Heat conduction oil boiler

A heat-conducting oil boiler and furnace technology, which is applied in the boiler field, can solve the problems of furnace tube wear, heavy weight, and large furnace roof weight, and achieve the effect of reducing the amount of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

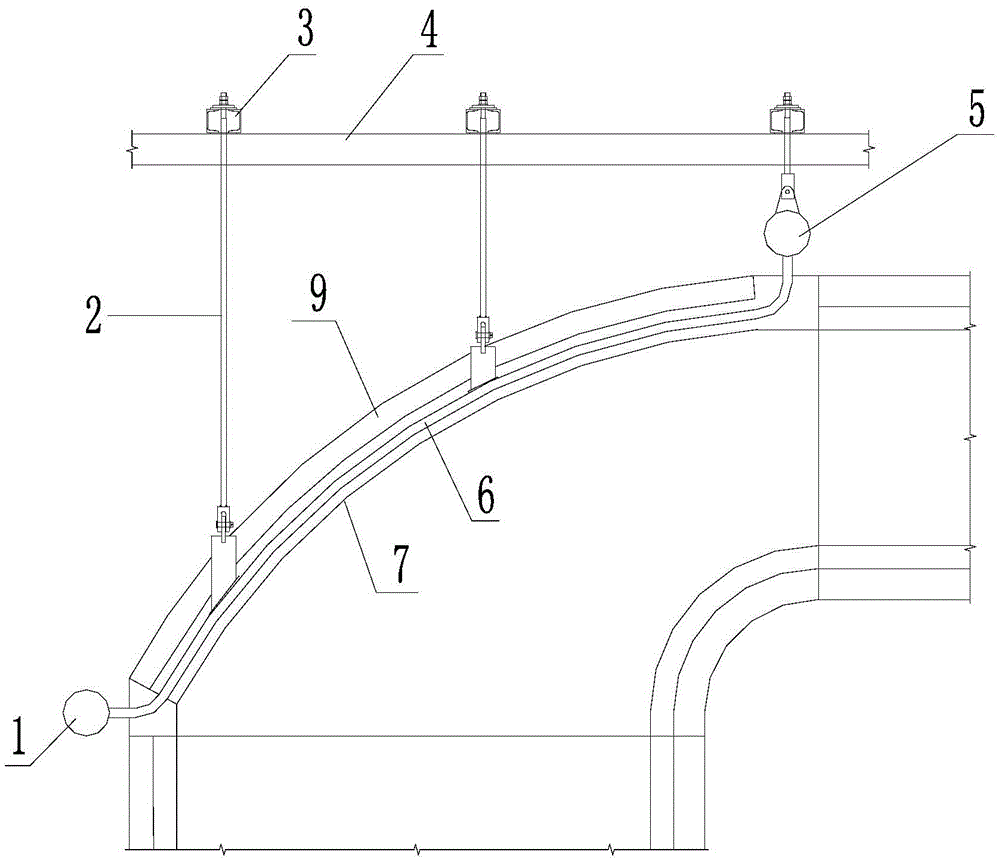

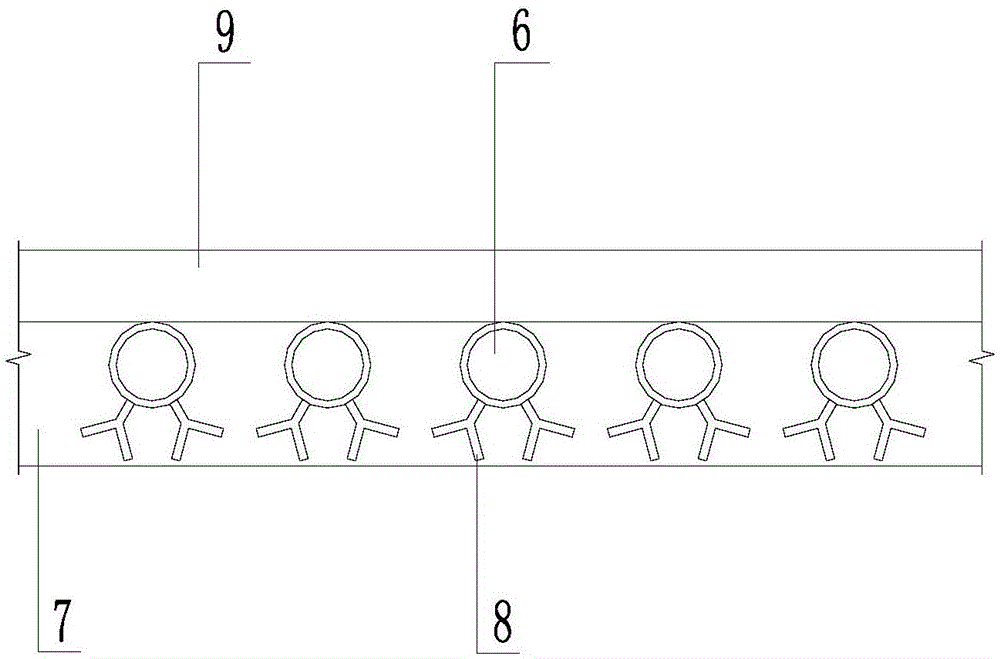

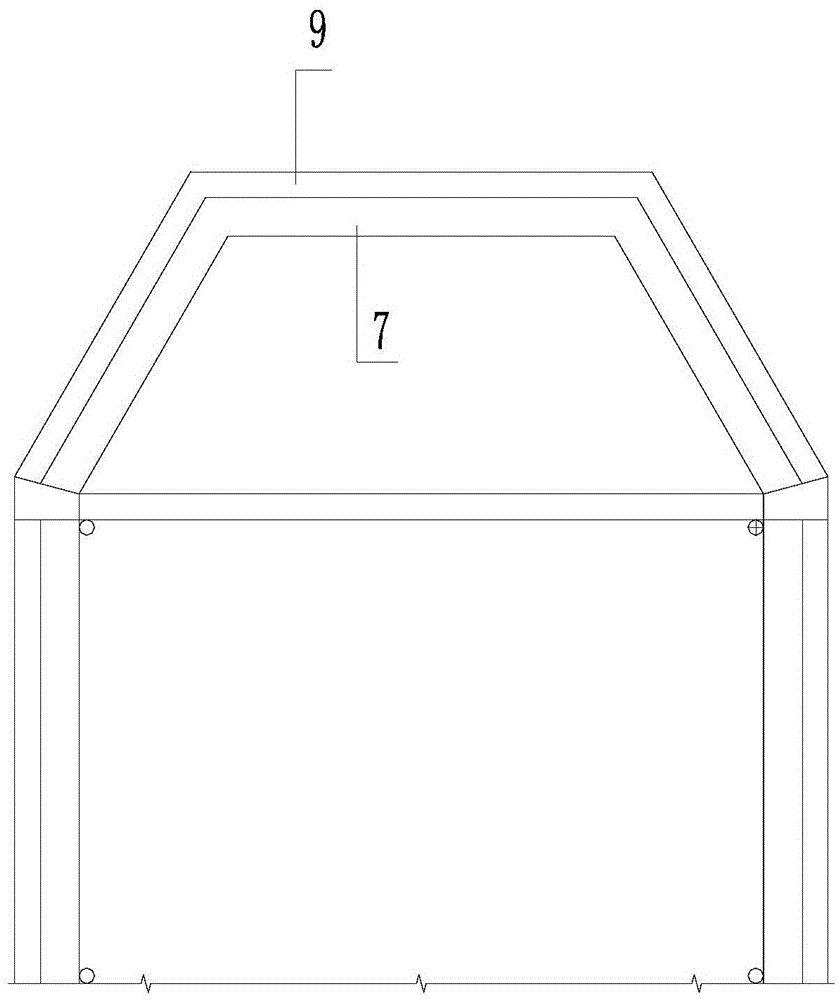

[0026] Such as Figure 1-3 As shown, a heat-conducting oil boiler according to an embodiment of the present invention includes: a furnace, and a heat dissipation device installed at the furnace; the furnace is provided with a furnace top and a furnace side, and the furnace top and the furnace side The part is in the shape of a smooth transition tapered mouth, and the two sides of the tapered mouth shape are provided with an inlet and an outlet. The cross-sectional shape of the inlet is equal to the top cross-section of the furnace. A separator is installed at the outlet, and the cross-sectional shape of the outlet is equal to the inlet of the separator. The heat dissipation device includes a plurality of ceiling pipes evenly installed in the top of the furnace, one end of the ceiling pipe is installed with a cooling medium inlet header, and the other end is installed with a cooling medium outlet header, and the ceiling pipe passes through the hanging device Connect with beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com