Composite electrode for water treatment based on metal-based fiber material

A composite electrode and fiber material technology, applied in the field of water treatment, can solve the problems of stability and catalytic inapplicability, achieve excellent electrocatalytic performance, reduce electrode quality, and reduce quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

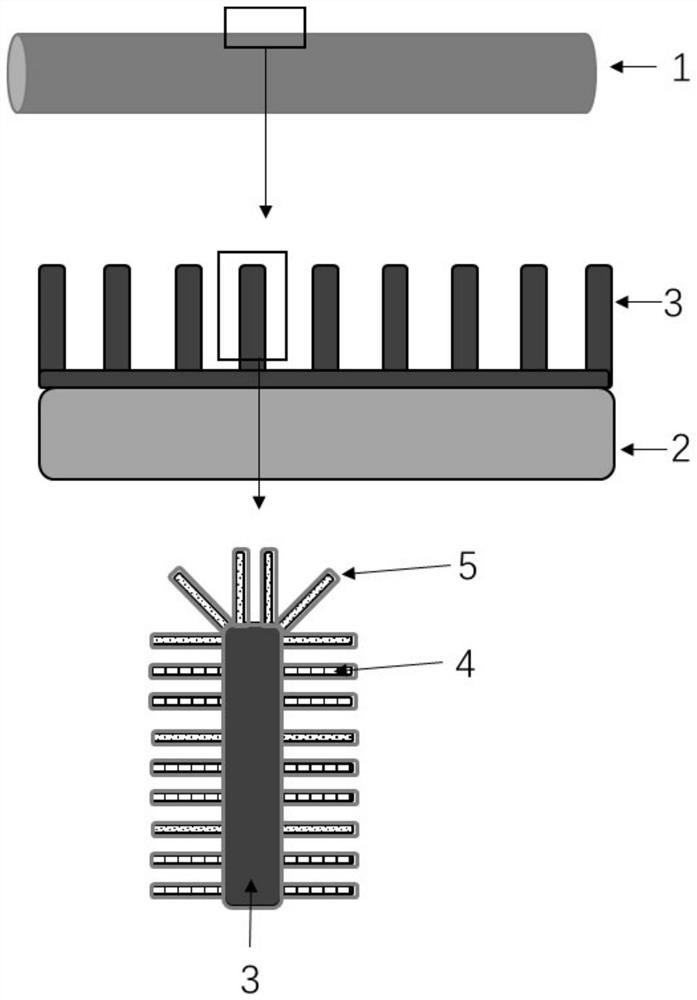

[0039] The embodiment of the present invention provides a composite electrode 1 for water treatment based on a metal-based fiber material, such as figure 1 As shown, it includes: a metal fiber matrix 2 , a micro-nano configuration metal surface layer 3 , a metal oxide catalyst layer 4 and a surface modification layer 5 . The micro-nano configuration metal surface layer 3 is a metal surface layer with micro-nano morphology of micro-columns, micro-wires, micro-rods, nano-rods or nano-wire arrays grown on the metal fiber matrix 2; A metal oxide array with nanowires, nanorods or nanocones grown in situ on the configuration metal surface layer 3; the surface modification layer 5 is a superhydrophobic coating or conductive layer supported on the metal oxide catalytic layer 4 coating. Among them, the superhydrophobic coating is a polytetrafluoroethylene coating or a fluorosilane coating; the conductive coating is one or more of graphene, graphene oxide, redox graphene, fullerene, or...

Embodiment 2

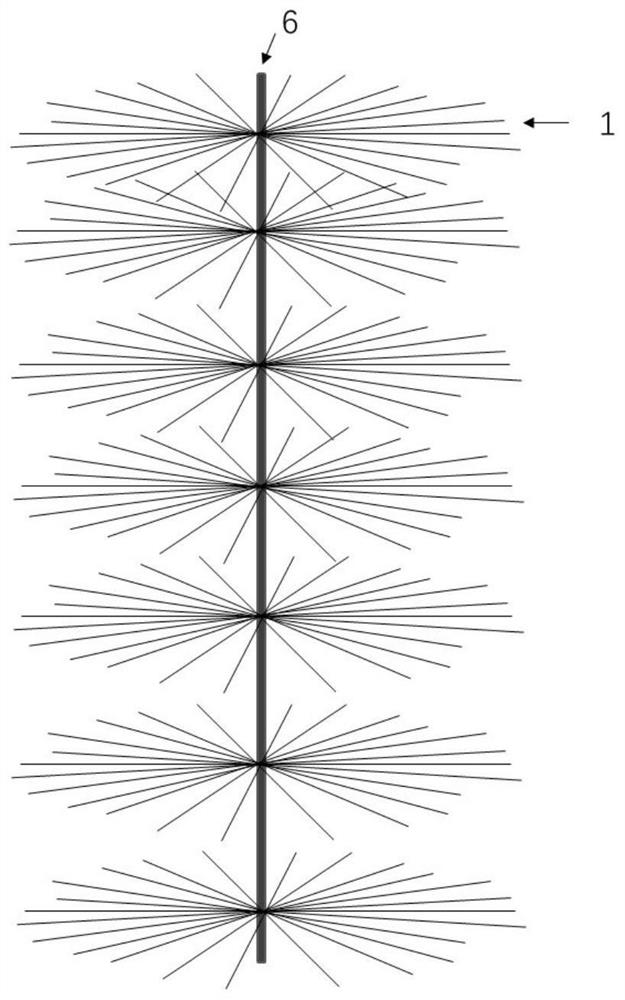

[0046] The embodiment of the present invention provides a composite electrode for water treatment based on a metal-based fiber material, such as figure 1 and 2 As shown, the composite electrode 1 includes: a metal fiber matrix 2 , a micro-nano configuration metal surface layer 3 , a metal oxide catalyst layer 4 and a surface modification layer 5 . The metal fiber matrix 2 is Ti filament fibers, the micro-nano configuration metal surface layer 3 is an array of titanium micro-pillars produced by uniform acid etching, and the metal oxide catalyst layer 4 is TiO grown on the titanium micro-pillar fibers in situ by hydrothermal method. 2 Nanorod array, surface modification layer 5 is in TiO 2 For the superhydrophobic coating further loaded on the nanorod array, the fiber diameter of the composite electrode 1 is in the range of 0.1 mm, and the superhydrophobic coating is a fluorosilane coating. According to actual needs, such as figure 2 As shown, the composite electrode 1 is pr...

Embodiment 3

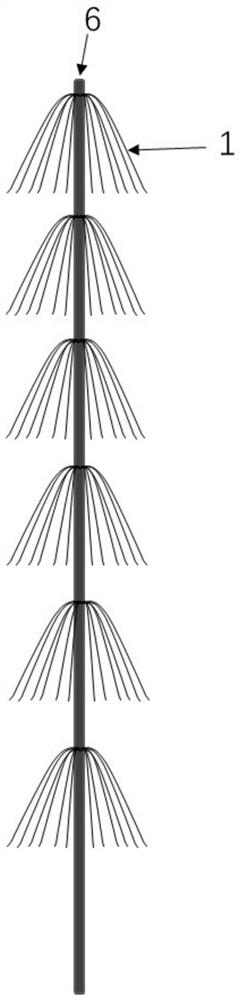

[0048] The embodiment of the present invention provides a composite electrode for water treatment based on a metal-based fiber material, such as figure 1 and 3 shown. The composite electrode 1 includes: a metal fiber matrix 2 , a micro-nano configuration metal surface layer 3 , a metal oxide catalyst layer 4 and a surface modification layer 5 . The metal fiber matrix 2 is Cu silk fibers, the micro-nano configuration metal surface layer 3 is a Cu micro-wire array produced by electrodeposition, and the metal oxide catalyst layer 4 is a CuO nanorod array grown in-situ on the titanium micro-pillar fiber by hydrothermal method, The surface modification layer 5 is a superhydrophobic coating further supported on the CuO nanorod array, the fiber diameter range of the composite electrode 1 is 0.5 mm, and the superhydrophobic coating is a polytetrafluoroethylene coating. According to actual needs, such as image 3 As shown, the composite electrode 1 is processed into the shape of sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com