Mould device for removing trimming of power material forming at a time through mould pressing

A powder material and molding powder technology is applied in the field of mold devices for removing burrs from one-time molding powder materials. The effect of pressure, reducing the amount of material particles, and controlling the flash of the compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

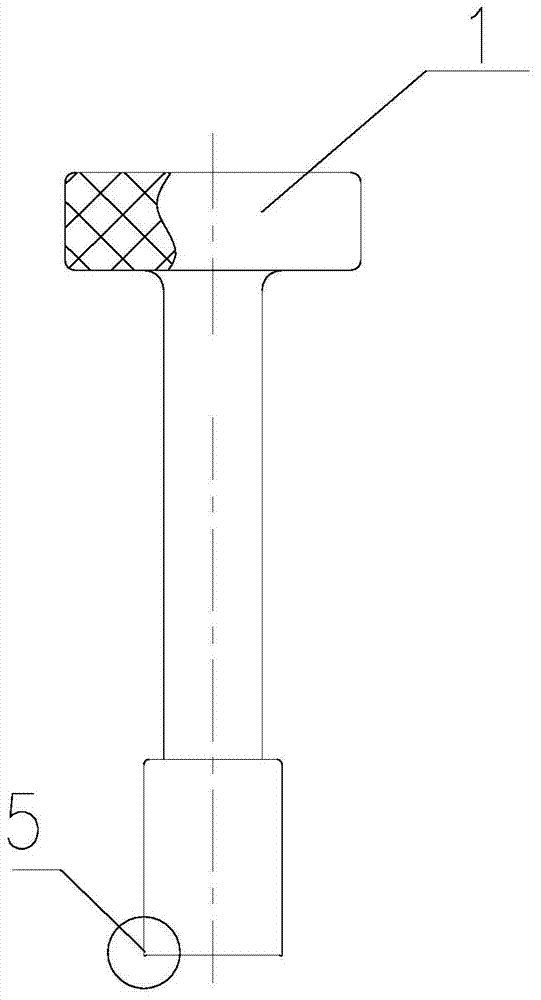

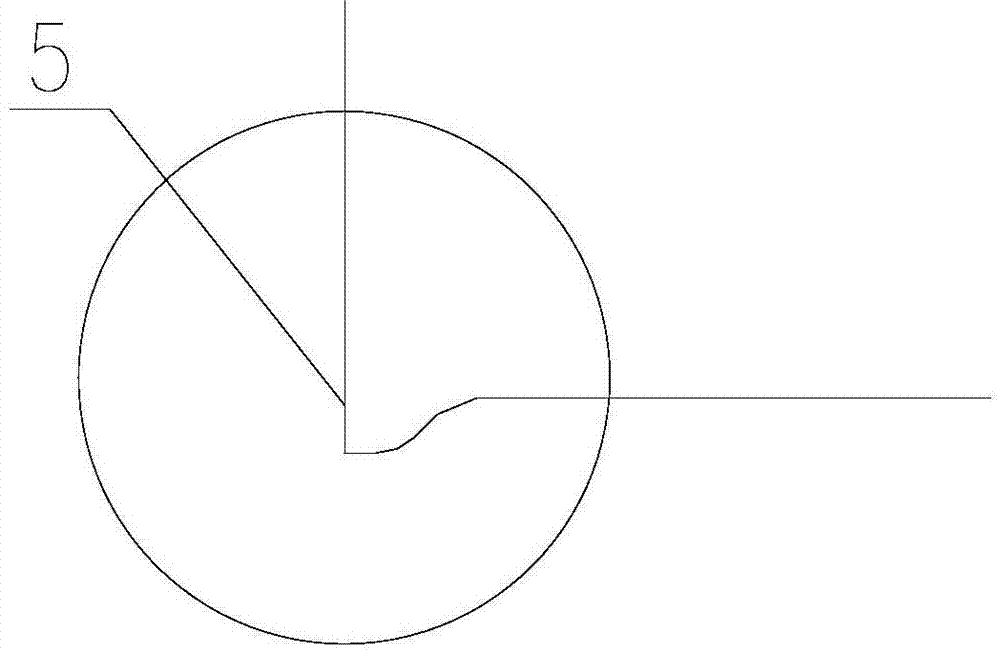

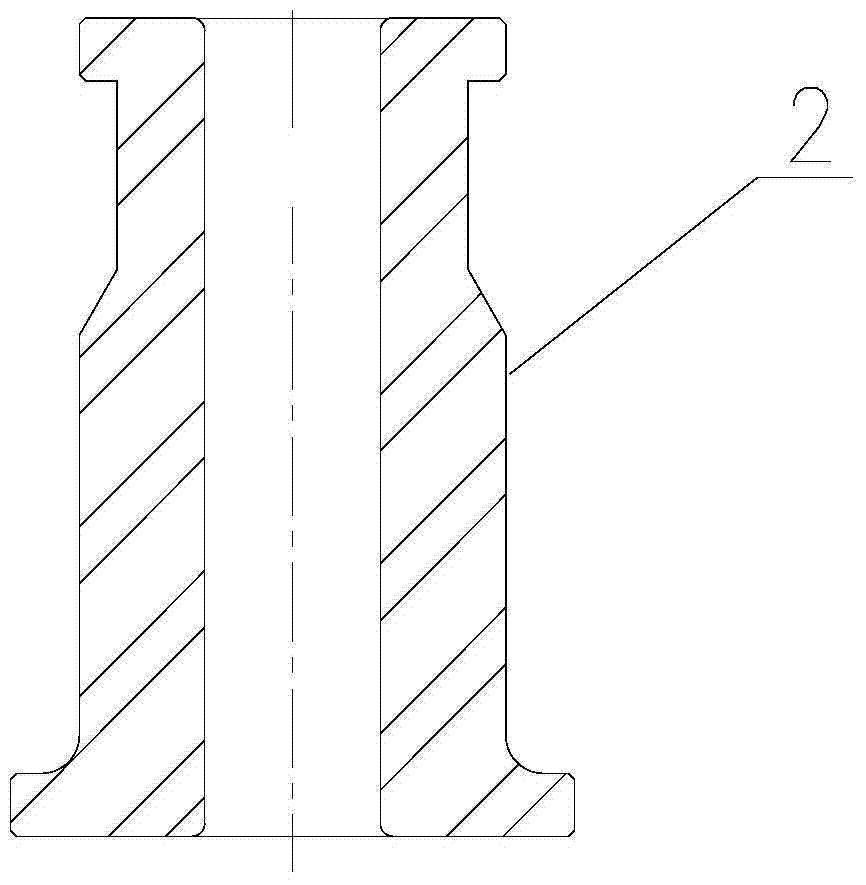

[0027] Such as Figure 1-Figure 12 As shown, the mold device for removing the flash of the primary molding powder material includes a punch 1 , a die sleeve 2 , a base 3 and an ejection table 4 . The punch 1 has a ring of protrusions 5 facing the powder material 6 at the outer edge of the end surface in contact with the powder material 6 . The base 3 has a circle of protrusions 5 facing the powder material 6 at the outer edge of the end surface in contact with the powder material 6 . Preferably, the shape of the raised cross-section is a right-angled trapezoid or a right-angle plus transitional arc structure, and the right-angle plus transitional arc structure is composed of a set of parallel line segments, a straight line segment connecting the two ends of the set of parallel line segments, and a circular arc. In addition, the present invention also controls the gap between the punch 1 and the die sleeve 2 at 0-0.019mm, which can further achieve the effect of effectively rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com