Net brick

A technology of mesh bricks and brick bodies, which is applied in the field of bricks for structures and buildings, can solve the problems of inability to form intersections in internal passages, small passing capacity, waste of raw materials, etc., and achieve the effect of simple and convenient laying, convenient maintenance of road surfaces, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

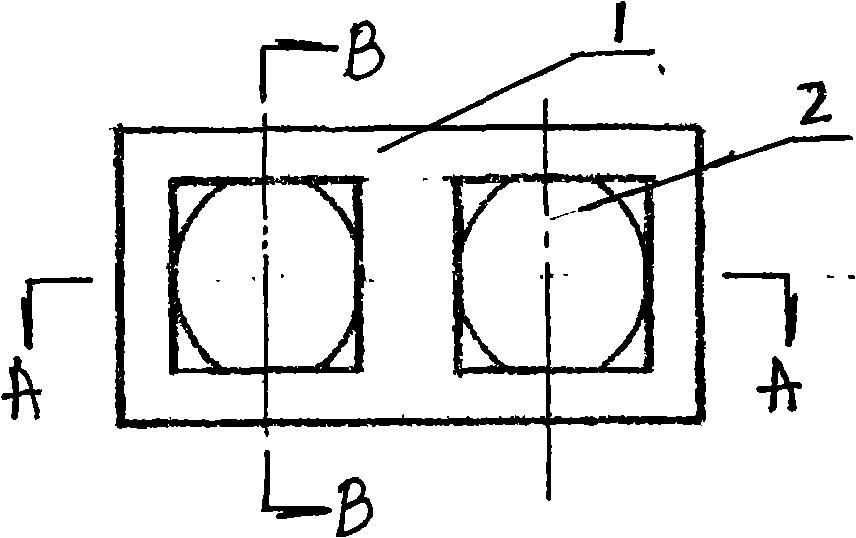

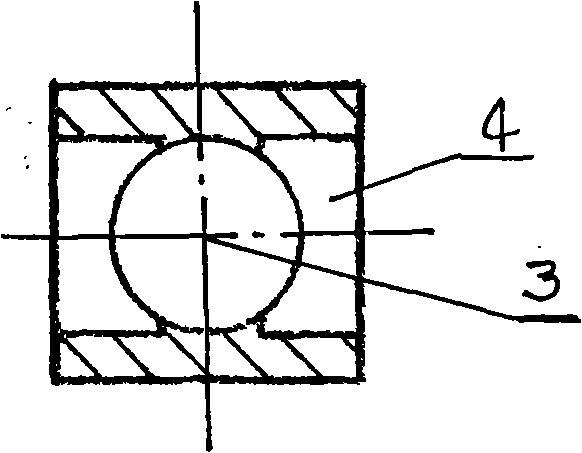

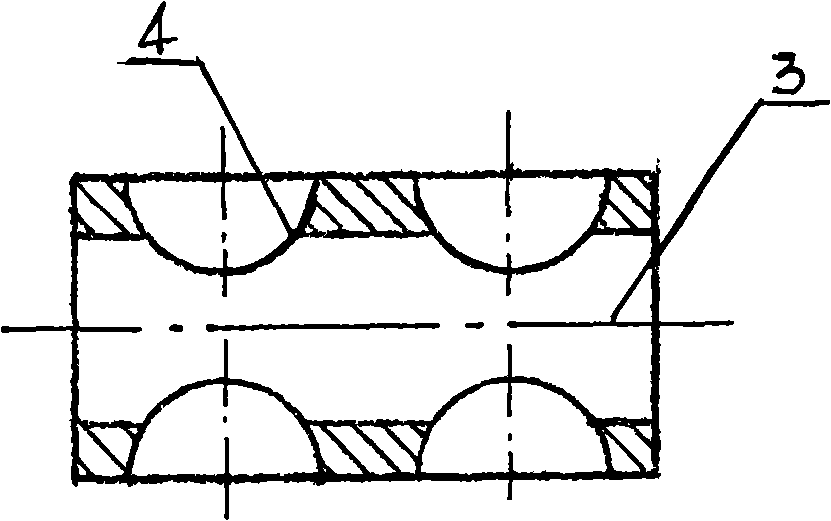

[0042] Figure 1 to Figure 3 Among them, the brick body 1 is a polyhedron, which is made of different raw materials according to the principle of mechanical bearing and actual needs, such as clay material, which is made by beating and firing; concrete material, which is made by vibration and extrusion In short, according to different actual needs, different raw materials can be selected, and the corresponding production methods can be determined to make plastic, rubber, plastic foam, nylon, cement, gypsum, and metal, ceramic, glass and other mesh brick products. In the brick body 1, there are left and right transverse through holes 3, four semicircular longitudinal through holes 4 forward and backward, and the four semicircular longitudinal through holes 4 are front and rear double rows and left 1. The right double-row spaces are arranged parallel to each other, and the transverse through holes 3 and 4 semicircular longitudinal through holes 4 are connected to each other, so t...

Embodiment 2

[0044] Figure 4 to Figure 6 Among them, in the brick body 1, there are left and right horizontal through holes 3, and four semicircular longitudinal blind holes 8 upward and downward. Double row and the spaces are arranged parallel to each other, and communicate with the top of the brick body 1. Moreover, the transverse through hole 3 and the four semicircular longitudinal blind holes 8 communicate with each other, so that double rows of longitudinal passages 6 arranged parallel to each other are formed in the brick body 1, which communicate with the front and back of the brick body 1, and the left and right direction The horizontal passage communicates with the left and right sides of the brick body 1, and the four semicircular vertical single-sided passages 9 and 7, which are vertically arranged in parallel with each other in the front and back double rows and the left and right double rows, communicate with the top of the brick body 1 , and the left and right horizontal p...

Embodiment 3

[0046] Figure 7 to Figure 9 In the brick body 1, there are left and right horizontal through holes 3, and four semicircular vertical through holes 12 up and down. The four semicircular vertical through holes 12 are arranged in double rows The horizontal through holes 3 and the four semicircular vertical through holes 12 are connected to each other, forming double rows of longitudinal passages 11 arranged in parallel to each other in the brick body 1, and are connected with the brick body. The front and back of 1 are connected, the left and right horizontal passages are connected with the left and right sides of the brick body 1, and four semicircular vertical passages 13, 10 are vertically arranged in parallel with each other in two rows of front and back and double rows of left and right. , communicate with the upper and lower sides of the brick body 1, and the left and right transverse passages and longitudinal passages 11 and vertical passages 13, 10 communicate with each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com