Oxygen-enriched igniting and firing stabilizer without oil

A technology of oil-free ignition and stable combustion device, which is applied in the directions of combustion ignition, incandescent ignition, and ignition through guide flares, etc., can solve the problems of poor coal adaptability, low air heat capacity, cathode and anode burning damage, etc., to prevent safety accidents, The effect of high combustion temperature and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

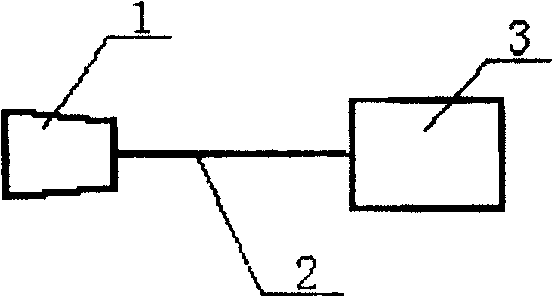

[0030] Such as figure 1 As shown, an oxygen-enriched oil-free ignition and stable combustion device of the present invention is composed of an ignition and stable combustion nozzle 1 and a connecting control pipeline 2. The ignition and stable combustion nozzle is connected with an oxygen source 3 through a control pipeline, and the oxygen source can be Oxygen is produced from bottled industrial oxygen or from an air separation oxygen generator.

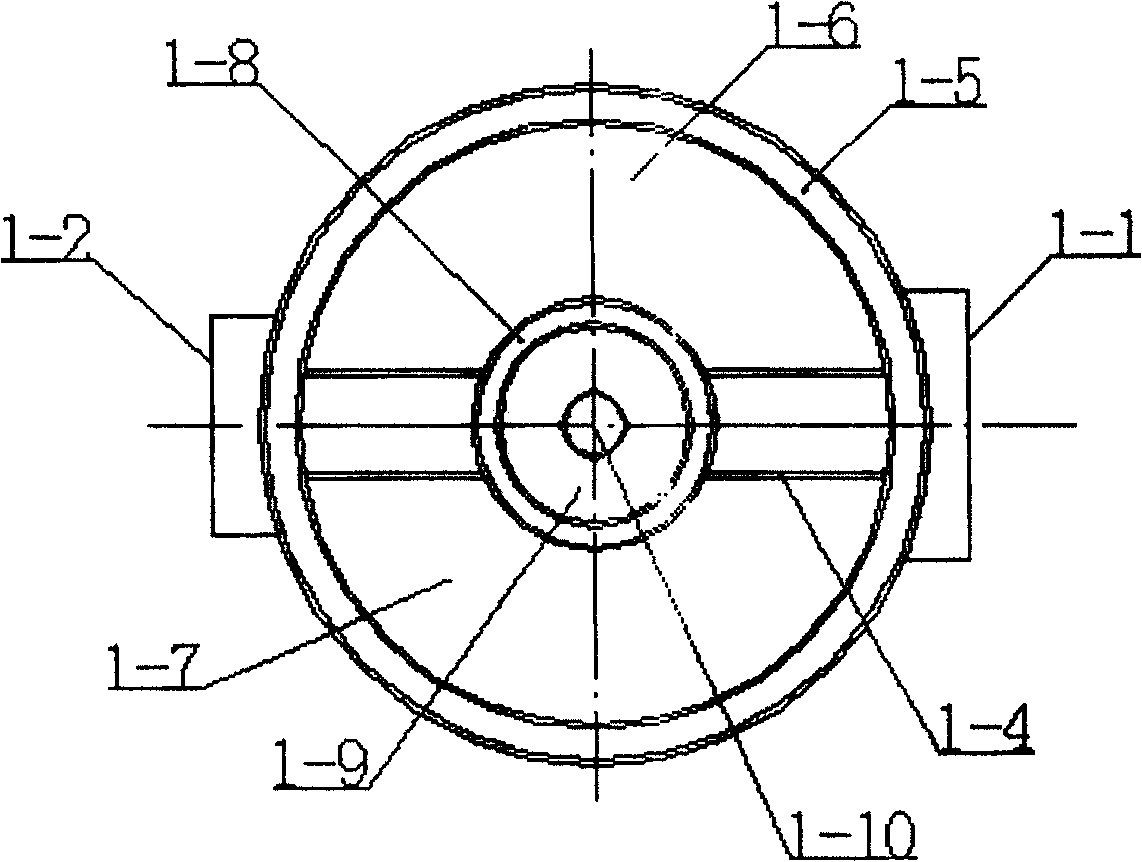

[0031] Such as Figure 3-1 , 3-2 , 3-3, 3-4, and 3-5, the outlet side of the ignition and stable combustion nozzle of the present invention has a round or rectangular appearance, including a primary air inlet 1-1, a secondary air inlet 1-2, and an oxygen-enriched inlet 1 -3. The ignition and stable combustion nozzle consists of five layers of shells. The shells are separated by partitions 1-4, forming secondary air channels 1-5, previous air channels 1-6 and next air channels 1 from outside to inside. -7, the central ring secondar...

Embodiment 2

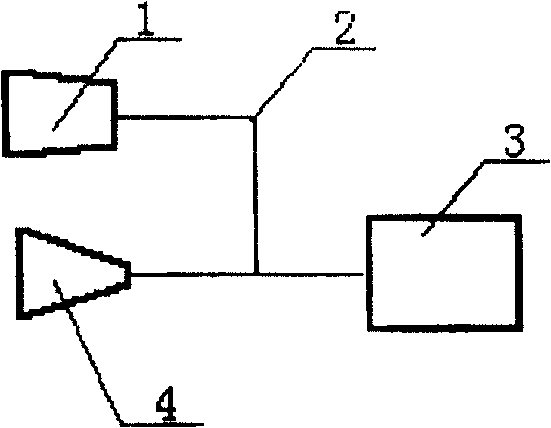

[0036] Such as figure 2 As shown, an oxygen-enriched oil-free ignition and stable combustion device of the present invention consists of an ignition and stable combustion nozzle 1, an oxygen-rich nozzle 4 in a stable combustion and reflow area of the upper or lower coal powder nozzle adjacent to the ignition and stable combustion nozzle, and a connected control pipeline 2, the ignition stable combustion nozzle and the oxygen-rich nozzle in the stable combustion recirculation zone are connected to the oxygen source 3 through the control pipeline. The oxygen source can be bottled industrial oxygen or oxygen from an air separation oxygen generator.

[0037] Such as Figure 3-1 , 3-2 , 3-3, 3-4, and 3-5, the outlet side of the ignition and stable combustion nozzle of the present invention has a round or rectangular appearance, including a primary air inlet 1-1, a secondary air inlet 1-2, and an oxygen-enriched inlet 1 -3. The ignition and stable combustion nozzle consists of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com