A Welding Method for Tension Ribs of Weld Joints of Pipelines in High Temperature Environment

A high-temperature environment and welding method technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as incomplete and leaky maintenance of pipeline welding joints, so as to ensure safe and smooth operation, reduce spare parts consumption, and solve incomplete maintenance. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

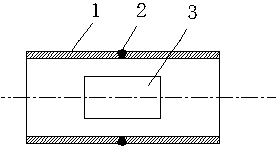

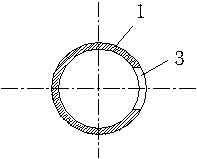

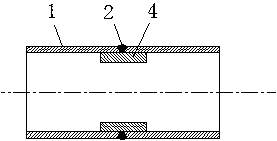

[0020] The invention is the first creation of pipeline maintenance under high-temperature environment, breaks through the traditional method of welding tension ribs, and creatively welds tension ribs to the inner wall of the pipeline. In actual operation, the cracked part of the water-cooling pipe is cut open, and high-temperature-resistant steel strips are embedded as internal tension ribs. Strict welding processes and corresponding high-temperature-resistant strength welding rods are used, and then the cut-away skylight holes are welded and sealed. Since the tension ribs are placed in the water-cooled pipe, the tension ribs will not be burned in the water-cooled environment, which completely solves the problems of water leakage and incomplete maintenance of the pipe welds in the industry.

[0021] The present invention adopts following steps to carry out:

[0022] a. Cut out the skylight hole 3 at the cracked part 2 of the welding joint of the pipeline 1, the skylight hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com