Coolant valve for a motor vehicle

A technology for coolant valves and motor vehicles, applied in the direction of engine cooling, coolant flow control, devices for pressure relief on sealing surfaces, etc., can solve problems that cannot prevent pressure balance hole failures, and cannot reliably reduce pollution Problems such as sedimentation, pressure balance function and normal functional threat of regulating body, etc., to achieve the effect of particle reduction, long-lasting functionality and increased flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

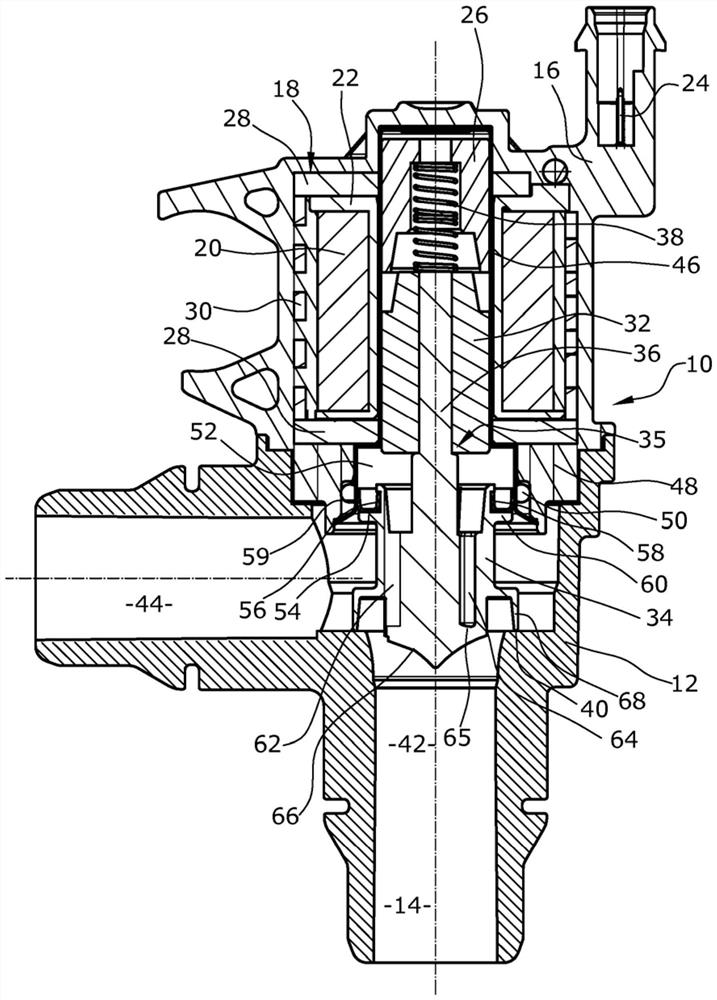

[0023] figure 1 The coolant valve shown includes a housing, and the housing 10 is designed to have a flow housing 12 and an actuator housing 16, the flow housing 12 with a flow channel 14 designed therein. And the actuator housing 16 arranged in which the electromagnetic actuator 18 is fixed to the flow housing 12.

[0024] The electromagnetic actuator 18 has an electromagnetic circuit, the electromagnetic circuit comprising: a coil 20, a coil 20 that can be powered by a plug 24, a magnetized core 26, a baffle element 28, a yoke 30, and a movable Armature 32. When the coil 20 is powered, the armature 32 is moved in the direction of the generated magnetic force along the core portion 26 in a known manner.

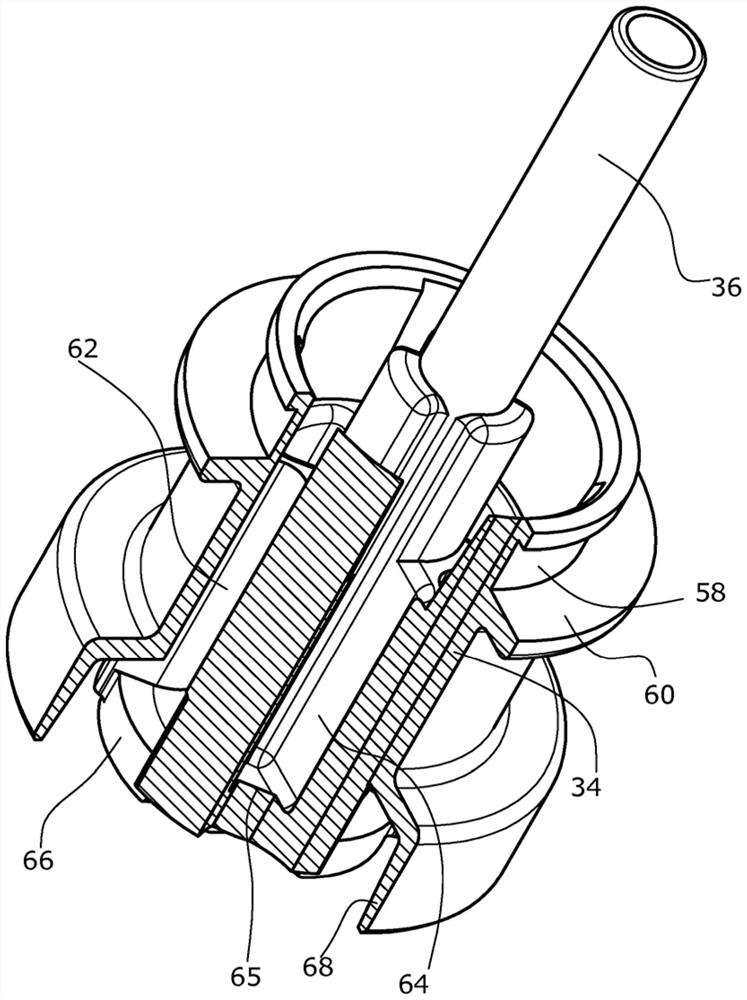

[0025] By coupling the armature 32 and the adjustment body 34 by the coupling member 36, the moving unit 35 is formed from the armature 32 and the adjustment body 34, and the coupling member 36 is designed as a one-piece and extended to the armature 32. The bore is fixed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com