Thyristor direct switching on-load tap-changer

An on-load tap, thyristor technology, applied in electronic switches, transformers, electrical components, etc., can solve the problems of poor fast performance, large maintenance, low reliability, etc., and achieve the effect of high fast performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

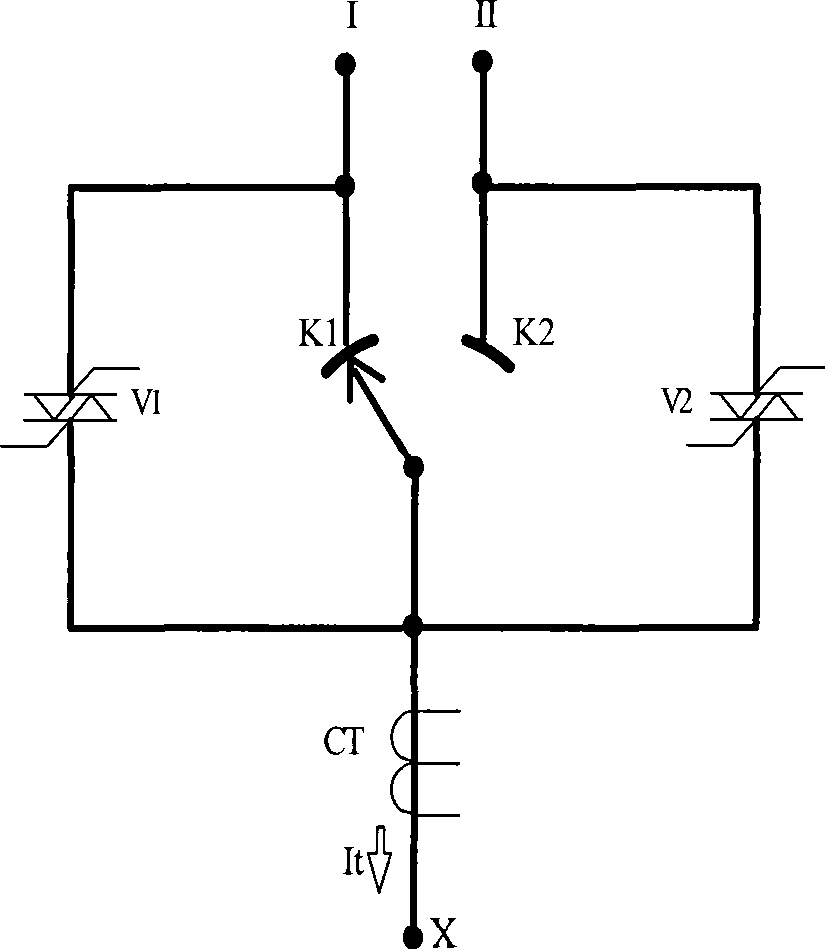

[0022] What this embodiment is going to explain is that the thyristor direct switching on-load tap-changer is a thyristor combined direct switching on-load tap-changer, and its switching circuit includes a thyristor direct switching that realizes current switching between taps when the transformer current crosses zero. circuit.

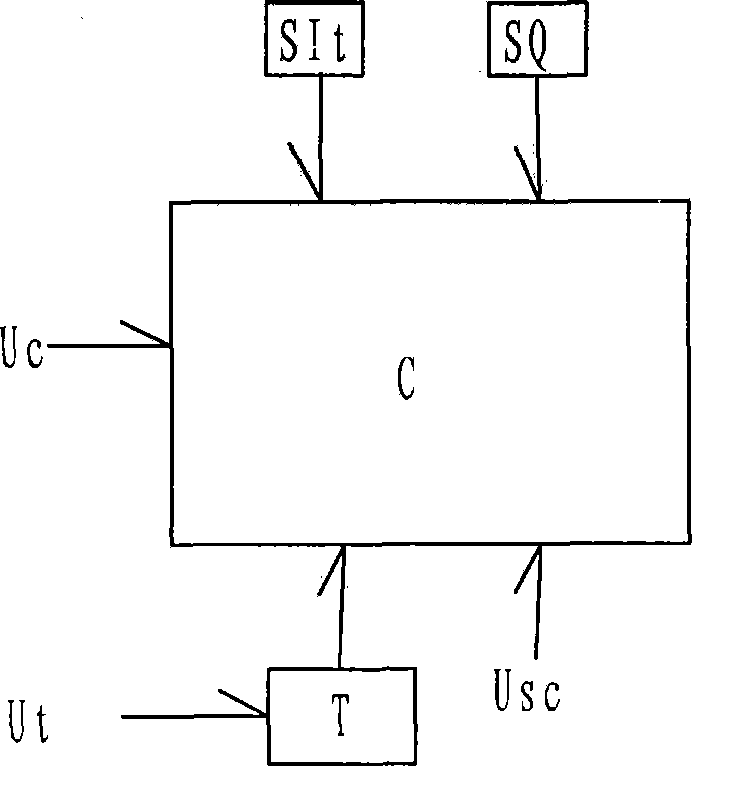

[0023] see figure 1 , Thyristor direct switching circuits are connected to the fixed contacts of odd-numbered taps and even-numbered taps. When switching, the gate circuit of the newly tapped thyristor switch must be connected at a moment near the zero crossing point of the transformer current; the original tap must be disconnected before the zero crossing point (in this embodiment, at a time near the 90° electrical angle). The gate circuit of the upper thyristor. To do this, it is necessary to detect the zero crossing of the transformer current and to control the gate of the thyristor with an electronic switch. In this embodiment, a current transf...

Embodiment 2

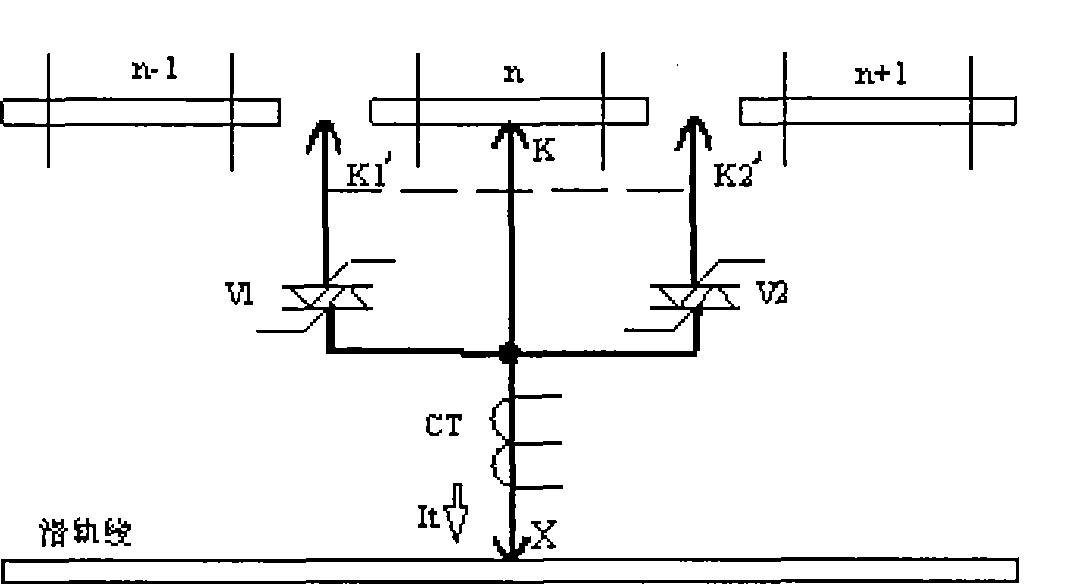

[0035] What this embodiment is going to explain is the thyristor compound type direct switching on-load tap-changer (see figure 2 ). A thyristor switch branch is connected to the two transition moving contacts. During the switching process, when the moving contact has moved to one transition moving contact and the original tap fixed contact, and the thyristor on the branch passes through the current of the transformer; the other transition moving contact connects to the new tap Switching can be performed when the fixed contact is connected but the thyristor on the branch is not connected. When switching, the gate circuit of the newly tapped thyristor switch must be connected at a moment near the zero crossing point of the transformer current; the original tap must be disconnected before the zero crossing point (in this embodiment, at a time near the 90° electrical angle). The gate circuit of the upper thyristor switch.

[0036] see figure 2 , in order to achieve the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com