Method for preparing nano conductive carbon by cracking organic compound through hybrid plasma technology

A technology of mixing plasma and organic compounds, which is applied in the field of nano-conductive carbon prepared by plasma technology, can solve the problems of less mention of solid products and difficulties in recycling, and achieve excellent product performance, good operation stability and continuity, and improved loop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

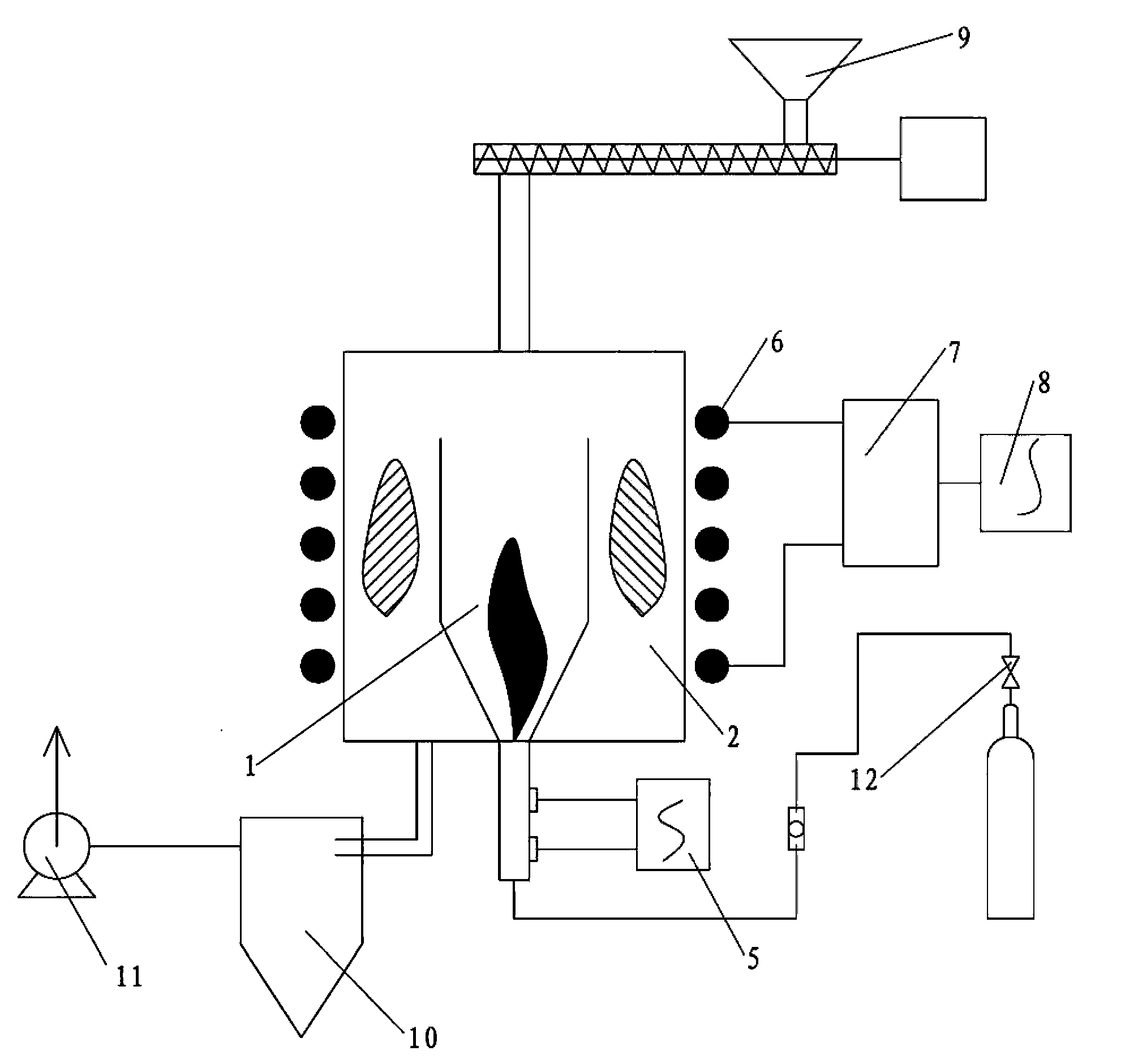

[0030] In this embodiment, tire powder is used as raw material to prepare conductive carbon, and the device used in the method is as follows: figure 1 As shown, firstly, an appropriate amount of tire powder is loaded into the screw feeder 9; the air pump 11 is opened, and the nitrogen valve 12 is opened, and the flow rate is controlled within the required range of the plasma torch to provide working gas for the plasma generation; DC arc plasma Body power supply 5 output power 0~10kW, start DC arc plasma power supply 5, form DC arc plasma pyrolysis reaction zone 1, high frequency plasma power supply 8 model JG-10K-B, output power 0~10kW, equipped with high frequency The power supply matching device 7, the induction electrode 6 is wound with copper tubes; the high-frequency plasma power supply 8 is started, and the high-frequency power supply matching device 7 is adjusted to form the high-frequency plasma pyrolysis reaction zone 2; the screw feeder 9 is started to make the tire ...

Embodiment 2

[0032] In this embodiment, rice husk is used as a method for preparing conductive carbon as a raw material, and the device used is as figure 1As shown, firstly, an appropriate amount of rice husk is loaded into the screw feeder 9; the air pump 11 is opened, and the nitrogen valve 12 is opened, and the flow rate is controlled within the required range of the plasma torch to provide working gas for plasma generation; DC arc plasma Body power supply 5 output power 0~10kW, start DC arc plasma power supply 5, form DC arc plasma pyrolysis reaction zone 1, high frequency plasma power supply 8 model JG-10K-B, output power 0~10kW, equipped with high frequency The power matching device 7, the induction electrode 6 is wound with copper tubes; the high-frequency plasma power supply 8 is started, and the high-frequency power matching device 7 is adjusted to form the high-frequency plasma pyrolysis reaction zone 2; the screw feeder 9 is started to make the rice The shell raw material enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com