Water treatment composite electrode based on metal-based fiber material

A composite electrode and fiber material technology, applied in the field of water treatment, can solve the problems of stability and inapplicability of catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

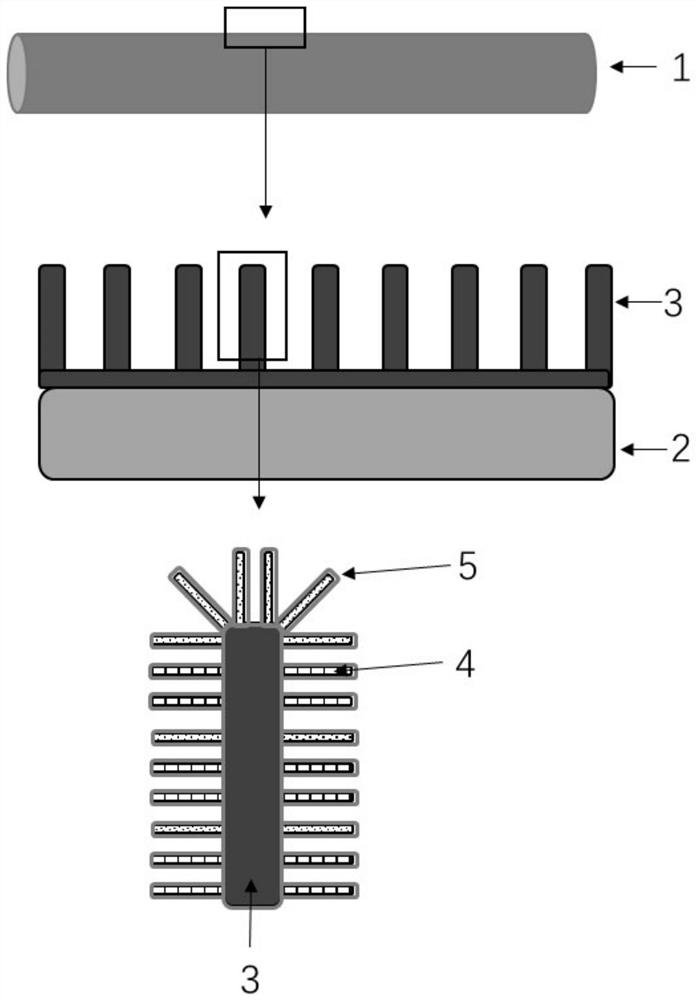

[0039] The embodiment of the present invention provides a water treatment composite electrode 1 based on a metal-based fiber material, such as figure 1 As shown, it includes: metal fiber substrate 2 , metal surface layer 3 with micro-nano configuration, metal oxide catalytic layer 4 and surface modification layer 5 . The micro-nano configuration metal surface layer 3 is a metal surface layer with a micro-nano shape of a micro-column, a micro-wire, a micro-rod nano-rod or a nano-wire array grown on the metal fiber substrate 2; A metal oxide array with the morphology of nanowires, nanorods, or nanocones grown in situ on the configuration metal surface layer 3; the surface modification layer 5 is a superhydrophobic coating or conductive coating loaded on the metal oxide catalytic layer 4 coating. Wherein, the superhydrophobic coating is a polytetrafluoroethylene coating or a fluorosilane coating; the conductive coating is one or more of graphene, graphene oxide, redox graphene, ...

Embodiment 2

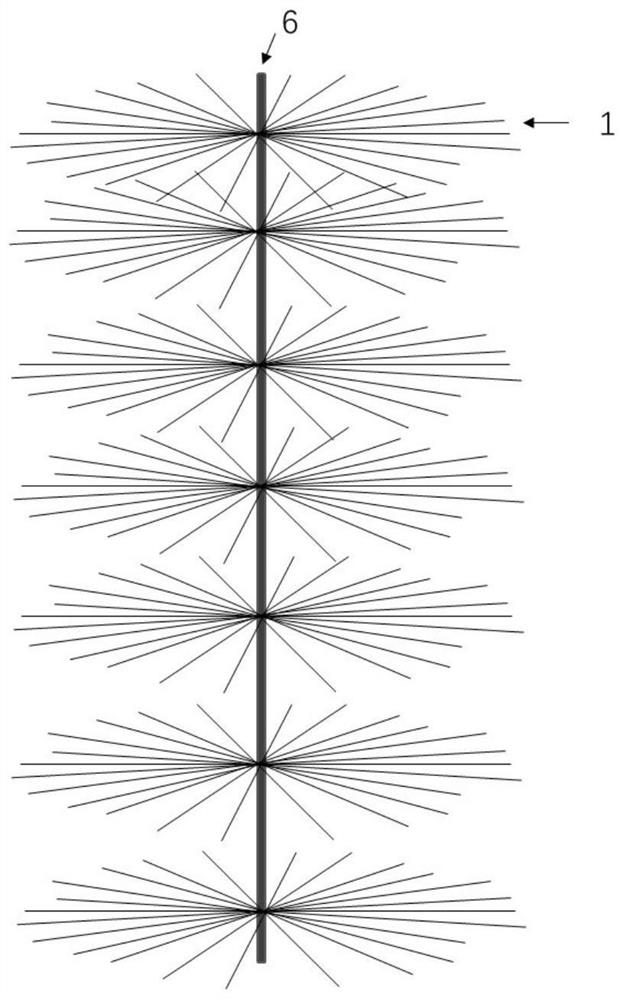

[0046] A water treatment composite electrode based on a metal-based fiber material provided by an embodiment of the present invention, such as figure 1 and 2 As shown, the composite electrode 1 includes: a metal fiber matrix 2 , a metal surface layer 3 with a micro-nano configuration, a metal oxide catalytic layer 4 and a surface modification layer 5 . The metal fiber matrix 2 is Ti wire fiber, the micro-nano configuration metal surface layer 3 is uniformly etched with acid to produce a titanium microcolumn array, and the metal oxide catalytic layer 4 is TiO grown in situ on the titanium microcolumn fiber by hydrothermal method 2 nanorod arrays, the surface modification layer 5 is on TiO 2 The superhydrophobic coating further loaded on the nanorod array, the fiber diameter range of the composite electrode 1 is 0.1 mm, and the superhydrophobic coating is a fluorosilane coating. According to actual needs, such as figure 2 As shown, the composite electrode 1 is processed into...

Embodiment 3

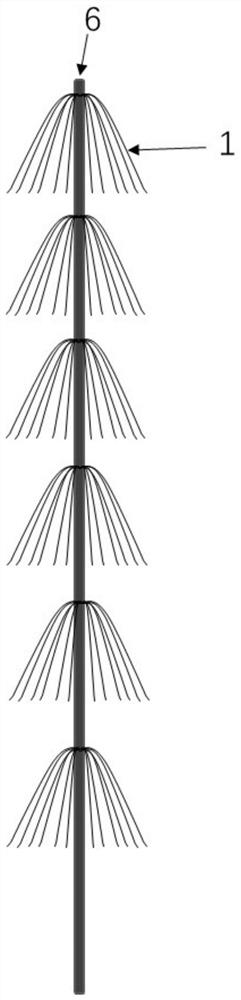

[0048] A water treatment composite electrode based on a metal-based fiber material provided by an embodiment of the present invention, such as figure 1 and 3 shown. The composite electrode 1 includes: a metal fiber matrix 2 , a metal surface layer 3 with a micro-nano configuration, a metal oxide catalytic layer 4 and a surface modification layer 5 . The metal fiber matrix 2 is a Cu wire fiber, the Cu micron line array produced by electrodeposition of the micronano configuration metal surface layer 3, and the metal oxide catalytic layer 4 is a CuO nanorod array grown in situ on the titanium microcolumn fiber by hydrothermal method, The surface modification layer 5 is a super-hydrophobic coating further supported on the CuO nanorod array, the fiber diameter of the composite electrode 1 is 0.5 mm, and the super-hydrophobic coating is a polytetrafluoroethylene coating. According to actual needs, such as image 3 As shown, the composite electrode 1 is processed into the shape of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com