Sunk type gas shield dam

A gas shield and airbag technology, applied in the field of submerged gas shield dams, can solve the problems of affecting water flow, uneven shield plate, affecting flow rate, etc., and achieves the effect of simple structure, reduced cost, and simplified replacement work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

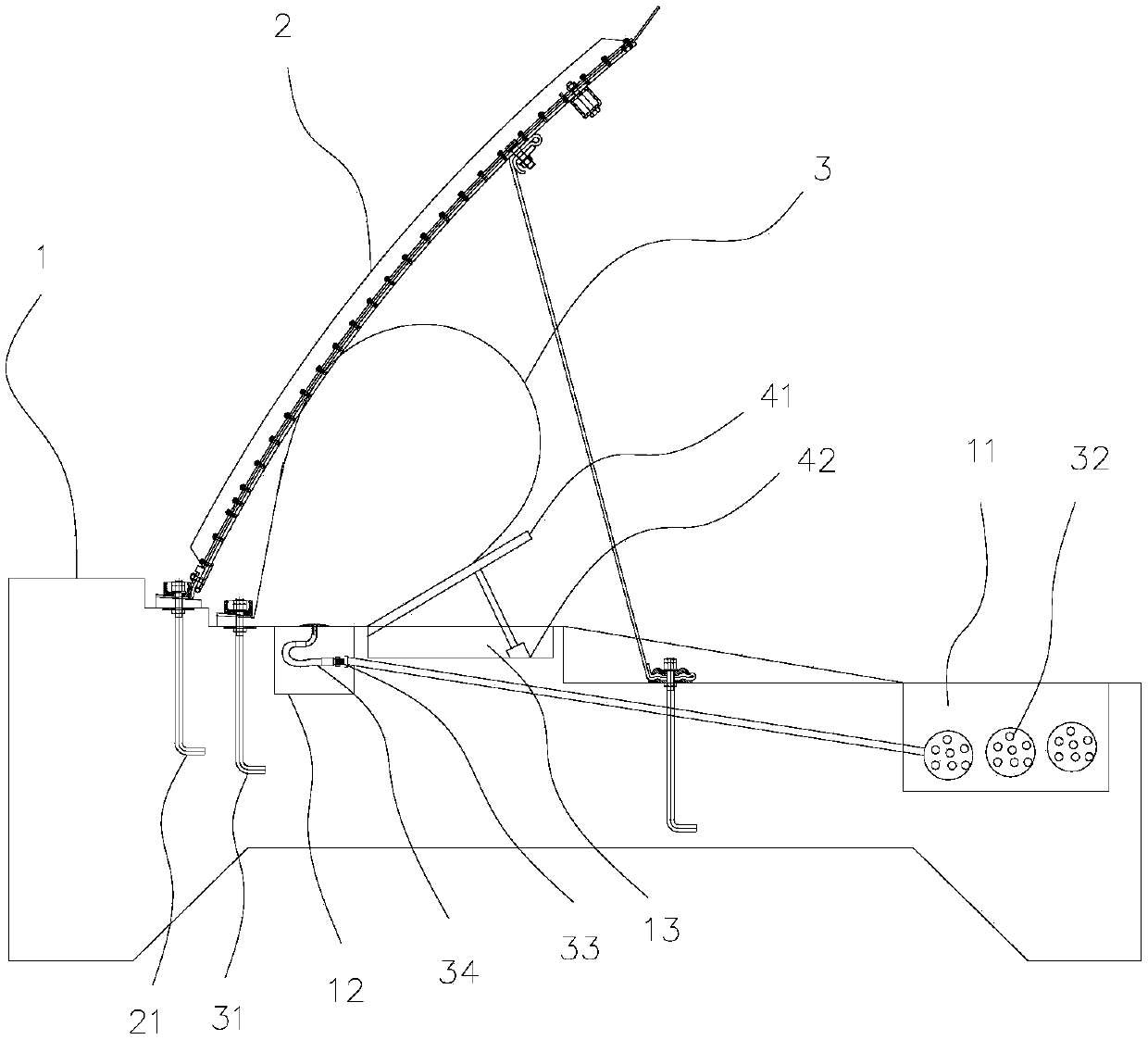

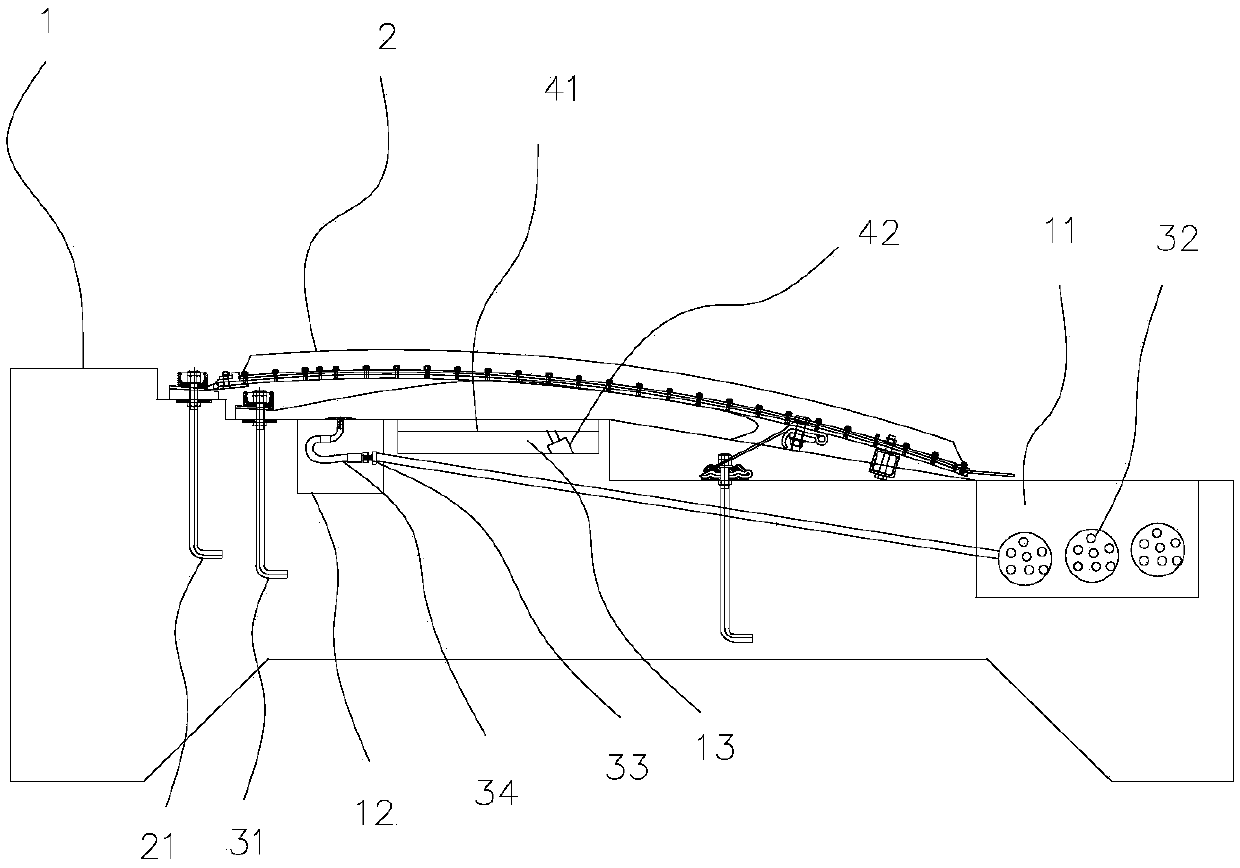

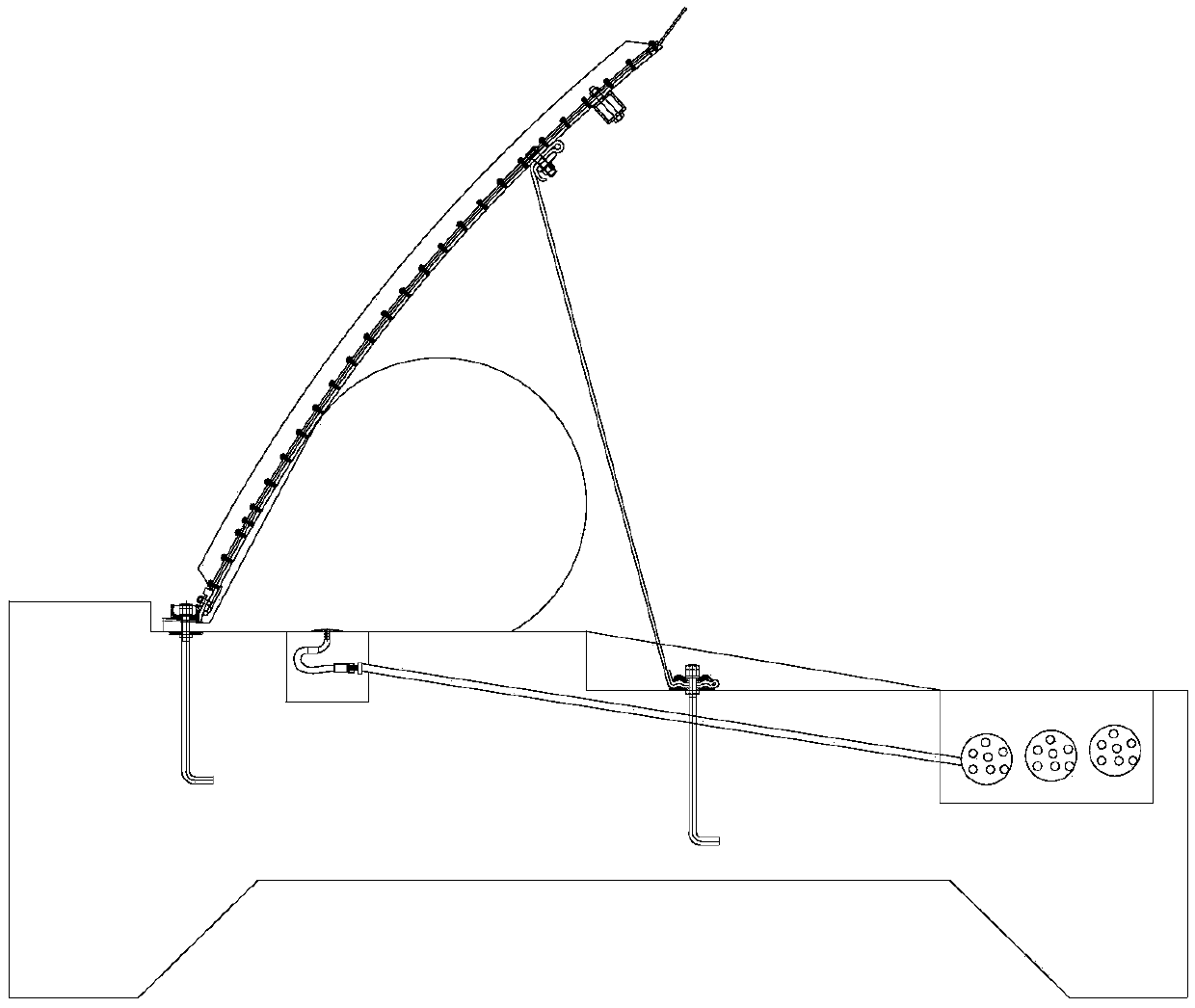

[0019] The first embodiment of the present invention, such as figure 1 As shown, one side of the lifting plate 41 is hinged on the side wall of the groove three 13, and the lifting machine 42 is placed obliquely toward the airbag anchor bolt two. Groove three 13 is positioned at groove two 12 away from the side of airbag 3 anchor bolt two 31, and inclined hoist 42 will lift plate 41 and send to airbag obliquely, makes airbag closer to shield plate.

[0020] The lifter 42 is an air cylinder or an oil cylinder.

[0021] The invention has a simple structure, improves the existing air shield dam, simplifies the replacement work of the air bag, and reduces the improved use cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com