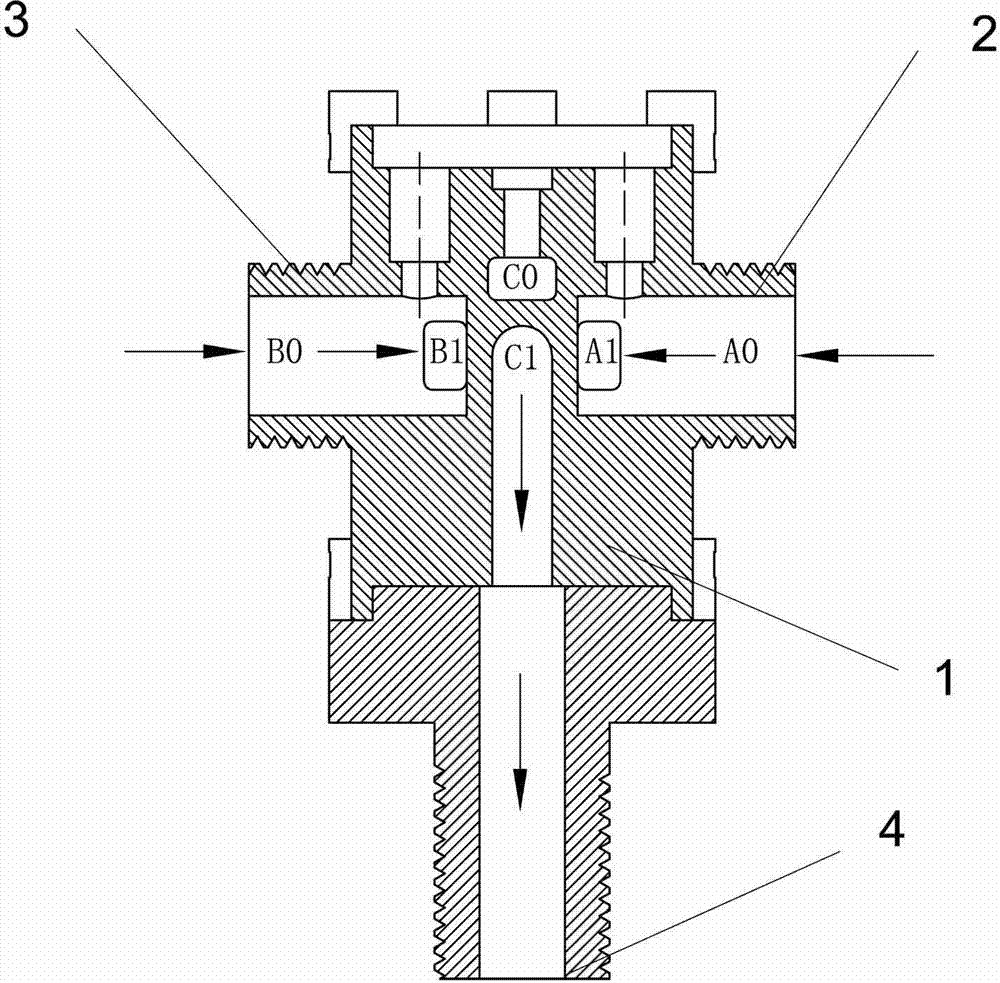

Valve core structure of water heater

ActiveCN103206560AScientific and reasonable structure designCompact designMultiple way valvesMechanical engineeringWater heater

The invention discloses a valve core structure of a water heater. The valve core structure comprises an automatic valve core and a hand-operated valve core arranged in an automatic valve cavity and in a hand-operated valve cavity, wherein the automatic valve core and the hand-operated valve core comprise valve core shells, bases, moving pieces, fixed pieces and valve core rotating handles; the valve core rotating handles are connected to the moving pieces in a clamping manner, each fixed pieces is provided with a first valve port, a second valve port, a third valve port and a fourth valve port, each moving piece is provided with a groove cavity, the center round part of the groove cavity and the first valve port of each fixed piece are correspondingly arranged, and a fan part of the groove cavity and the second valve port and the third valve port on each fixed piece are positioned on the same circumference line; and the second valve port and the third valve port are respectively communicated with a hot water flow channel and a cold water flow channel of a valve body, the valve body is internally provided with a mixing water flow channel so that the fourth valve port of the fixed piece of the automatic valve core and the fourth valve port of each fixed piece are communicated, and the first valve port of the fixed piece of the hand-operated valve core is communicated with a water outlet flow channel of the valve body. The valve core structure provided by the invention meets a scouring bath use comfort requirement.

Owner:广东新威博电器有限公司

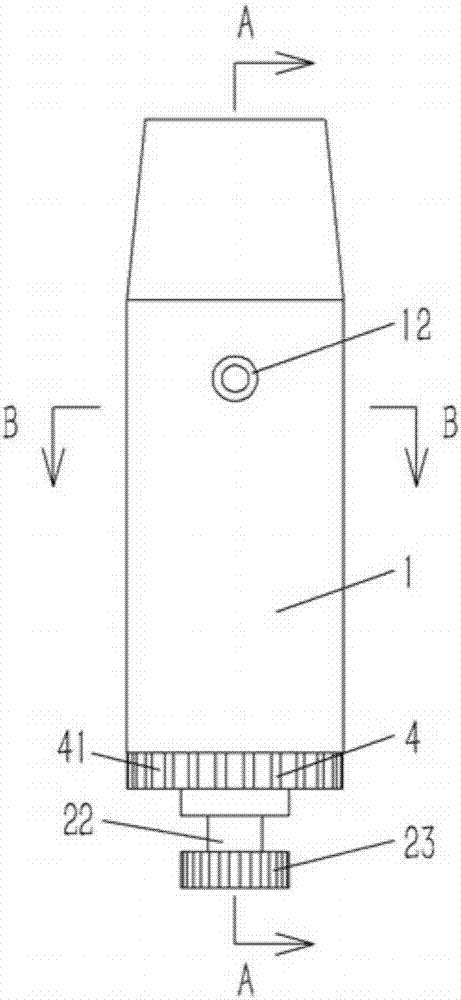

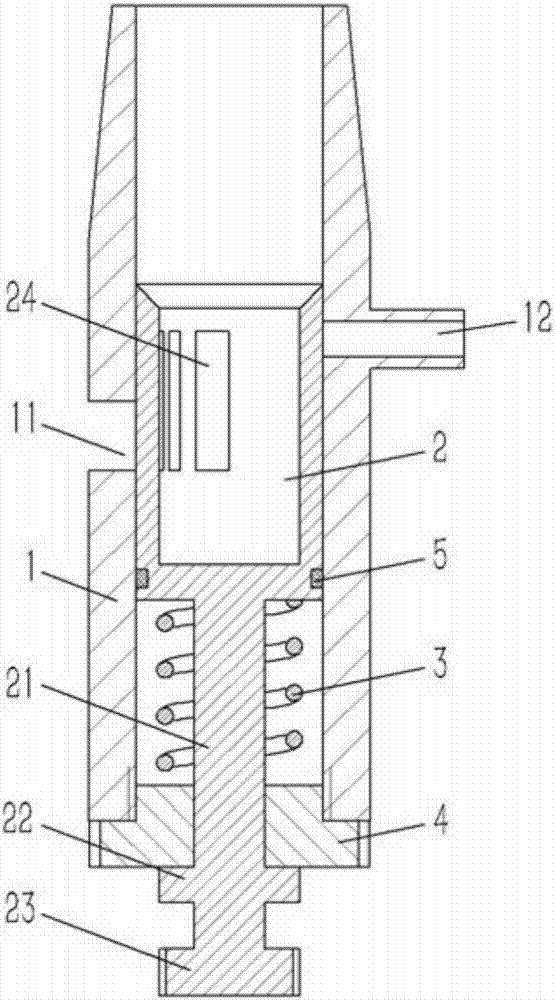

Pressure release nozzle applied to filtering machine

The invention discloses a pressure release nozzle applied to a filtering machine. The pressure release nozzle comprises a nozzle pipe. A water outlet is formed in the side wall of the nozzle pipe. An annular valve seat is connected into the nozzle pipe in an inserted manner. Multiple water outlet grooves different in width are formed in the valve seat. The water outlet grooves are opposite to the water outlet in the nozzle pipe. A pressure release pipe is formed at the position, between the lower side of the upper end face of the valve seat and the upper side of the water outlet, on the nozzle pipe. A vertical guide pillar is formed on the lower end face of the valve seat. The lower end of the guide pillar penetrates an inverted-T-shaped end cover to form a ring table. The ring table abuts against the lower end face of the end cover in a pressing manner. The end cover is in screw joint to the bottom end of the nozzle pipe. The guide pillar is sleeved with a compression spring in an inserted manner. The two ends of the compression spring abut against the end cover and the valve seat correspondingly in a pressing manner. The pressure release nozzle is simple in structure, the water outlet flow of the nozzle can be mechanically adjusted conveniently, meanwhile, the nozzle can be demounted, and cleaning is convenient.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

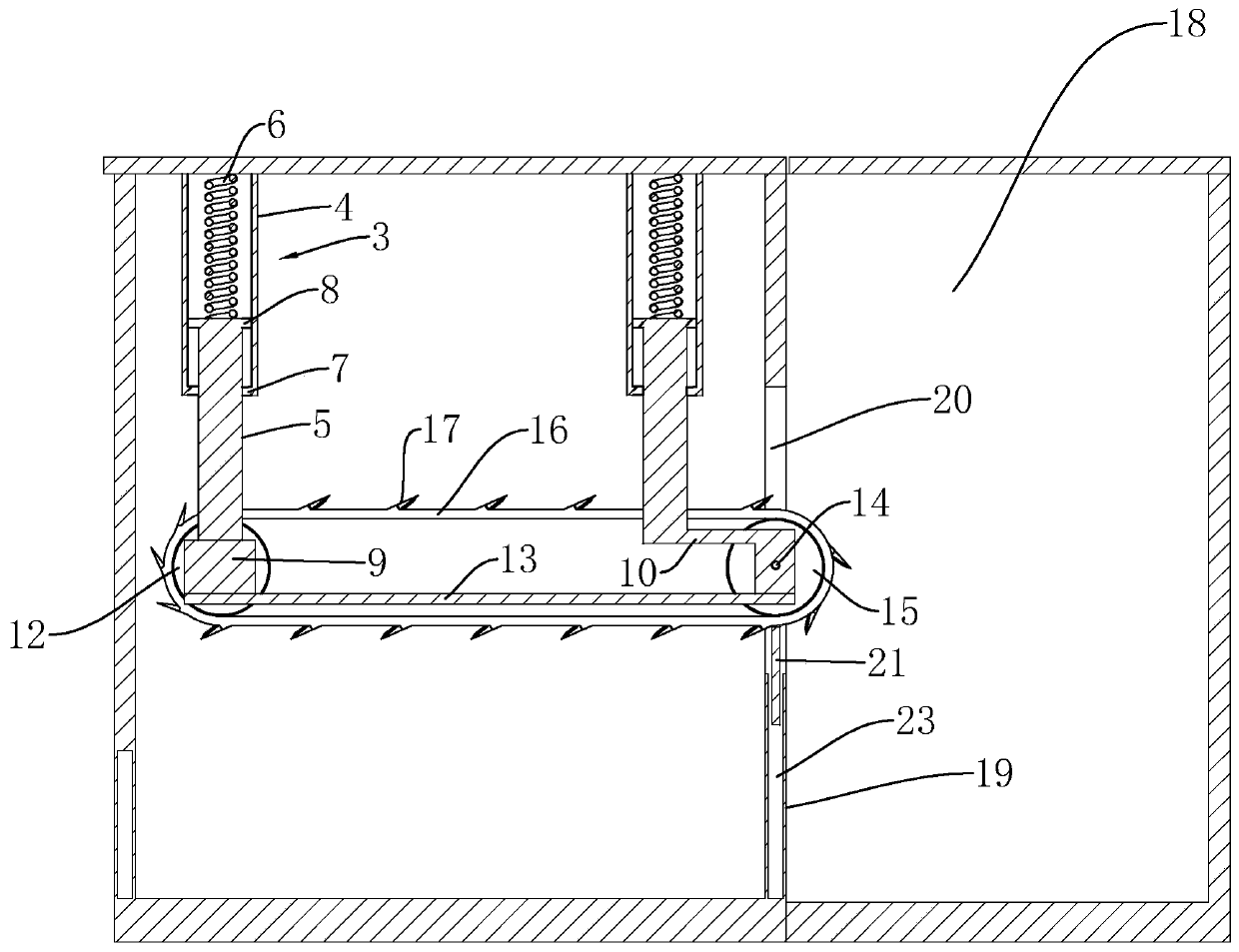

A municipal water supply and drainage structure with anti-clogging function

The invention discloses a municipal water supply and drainage structure having an anti-blocking function. The municipal water supply and drainage structure comprises a ditch body, wherein a ditch cover is arranged at the upper side of the ditch body; a cleaning mechanism, which lifts along with a water level in the ditch body, is arranged at the lower side of the ditch cover; the cleaning mechanism comprises a conveying belt; barbs are arranged on the conveying belt; the barbs obliquely point to the moving direction of the conveying belt; a collection groove is arranged in the end, close to atensioning roller, of the ditch body; a partition board is arranged between the collection groove and the ditch body; a collection port, which communicates with the collection groove and the ditch body, is arranged in the partition board; one end of the tensioning roller extends into the collection groove via the collection port; baffle plates are arranged at two ends of a rotating shaft; baffle notches, which are matched with the barbs, are arranged in the baffle plates; and moving cavities, which are matched with the baffle plates, are arranged in the partition board at the lower end of thecollection port. According to the municipal water supply and drainage structure provided by the invention, an effect of cleaning plastic bags floating a drainage ditch can be cleaned more effectivelycan be achieved.

Owner:QIJIAN GRP CO LTD

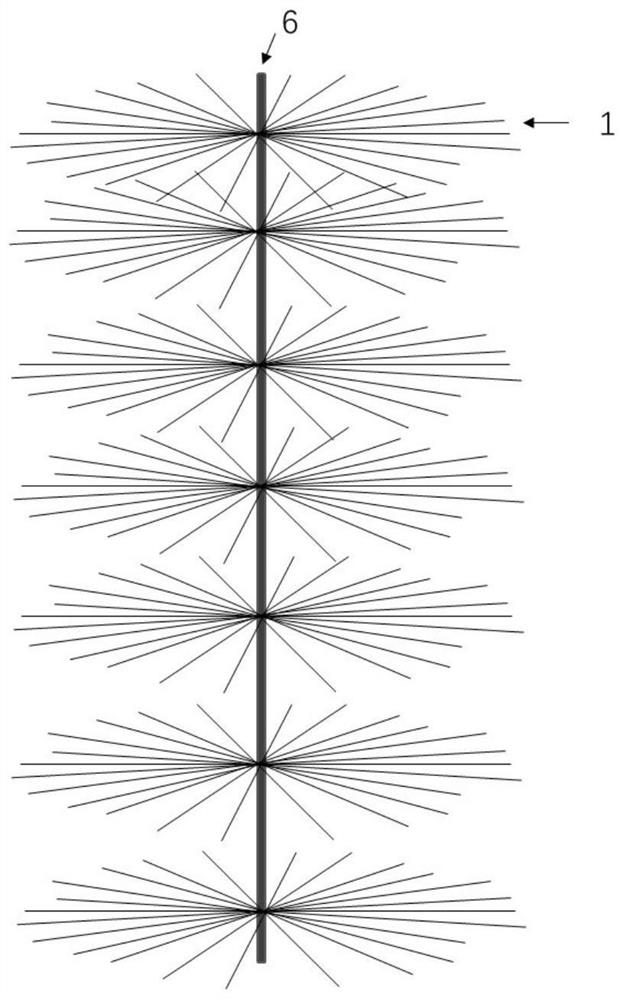

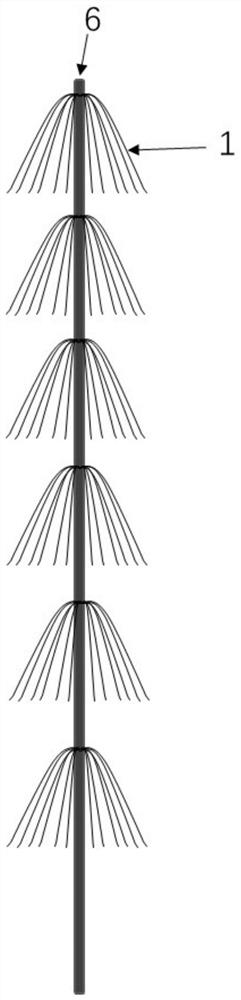

Water treatment composite electrode based on metal-based fiber material

ActiveCN112811527AReduce matrix massHigh aspect ratioWater/sewage treatmentMetal fiberComposite electrode

The embodiment of the invention provides a water treatment composite electrode based on a metal-based fiber material. The water treatment composite electrode comprises a metal fiber matrix, a micro-nano configuration metal surface layer, a metal oxide catalyst layer and a surface modification layer, wherein the micro-nano configuration metal surface layer is a metal surface layer which grows on the metal fiber matrix and has a micro-nano morphology of a micro column, a micro wire, a micro rod, a nano rod or a nano wire array; the metal oxide catalyst layer is a metal oxide array which grows in situ on the micro-nano-configuration metal surface layer and has a nanowire, nanorod or nano-cone appearance; and the surface modification layer is a super-hydrophobic coating or a conductive coating loaded on the metal oxide catalyst layer. According to the invention, surface-to-body ratio is high, the surface area is high, the effective area under a unit mass electrode (the specific electrode mass active area) is large; due to the special micro-nano interface characteristic and the open structure of the fiber electrode, the water treatment electrode is suitable for different water treatment scenes, and meanwhile, the water treatment electrode has the advantages of being high in oxidation capacity, excellent in mass transfer performance, long in service life, easy to machine and low in energy consumption.

Owner:BEIJING JIAOTONG UNIV

Pipe making method for suspension roller type spigot and socket muoth steel bar concrete pipe

InactiveCN1295063CSimple structureAchieve strengthShaping reinforcementsReinforced concreteHigh intensity

The reinforced concrete pipe making machine consists of mainly frame, suspension roller shaft fixed to the frame, gate head supported in the front of the suspension roller shaft, main shaft connected to the back end of the suspension roller shaft, driving mechanism connected to the main shaft, material feeding mechanism and pipe mold. The bearing in the front end of the suspension roller shaft is supported in the gate head bearing seat, the main shaft bearing is in the frame bearing seat, the jack fixed in the back end of the main shaft on the frame has head perpendicular to the main shaft axis, and the main shaft and the suspension roller shaft have angle to the horizontal plane of 0-3 deg. The pipe mold has flanged edges on two ends connected separately with spigot mold and socket mold separately. The present invention is suitable for producing high strength reinforced concrete pipe with spigot mold and socket.

Owner:黄博

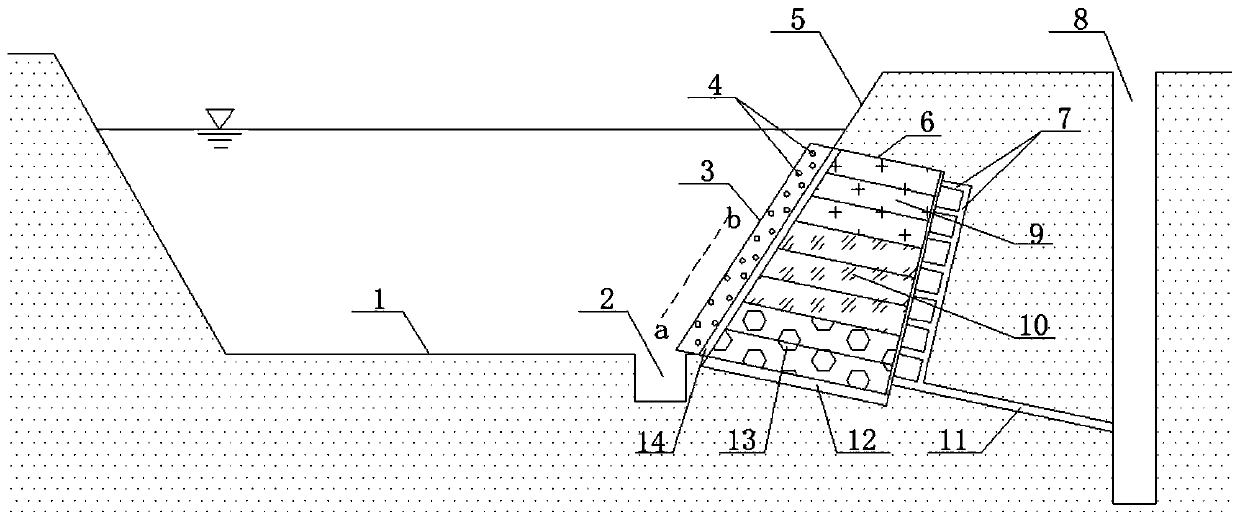

A ditch anti-clogging refill filter device

InactiveCN109183720BIncrease supplyDoes not affect water flowArtificial water canalsFiltration circuitsWater storageWater flow

Owner:UNIV OF JINAN

A reverse flushing pre-filter

ActiveCN106422461BExtended service lifeEasy to operateStationary filtering element filtersEngineeringMechanical engineering

The invention discloses a reverse washing prefilter which comprises a filter element and a shell arranged outside the filter element. The shell comprises an upper shell and a lower shell which are hermetically and integrally connected, a water inlet and a water outlet are formed in the upper shell, a water inlet cavity is formed in the upper shell, the water inlet is communicated with the inside of the water inlet cavity, the water outlet is communicated with the inside of the filter element, the upper shell comprises an upper sealing part and a lower sealing part which are positioned on the upper portion and the lower portion of the water inlet cavity respectively, water through openings are formed in the upper sealing part and the lower sealing part, a conversion rod is inserted into the water inlet cavity, the upper portion of the conversion rod sequentially penetrates the water through opening of the upper sealing part and the top of the upper shell, a sealing gasket for hermetically matching with the water through openings is arranged at the conversion rod between the upper sealing part and the lower sealing part, and a drainage valve is arranged at the bottom of the lower shell. According to the reverse washing prefilter, reverse washing operations are simple, and the filter element does not need to be disassembled, washed or replaced by professional staff.

Owner:NANJING FANSKI IND

Sunk type gas shield dam

InactiveCN110616686ADoes not affect replacement workSimplify replacement workBarrages/weirsWater flowTurning action

The invention provides a sunk type gas shield dam, and relates to a water retaining dam, in particular to the sunk type gas shield dam. The invention provides the sunk type gas shield dam with the advantages that an air bag can be conveniently dismounted and mounted; and a shield plate can be completely placed flatly. The sunk type gas shield dam comprises a concrete foundation, the shield plate and the air bag, wherein the shield plate is hinged onto the concrete foundation; the air bag is arranged at the lower part of the shield plate and drives the shield plate to do turning action; the shield plate is anchored on a shield plate anchoring surface through a first anchoring screw bolt; the air bag is anchored onto an air bag anchoring surface through a second anchoring screw bolt; a lifting machine is vertically placed; and a lifting plate is horizontally placed. The sunk type gas shield dam has the advantages that the structure is simple; the existing gas shield dam is improved; thereplacing work of the air bag is simplified; and meanwhile, the waterflow during dam collapse flow passing of the gas shield dam cannot be influenced.

Owner:刘益贤

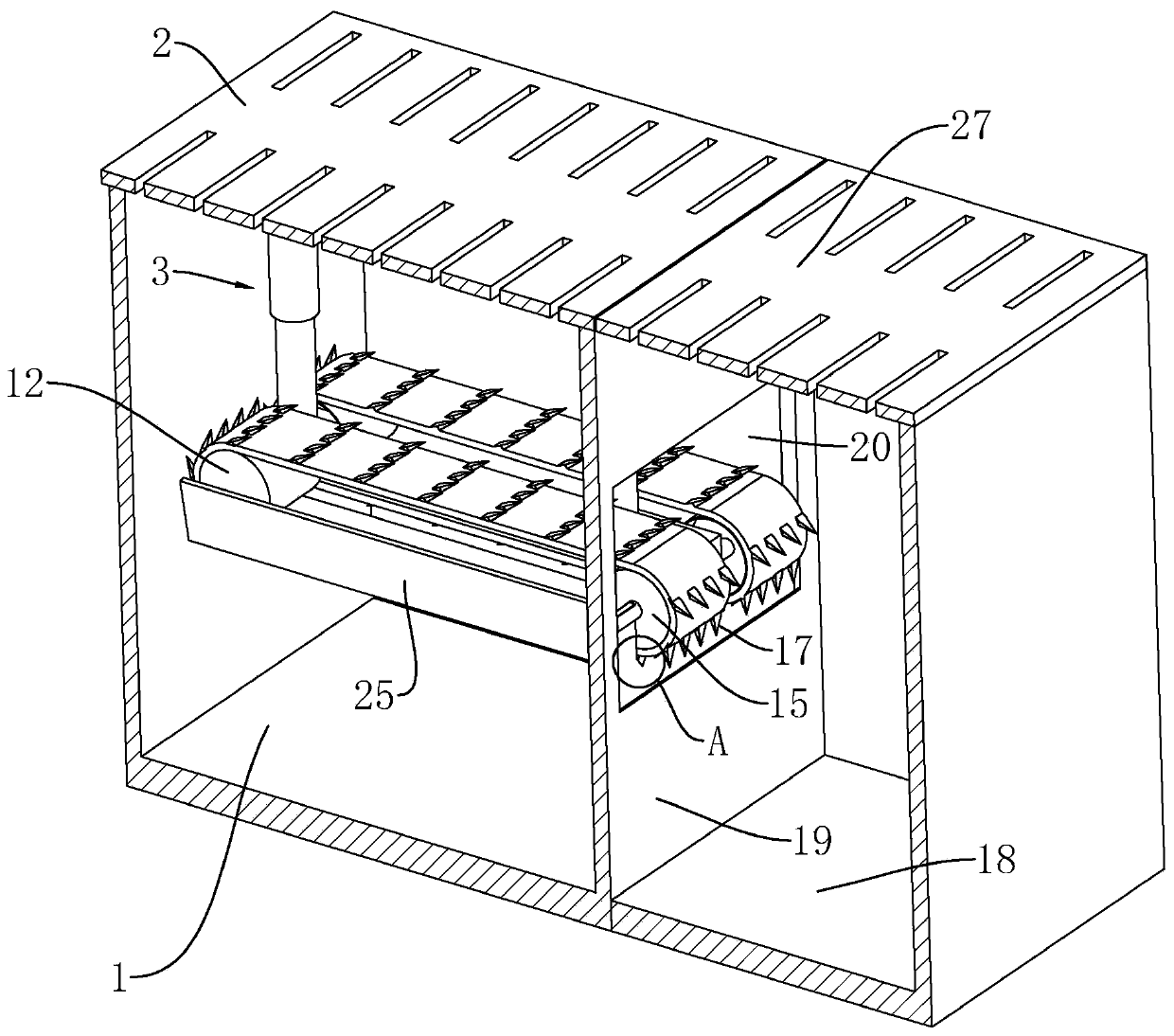

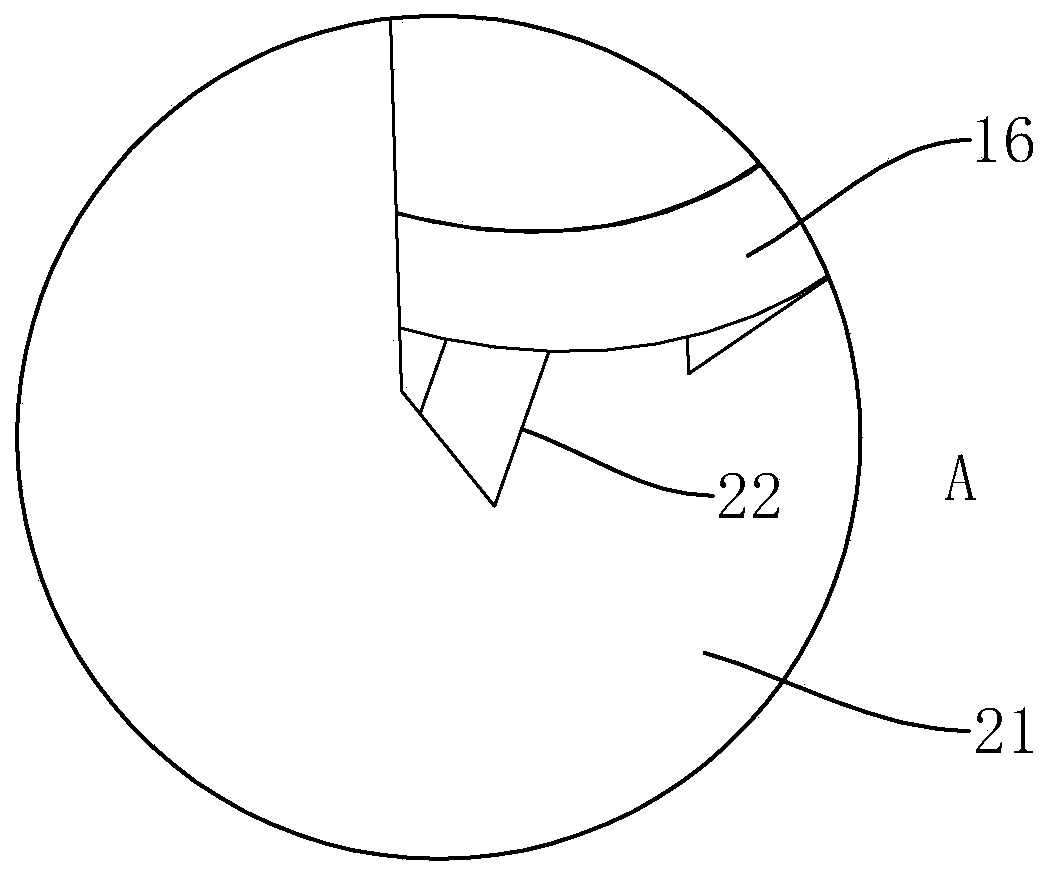

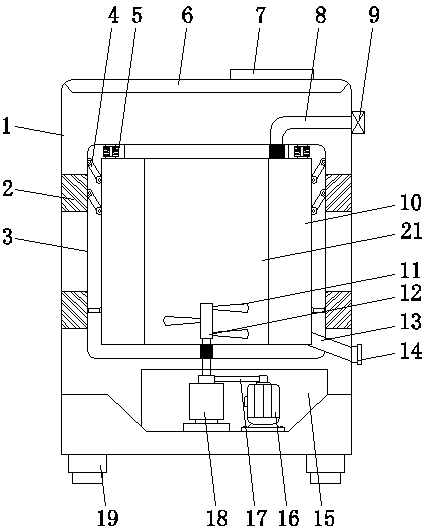

Water cooling speeding-up high-efficiency flowing water crusher

The invention discloses a water cooling speeding-up high-efficiency flowing water crusher. The water cooling speeding-up high-efficiency flowing water crusher comprises a machine body, and an outer cylinder body is installed in the machine body through a fixed block. An inner cylinder body is connected with the inner side of the outer cylinder body through a pull rod. A rotating cylinder is fixedin the inner cylinder body. At the same time, a cover plate is arranged at the top end of the machine body. A control panel is installed on the outer wall of the cover plate in a protruding mode, anda water inlet valve is arranged on the side wall of the machine body. The output end of the water inlet valve is connected with the top end of the inner cylinder body through the water inlet pipe, thebottom end of the inner cylinder body is connected with an water outlet pipe, the water outlet valve connected with the other end of the water outlet pipe is located outside the machine body, and a supporting pad is fixed to the lower end of the machine body. According to the water cooling speeding-up high-efficiency flowing water crusher, through arrangement of the outer cylinder body, the pulling rod, the control panel, the water inlet valve, the inner cylinder body, the water outlet valve and the rotating cylinder, and the problems of single function, no screening function and unsatisfactory cleaning effect existing in present beverage stirring and cleaning equipment are solved.

Owner:新乡市雷公饮片有限责任公司

Air shield dam

InactiveCN110616685ASimplify replacement workDoes not compromise connection tightnessBarrages/weirsWater flowEngineering

The invention relates to a water retaining dam, in particular to an air shield dam. The air shield dam with a conveniently-dismounted and mounted air bag and a completely flattened shield plate aims to solve the problems in the prior art. The air shield dam comprises a concrete foundation, the shield plate hinged to the concrete foundation, and an airbag arranged on the lower portion of the shieldplate and driving the shield plate to perform overturning action, wherein the shield plate is anchored on a shield plate anchoring surface through an anchor bolt I; and the air bag is anchored on anair bag anchoring surface through an anchor bolt II, the air bag is provided with an air inlet, an air inlet device of the air bag is arranged in the concrete foundation, and the air bag anchoring surface is lower than the shield plate anchoring surface. The air shield dam is simple in structure, an existing air shield dam is improved, and water flow when the air shield dam collapses and overflowsis not influenced while the replacement work of the air bag is simplified.

Owner:刘益贤

A double-sealing automatic retracting air bag valve mechanism

ActiveCN108413070BReduce wearIncrease contact areaDiaphragm valvesEngine diaphragmsEngineeringAirbag

The invention discloses a double-sealing automatic folding air bag valve mechanism. The double-sealing automatic folding air bag valve mechanism comprises a sleeve, two limiting supports and an adjusting mechanism, wherein the two limiting supports are arranged in the sleeve, and the adjusting mechanism is arranged in the position, located between the two limiting supports, of the upper wall bodyof the sleeve; and the adjusting mechanism comprises a ventilation pipe, a hollow air adjusting pressing cap, a sealing film, a deflation bolt, an air bag, a first vent hole, a second vent hole, a self-folding mechanism and an air closing flap, wherein the lower end of the ventilation pipe is provided with the sealed air adjusting pressing cap capable of sliding up and down and not separated fromthe ventilation pipe, the sealing film is arranged in the air adjusting pressing cap, and the bottom of the sealing film is provided with the deflation bolt for pushing the air closing flap. Comparedwith the prior art, the double-sealing automatic folding air bag valve mechanism has the advantages of being easy to operate, good in applicability, low in cost, good in sealing effect, and small in adjustment abrasion; and moreover, natural materials are adopted for machining, so that a certain bacteriostasis and health care effect is achieved, and the flow of water is not influenced.

Owner:江苏耐斯德阀门有限公司

Composite electrode for water treatment based on metal-based fiber material

ActiveCN112811527BReduce matrix massHigh aspect ratioWater/sewage treatmentMetal fiberComposite electrode

An embodiment of the present invention provides a composite electrode for water treatment based on a metal-based fiber material, comprising: a metal fiber matrix, a micro-nano configuration metal surface layer, a metal oxide catalyst layer and a surface modification layer; the micro-nano configuration metal surface layer is A metal surface layer with micro-nano morphology of micro-columns, micro-wires, micro-rods, nano-rods or nano-wire arrays grown on a metal fiber substrate; the metal oxide catalytic layer is an in-situ growth on the micro-nano configuration metal surface with A metal oxide array with nanowire, nanorod or nanocone morphology; the surface modification layer is a superhydrophobic coating or a conductive coating supported on the metal oxide catalytic layer. The invention has high surface area ratio, high surface area, high effective area under unit mass electrode (specific electrode mass active area), and is suitable for different water treatment scenarios due to the special micro-nano interface characteristics and the open structure of the fiber electrode, and has strong oxidizing ability at the same time. , excellent mass transfer performance, long service life, easy processing, low energy consumption.

Owner:BEIJING JIAOTONG UNIV

Valve core structure of water heater

ActiveCN103206560BScientific and reasonable structure designScientific and reasonable flow path designMultiple way valvesWater flowMechanical engineering

The invention discloses a valve core structure of a water heater. The valve core structure comprises an automatic valve core and a hand-operated valve core arranged in an automatic valve cavity and in a hand-operated valve cavity, wherein the automatic valve core and the hand-operated valve core comprise valve core shells, bases, moving pieces, fixed pieces and valve core rotating handles; the valve core rotating handles are connected to the moving pieces in a clamping manner, each fixed pieces is provided with a first valve port, a second valve port, a third valve port and a fourth valve port, each moving piece is provided with a groove cavity, the center round part of the groove cavity and the first valve port of each fixed piece are correspondingly arranged, and a fan part of the groove cavity and the second valve port and the third valve port on each fixed piece are positioned on the same circumference line; and the second valve port and the third valve port are respectively communicated with a hot water flow channel and a cold water flow channel of a valve body, the valve body is internally provided with a mixing water flow channel so that the fourth valve port of the fixed piece of the automatic valve core and the fourth valve port of each fixed piece are communicated, and the first valve port of the fixed piece of the hand-operated valve core is communicated with a water outlet flow channel of the valve body. The valve core structure provided by the invention meets a scouring bath use comfort requirement.

Owner:广东新威博电器有限公司

A Welding Method for Tension Ribs of Weld Joints of Pipelines in High Temperature Environment

ActiveCN108161267BNo burning problemGuaranteed welding strengthWelding apparatusWater leakageStructural engineering

The invention relates to a welding method for tension rib plates for welding seams of high-temperature environment pipelines and belongs to the technical field of high-temperature pipeline maintenancemethods. The welding method is used for welding the tension rib plates to the high-temperature environment pipeline welding seams. According to the technical scheme, sunroof holes are cut in the welding seam cracking portions of the pipelines, the tension rib plates are welded to the inner walls of the pipeline welding seam cracking portions where the sunroof holes are located of the pipeline, the tension rib plates are evenly distributed on the periphery of the inner wall of each pipeline, and due to the fact that no burning problem is generated when the tension rib plates are in the water-cooling pipelines, the welding seam strength is ensured, and the function of long-term reinforcement of the pipeline welding seam cracking portions is played. The welding method is the first of pipeline maintenance in the high temperature environment, a traditional tension rib plate welding method is broken through, the tension rib plates are creatively welded to the inner walls of the pipelines, the burning problem of the tension rib plates in the water-cooling environment is prevented, the problems of incomplete water leakage and maintenance of the pipeline welding seams in the industry are solved completely with the simplest method, meanwhile the consumption of spare parts can be lowered, and safe and smooth production is ensured.

Owner:WUYANG IRON & STEEL

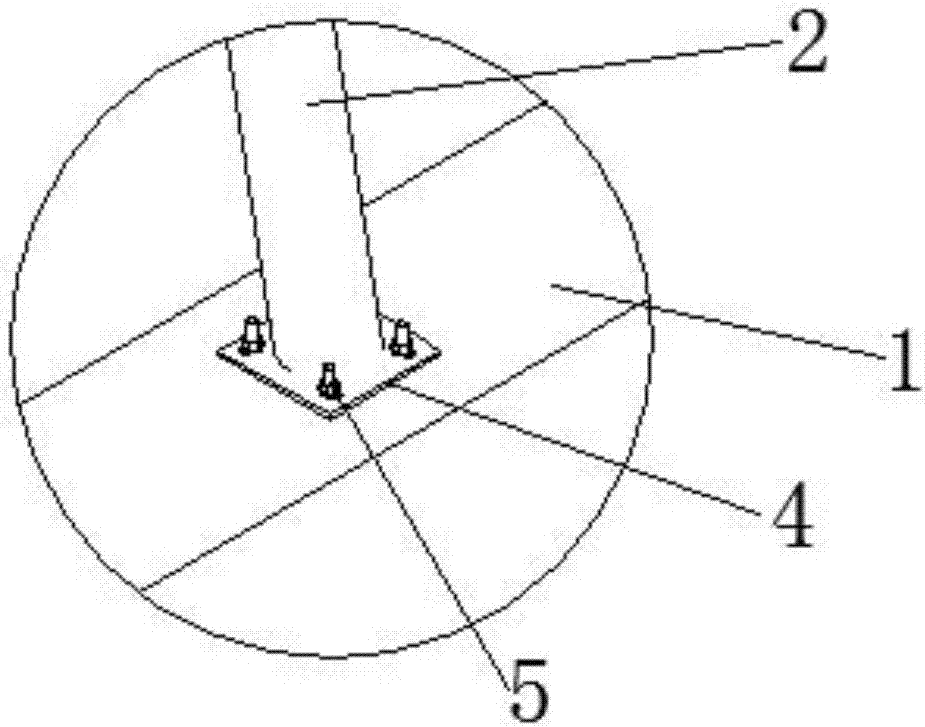

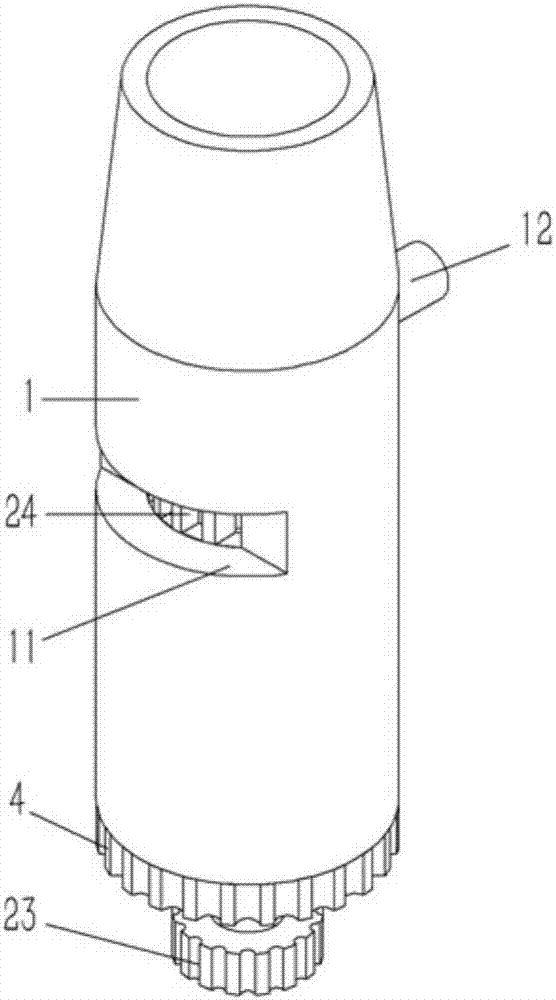

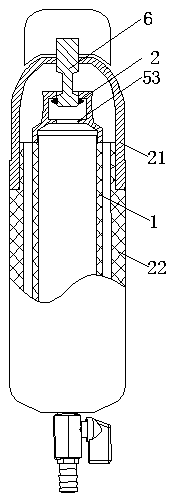

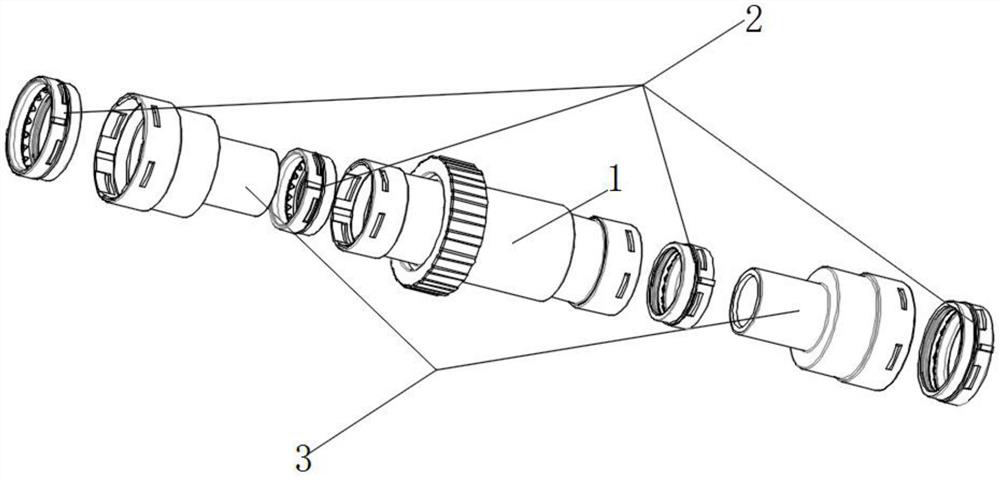

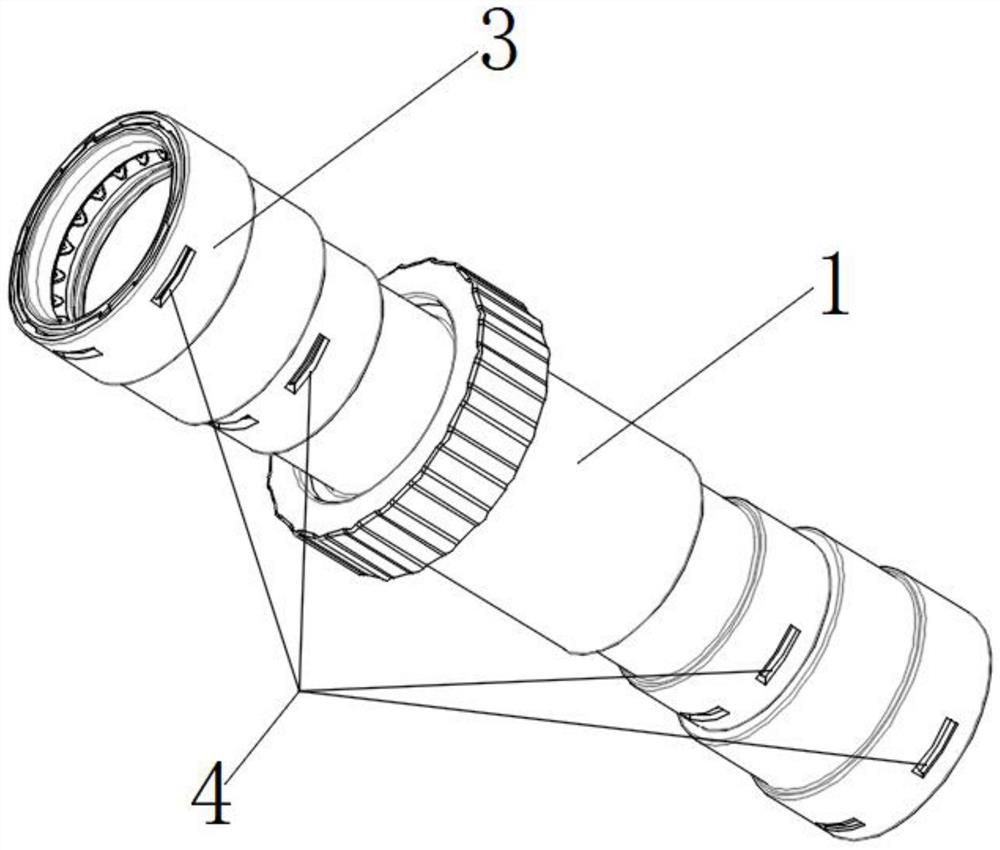

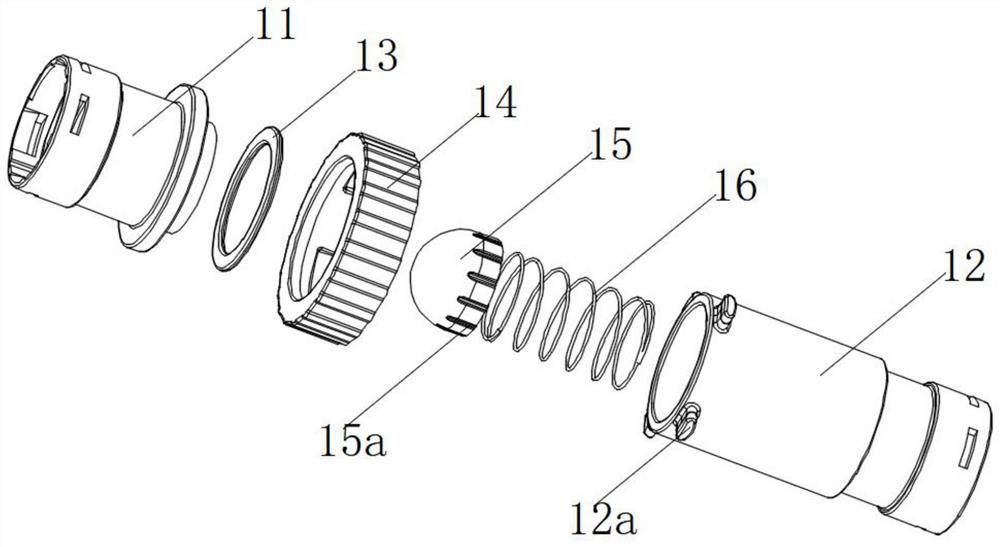

Peculiar smell isolator and using method thereof

InactiveCN112695854AAchieve odorIsolate odorDomestic plumbingStructural engineeringMechanical engineering

The invention discloses a peculiar smell isolator and a using method thereof, and belongs to the technical field of pipeline deodorization. A spring is embedded inside a peculiar smell isolator main body, a ball cap is fixed at the top end of the spring, the ball cap freely slides on the peculiar smell isolator main body, adapters are clamped at the water inlet end and the water outlet end of the peculiar smell isolator main body, the peculiar smell isolator main body is detachably connected to the adapters, sealing assemblies are arranged at the joints of the peculiar smell isolator main body and the adapters and in the ends, away from the peculiar smell isolator main body, of the adapters, and the peculiar smell isolator main body is connected to the adapters through the sealing assemblies. According to the peculiar smell isolator and the using method thereof, the isolator is separated from the design of a traditional U-shaped pipe, the isolator is additionally arranged on the basis of not changing the shape of the pipeline so that peculiar smell in the pipeline can be isolated, by adopting the design of the adapters and the sealing assemblies, the adaptation of the peculiar smell isolator to pipelines of different models and sizes is ensured, and different peculiar smell isolators do not need to be replaced according to the pipelines of different models.

Owner:HANGZHOU WENGER SCI & TECH CO LTD

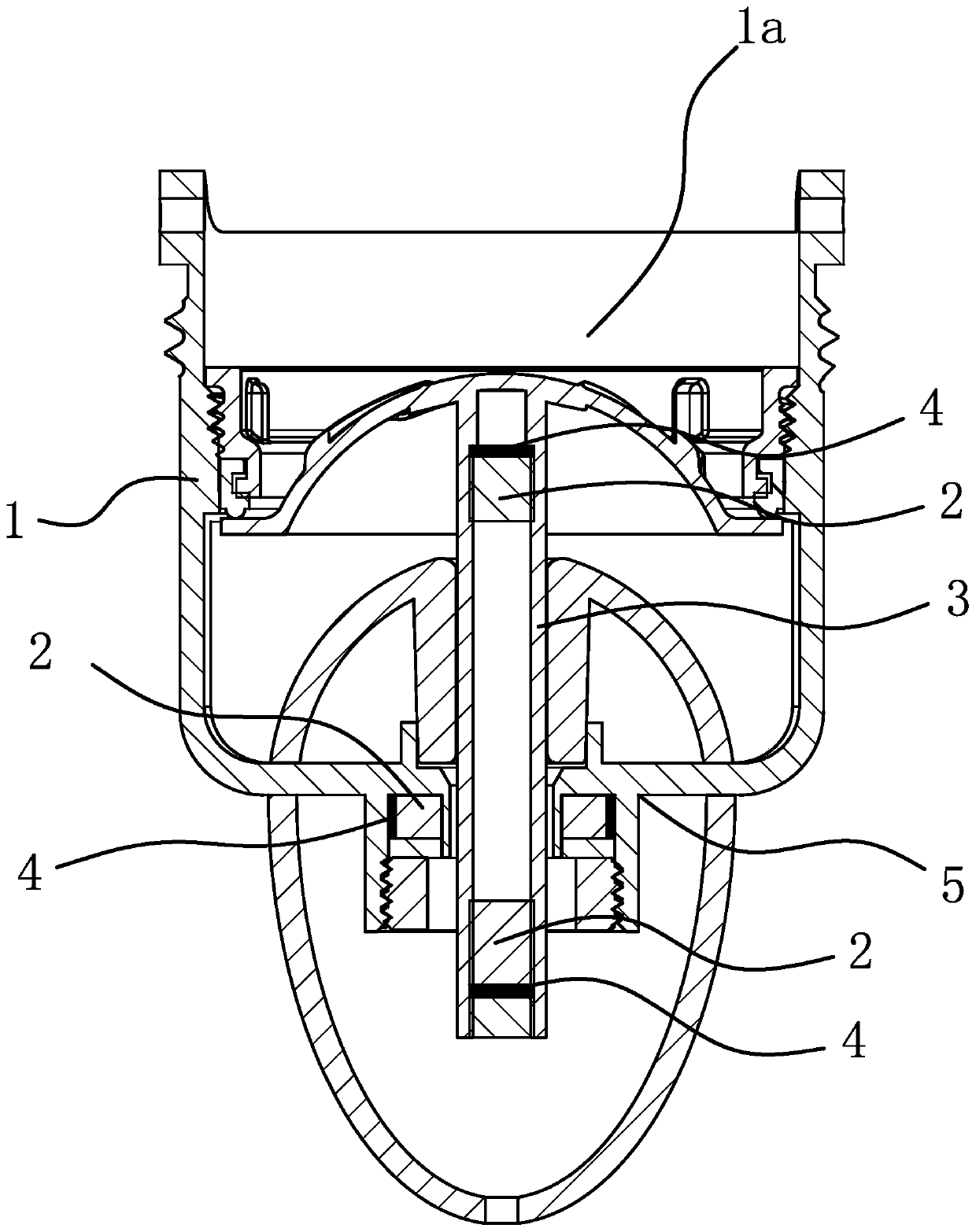

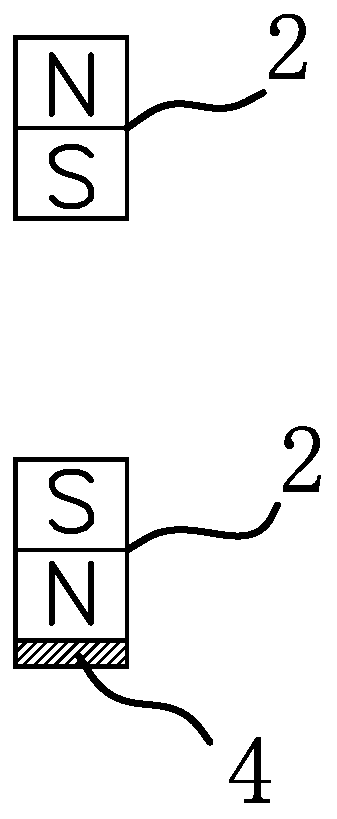

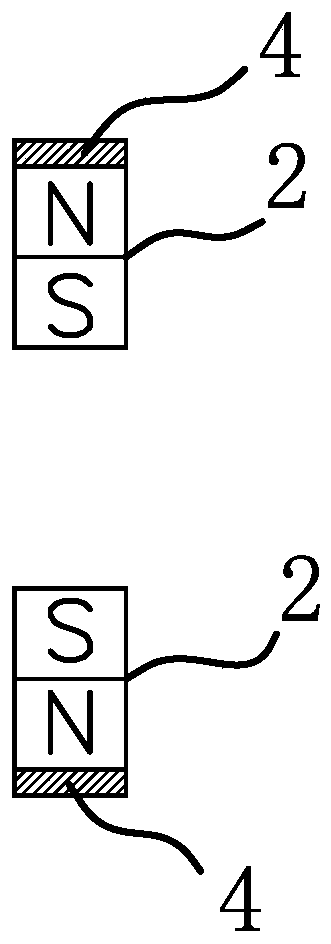

Odor-resistant drainage device

PendingCN111501975AIncrease the magnetic field strengthEnhance the size of the magnetic forceSewerage structuresMagnetic tension forceConductive materials

The invention provides an odor-resistant drainage device, and belongs to the technical field of machinery. The odor-resistant drainage device solves the problem that a sealing element in an existing odor-resistant drainage device is difficult to stably reset and seal. The odor-resistant drainage device comprises a shell with a water passing hole, a support connected with the shell and a sealing cover, wherein magnets are fixed to the support and the sealing cover; the sealing cover can block the water passing hole under the magnetic force effect of the magnets; at least one magnet is providedwith a shielding part; and the shielding parts are made of magnetic conductive materials and are fixed to the side faces, away from other magnets, of the magnets. The odor-resistant drainage device has the advantage of being good in sealing stability.

Owner:吕家杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com