Coolant valve for a motor vehicle

A technology for coolant valves and motor vehicles, applied in the direction of engine cooling, coolant flow control, devices for pressure relief on sealing surfaces, etc., can solve the problem of unreliable reduction of impurity deposition, endangering pressure equalization function and The correct function of the regulating body, the failure of the pressure equalization hole can not be prevented, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

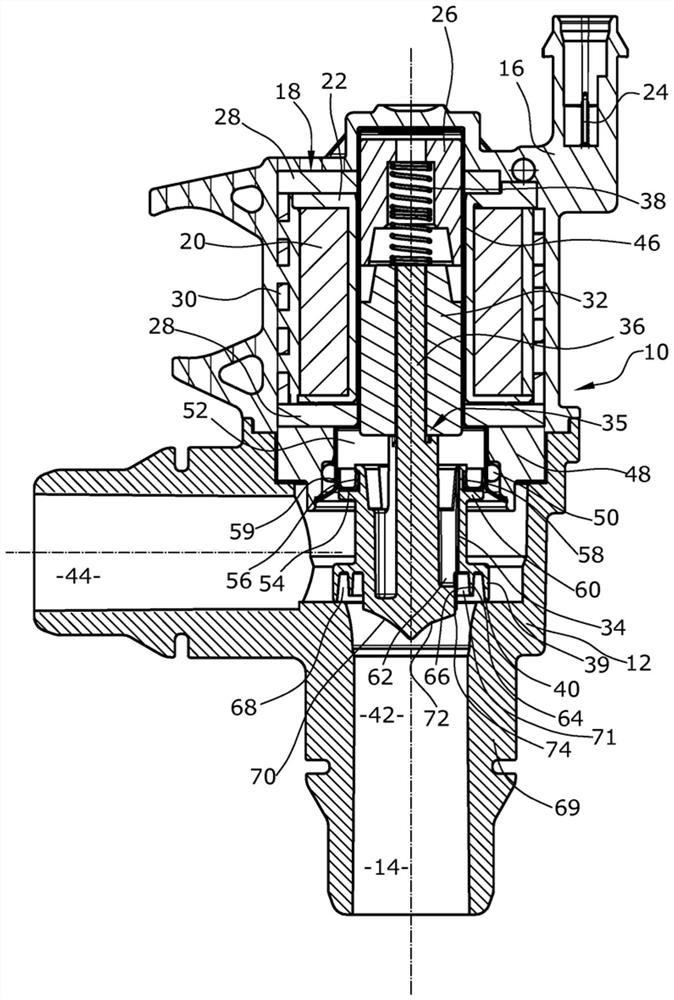

[0024] figure 1 The shown coolant valve consists of a housing 10 which is designed in two parts and has a flow housing 12 in which a flow channel 14 is formed and an actuator housing 16 fixed to the flow housing 12, in which An electromagnetic actuator 18 is arranged in the actuator housing 16 .

[0025] The electromagnetic actuator 18 has an electromagnetic circuit consisting of a coil 20 which is wound on a coil carrier 22 and which can be energized via a plug 24 , as well as a magnetizable core 26 , a return element 28 , a yoke 30 and a movable armature 32 . When the coil 20 is energized, the armature 32 is moved in the direction of the core 26 in a known manner by the magnetic force generated.

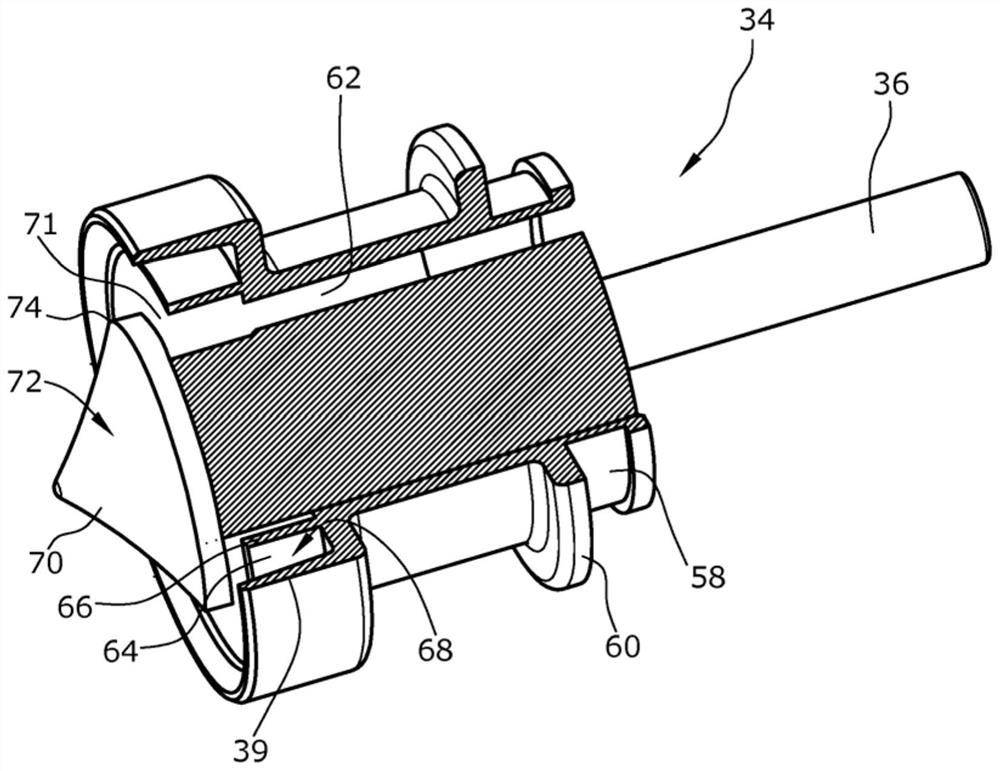

[0026] The armature 32 and the adjusting body 34 form a movement unit 35 by coupling the armature 32 to the adjusting body 34 via a coupling member 36 which is integrally formed with the adjusting body 34 and extends into a bore of the armature 32 and is fixed in In the hole on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com