Patents

Literature

33results about How to "Reduce the amount of particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-component extrusion molding conductive rubber for electromagnetic shielding and preparation method of single-component extrusion molding conductive rubber

InactiveCN102220012ALarge specific surface areaConducive to direct contactCross-linkElectromagnetic shielding

The invention discloses a single-component extrusion molding conductive rubber for electromagnetic shielding and a preparation method of the single-component extrusion molding conductive rubber, belonging to the technical field of electromagnetic shielding materials. The single-component extrusion molding conductive rubber is composed of dendritic silver coated copper powder, silvered glass fiber, polydimethylsiloxane containing vinyl by rubber base body, reinforcing agent gaseous phase white carbon black, alkynol inhibitor, metal platinum catalyst, and cross-linking agent methylhydropolyorganosiloxane. The preparation method comprises the following steps: pretreatment is carried out to the dendritic silver coated copper powder and the silvered glass fiber through amido coupling agent methyl organodisilane according to the formula, the rubber base body and the gaseous phase white carbon black are added in a vacuum kneading machine, are mixed uniformly and are added in a double-planet mixing plant, and then the alkynol inhibitor, the metal platinum catalyst and the treated electric conduction powder are mixed uniformly to form a component 1; the treated electric conduction powder is added in a cross-linking agent and is mixed uniformly to form a component 2; and two components in the double planets are mixed to form the single-component on-site forming electromagnetic shielding silicon rubber. The rubber has good shielding performance and good mechanical property.

Owner:BEIJING UNIV OF TECH

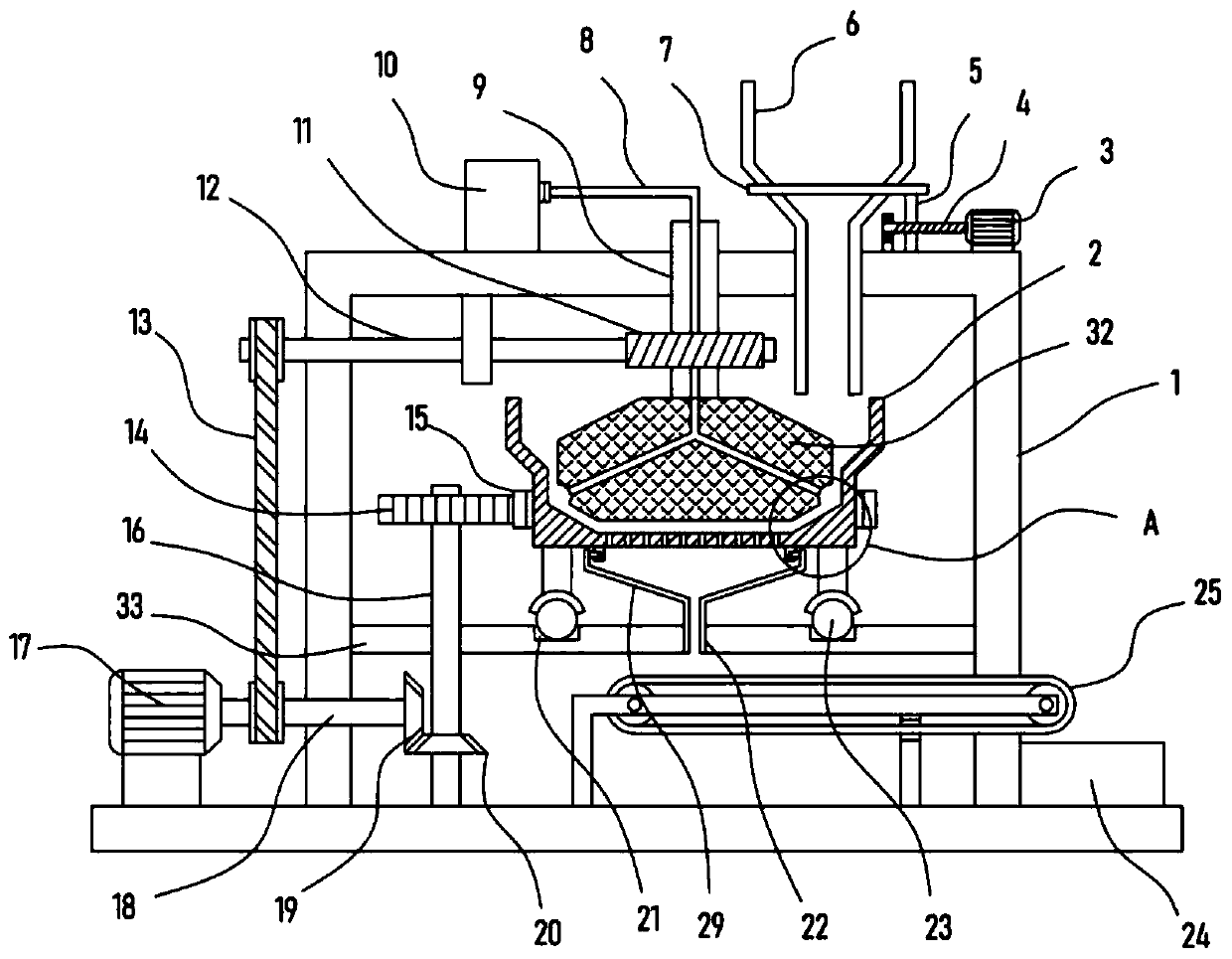

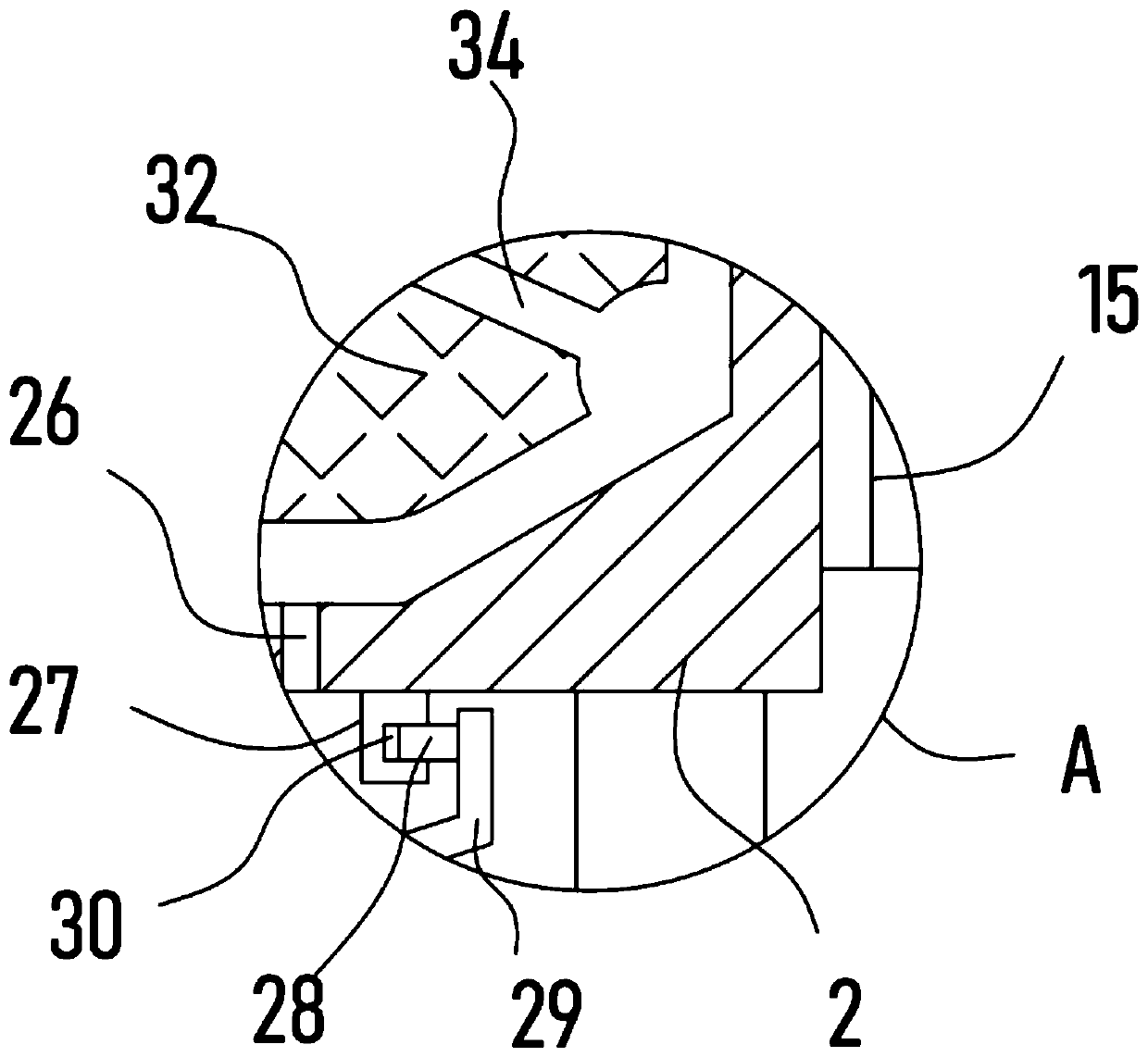

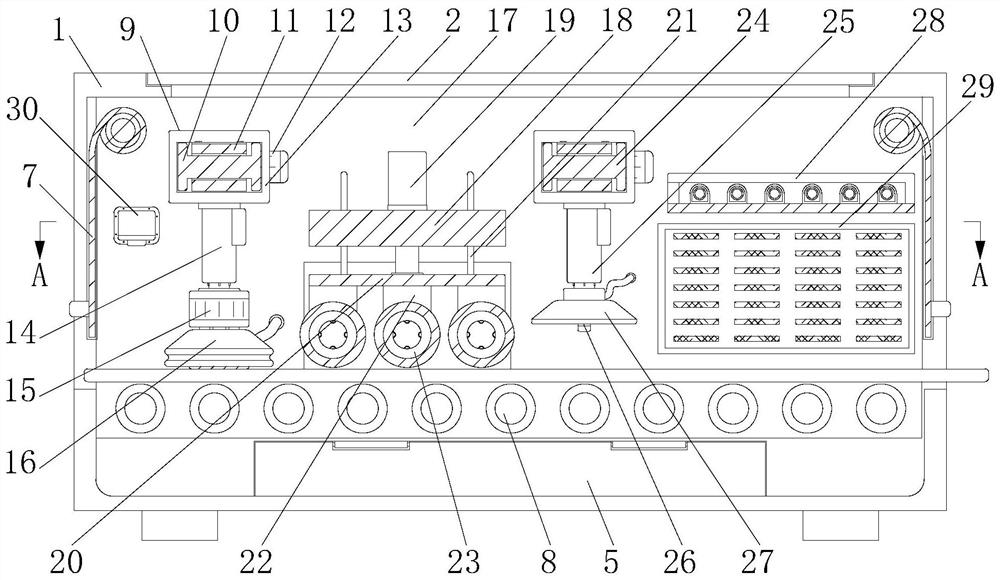

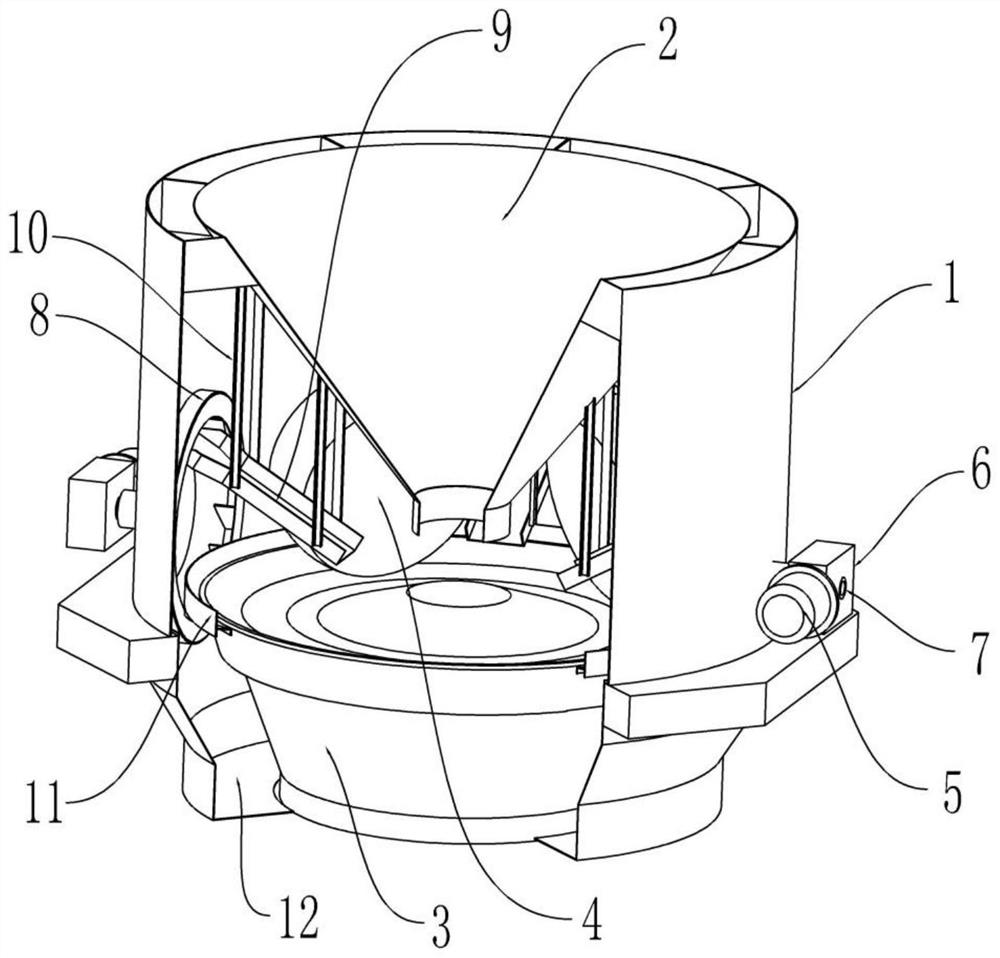

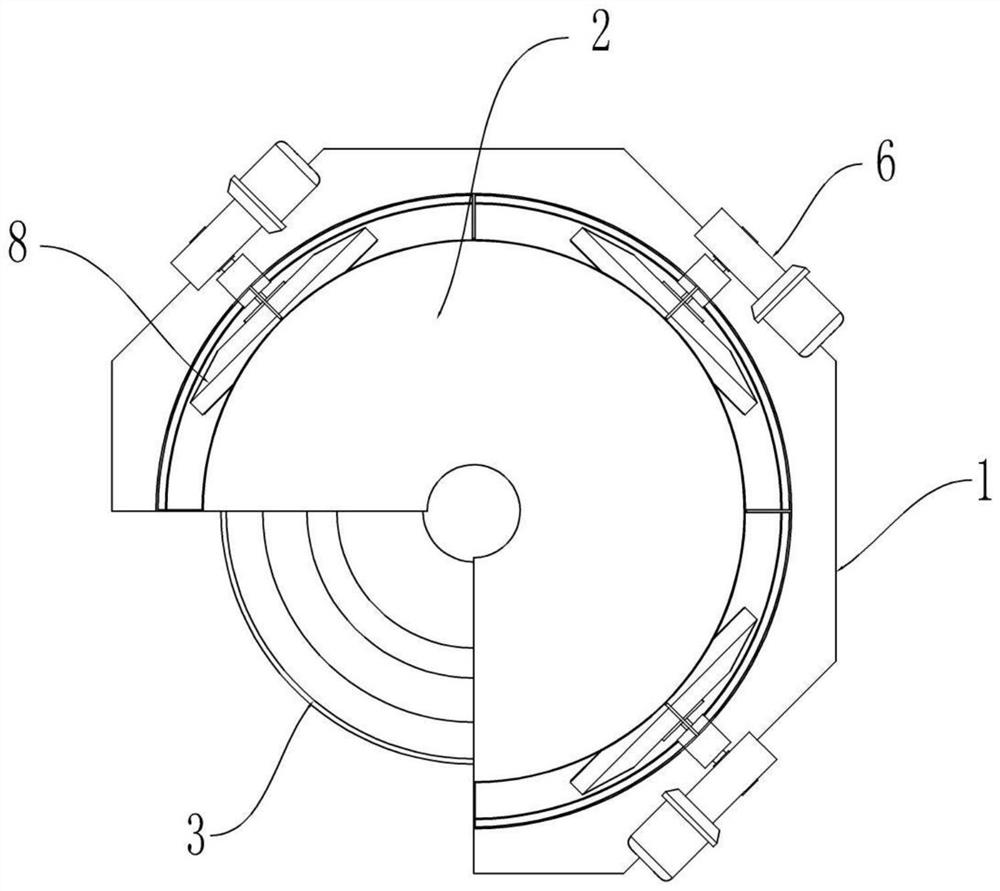

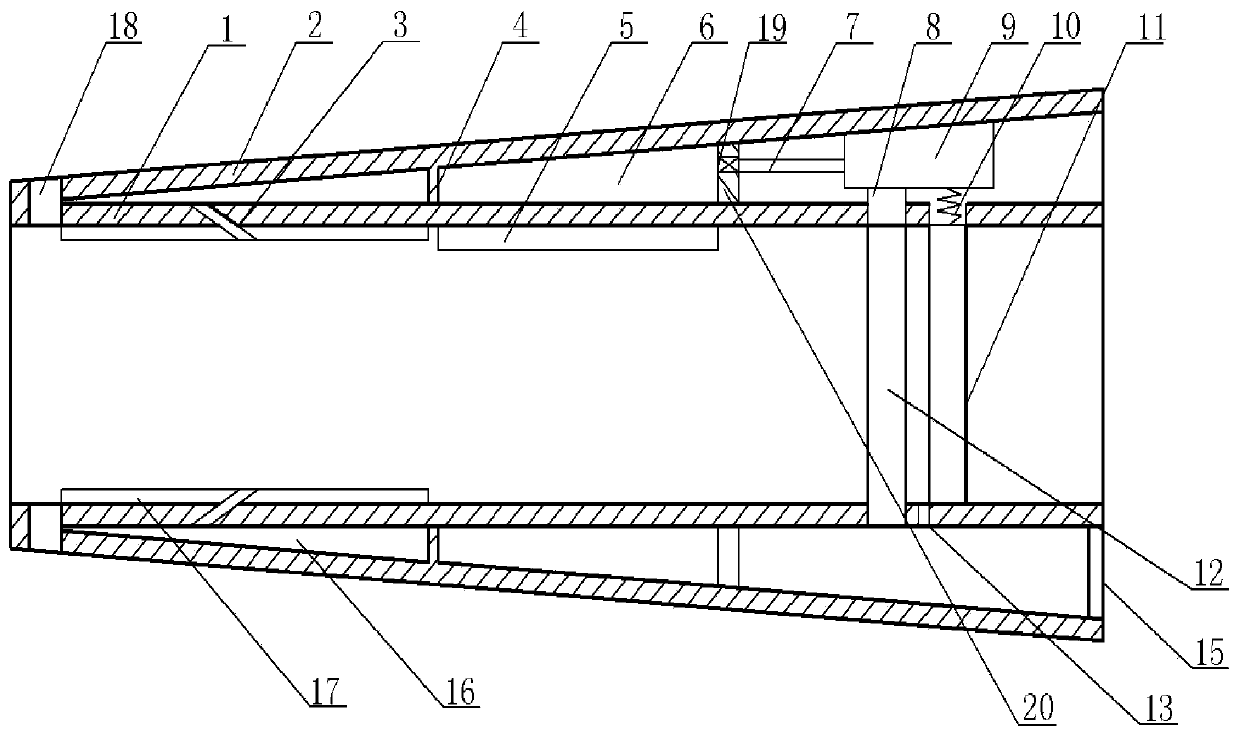

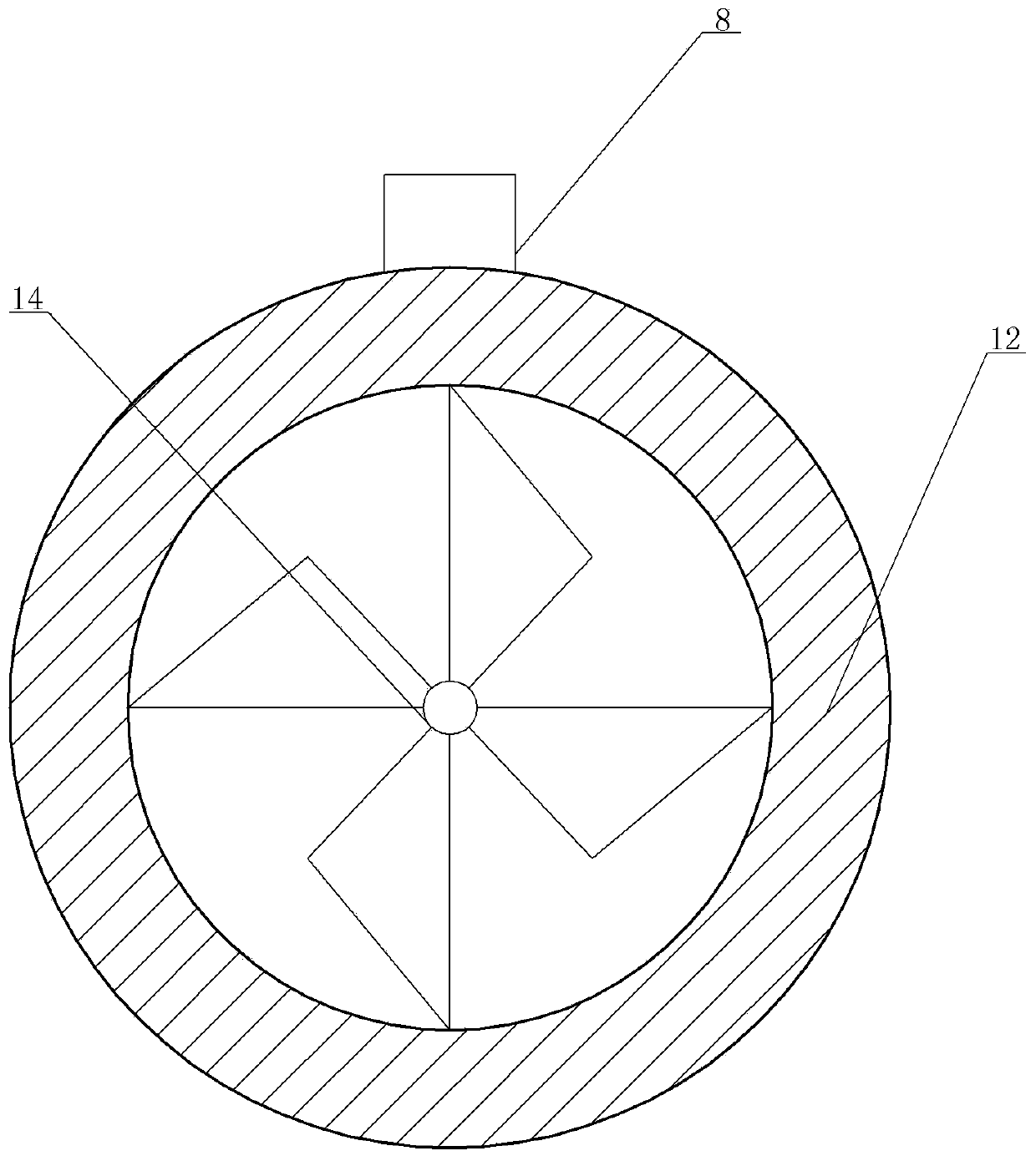

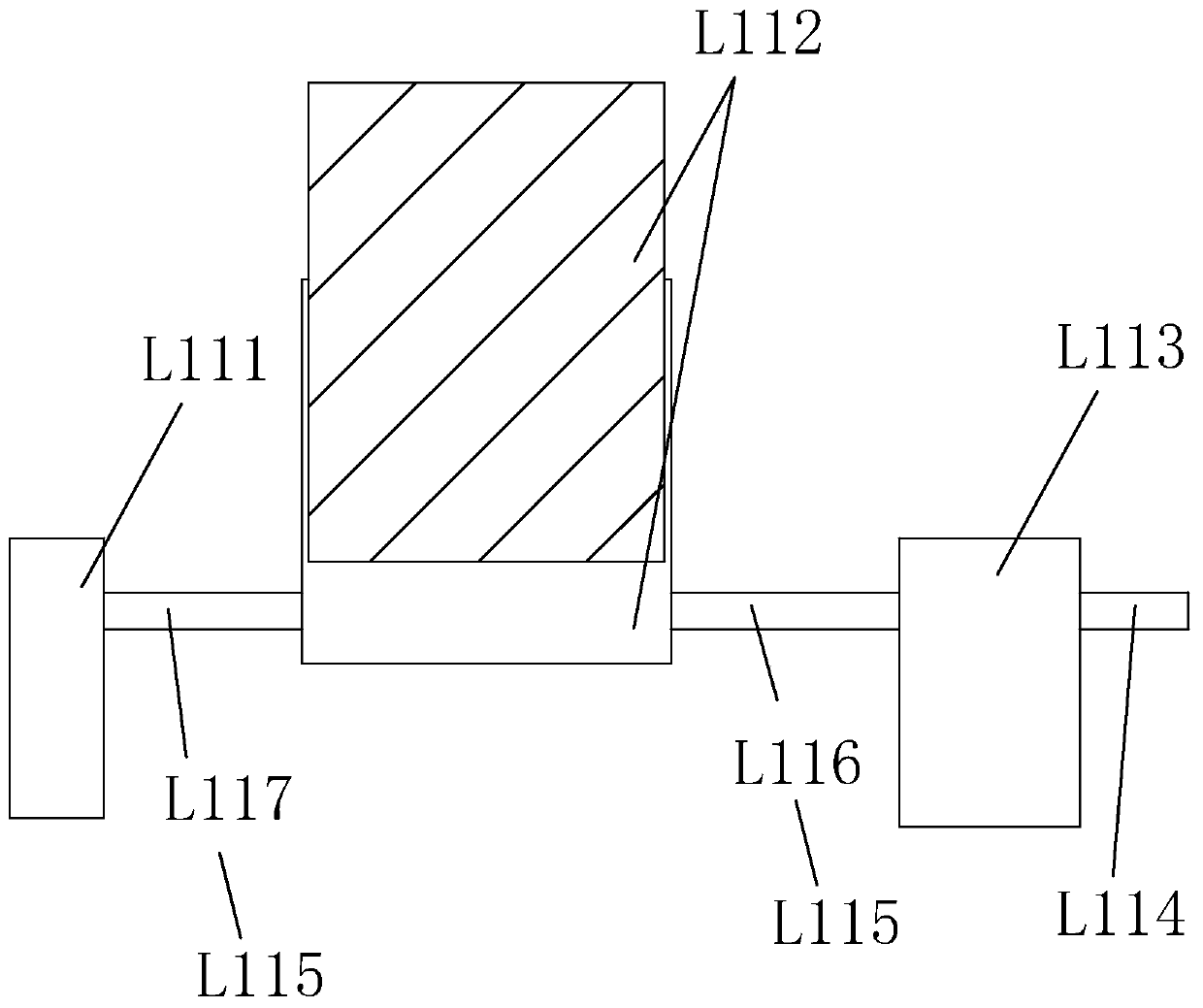

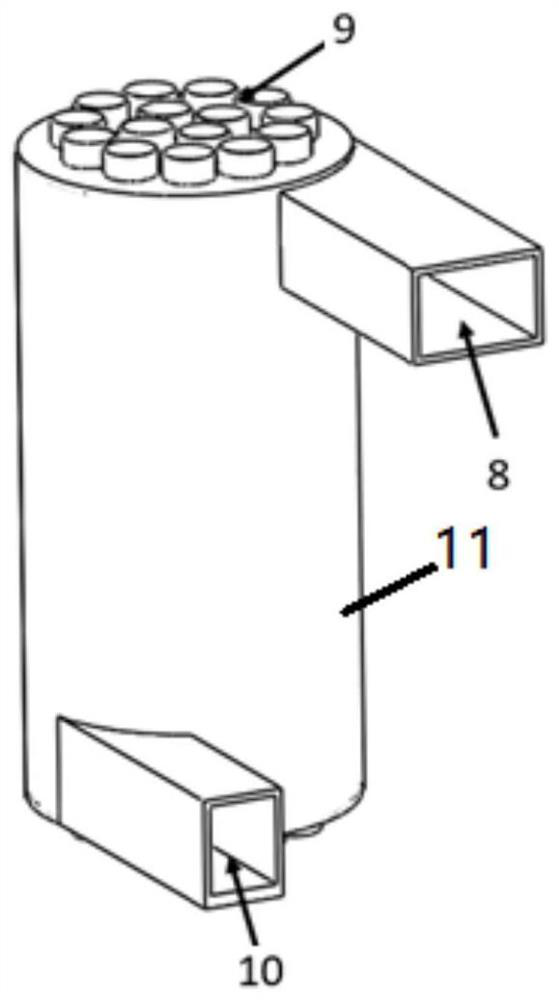

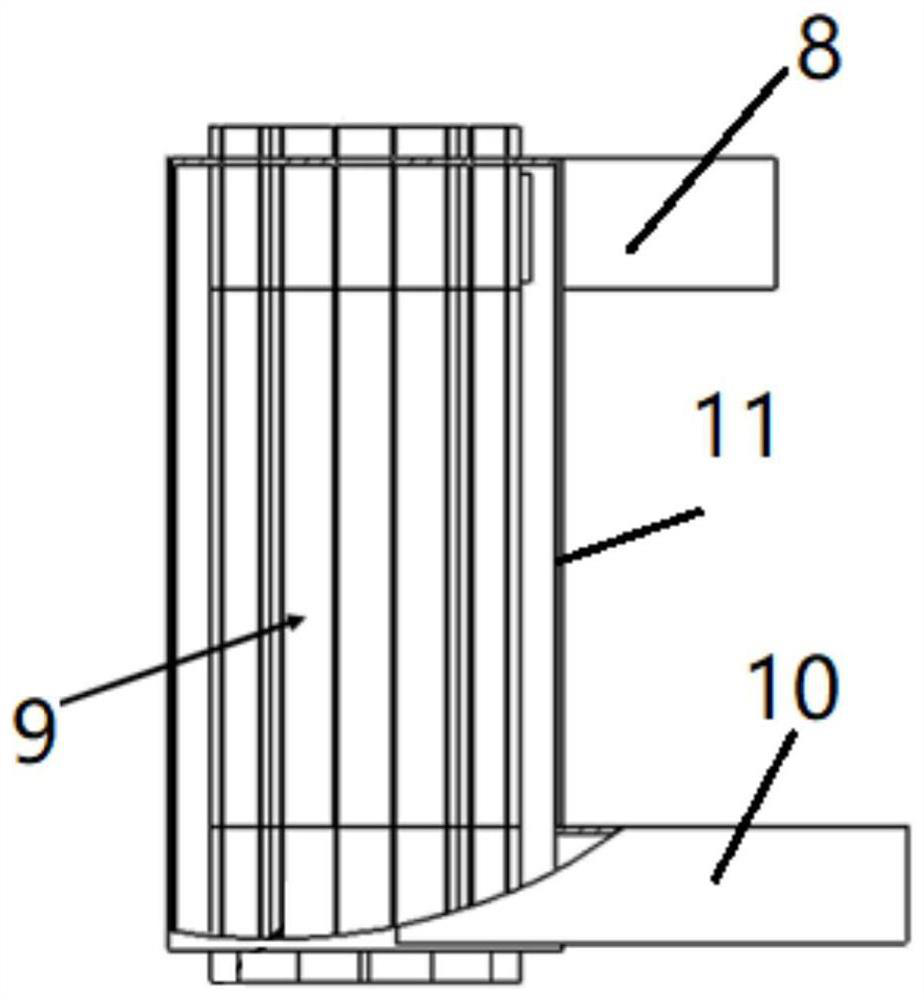

Material chemical processing grinding device

InactiveCN109718922AReduce the amount of particlesAvoid accumulationGrain treatmentsEngineeringLarge size

The invention discloses a material chemical processing grinding device and relates to the technical field of chemical material grinding. The material chemical processing grinding device comprises a supporting frame. The supporting frame is horizontally and fixedly provided with a fixing plate. The fixing plate is provided with a grinding head matched with a grinding groove. The bottom of the grinding groove is evenly provided with a plurality of material falling mesh holes. A material falling hopper is arranged under the grinding groove. The rotation direction of a rotating shaft is opposite to that of the grinding groove. The supporting frame is provided with a discharging hopper with a lower end opening located above the grinding groove. According to the material chemical processing grinding device, rotary grinding is carried out on chemical materials in the grinding groove through rotation of the grinding head, the grinding groove rotates during the grinding period, the rotation direction of the grinding groove is opposite to that of the grinding head, and the grinding speed of chemical material particles is greatly increased; and during the grinding period, particles in a certain size fall through the material falling mesh holes, timely separation of the particles in a certain size from material particles in a relatively large size is achieved, ,the number of the material particles in the grinding groove is gradually reduced, accumulation of the material particles is avoided, and the grinding effect is greatly improved.

Owner:HEFEI NORMAL UNIV

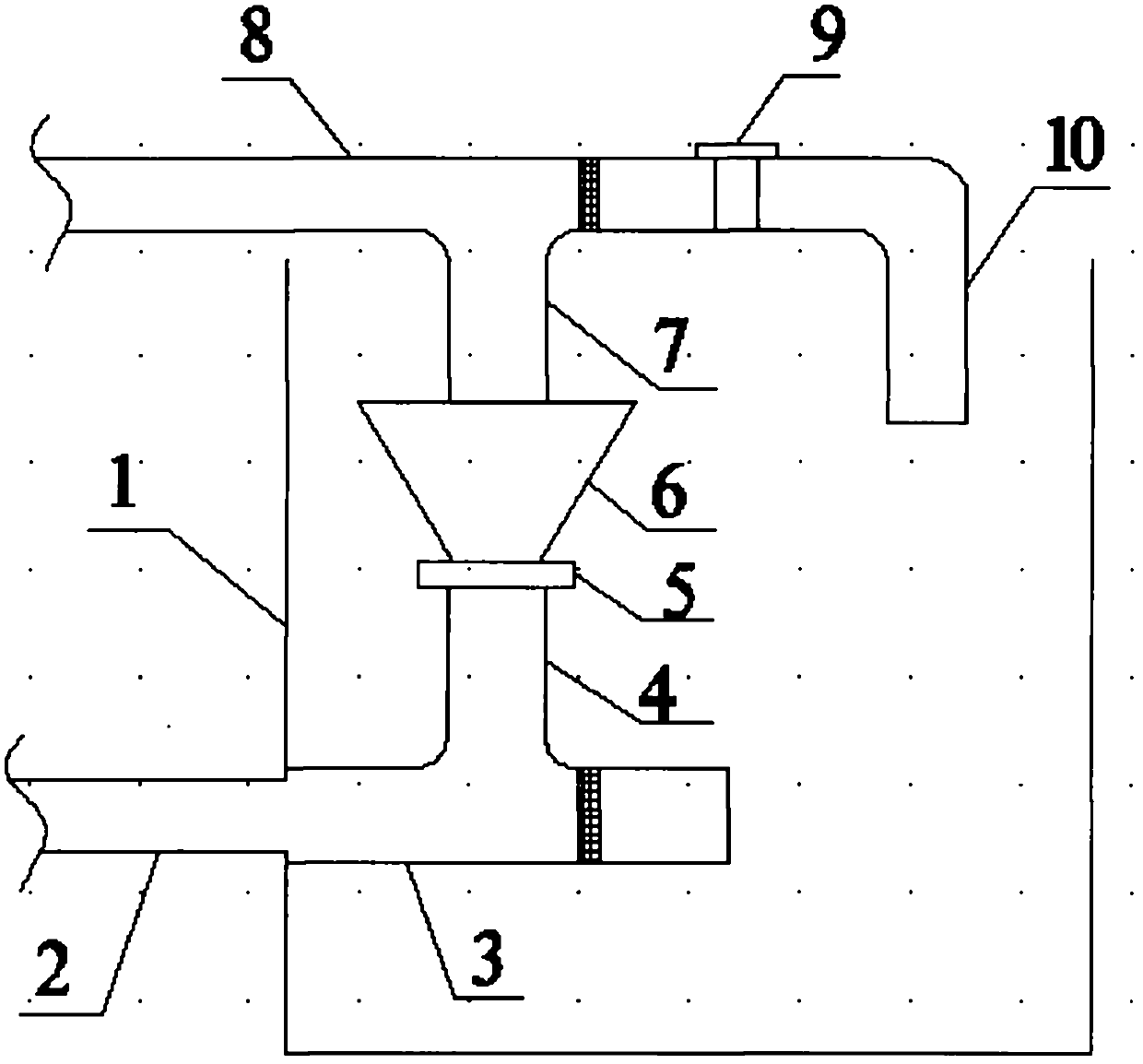

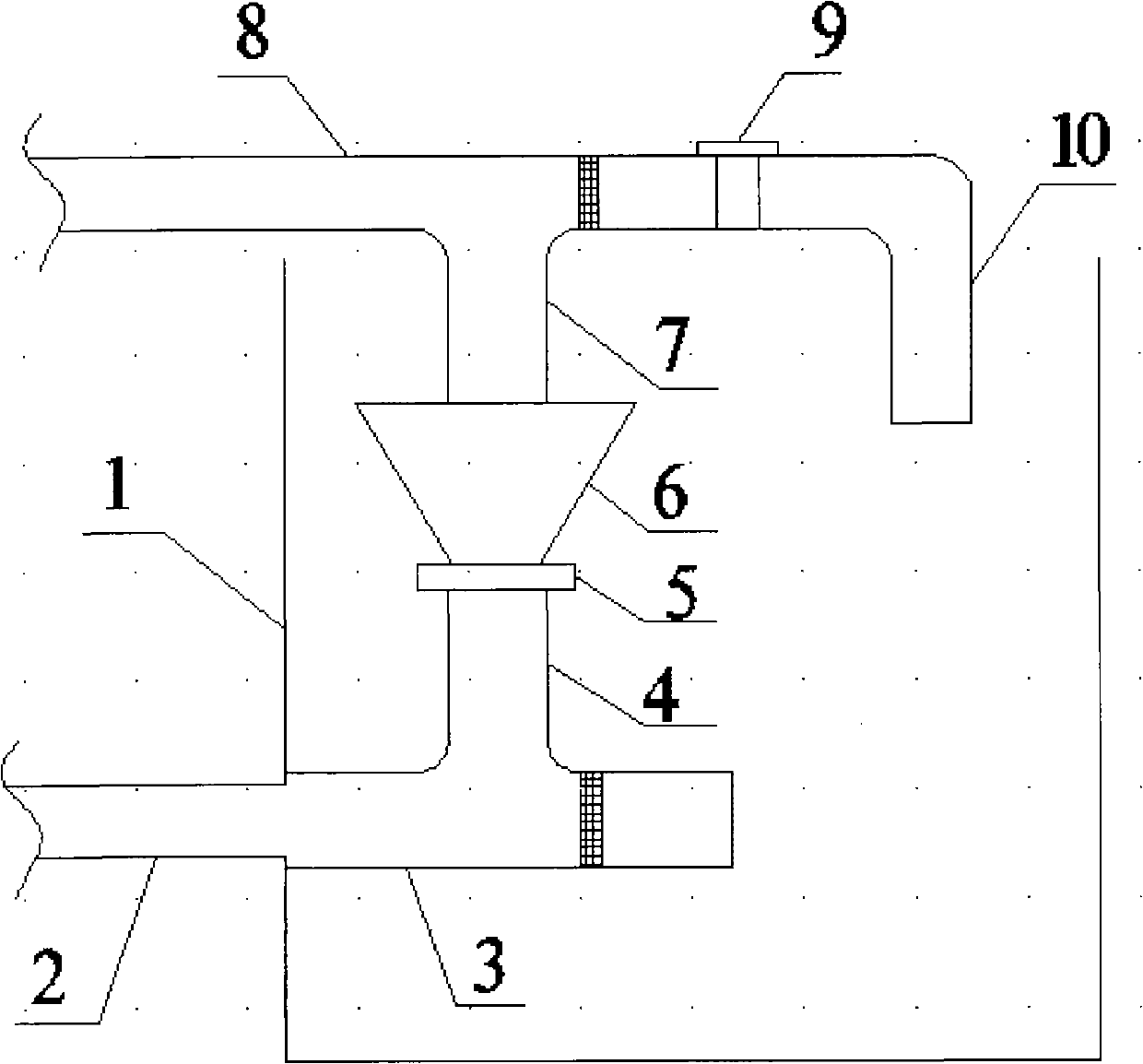

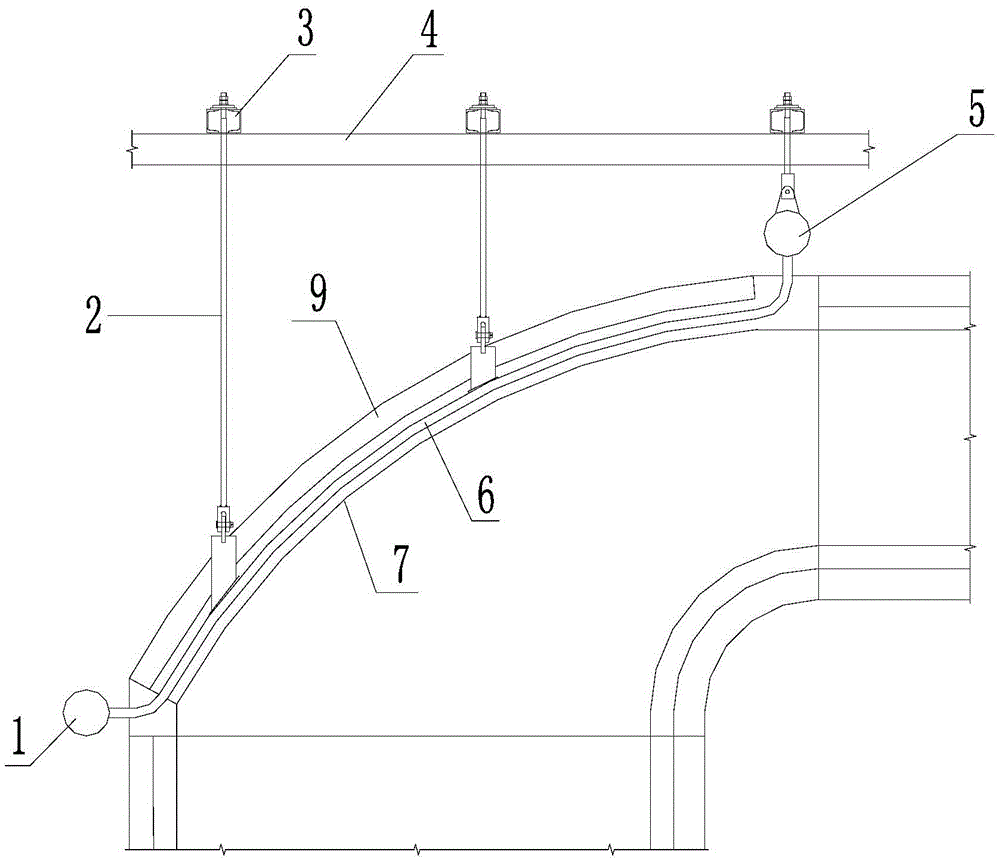

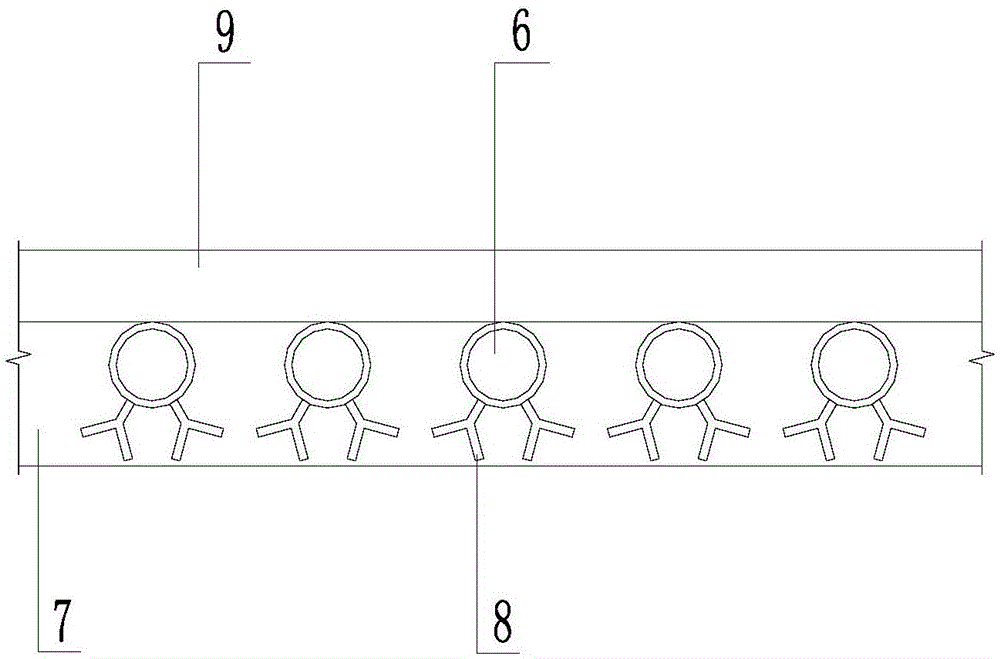

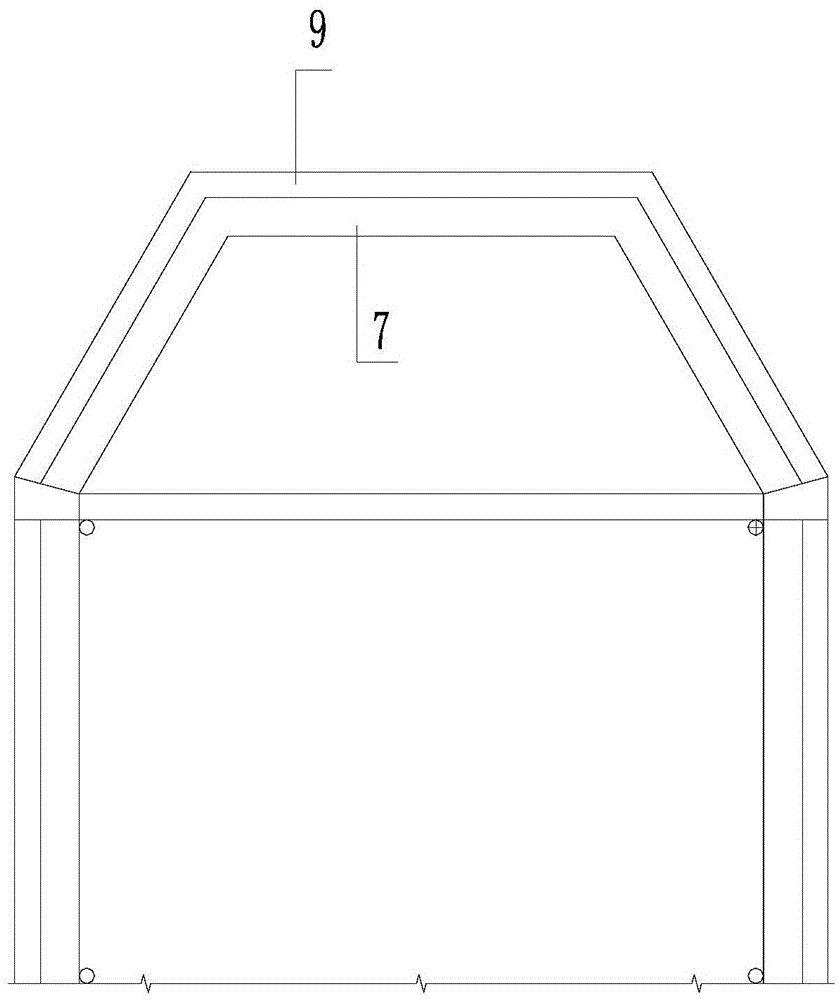

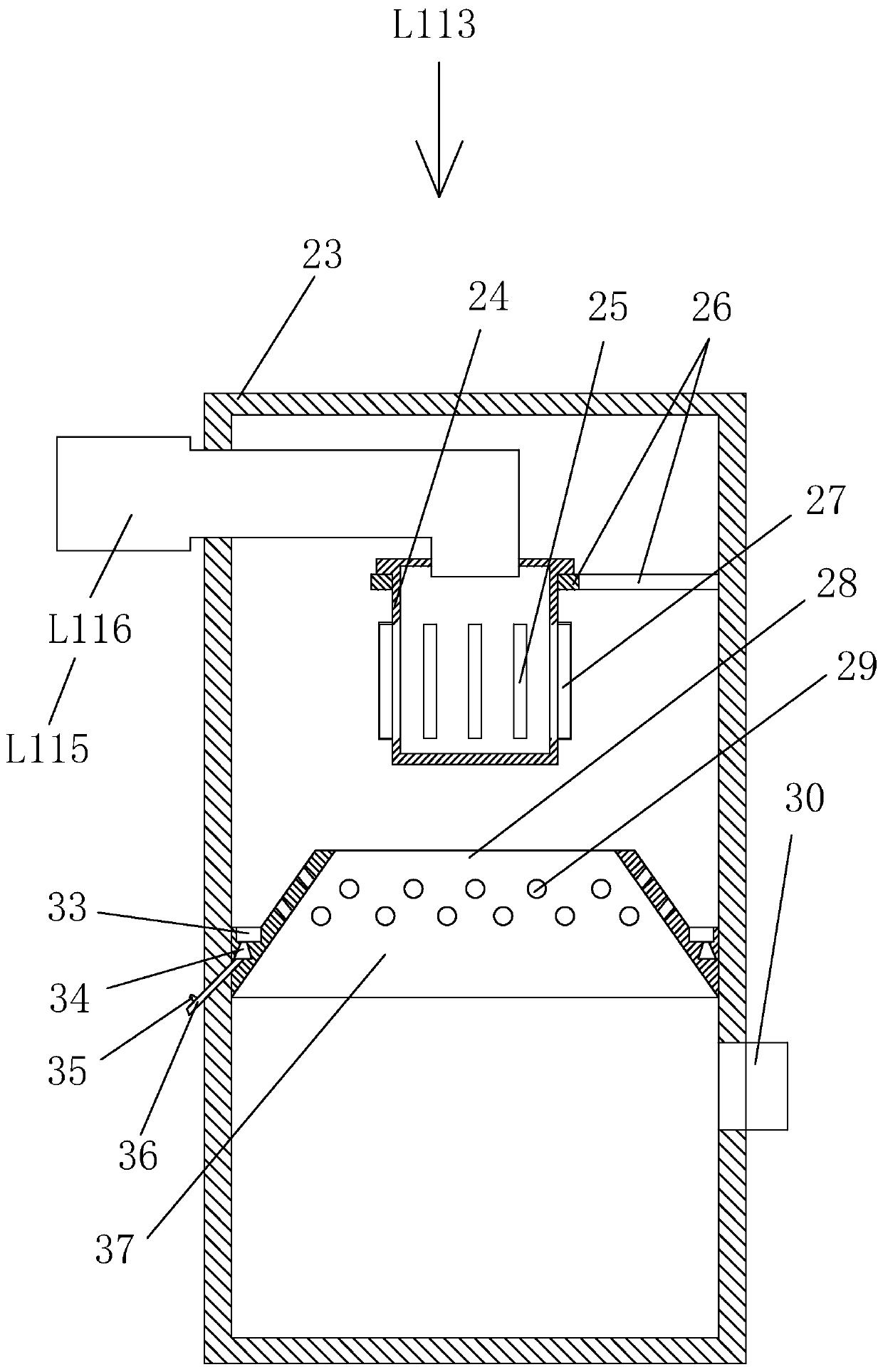

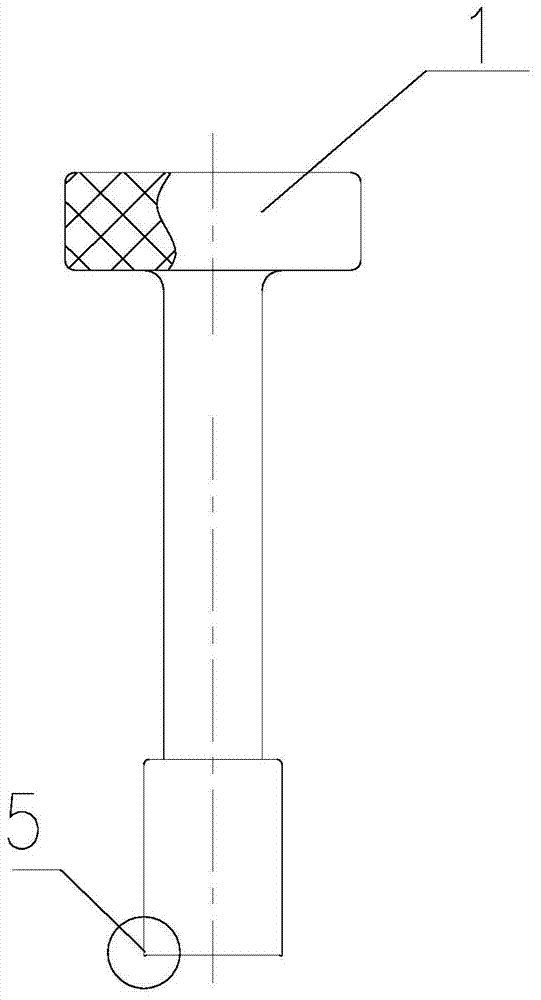

Adding method and device for conveying experimental large particles in solid-liquid two-phase flow

The invention provides an adding method and a device suitable for conveying experimental large particles in a solid-liquid two-phase flow, which are characterized in that: the device comprises a particle injection hopper, a two-phase fluid return pipeline with branch pipelines and a liquid storage tank. The particle injection hopper is mounted in the liquid storage tank; the particle injection hopper is connected with a pump suction pipeline inside the liquid storage tank through a particle injection pipeline; a gate valve with a filter screen is mounted between the particle injection hopper and the particle injection pipeline; a filter screen is arranged at a liquid-phase suction section of the pump suction pipeline inside the liquid storage tank; the liquid-phase suction section of the pump suction pipeline inside the liquid storage tank sucks in liquid in the liquid storage tank; a two-phase fluid return branch pipeline and a liquid return branch pipeline are arranged on the two-phase fluid return pipeline; the two-phase fluid return branch pipeline is used for returning solid-liquid two-phase fluid to the particle injection hopper; and the liquid return branch pipeline returns partial liquid to the liquid storage tank. According to the method and the device, the device has a simple structure, the adding and the recycling of the large particles are convenient, the concentration of the particles is convenient to control, the mixing of the particles is even, and the pipelines are convenient to flush.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

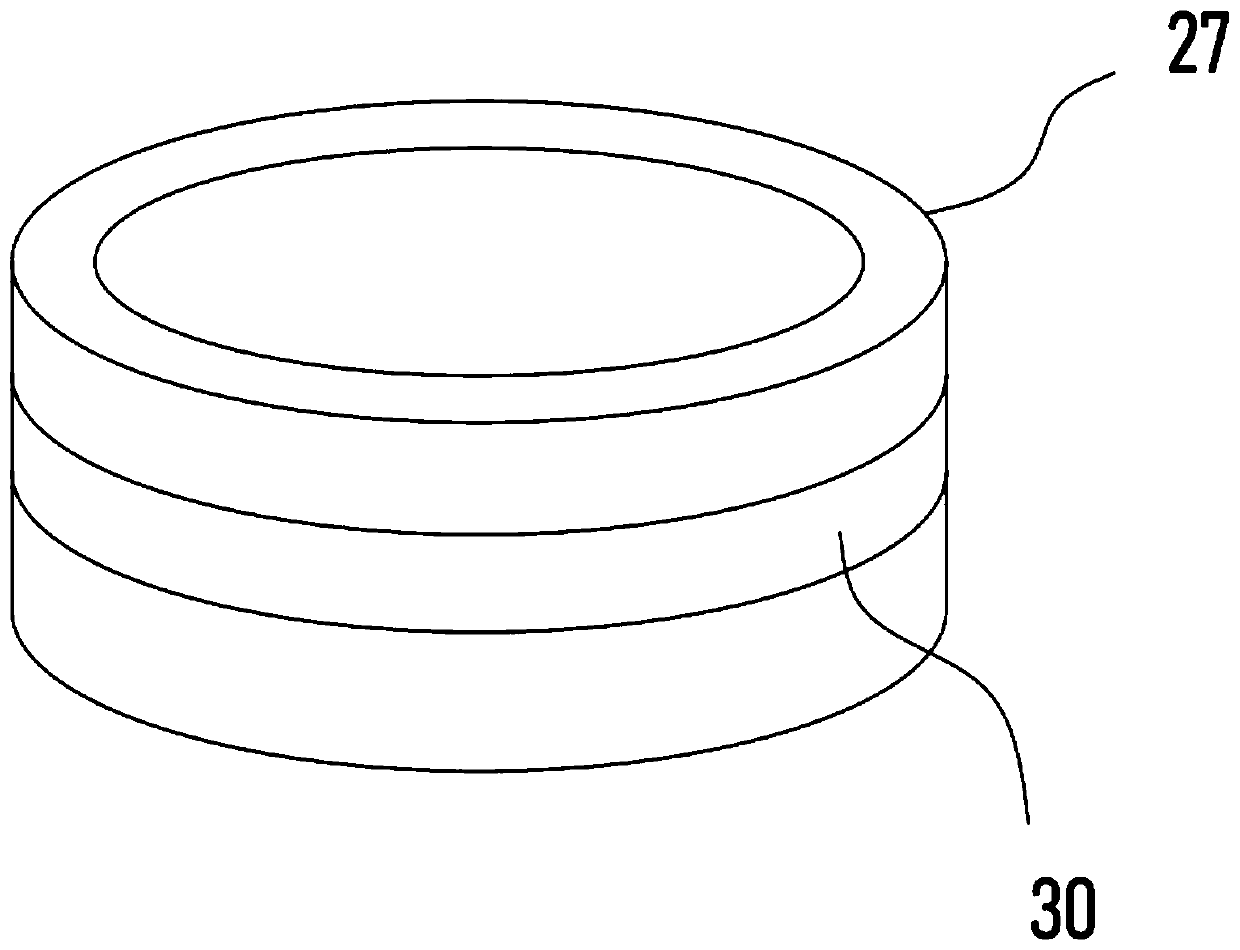

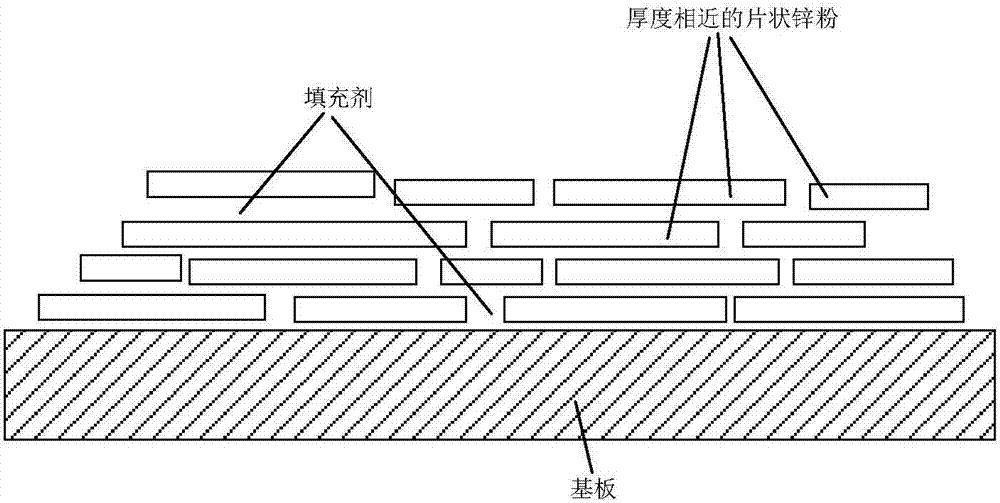

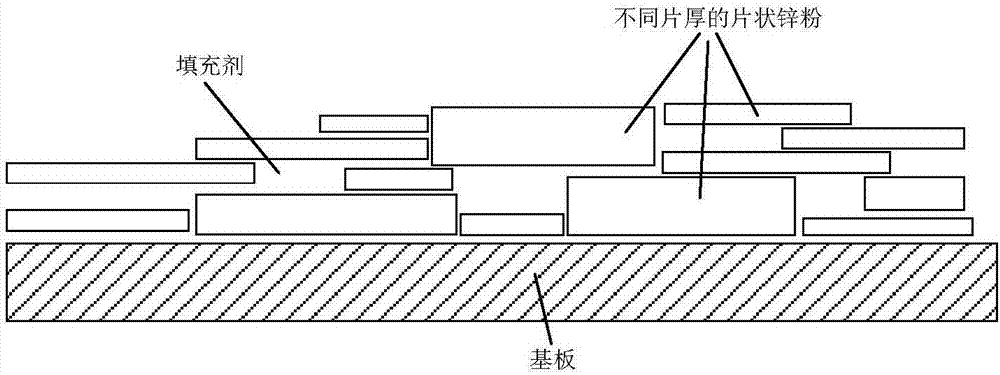

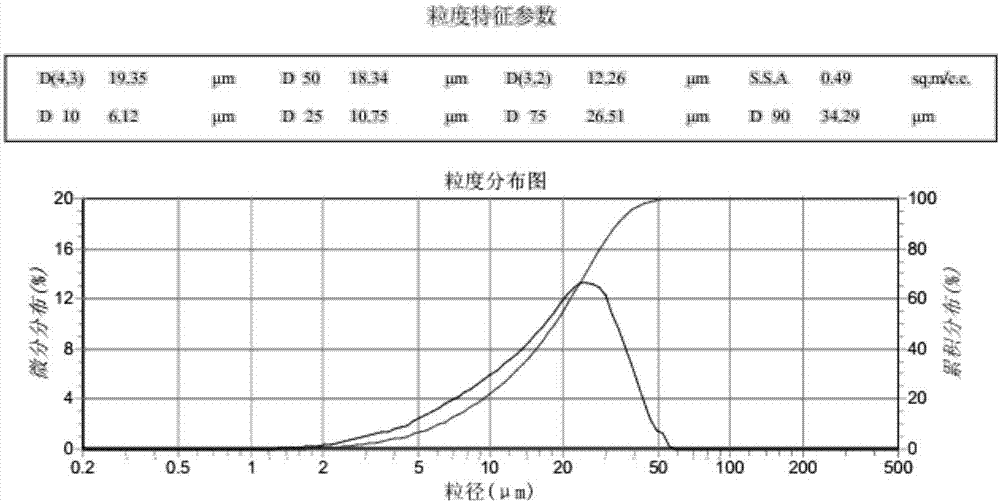

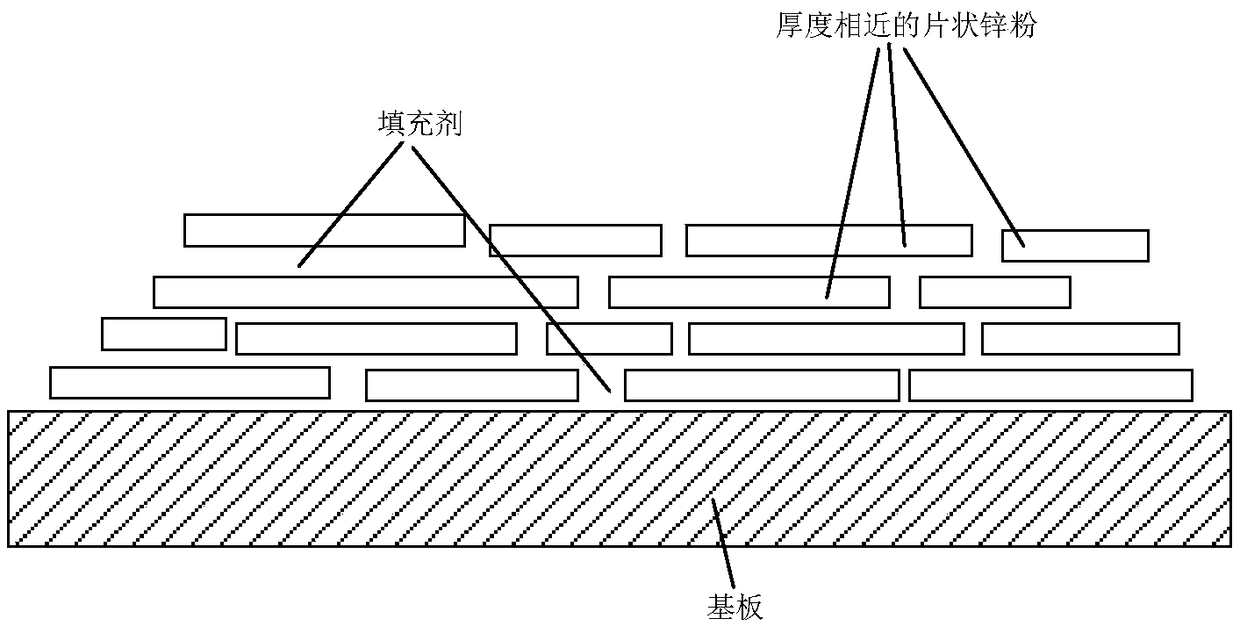

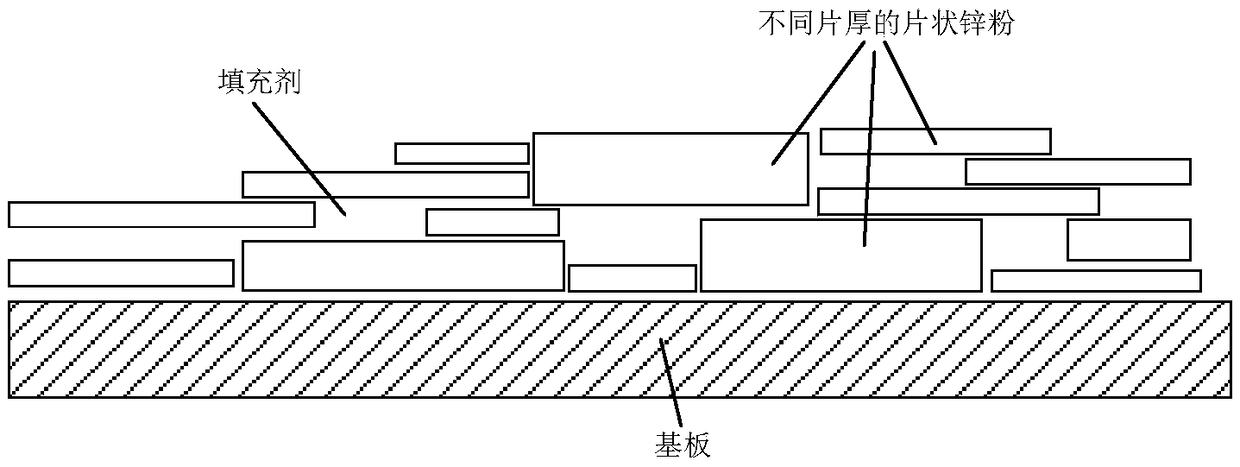

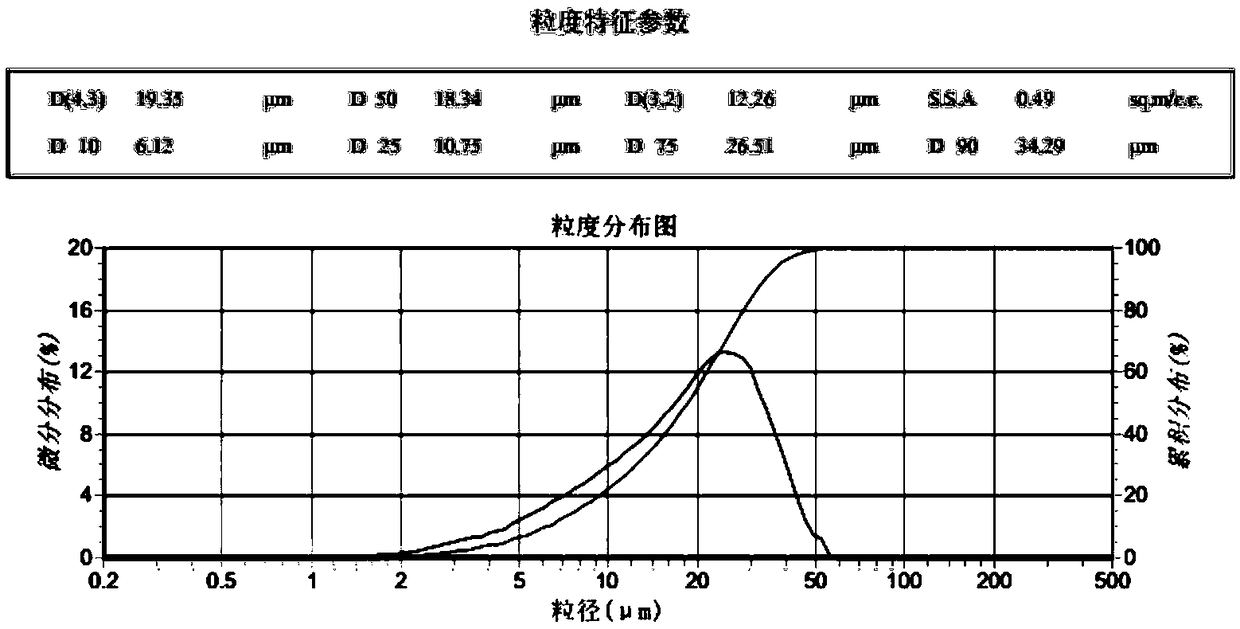

Screening-ball-milling method sheet metal powder and preparation method thereof

ActiveCN106891013AUniform thicknessReduce outputTransportation and packagingMetal-working apparatusNitrogenMetal particle

The invention provides screening-ball-milling method sheet metal powder and a preparation method thereof. The preparation method of the screening-ball-milling method sheet metal powder comprises the following steps that every 25-50 meshes of raw material metal powder are screened into metal powder of different meshes; the metal powder, ball milling steel balls and metal powder surface treatment auxiliaries are put into ball milling equipment according to different meshes, vacuumizing and nitrogen filling are conducted, ball milling is conducted according to different meshes time by time, and ball milling time is adjusted according to the particle size of the screened metal powder; and all grades of ball-milled powder is collected and is graded again in an airflow classification mode. With the adoption of the technical scheme of the screening-ball-milling method sheet metal powder and the preparation method thereof, the thickness of the obtained sheet metal powder is uniform, the yield of over-milled metal powder can be reduced substantially, meanwhile, the quantity of milled coarse metal particles is small, the coarse metal particles can be milled again into qualified products, the finished product rate is high and can reach 100%, and production efficiency is high.

Owner:SHENZHEN NONFEMET TECH

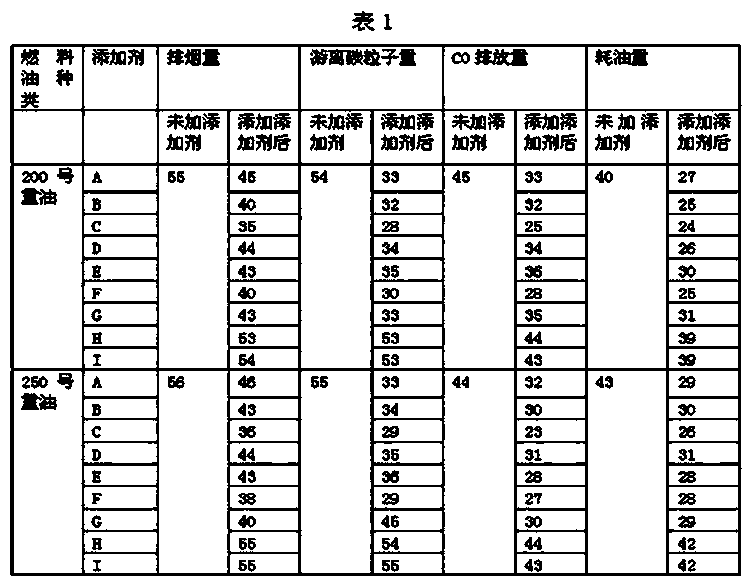

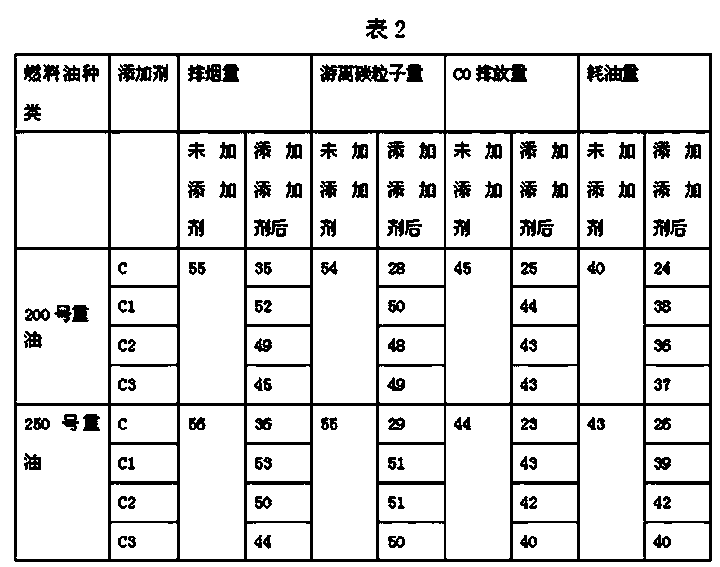

Multifunctional fuel oil additive

ActiveCN103421557AReduce the amount of particlesEmission reductionLiquid carbonaceous fuelsPhysical chemistryOil additive

The invention belongs to the technical field of additives, and particularly relates to a multifunctional fuel oil additive, which is formed by the following components in weight part: 10-15 parts of antiknock agent, 5-10 parts of antioxidant, 5-10 parts of antistatic agent and 10-20 parts of flow improver. For different fuel oil, the fuel oil additive prepared by the invention can reduce 36.4 percent of smoke dust exhausting amount, 48.1 percent of free carbon particles, and 47.7 percent of CO emission load to the greatest extent, and increases fuel saving ratio by 40.0%.

Owner:临沂星火知识产权服务有限公司

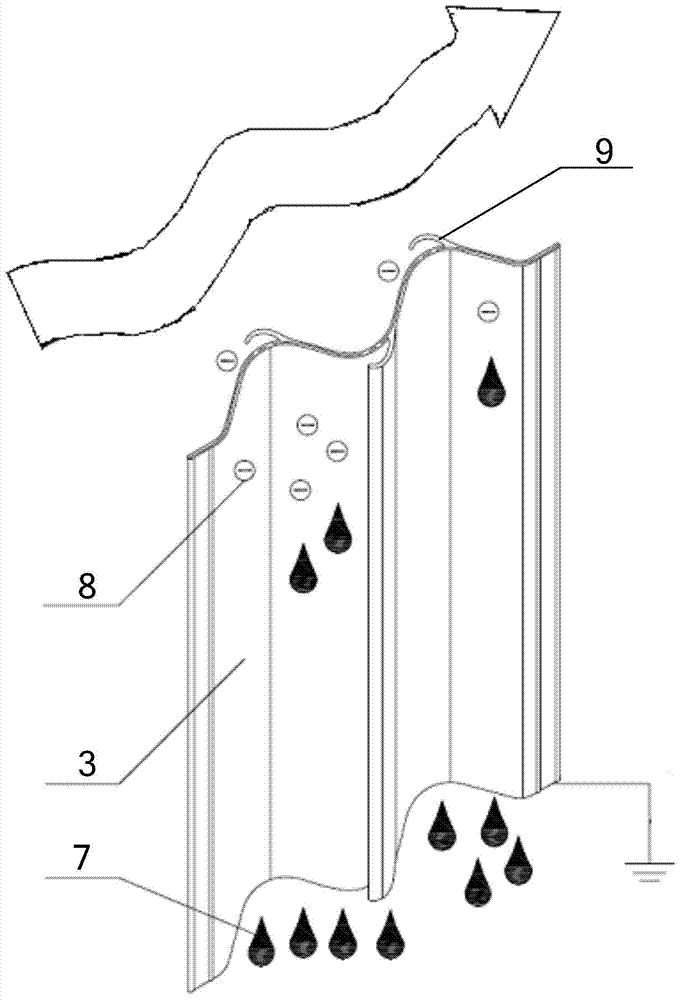

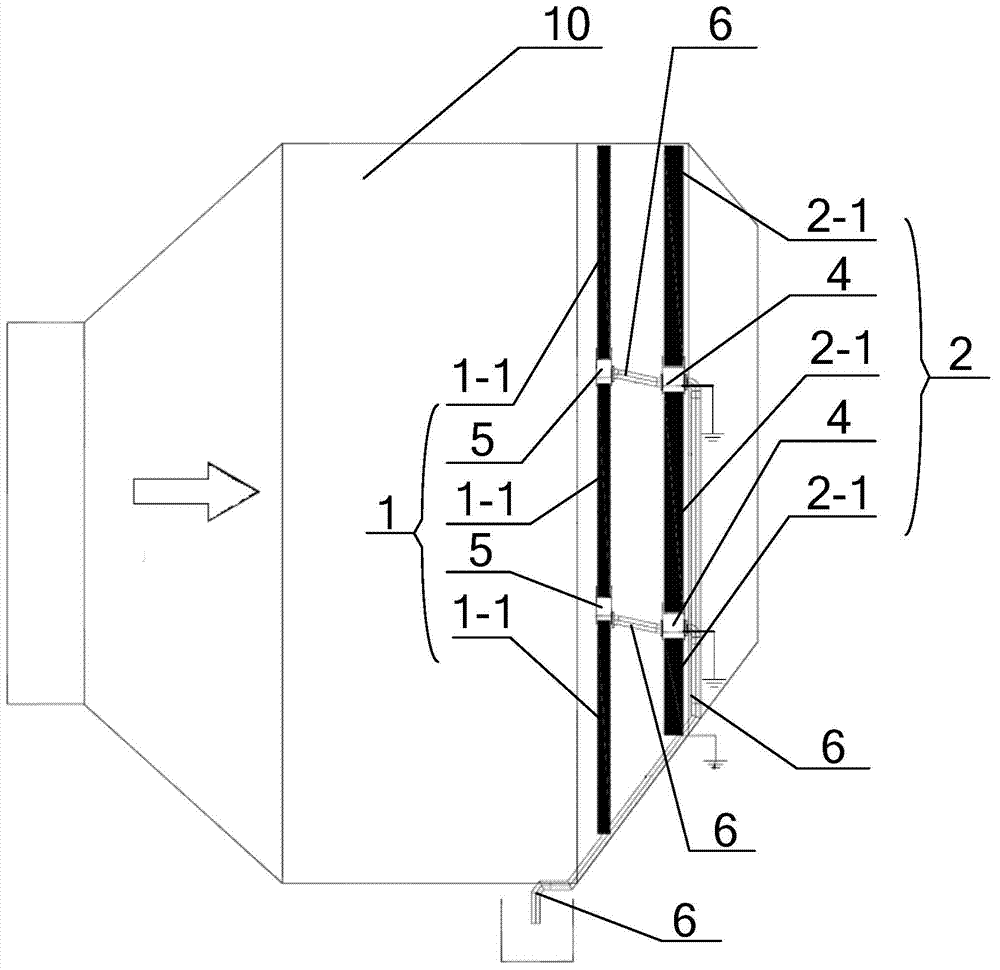

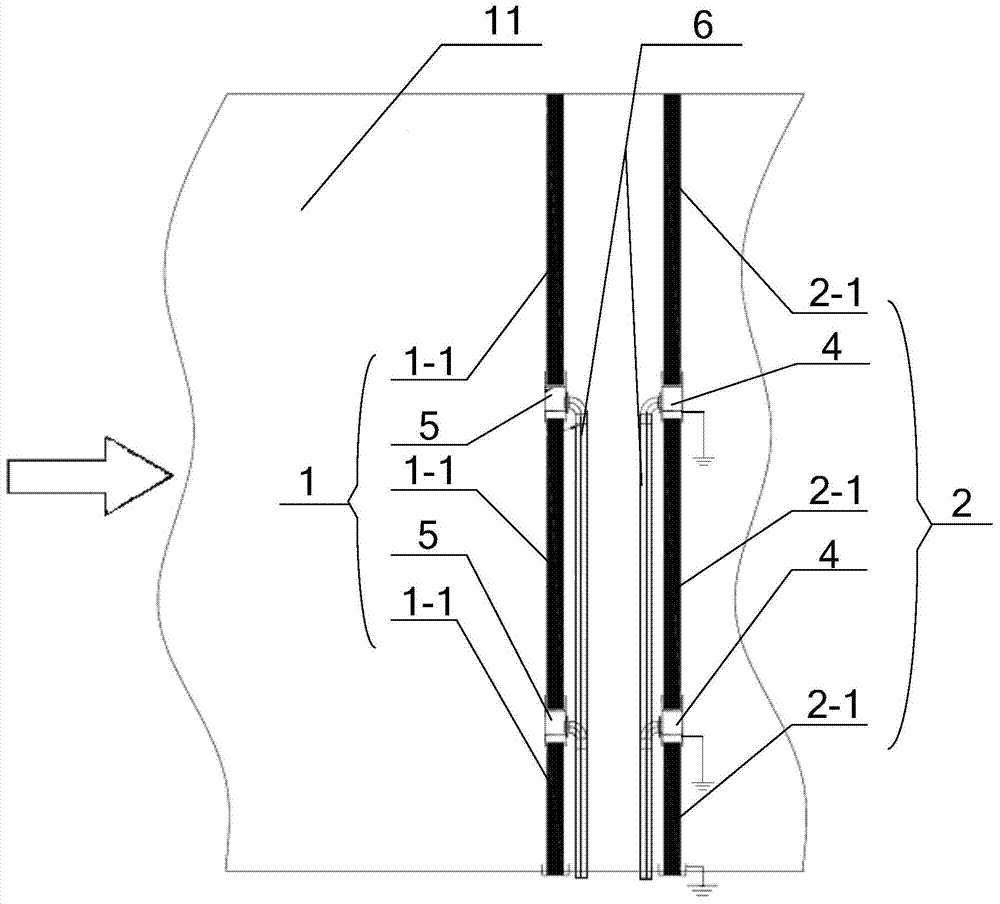

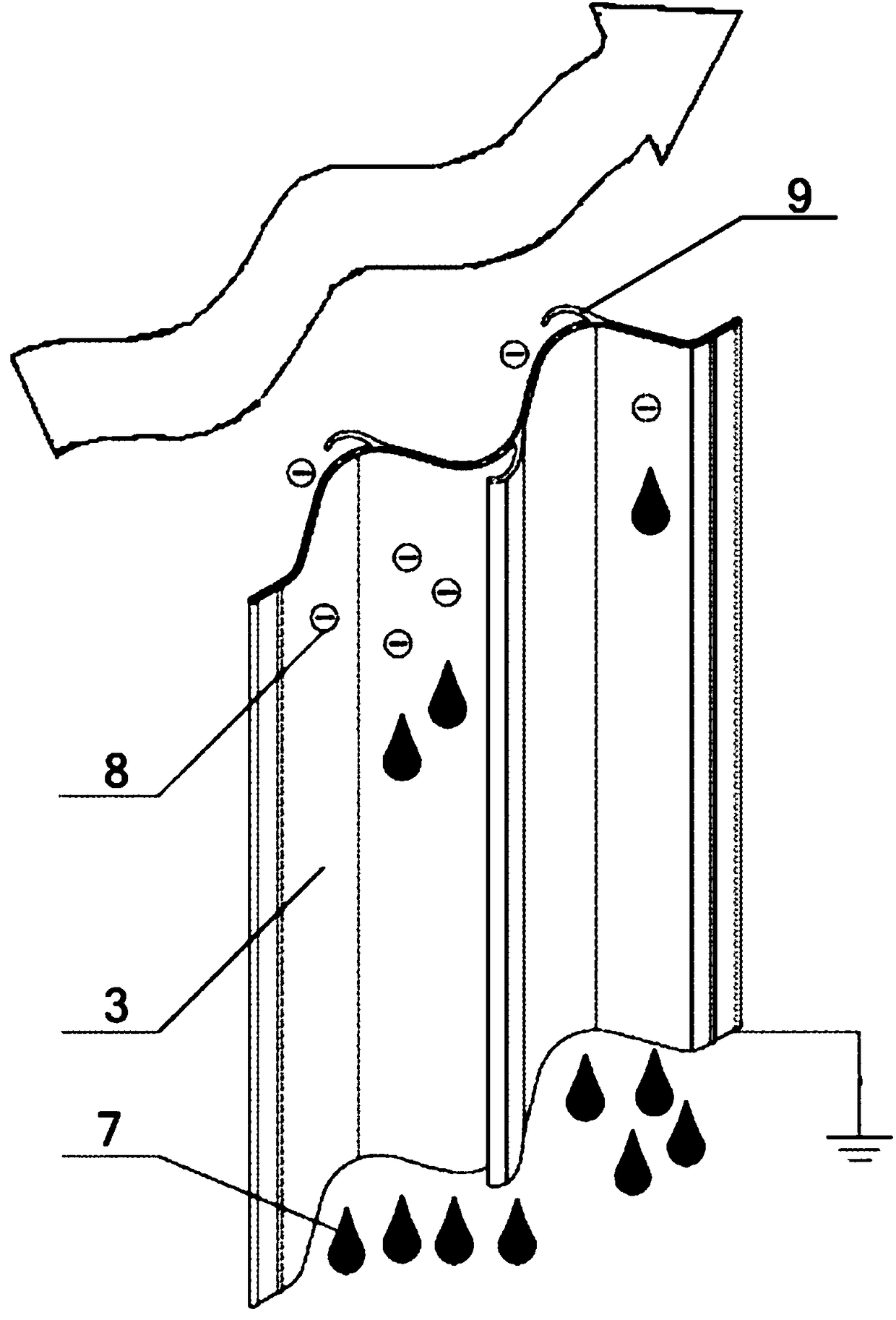

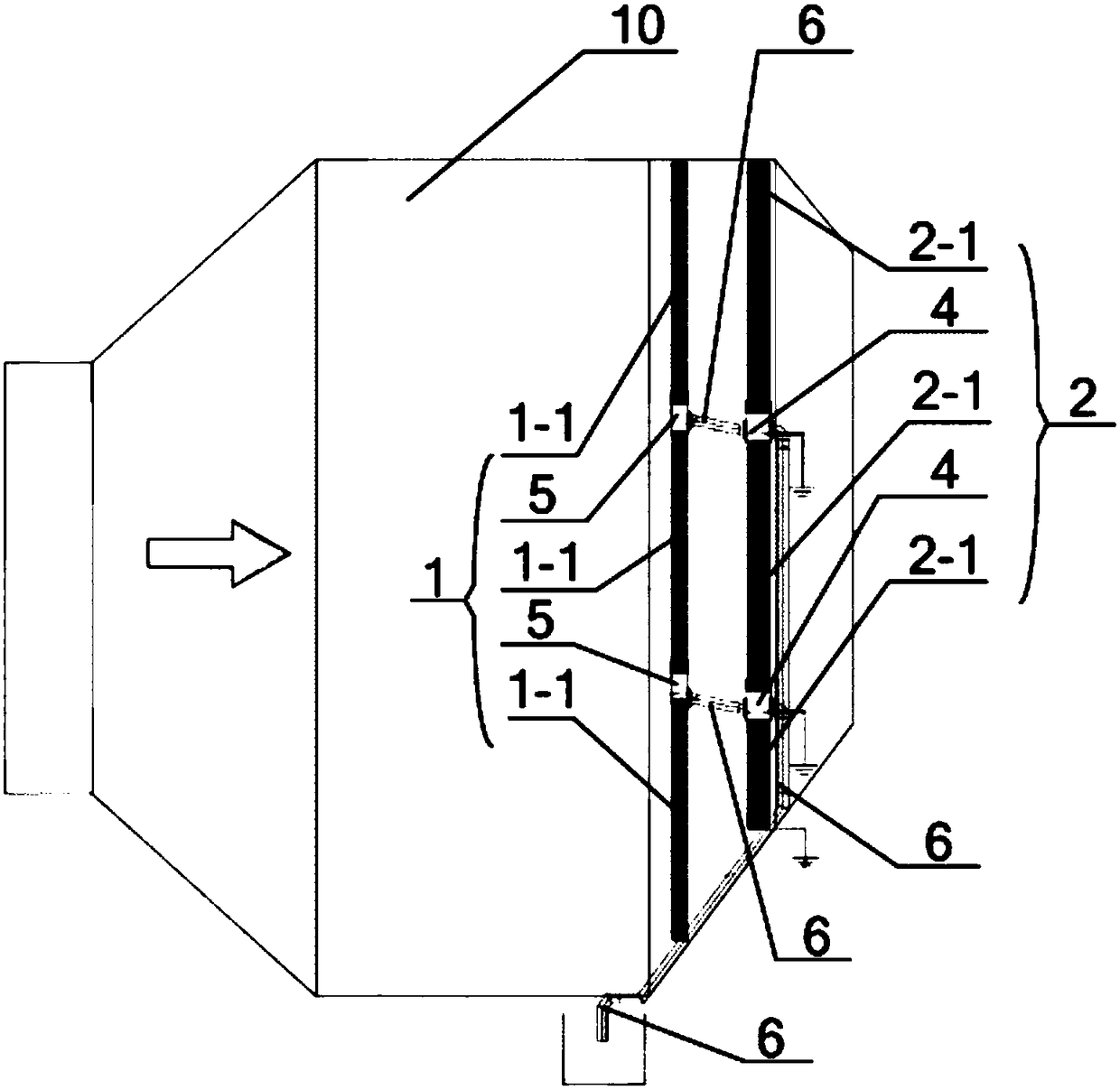

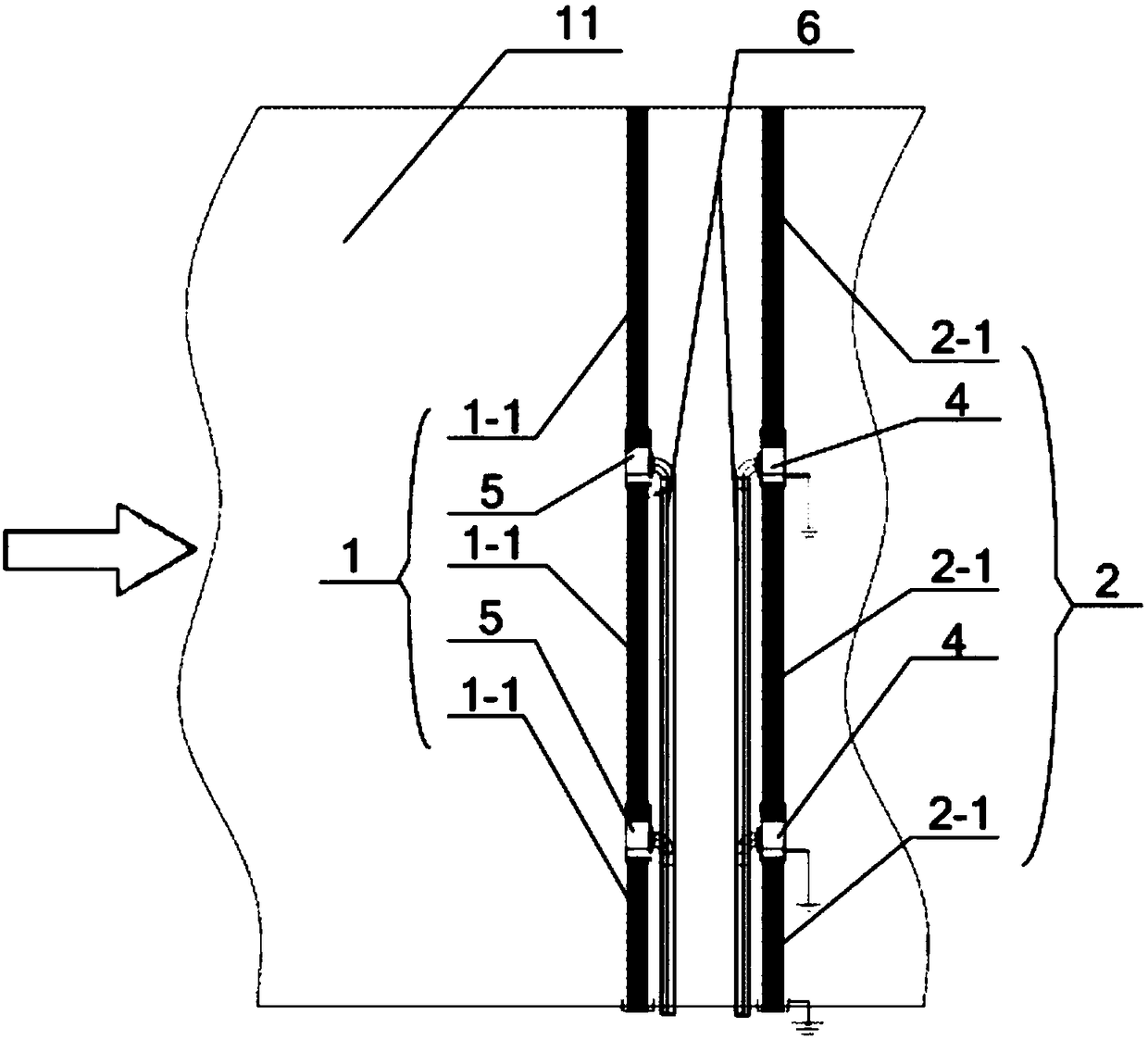

Dedusting and defogging device

InactiveCN104707428AReduce drop volumeReduce the amount of particlesCombination devicesSmall dropletFlue gas

The application discloses a dedusting and defogging device which comprises a dedusting and defogging device body, wherein blades of the dedusting and defogging device body are conductive blades, water collecting tanks corresponding to the conductive blades are conductive water collecting tanks; the end parts of the conductive blades are placed in the conductive water collecting tanks; the conductive blades and the conductive water collecting tanks are all grounded. According to a smoke dust purification system and the dedusting and defogging device provided by the invention, liquid drops, small droplets with negative charges and fine particulate matters in flue gas can be intercepted, especially, liquid drops and particles with the size being smaller than 20 microns can be intercepted, so that the amount of droplets and dust carried by the flue gas can be greatly reduced.

Owner:RPT SHANGHAI ENVIRONMENTAL EQUIP

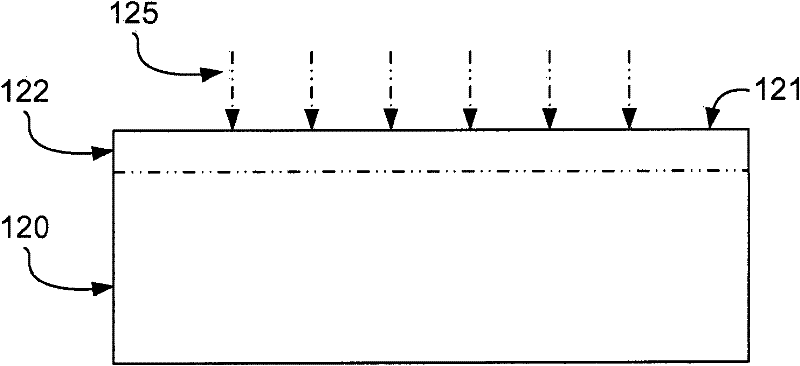

Semiconductor on insulator and methods of forming same using temperature gradient in an anodic bonding process

InactiveCN102484094AReduce the amount of particlesSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingIndirect contactAnodic bonding

Methods and apparatus for producing a semiconductor on glass (SOG) structure include: bringing a first surface of a glass substrate into direct or indirect contact with a semiconductor wafer; heating at least one of the glass substrate and the semiconductor wafer such that a second surface of the glass substrate, opposite to the first surface thereof, is at a lower temperature than the first surface; applying a voltage potential across the glass substrate and the semiconductor wafer; and maintaining the contact, heating and voltage to induce an anodic bond between the semiconductor wafer and the glass substrate via electrolysis.

Owner:CORNING INC

Dust and fog removing device

InactiveCN108080147AReduce drop volumeReduce the amount of particlesExternal electric electrostatic seperatorFine particulateEngineering

The invention relates to the technical field of air purification, and discloses a dust and fog removing device which comprises a dust and fog remover. A blade of the dust and fog remover is a conductive blade, a water collection groove corresponding to the conductive blade is a conductive water collection groove, the end of the conductive blade is arranged in the conductive water collection groove, and both the conductive blade and the conductive water collection groove are grounded. According to a smoke dust purifying system and the dust and fog removing device of the smoke dust purifying system, liquid drops in smoke and fine liquid drops and fine particulate matter which have negative charge, particularly liquid drops and particulate matter with the diameter being 20 micrometers or below can be intercepted, and therefore the liquid drop volume and dust capacity in smoke can be greatly reduced.

Owner:宁波江北峰尚环保设备有限公司

Single-component extrusion molding conductive rubber for electromagnetic shielding and preparation method of single-component extrusion molding conductive rubber

InactiveCN102220012BLarge specific surface areaConducive to direct contactCross-linkElectromagnetic shielding

The invention discloses a single-component extrusion molding conductive rubber for electromagnetic shielding and a preparation method of the single-component extrusion molding conductive rubber, belonging to the technical field of electromagnetic shielding materials. The single-component extrusion molding conductive rubber is composed of dendritic silver coated copper powder, silvered glass fiber, polydimethylsiloxane containing vinyl by rubber base body, reinforcing agent gaseous phase white carbon black, alkynol inhibitor, metal platinum catalyst, and cross-linking agent methylhydropolyorganosiloxane. The preparation method comprises the following steps: pretreatment is carried out to the dendritic silver coated copper powder and the silvered glass fiber through amido coupling agent methyl organodisilane according to the formula, the rubber base body and the gaseous phase white carbon black are added in a vacuum kneading machine, are mixed uniformly and are added in a double-planet mixing plant, and then the alkynol inhibitor, the metal platinum catalyst and the treated electric conduction powder are mixed uniformly to form a component 1; the treated electric conduction powder is added in a cross-linking agent and is mixed uniformly to form a component 2; and two components in the double planets are mixed to form the single-component on-site forming electromagnetic shieldingsilicon rubber. The rubber has good shielding performance and good mechanical property.

Owner:BEIJING UNIV OF TECH

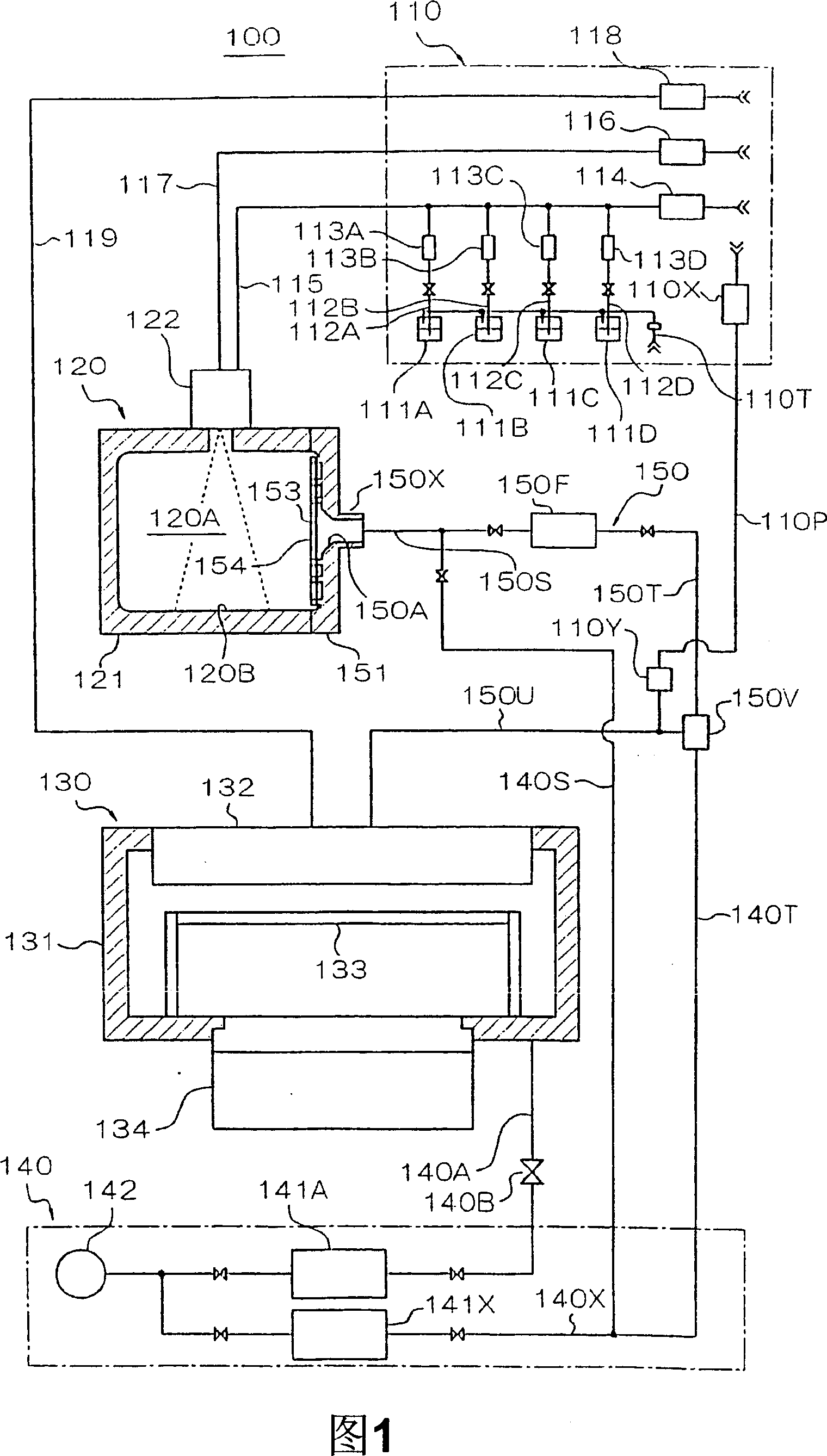

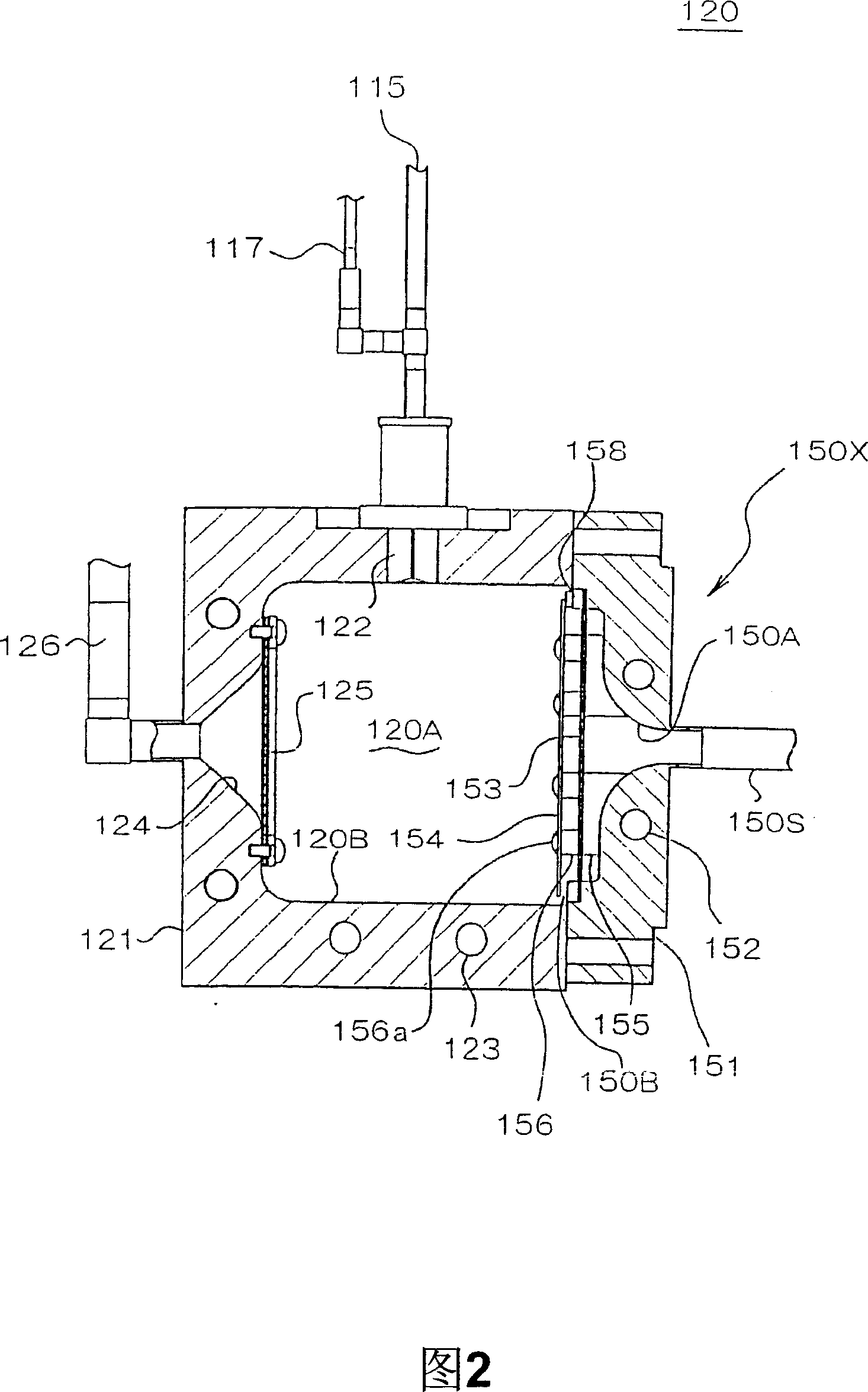

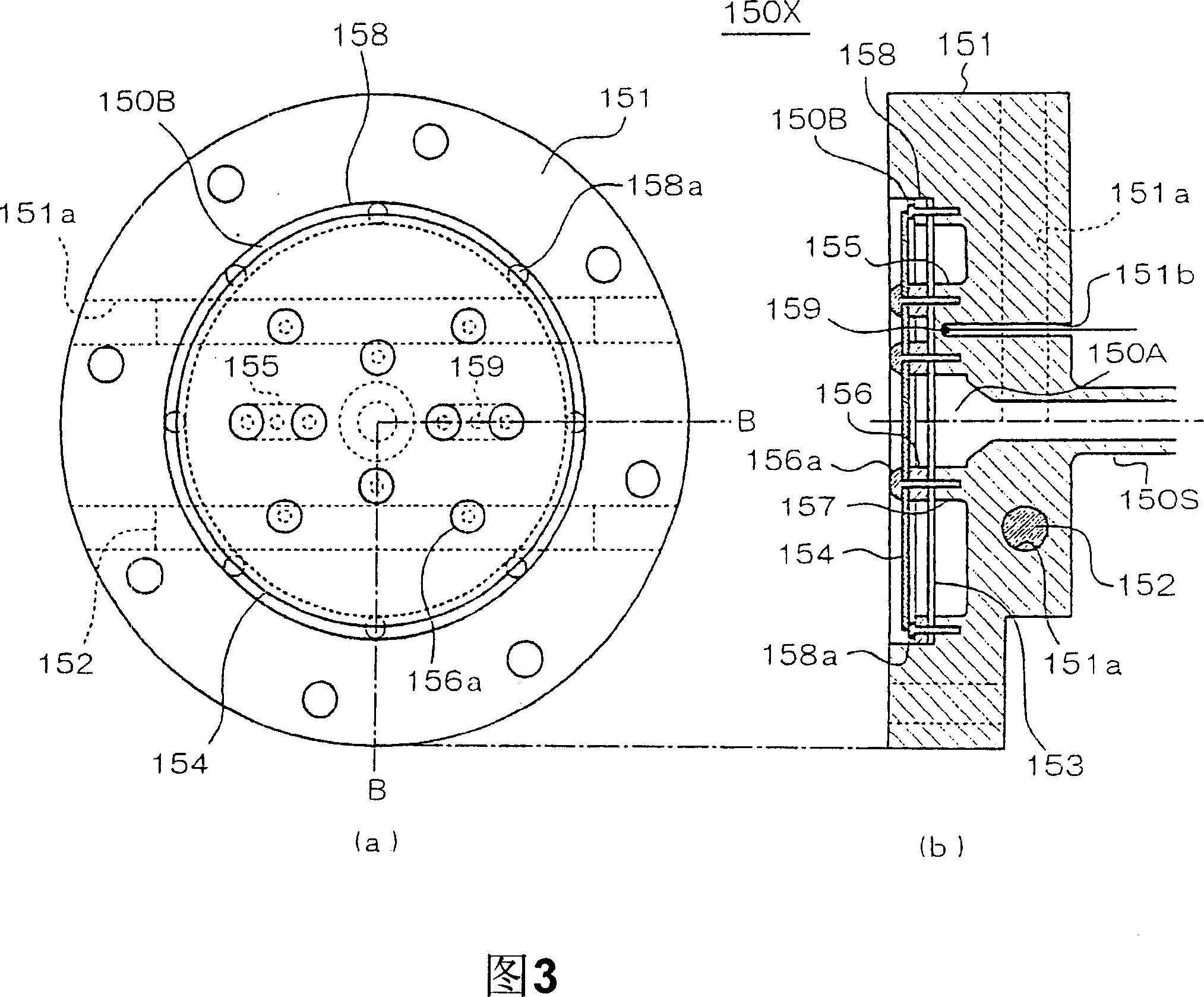

Film forming apparatus and gasifier

InactiveCN1969375AReduce the amount of particlesRaise the gradeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringProduct gas

A film forming apparatus having a raw material supplying section for supplying a raw material composed of a liquid or a gas-liquid mixture, a raw material vaporizing section for vaporizing the raw material to form a raw material gas, and a film forming section for conducting a film forming treatment using the raw material gas formed, wherein a filter (153) is provided on the way of the transport path for the raw material gas from the raw material vaporizing section to an introduction port of the film forming section, and wherein an outer edge (153a) of the filter (153) is pressed to the inner surface of the transport path over the whole perimeter thereof by a cyclic supporting member (158), which is less prone to be deformed by a loading in the direction of pressing than the above outer edge (153a), and is fixed to the inner surface of the transport path in a state of being compressed between the inner surface of the transport path and the supporting member (158).

Owner:TOKYO ELECTRON LTD

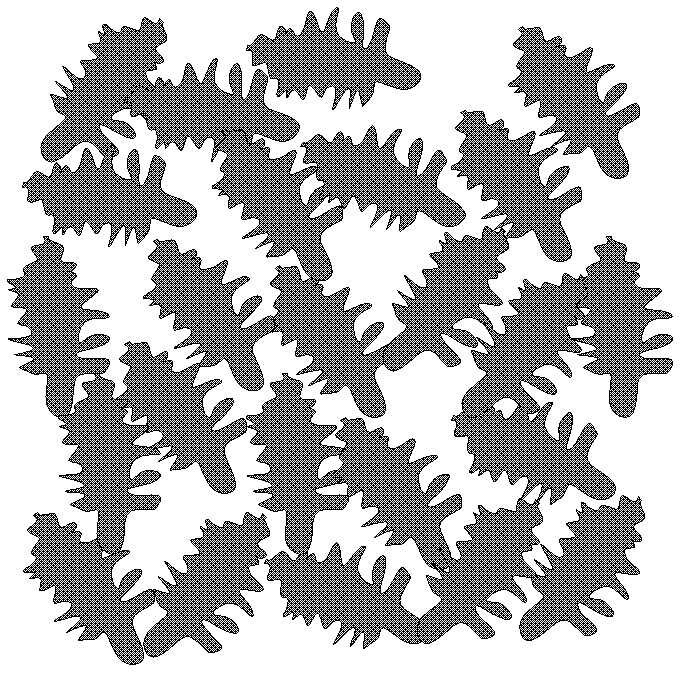

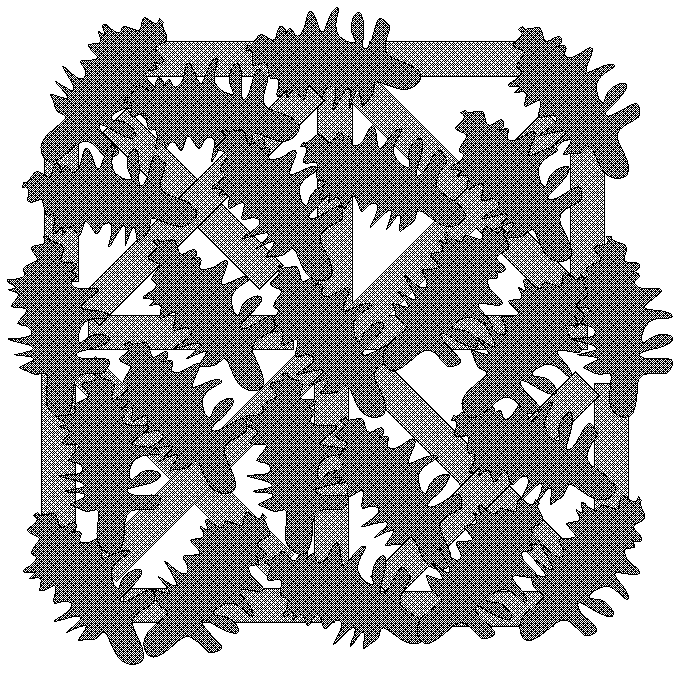

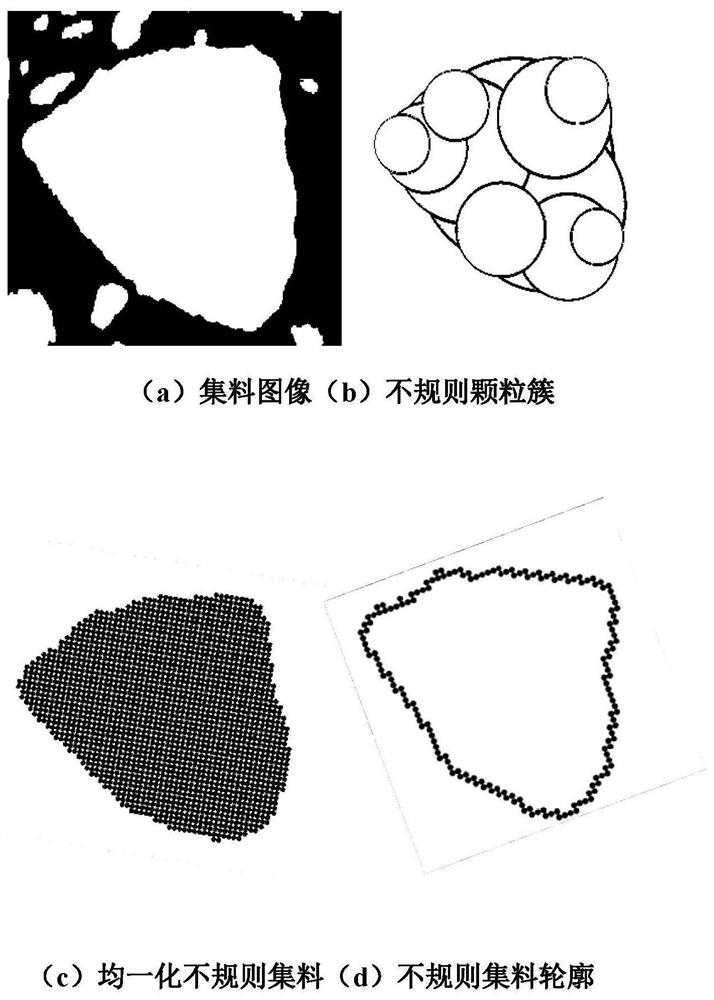

Asphalt mixture shear strength analysis methodbased on discrete elements

PendingCN113176153AReflect frictionGuaranteed accuracyMaterial strength using steady shearing forcesShearing deformationUltimate tensile strength

The invention discloses an asphalt mixture shear strength analysis method based on discrete elements, and belongs to the technical field of asphalt mixture numerical calculation. The method mainly comprises the following steps: establishing a two-dimensional irregular aggregate library by processing an indoor asphalt mixture test piece image; generating discrete element samples according to test specifications; replacing the circular aggregate with an irregular aggregate particle cluster; uniformly filling the sample space with circular particles with the same size, converting the particles overlapped with the irregular particle cluster into new irregular aggregates, retaining the contour parts of all the irregular aggregates, and deleting the filled particles inside; giving specific contact models to different inter-particle contact types, and applying corresponding contact parameters at the same time; confining pressure is applied to the sample through a servo mechanism, and consolidation is carried out; and controlling the lateral confining pressure, moving the upper wall body downwards, and testing the shear strength of the sample. The method can also be used for a three-dimensional model, influence of different grades on the shear strength of the asphalt mixture is analyzed, the shear deformation micromechanism of the asphalt mixture is studied, and the accuracy is high.

Owner:ZHEJIANG UNIV

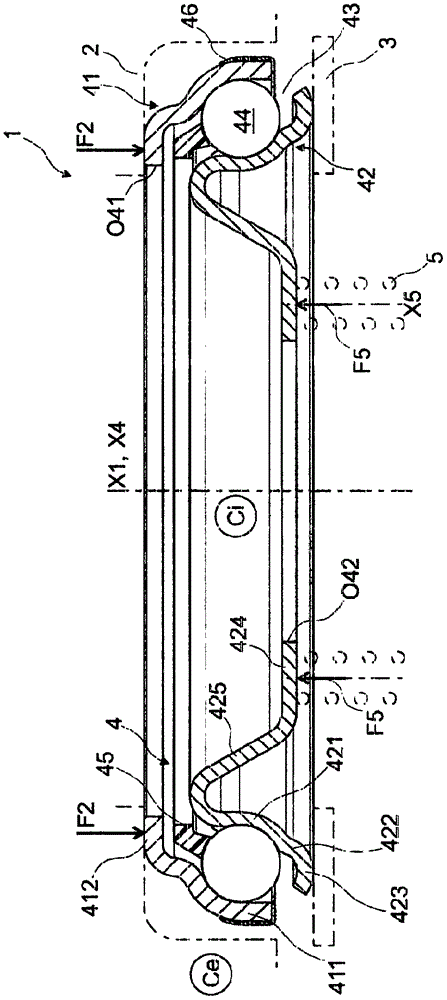

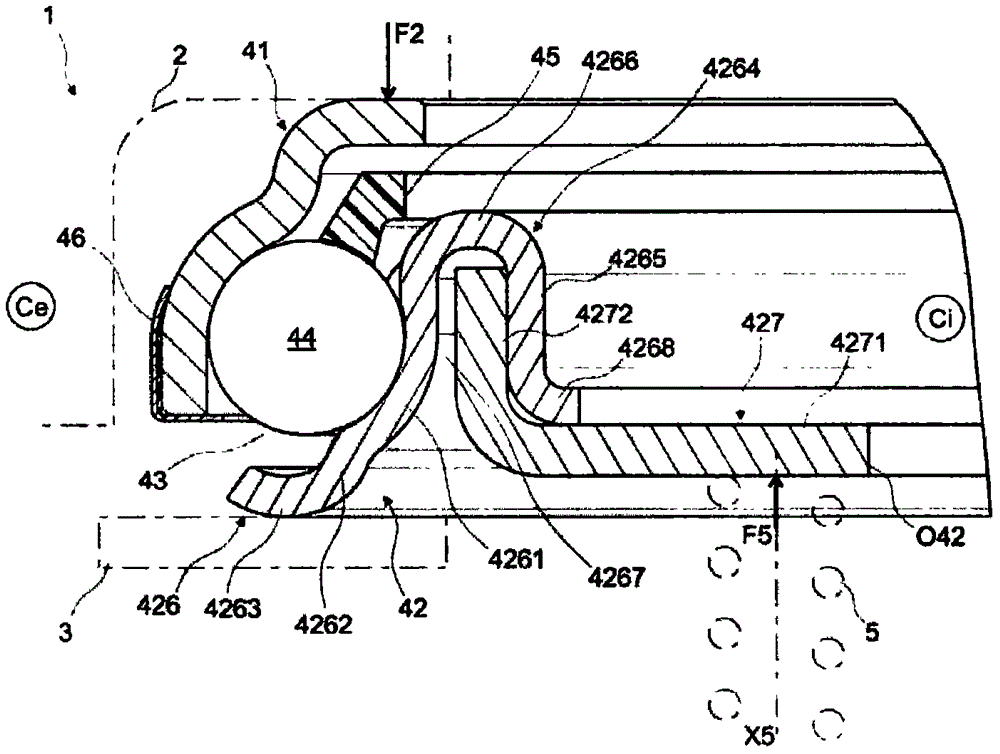

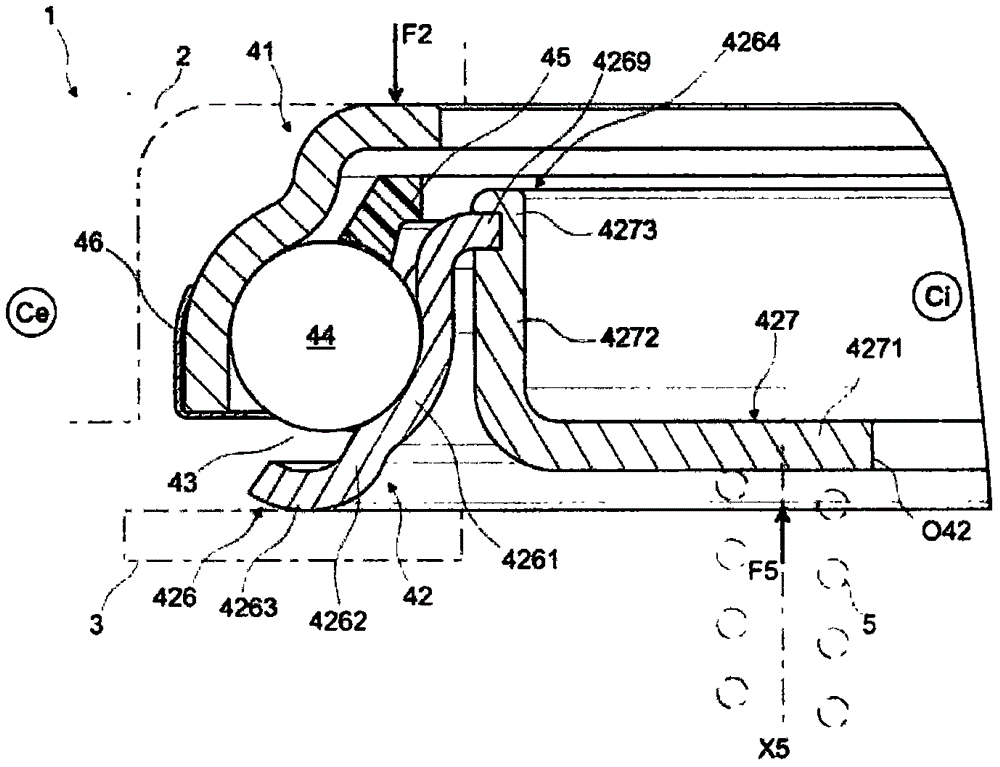

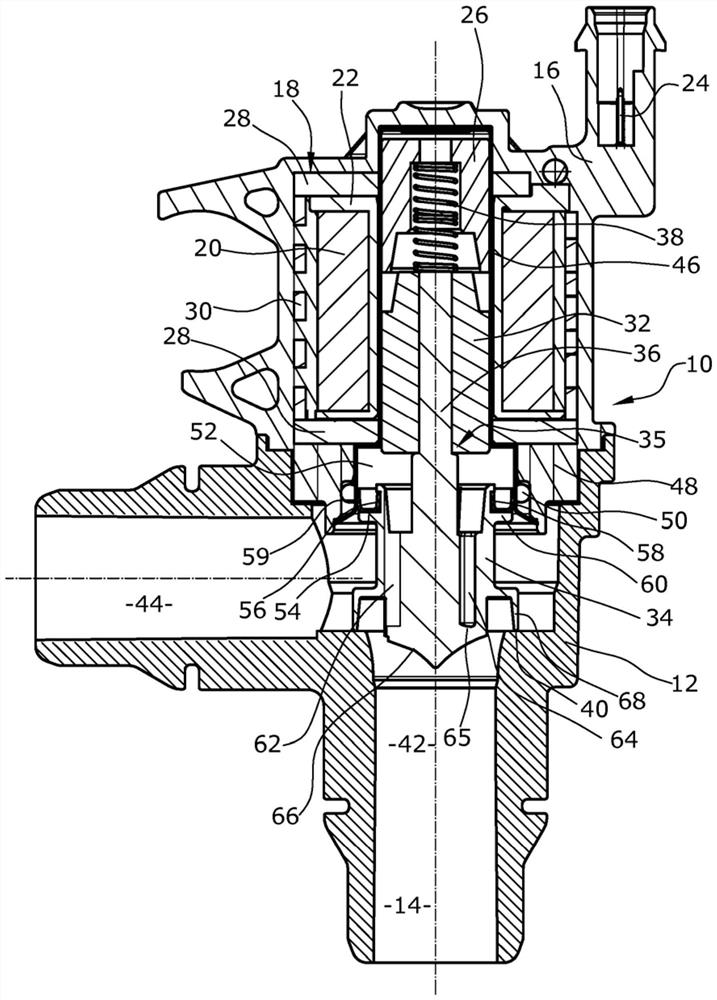

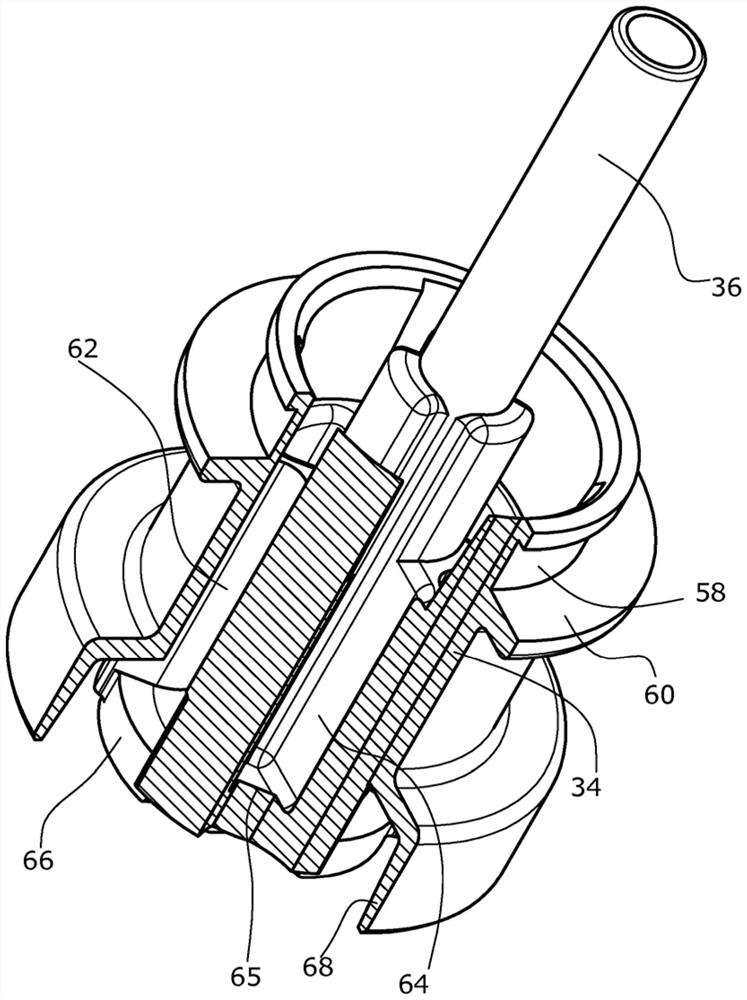

Clutch release bearing device and motor vehicle equipped with such bearing

ActiveCN106050901AReduce wearExtended service lifeMechanical actuated clutchesShaftsClutchEngineering

Owner:AB SKF

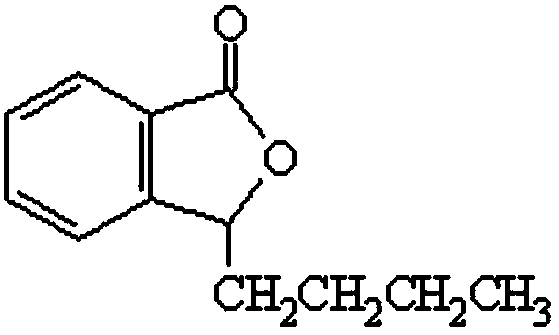

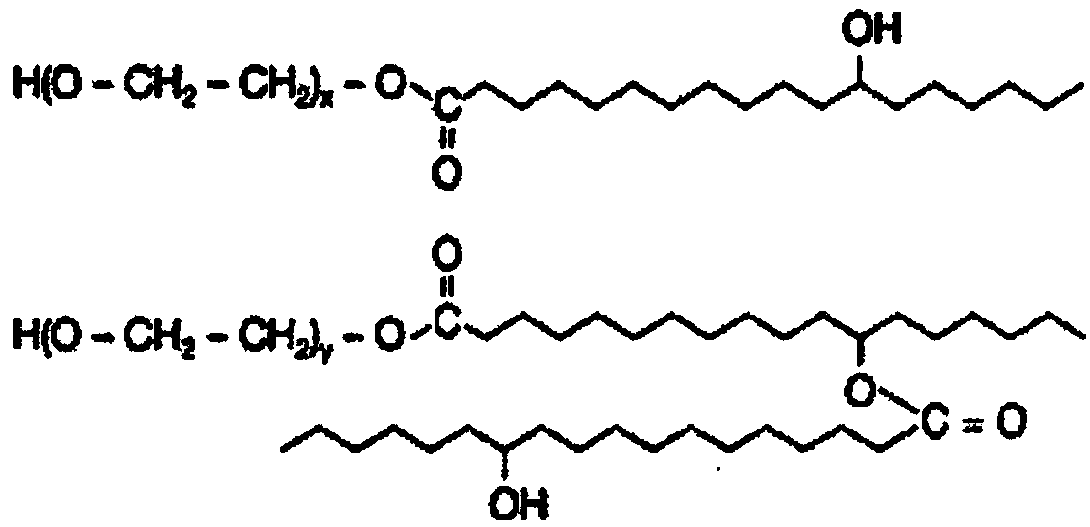

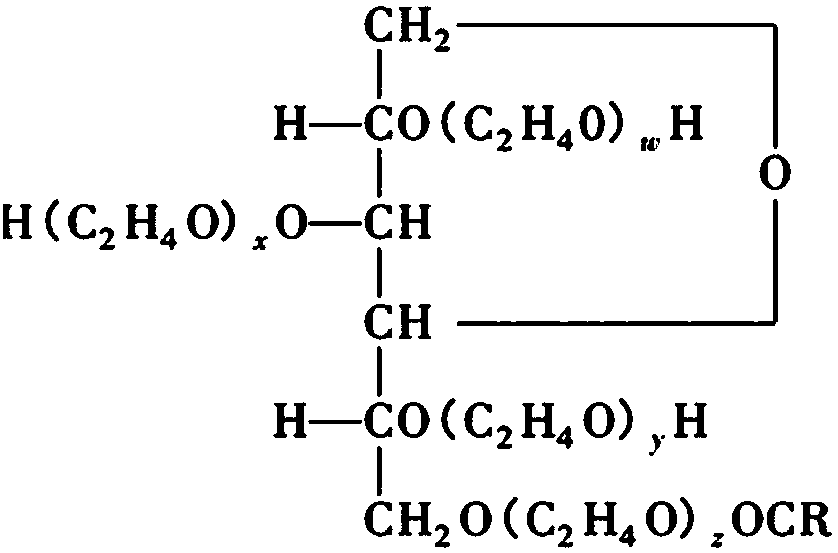

Stable 3-n-butylphthalide3-n-butylphthalide high-capacity injection and preparation method thereof

PendingCN110548004AMake up for the gap in the marketAvoid security risksOrganic active ingredientsInorganic non-active ingredientsActivated carbonSurface-active agents

The invention relates to a stable 3-n-butylphthalide high-capacity injection and a preparation method thereof. The stable 3-n-butylphthalide high-capacity injection contains dl-3-n-butylphthalide or l-3-n-butylphthalide, a surface active agent, an osmotic pressure regulator, a pH regulator, a stabilizer, and water for injecting, wherein the surface active agent is selected from one or more of polyethylene glycol-15-hydroxystearate, polysorbate-80, poloxamer188 and lecithin. The 3-n-butylphthalide high-capacity injection is stable in quality, does not contain activated carbon, and has few particles and higher safety, and the quantity of the particles does not increase along with storage time; the content of 3-n-butylphthalide is high, and therefore the 3-n-butylphthalide high-capacity injection can be directly applied to intravenous injection, and accordingly meets requirements for clinical drug delivery; and a preparation technology is simple, ensures the stability of the injection andis high in operability, and thus industrial production is easily achieved.

Owner:CHENGDU SHIBEIKANG BIOLOGICAL MEDICINE TECH CO LTD

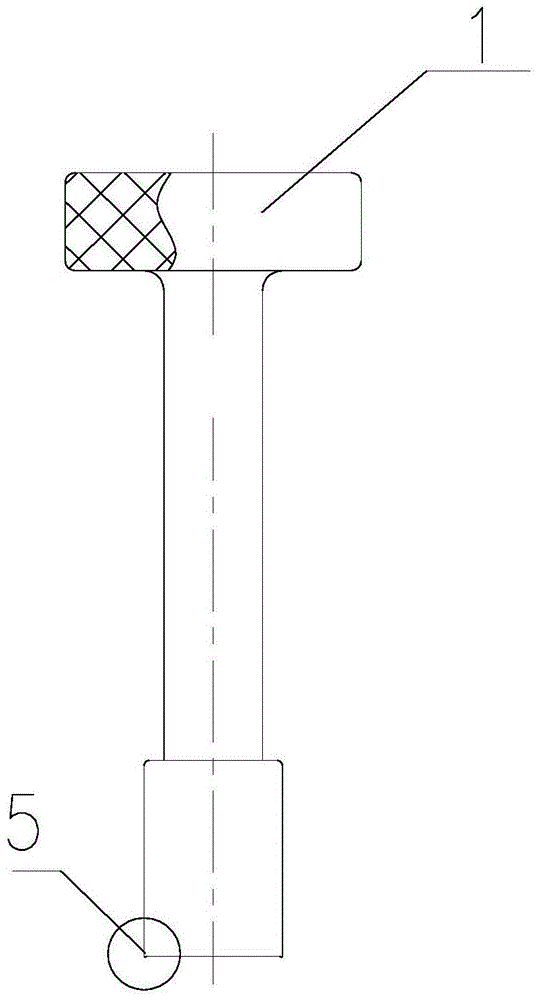

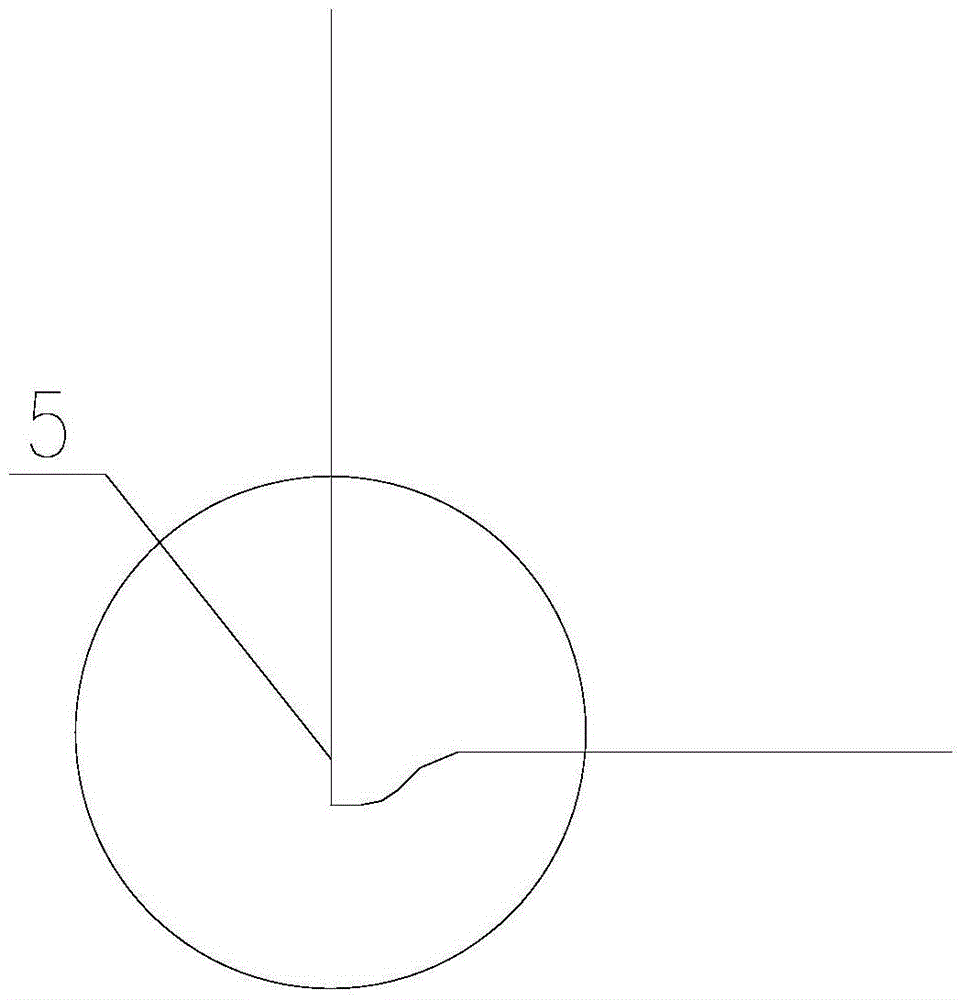

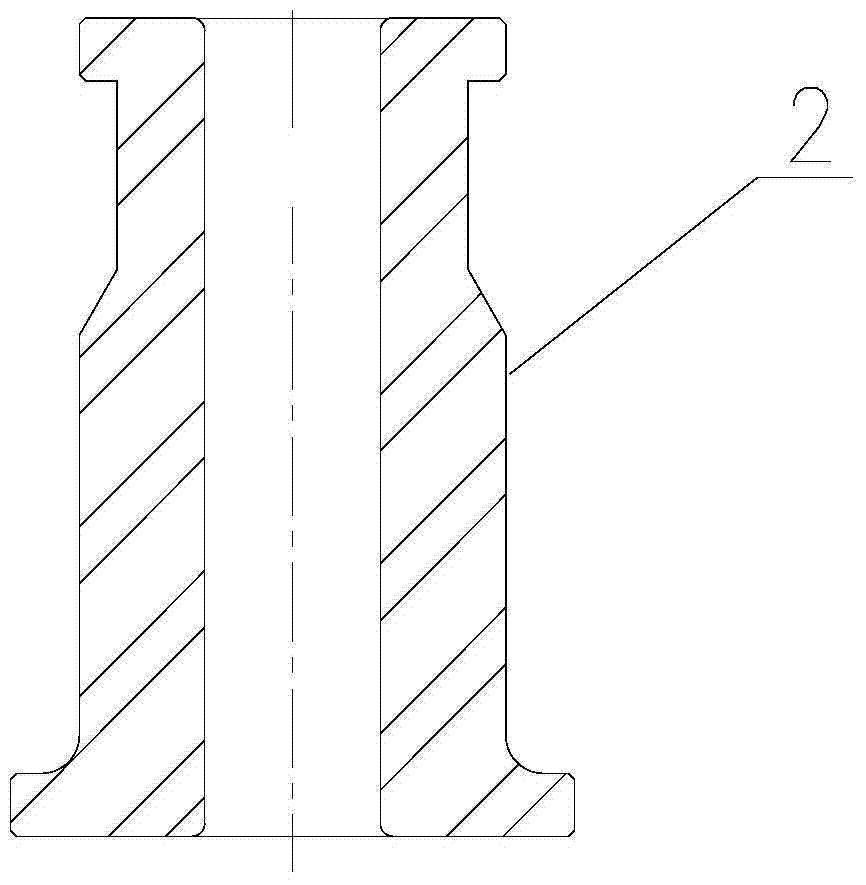

Mold device for removing flash from molding powder material

ActiveCN104742408BReduce the amount of particlesReduce extrusion pressurePressesMaterials processingMaterials science

The invention discloses a mould device for removing trimming of power materials forming at a time through mould pressing, and relates to the field of the power material forming at a time through mould pressing. The mould device for removing the trimming of the power materials forming at a time through the mould pressing comprises a punch, a mould sleeve, a base and a demoulding table. A circle of protrusions towards the power materials are formed in the outer edge of the contact end face of the punch and the power materials. A circle of protrusions towards the power materials are formed in the outer edge of the contact end face of the base and the power materials. According to the mould device for removing the trimming, the trimming structure can be controlled by the design, when the punch moves downwards, a component force towards the axis of the mould sleeve is conducted on the materials, edge material granules of the punch can be effectively controlled to move in the radial direction, and thereof the amount of the material granules heaped up in a clearance is reduced; by means of the structure, extrusion force conducted on the material granules in the clearance is favorable to reduced at the same time, and the purpose that the pressed shape trimming is effectively controlled is achieved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

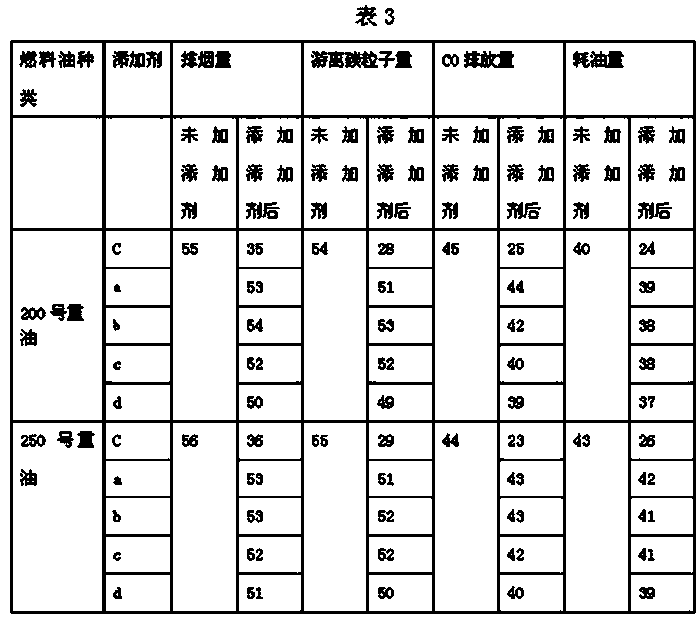

A kind of preparation method of fuel additive

InactiveCN108977238BReduce the amount of particlesEmission reductionLiquid carbonaceous fuelsMeth-Acrylic resin

The invention discloses a fuel additive, which is prepared from the following raw materials in parts by weight: 10 to 20 parts of aluminum oxide, 20 to 30 parts of iron trioxide, 10 to 15 parts of methylcyclopentadiene tricarbonyl manganese, 5 to 10 parts of antioxidants, 11 to 18 parts of antistatic agents, 12 to 20 parts of sodium benzene sulfonate, 0.5 to 1.5 parts of non-metallic nanometer quantum dot compound additives, 10 to 25 parts of hydrocarbon compounds and 5 to 10 parts of acrylic graft modified acrylic resin. The invention also discloses a preparation method of the fuel additive.The preparation process is simple; when the prepared fuel additive combusts together with fuel oil, the smoke dust quantity of the discharged smoke can be effectively reduced; the free carbon particlequantity and the CO discharge quantity are reduced; meanwhile, the oil saving rate is greatly improved.

Owner:天沐蓝(山东)能源有限公司

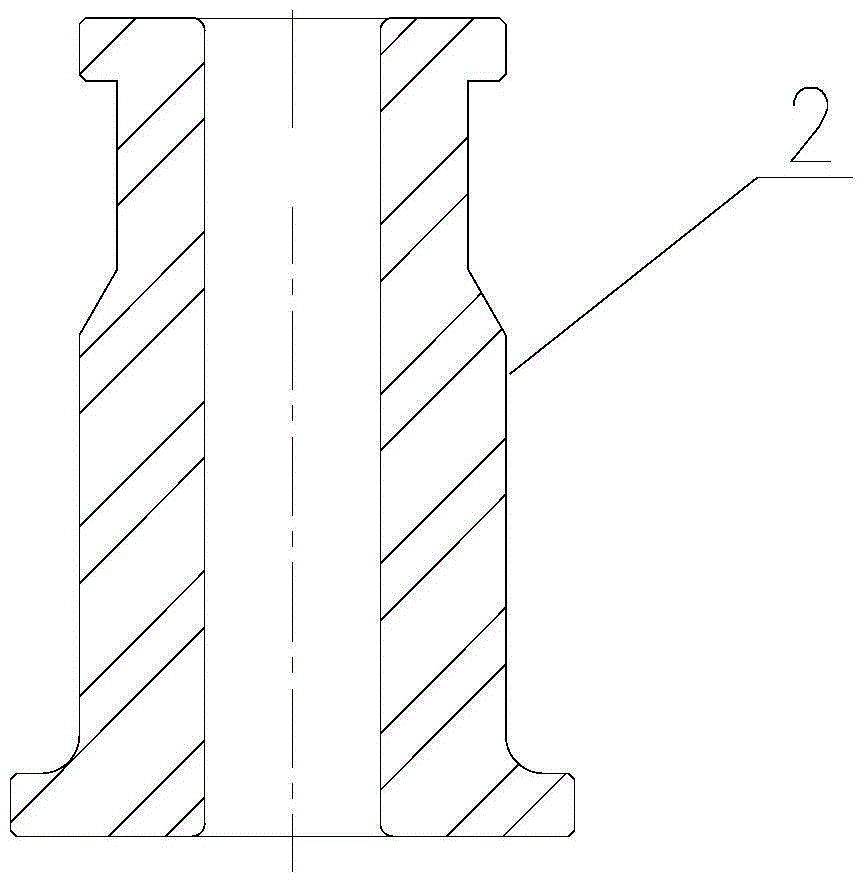

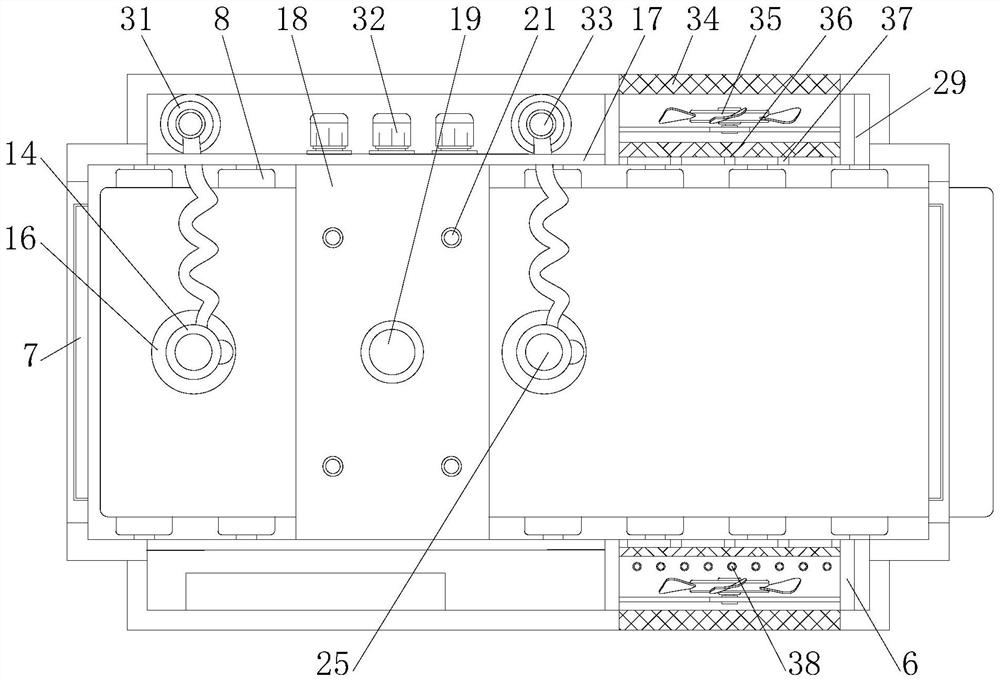

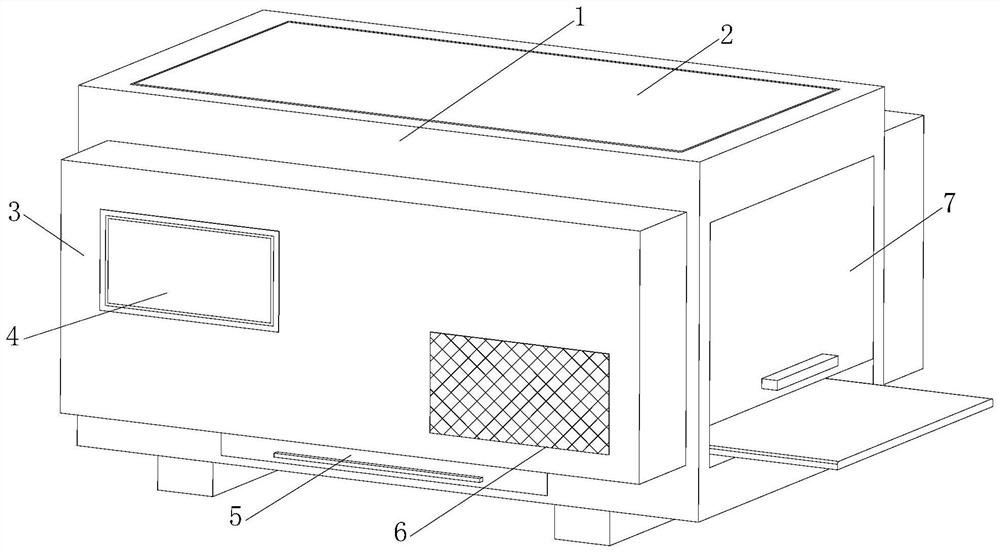

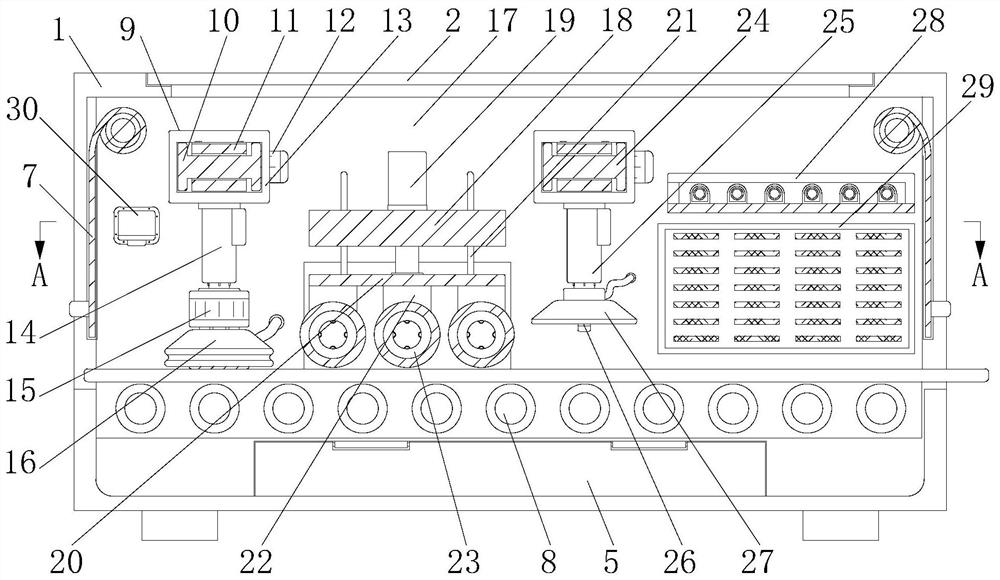

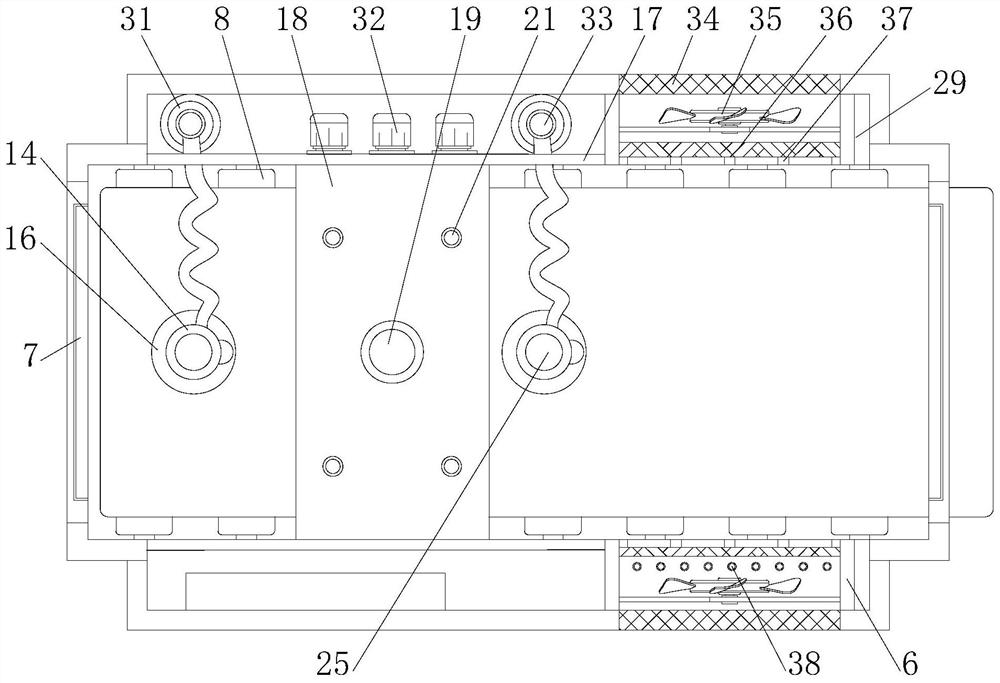

Metal plate rust removal and paint spraying machining equipment and using method

ActiveCN113798105AImprove processing efficiencyEasy to processPretreated surfacesCoatingsSurface cleaningMachining process

The invention relates to the technical field of metal plate machining, in particular to metal plate rust removal and paint spraying machining equipment and a using method. The metal plate rust removal and paint spraying machining equipment comprises a device body and a plurality of conveying rollers which are located in the device body and are perpendicular to the moving direction of a metal plate; a grinding assembly is arranged in an inlet end of the device body; the grinding assembly moves in the direction perpendicular to the moving direction of the metal plate to grind the metal plate; and a cleaning assembly used for cleaning the upper surface of the metal plate is arranged on the side, away from the inlet end, of the grinding assembly and located in the device body. The equipment does not need to transfer plates frequently in the machining process of the metal plates, and the machining efficiency of the metal plates can be effectively improved.

Owner:徐州威德金属制品有限公司

Metal plate derusting and painting processing equipment and using method

ActiveCN113798105BImprove processing efficiencyEasy to processPretreated surfacesCoatingsSurface cleaningEngineering

The present invention relates to the technical field of sheet metal processing, in particular to a sheet metal rust removal and painting processing equipment and a method of use, including a device body and a plurality of horizontally evenly arranged conveying rollers located inside the device body perpendicular to the moving direction of the metal sheet, The entrance end of the device body is provided with a grinding assembly, which moves along the direction perpendicular to the movement of the metal sheet to grind the metal sheet, and the side of the grinding assembly away from the entrance end is located inside the device body for cleaning the upper surface of the metal sheet. Clean components; the equipment does not need to transfer the sheet frequently during the processing of the sheet metal, which can effectively improve the processing efficiency of the sheet metal.

Owner:徐州威德金属制品有限公司

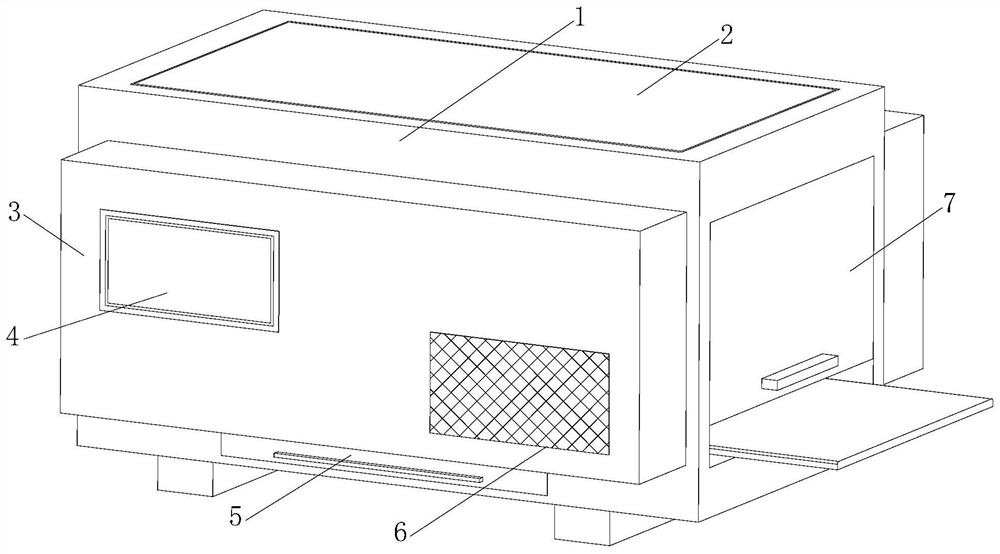

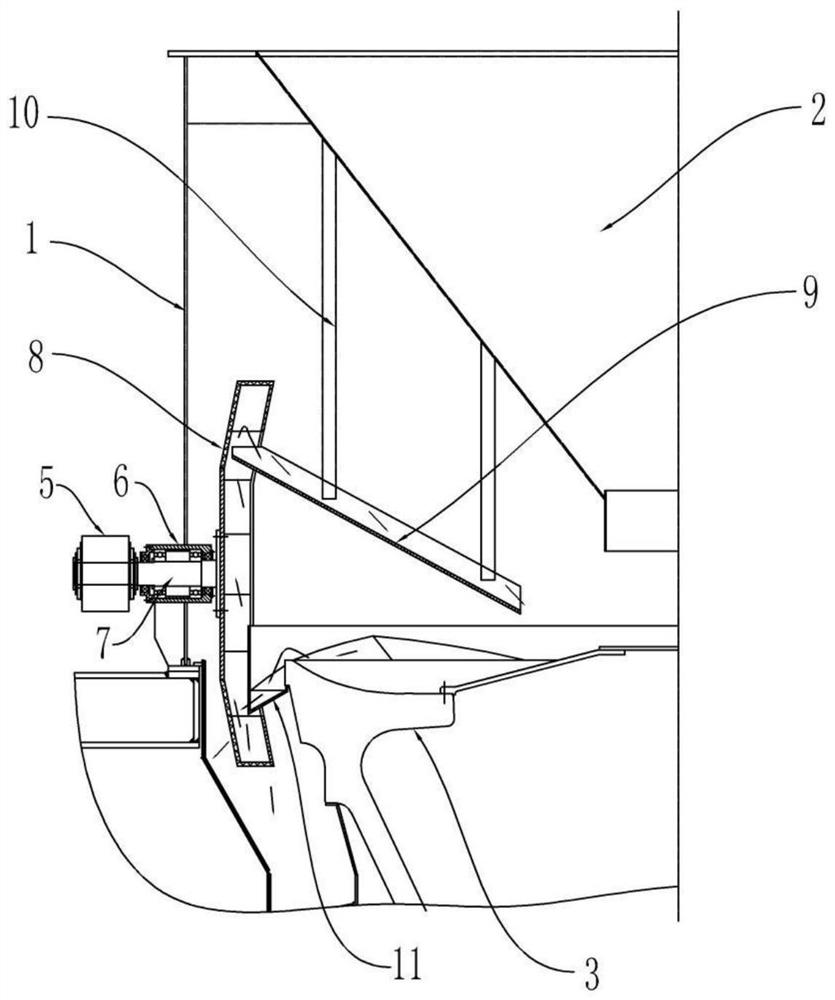

In-mill screening and lifting device and vertical roller mill

PendingCN112827579AReduce transportationReduce air volumeSievingScreeningMechanical engineeringEnergy conservation

The invention provides an in-mill screening and lifting device and a vertical roller mill. The in-mill screening and lifting device is applied to the vertical roller mill. The vertical roller mill comprises a shell, a grinding disc and a plurality of grinding rollers. The device comprises a collecting hopper, wherein the collecting hopper is arranged on the periphery of the grinding disc between the two adjacent grinding rollers, and a gap is formed between the inner side of the collecting hopper and the outer wall of the grinding disc; a rotary screen arranged on the outer side of the collecting hopper, wherein the bottom end part of the rotary screen is located below the collecting hopper, and the rotary screen is used for lifting materials discharged from the collecting hopper to the top end part of the rotary screen; a discharging chute, wherein the discharging chute is arranged above the grinding disc in a posture that the outer part is high and the inner part is low, and the top end part of the discharging chute is positioned under the top end part of the rotary screen; and a rotary screen driving part which is arranged on the outer side of the vertical roller mill and is in transmission connection with the rotary screen. The in-mill screening and lifting device and the vertical roller mill have the characteristics of a compact structure, convenience in installation and use, stability in operation and simplicity in maintenance. High economic value and social benefits are achieved in the aspects of energy conservation and emission reduction.

Owner:NANJING XIPU CEMENT ENG GROUP

A kind of flake metal powder of sieving-ball milling method and preparation method thereof

ActiveCN106891013BUniform thicknessReduce outputTransportation and packagingMetal-working apparatusNitrogenMetal particle

The invention provides a flaky metal powder by screening-ball milling method and a preparation method thereof, the preparation method of the flaky metal powder by the sieving-ball milling method comprises the following steps: Sieve into metal powders with different meshes; the metal powders are put into the ball milling equipment together with ball milling steel balls and metal powder surface treatment additives according to different meshes, vacuumize, fill with nitrogen, and carry out step by step according to different meshes Ball milling, the ball milling time is adjusted according to the particle size of the sieved metal powder; the ball milled powders of all levels are collected and classified again by airflow classification. Adopting the technical scheme of the present invention, the thickness of the flake metal powder obtained is uniform; the output of overgrinded metal powder can be greatly reduced, and at the same time, the slightly coarser metal particles after grinding are less and can be reground into qualified products. High, the yield rate can reach up to 100%, and the production efficiency is good.

Owner:SHENZHEN NONFEMET TECH

Exhaust pipe for automobile

ActiveCN108518267BIncrease flow rateAvoid cloggingExhaust apparatusSilencing apparatusSpiral bladeHigh pressure

The invention relates to the technical field of automobile accessories and discloses a smoke discharging pipe for an automobile. A smoke pipe and a protective plate are included; the smoke pipe is provided with a smoke inlet and a smoke outlet; the smoke pipe is provided with a gas inflow one-way valve; a dustproof structure is arranged in the smoke pipe; the dustproof structure comprises a filterscreen and a rotating fan which comprises spiral blades and an outer frame; a convex block is fixed to the outer frame; the smoke pipe is provided with a waste material port; the protective plate isfixedly connected with the smoke pipe; an annular cavity, a high-pressure gas cavity and a part portion are formed between the smoke pipe and the protective plate due to partition plates and a supporting plate; the annular cavity is provided with a gas outlet; the high-pressure gas cavity communicates with the annular cavity through a first gas outflow one-way valve; the upper portion of the partportion is provided with a gas bag; the gas bag communicates with the high-pressure gas cavity through a second gas outflow one-way valve; the gas bag is provided with a spring abutting against the filter screen; and the smoke pipe is provided with a heat insulating plate used for insulating heat of the annular cavity. The smoke discharging pipe for the automobile can prevent that the smoke discharging pipe for the automobile is blocked, and particle impurities in the smoke discharging pipe can be conveniently treated.

Owner:宁波高新区新柯保汽车科技有限公司

Heat conduction oil boiler

The invention relates to a heat conduction oil boiler which comprises a hearth and a heat dissipating device. The hearth is provided with a hearth top and a hearth side portion. The hearth top and the hearth side portion are in the shape of a smooth-transition gradually-shrunk opening. An inlet and an outlet are formed in the two sides of the shape of the gradually-shrunk opening. The shape of the cross section of the inlet is the same as that of the cross section of the hearth top. A separator is installed on the outlet, and the shape of the section of the outlet is the same with that of an inlet of the separator. The heat dissipating device comprises a plurality of roof tubes evenly installed in the hearth top. One ends of the roof tubes are provided with a cooling medium inlet header, and the other ends of the roof tubes are provided with a cooling medium outlet header. The roof tubes are connected with a beam through hanging devices. The heat conduction oil boiler has the beneficial effects that the two ends of the roof tubes are connected with the cooling medium inlet header and the cooling medium outlet header, the hearth interior can be cooled, the hearth is in the shape of the smooth-transition gradually-shrunk opening, the shape of the section of the outlet of the gradually-shrunk opening is the same as that of the inlet of the separator so that the number of particles, brought into the separator, of smoke can be reduced, and the advantages of firmness, durability and the like are achieved.

Owner:BEIJING ONE A HI TECH ENERGY TECH CO LTD

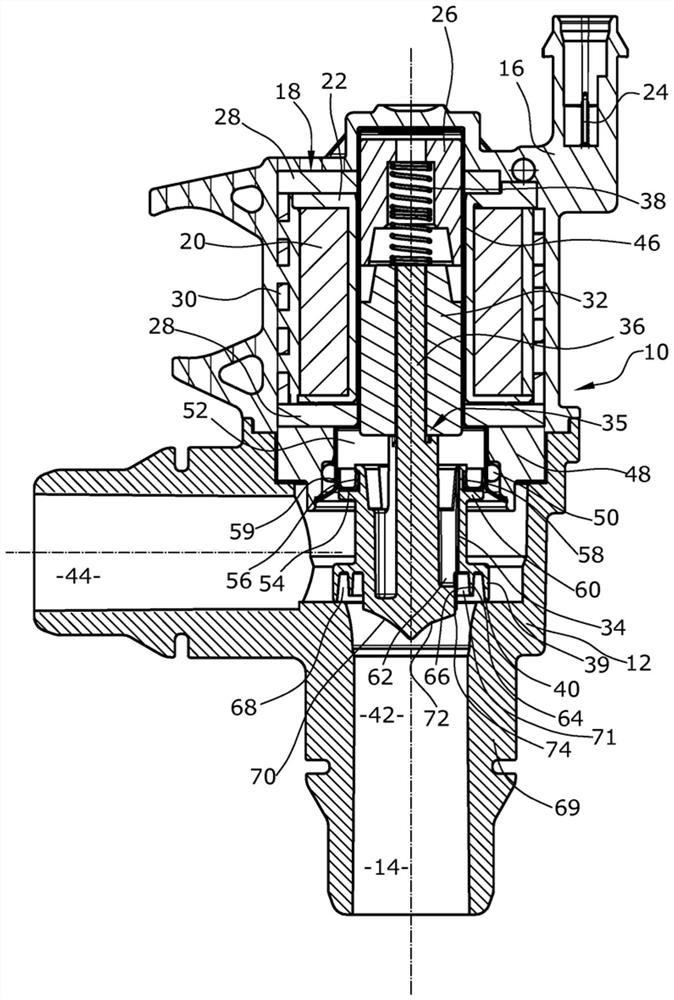

Coolant valve for a motor vehicle

PendingCN114041021AIncrease volumeImprove functionalityOperating means/releasing devices for valvesCoolant flow controlMotorized vehicleMechanics

Motor vehicles coolant valves are known that comprise a housing (10) which has an inlet (42) and an outlet (44), a flow cross-section which is formed between the inlet (42) and the outlet (44) and is surrounded by a valve seat (40), a control body (34) which can be placed on the valve seat (40) and which can be lifted from the valve seat (40), through-openings (62) in the control body (34), via which the inlet (42) is constantly connected to a chamber (52) on the control body (34) side facing away from the inlet (42), and an electromagnetic actuator (18) with an armature (32) which is coupled to and can be moved together with the control body (34). The aim of the invention is to maintain the functionality of the coolant valve for as long of a duration as possible even when dirt is present in the coolant. According to the invention, this is achieved in that at least one dirt pocket (64) is formed in the control body (34), said pocket having a closed base (65) which faces the inlet (42) and being open towards the chamber (52) formed on the control body (34) side facing away from the inlet (42).

Owner:PIERBURG GMBH & CO KG NEUSS

High speed deposition method and apparatus for same

ActiveCN105369218AReduce the amount of particlesSimple structureChemical vapor deposition coatingPlasma treatmentProduct gas

The invention relates to a high speed deposition method and an apparatus for the same. The deposition method comprises the following steps: carrying out a plasma treatment on a substrate by alternatively using a source gas and a reactant gas; and making the source gas and reactant gas carry out reactions on the surface of the substrate so as to form an inorganic film on the substrate; wherein the plasma treatments of source gas and reactant gas are independently carried out in separated plasma modules; the source gas comprises inert gas and precursor; and the precursor comprises free silicon, aluminum, zinc, and metals from groups of silicon, aluminum, and zinc.

Owner:RES & BUSINESS FOUNDATION SUNGKYUNKWAN UNIV

Filter

InactiveCN109104873ALow costReduce the amount of particlesDispersed particle filtrationLighting and heating apparatusEngineeringMaterials science

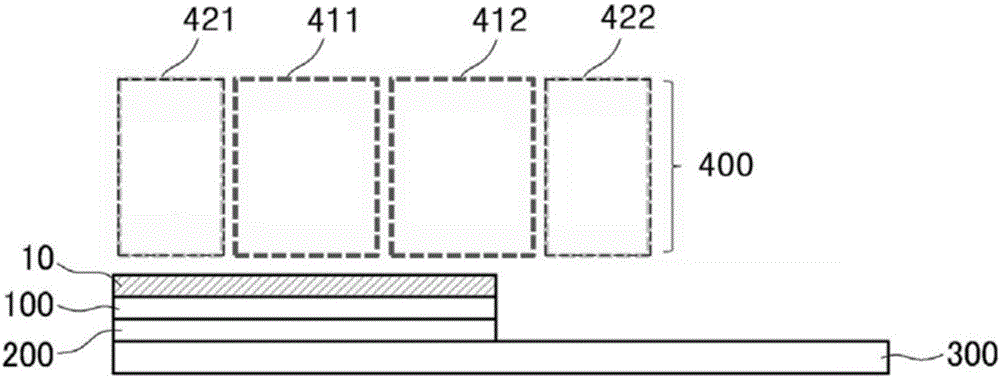

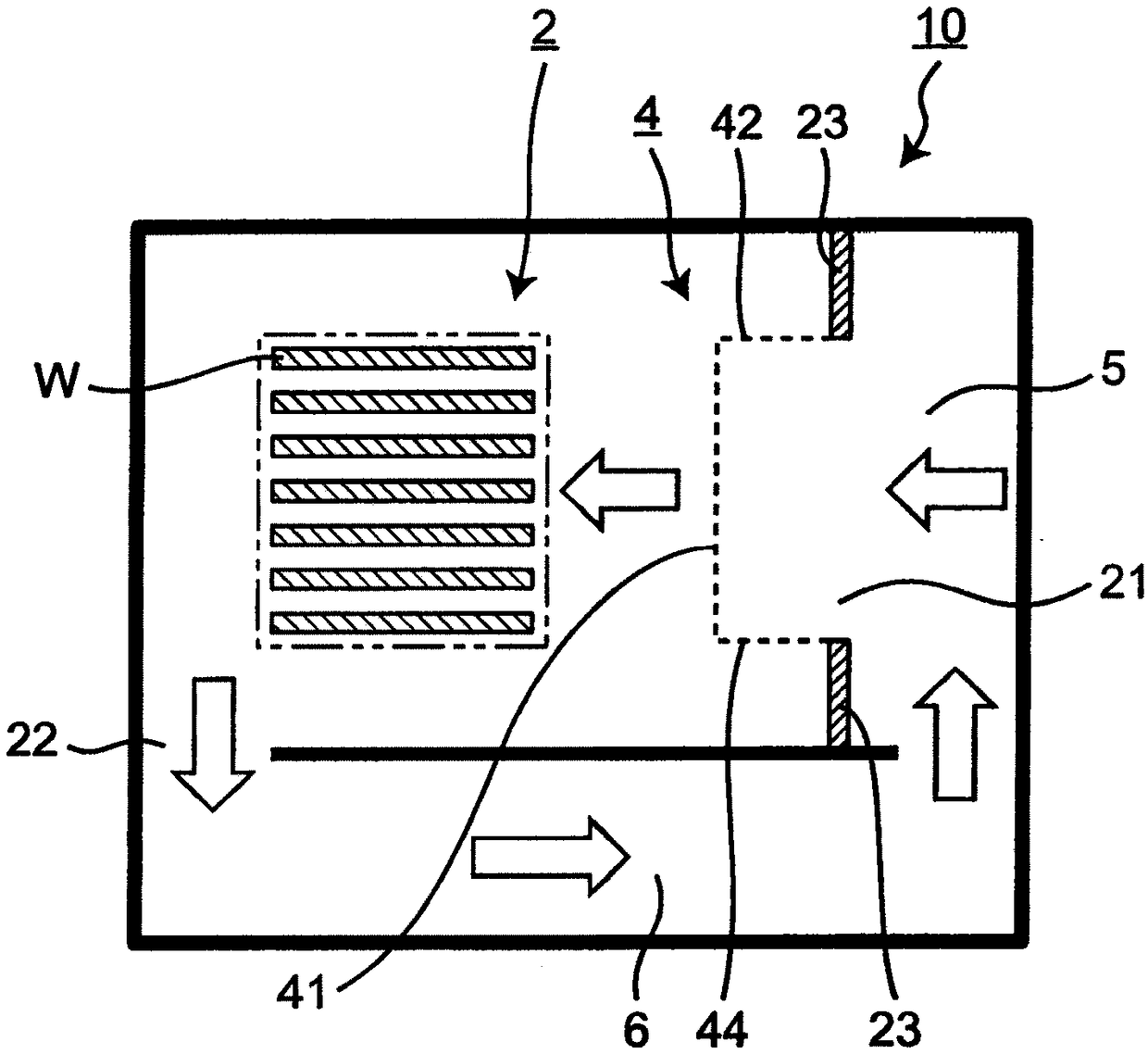

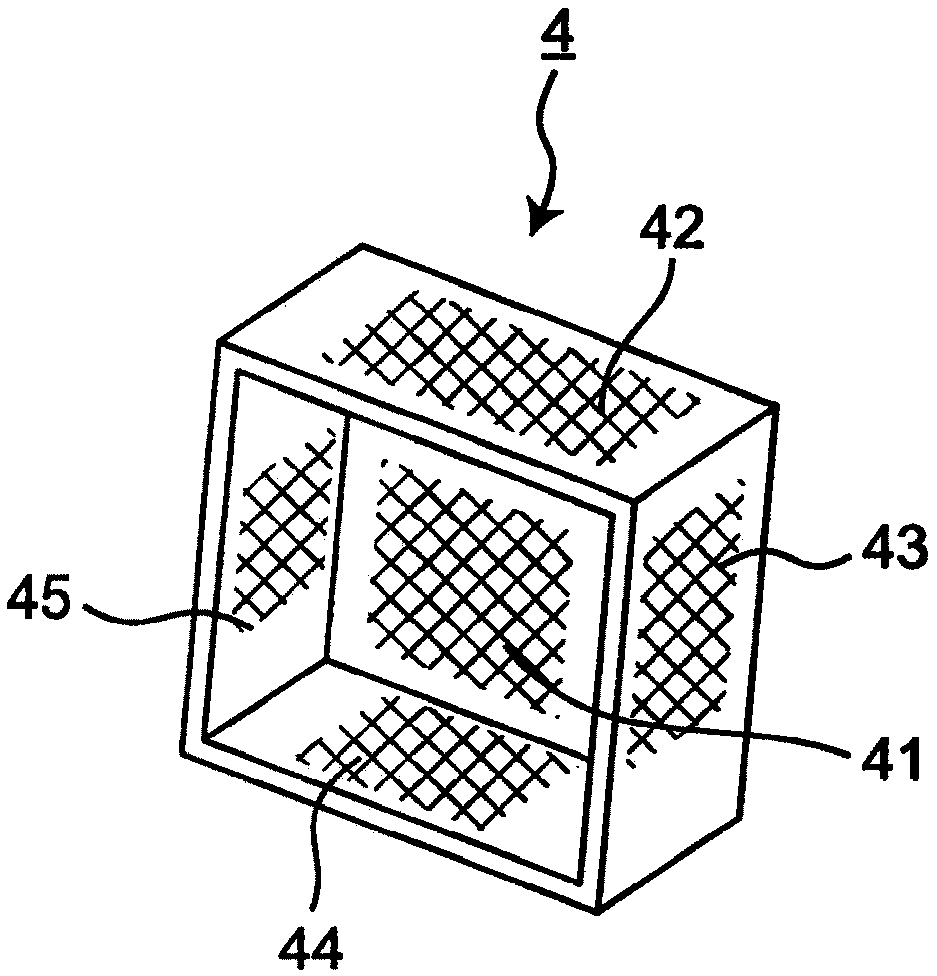

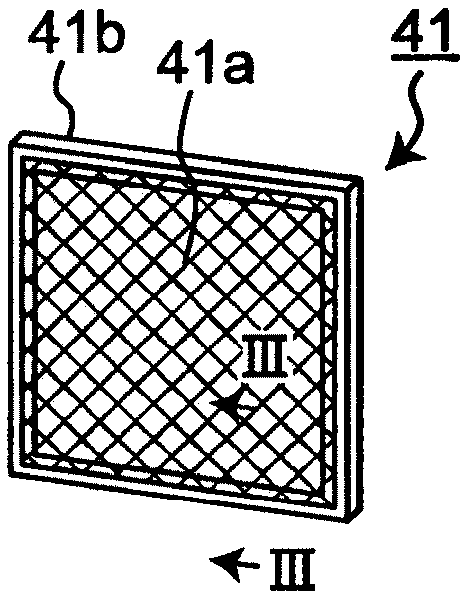

A metal filter (4) provided in a clean oven (10) which performs heat treatment of a workpiece by circulating a gas is characterized by being provided with: an apex portion (41) which projects toward aheat treatment chamber (2) in which the workpiece (W) to be heat treated is disposed; and side portions (42 to 45) formed continuously with the apex portion (41).

Owner:CHUGAI RO CO LTD

Thermoelectric desulfurization dcs system

ActiveCN107854941BReduce the amount of particlesImprove securityCombination devicesParticulatesVertical tube

The invention discloses a thermoelectric desulfurization DCS system. It belongs to the technical field of thermoelectric desulfurization solid-gas separation, and the system can reduce the amount of particles in the particle-containing desulfurization gas. It includes a desulfurization tower, a particle reduction mechanism and an exhaust pipe. The particle reduction mechanism includes a high-pressure box, and a bracket is arranged in the high-pressure box, and a gas-level rotating pipe is vertically arranged on the bracket. One end of a connecting pipe is connected to the desulfurization tower. The other end of the connecting pipe is rotatably connected to the upper nozzle of the gas-level rotating tube; a vertical hole communicating with the lumen of the gas-level rotating tube is provided on the vertical wall of the gas-level rotating tube , the orifice of each vertical hole is butted outward and fixedly connected with a reaction force port with the orifice inclined from left to right from inside to outside; the air inlet of the exhaust pipe is butted connected with the air outlet of the particle reduction mechanism.

Owner:CHINA ENERGY ENG EASTERN ELECTRIC POWER TESTING RES INST CO LTD

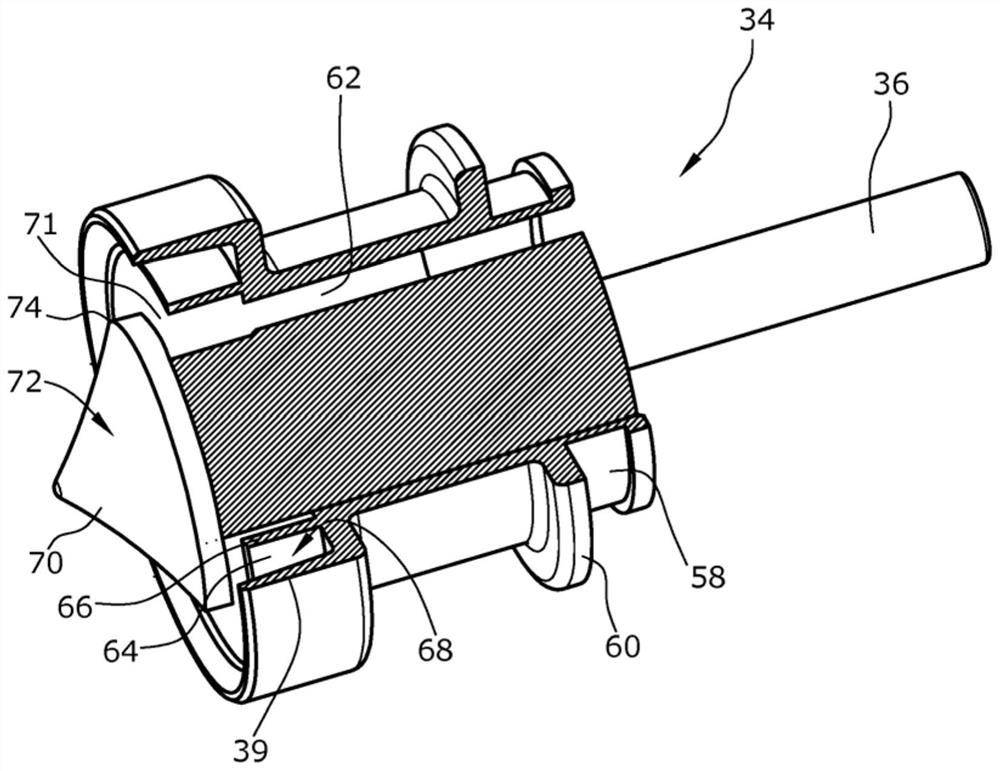

Coolant valve for a motor vehicle

PendingCN114041022AReduce inflowGuaranteed functionOperating means/releasing devices for valvesCoolant flow controlActuatorMotorized vehicle

Motor vehicles coolant valves are known that comprise a housing (10), which has an axial inlet (42) and a radial outlet (44), a flow cross-section which is formed between the inlet (42) and the outlet (44) and is surrounded by a valve seat (40), a control body (34) which can be placed on the valve seat (40) and which can be lifted from the valve seat (40) by means of an actuator (18), and through-bores (62) in the control body (34), via which the inlet (42) is constantly connected to a chamber (52) on the control body (34) side facing away from the inlet (42). The aim of the invention is to maintain the functionality of the coolant valve for as long of a duration as possible even when dirt is present in the coolant. According to the invention, this is achieved in that the control body (34) has a first annular protrusion (39) which extends axially in the direction of the valve seat (40) and by means of which the control body (34) can be placed on the valve seat (40), and an axial groove (68) which extends in the circumferential direction is formed on the control body (34), said axial groove being delimited outwardly by the first annular protrusion (39) and radially inwards by a wall (64) positioned radially between the first annular protrusion (39) and the through-bores (62).

Owner:PIERBURG GMBH & CO KG NEUSS

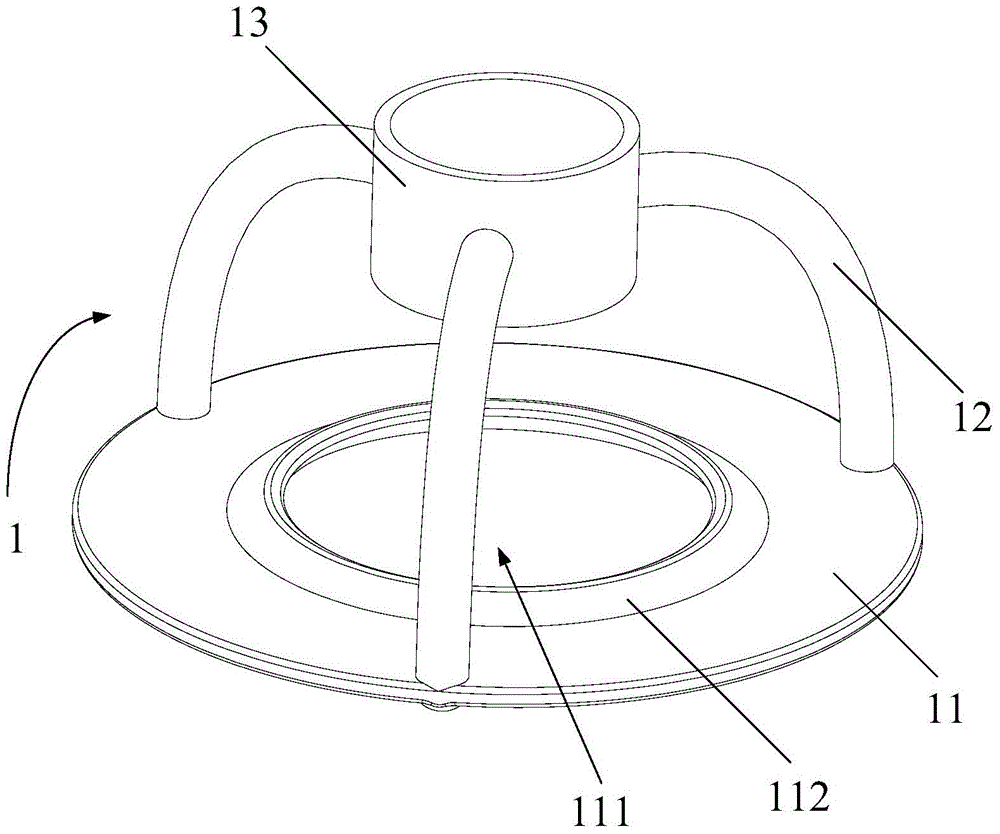

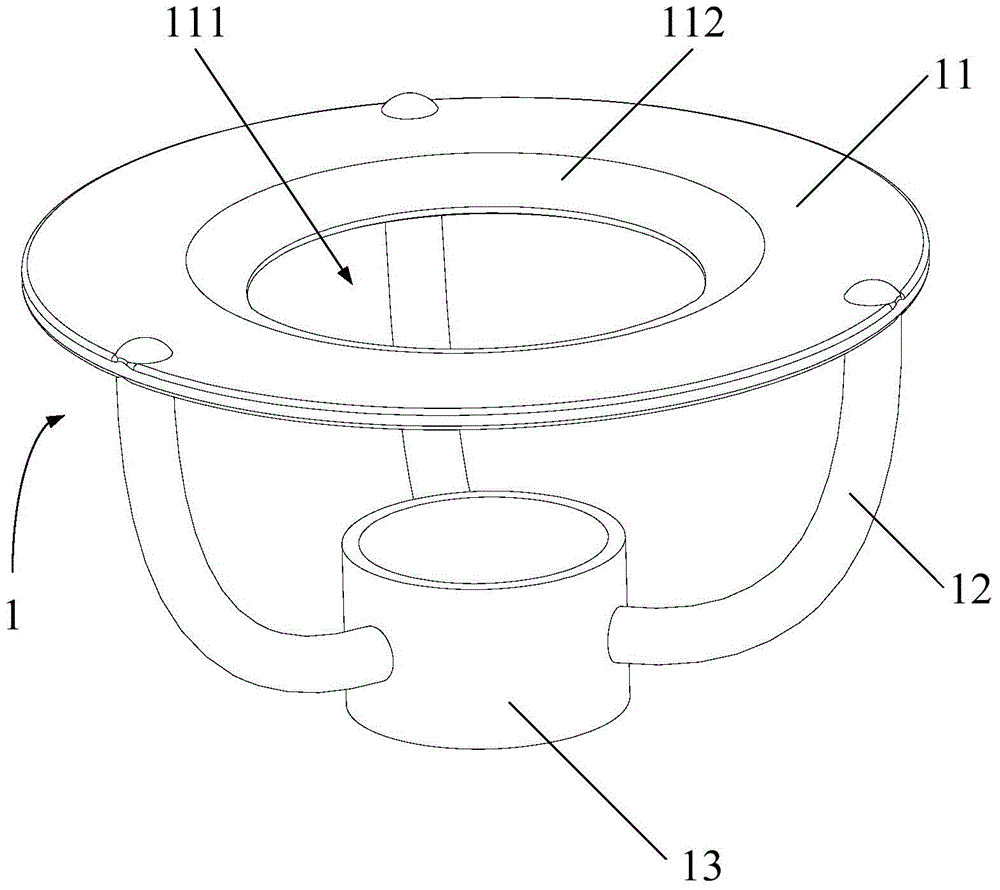

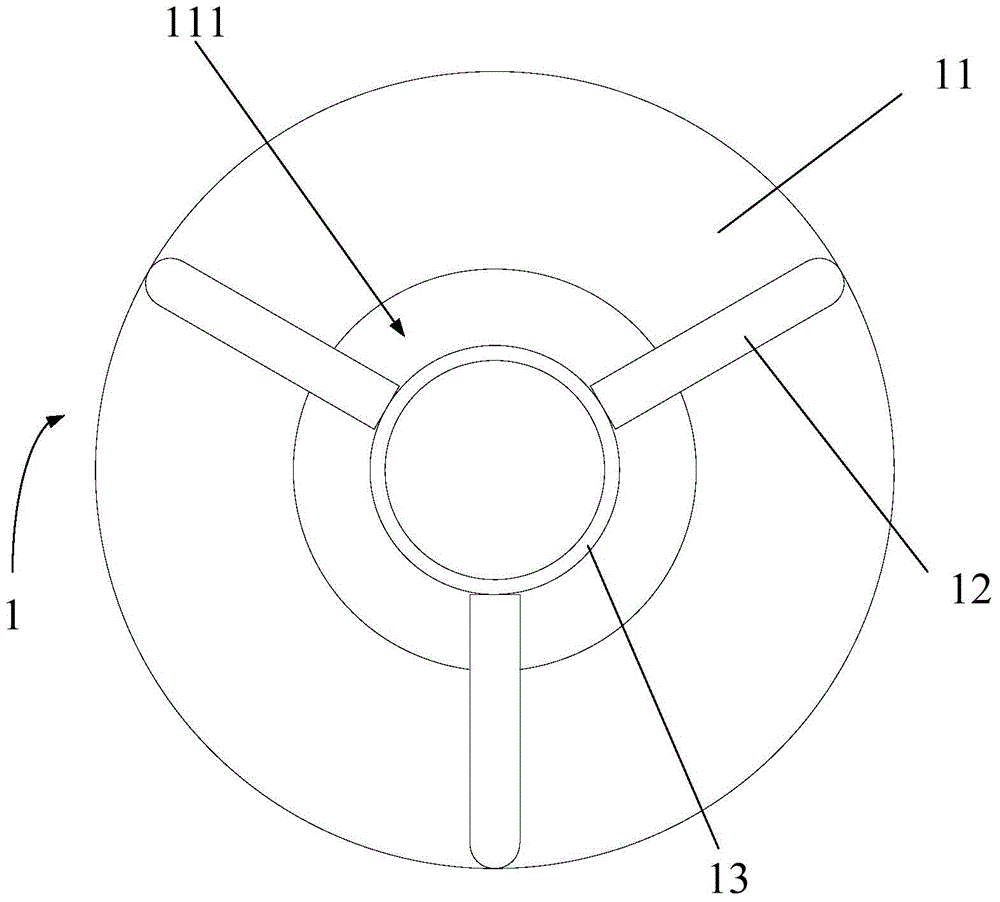

Flow guide plate, mashing assembly and cooking utensil

ActiveCN106264205AReduce the amount of particlesEasy to cleanKitchen equipmentMechanical engineeringEngineering

The invention provides a flow guide plate, a mashing assembly and a cooking utensil. The flow guide plate comprises a bottom plate and a plurality of connectors, wherein a feed inlet hole is formed in the bottom plate; the first end of each connector is connected with the bottom plate, the second end of each connector can be movably connected with a body of the cooking utensil, the flow guide plate can rotate relative to the body of the cooking utensil, and the connectors are arranged around the feed inlet hole at intervals. In the technical scheme, the bottom plate can be connected with the cooking utensil through the connectors, the connectors are arranged around the feed inlet hole at intervals, it is guaranteed that large gaps exist between the adjacent connectors, and a product is easy to clean. The bottom plate is provided with the feed inlet hole so as to guide flow of liquid in the cooking utensil, the liquid flows to a mashing device, and accordingly the product smashing effect is improved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Fe-Pt-OXIDE-BN SINTERED BODY FOR SPUTTERING TARGETS

InactiveCN111836915AReduce generationReduce the amount of particlesVacuum evaporation coatingSputtering coatingSputteringHigh density

Provided is an Fe-Pt-oxide-BN sintered body for high-density sputtering targets, which is capable of suppressing the generation of particles during sputtering. An Fe-Pt-oxide-BN sintered body for sputtering targets, which is configured such that the mass ratio of N to B, namely N / B is within the range of 1.30 plus and minus 0.1.

Owner:TANAKA PRECIOUS METAL IND

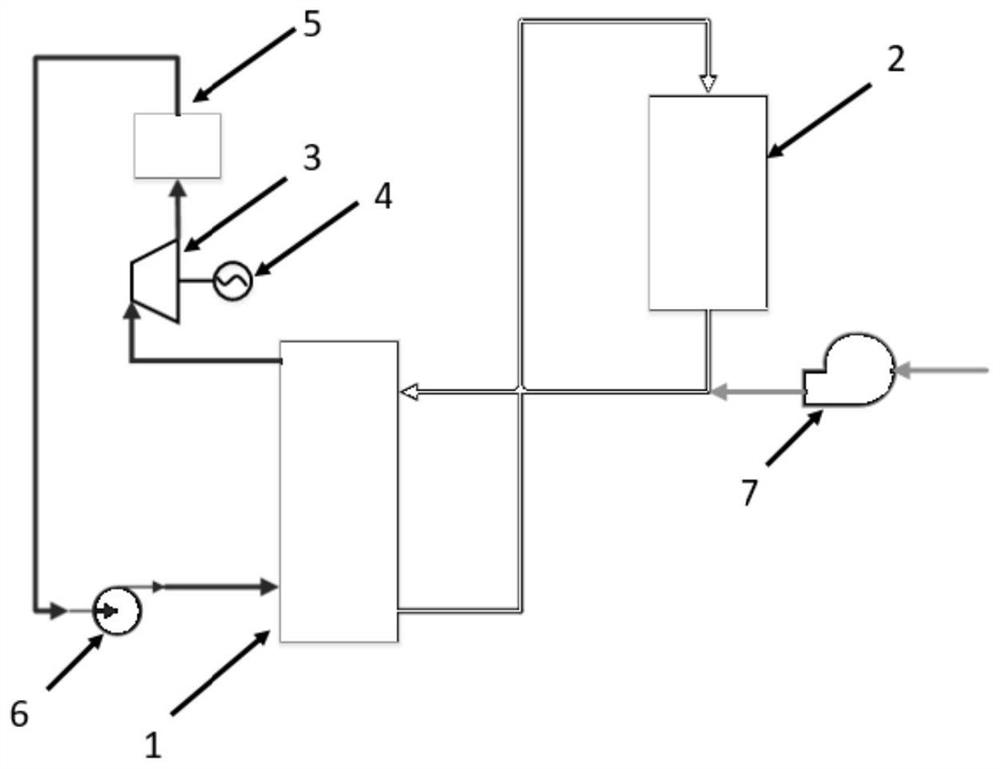

Cyclone separation type particle heat exchanger and heat storage power generation system

PendingCN113446878ALow wear resistanceImprove wear resistanceFrom solar energyDispersed particle separationEngineeringMechanical engineering

The invention discloses a cyclone separation type particle heat exchanger and a heat storage power generation system. The cyclone separation type particle heat exchanger comprises an outer cylinder and a plurality of water channels, the side walls of the two ends of the outer cylinder are connected with a high-temperature particle-air mixture inlet and a high-temperature particle-air mixture outlet which are tangent to the outer cylinder correspondingly, the multiple water channels and the outer cylinder are coaxially arranged and penetrate through the bottoms of the two ends of the outer cylinder, the water channels are in sealed connection with the bottom of the outer cylinder, and wear-resistant layers are arranged on the inner surfaces of the outer cylinder, the high-temperature particle air mixture inlet and the high-temperature particle air mixture outlet. Abrasion of particles to the heat exchanger can be effectively avoided and weakened, and the requirement for solar efficient particle heat storage power generation is met.

Owner:XIAN THERMAL POWER RES INST CO LTD

Mould device for removing trimming of power material forming at a time through mould pressing

ActiveCN104742408AReduce the amount of particlesReduce extrusion pressurePressesMaterials processingMaterials science

The invention discloses a mould device for removing trimming of power materials forming at a time through mould pressing, and relates to the field of the power material forming at a time through mould pressing. The mould device for removing the trimming of the power materials forming at a time through the mould pressing comprises a punch, a mould sleeve, a base and a demoulding table. A circle of protrusions towards the power materials are formed in the outer edge of the contact end face of the punch and the power materials. A circle of protrusions towards the power materials are formed in the outer edge of the contact end face of the base and the power materials. According to the mould device for removing the trimming, the trimming structure can be controlled by the design, when the punch moves downwards, a component force towards the axis of the mould sleeve is conducted on the materials, edge material granules of the punch can be effectively controlled to move in the radial direction, and thereof the amount of the material granules heaped up in a clearance is reduced; by means of the structure, extrusion force conducted on the material granules in the clearance is favorable to reduced at the same time, and the purpose that the pressed shape trimming is effectively controlled is achieved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com