Pipe inner combustion type nodular casting iron pipe conformal furnace shell annealing furnace

A technology of tube body and annealing furnace, which is applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of low production efficiency and large heat energy consumption, and achieve the effects of improving production efficiency, improving thermal efficiency, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

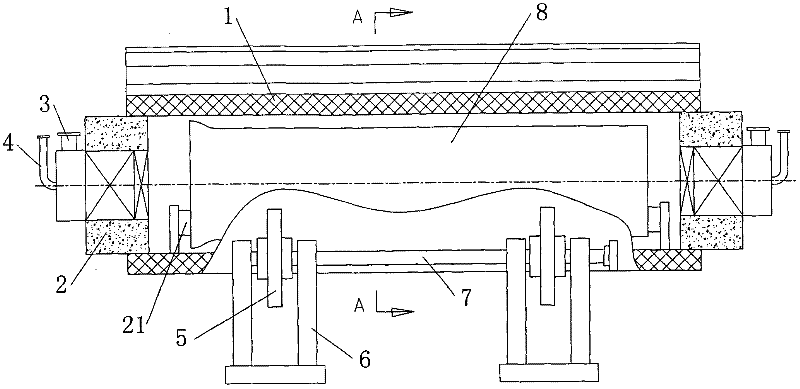

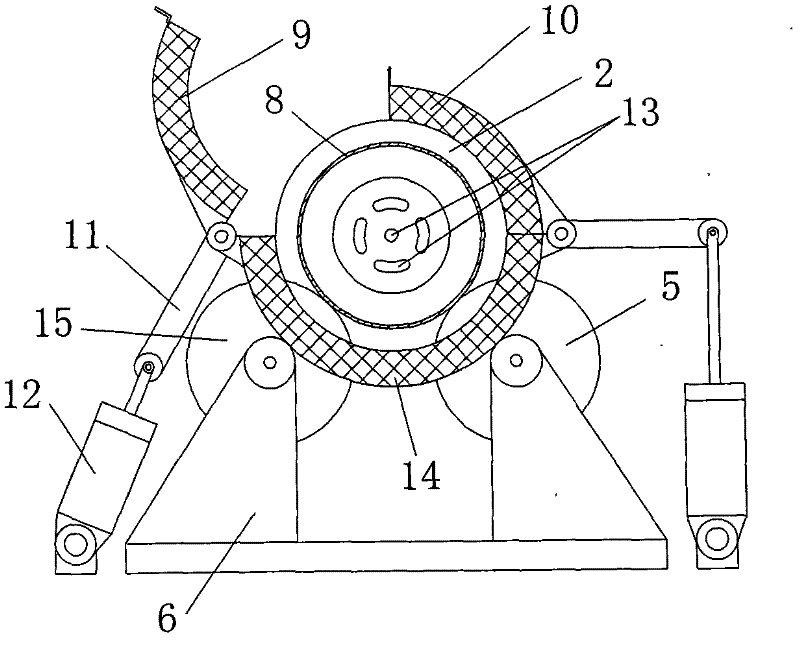

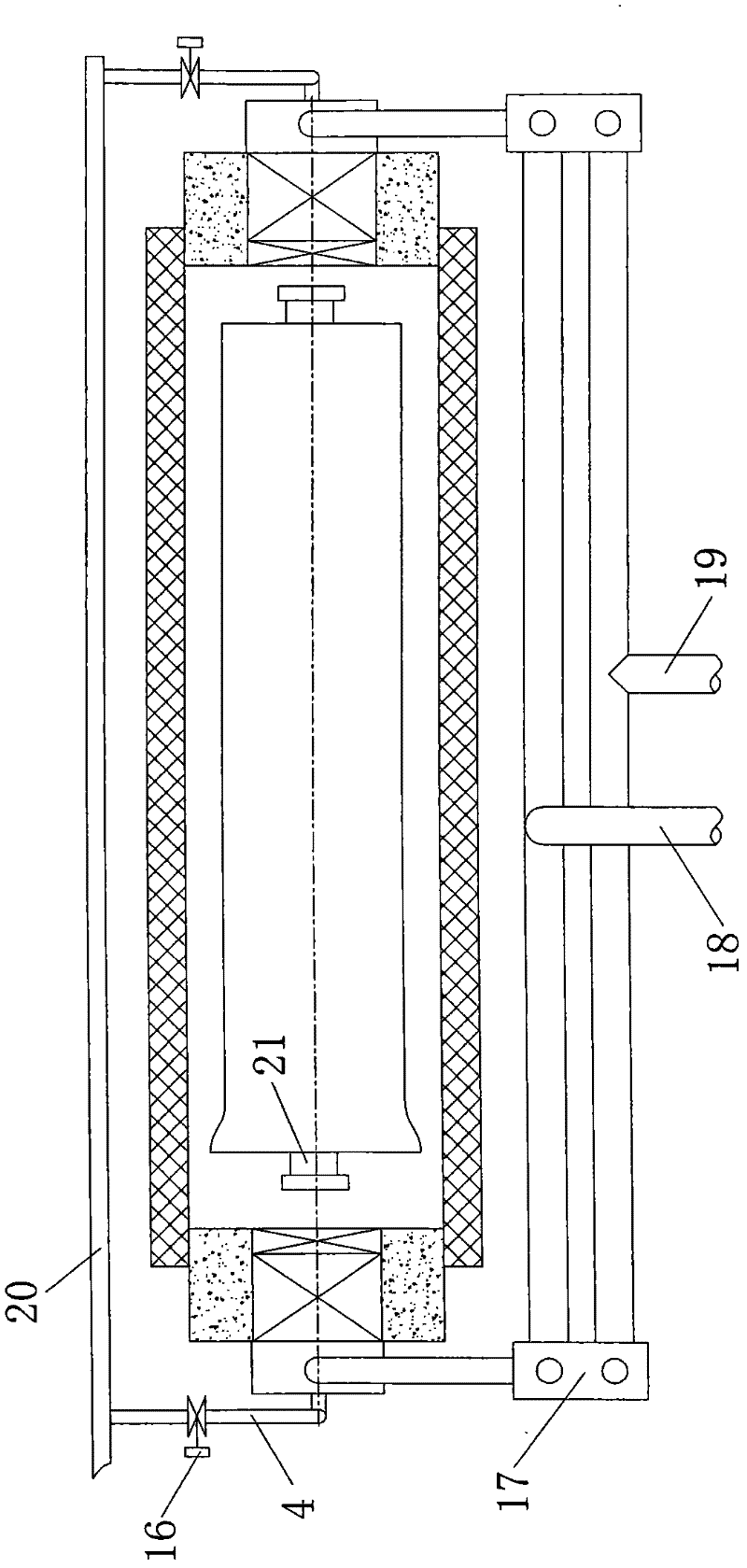

[0017] like figure 1 , figure 2 and image 3 As shown, the annealing furnace for ductile iron cast pipe conformal shell of the present invention includes a conformal shell 1, a supporting wheel mechanism and a heating system. see figure 2 , with the shape of the furnace shell 1 includes an upper opening and closing cover hinged together and a lower fixed shell 14, the upper opening and closing cover can be opened or closed under the drive of the opening and closing mechanism. For the convenience of operation (convenient for loading and unloading pipes), the upper opening and closing cover can be divided into two parts: the rear opening and closing cover 9 and the front opening and closing cover 10, and the rear opening and closing cover 9 and the front opening and closing cover 10 are connected with the lower fixed shell 14 respectively. The two sides of the cylinder are hinged, and when the three parts are combined together, a complete cylinder structure is formed. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com