Method for controlling positioning precision of PCB drill holes

A technology of PCB board and positioning accuracy, applied in metal processing and other directions, can solve problems such as scrap, cannot be found in time, and have partial holes, and achieve the effect of good feasibility, simple design, and easy monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

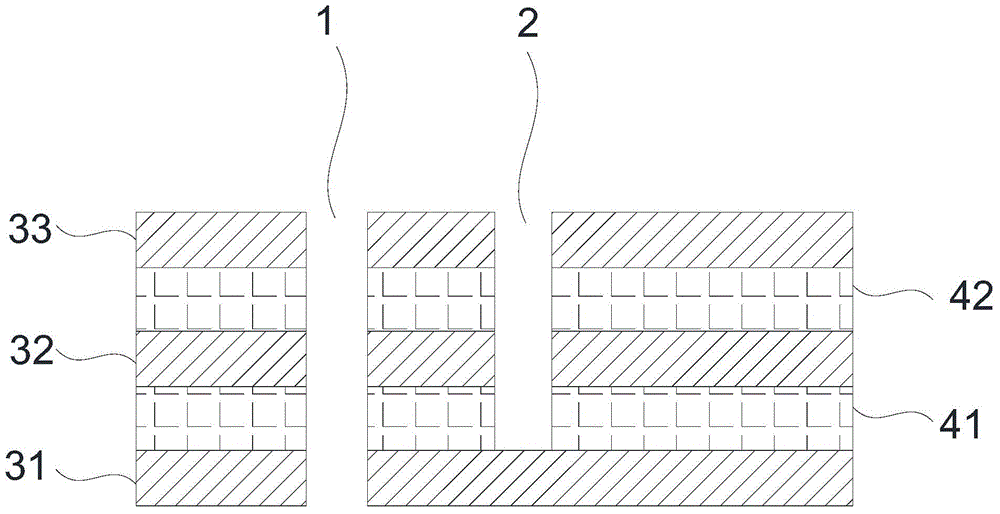

[0022] like figure 1 The shown PCB board includes the first PP layer 31, the first core board 41, the second PP layer 32, the second core board 42, and the third PP layer 33 stacked in sequence. It is necessary to make through holes 1 and 3 on the PCB board. The blind holes 2 from the first core board 41 to the third PP layer 33 . The production steps are as follows:

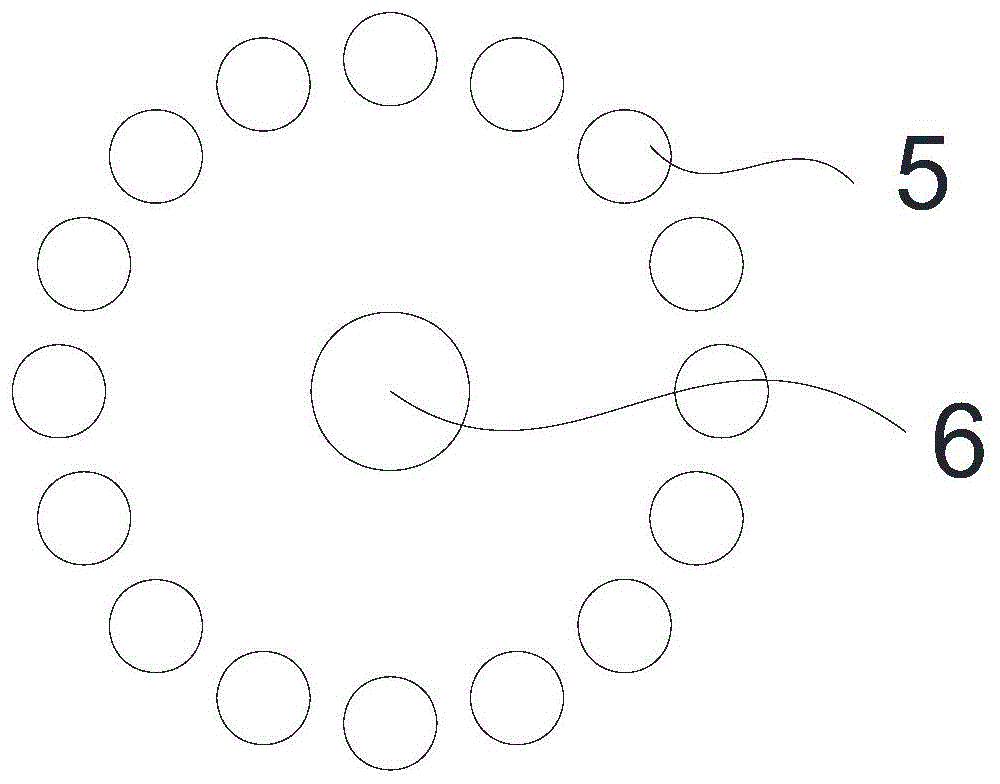

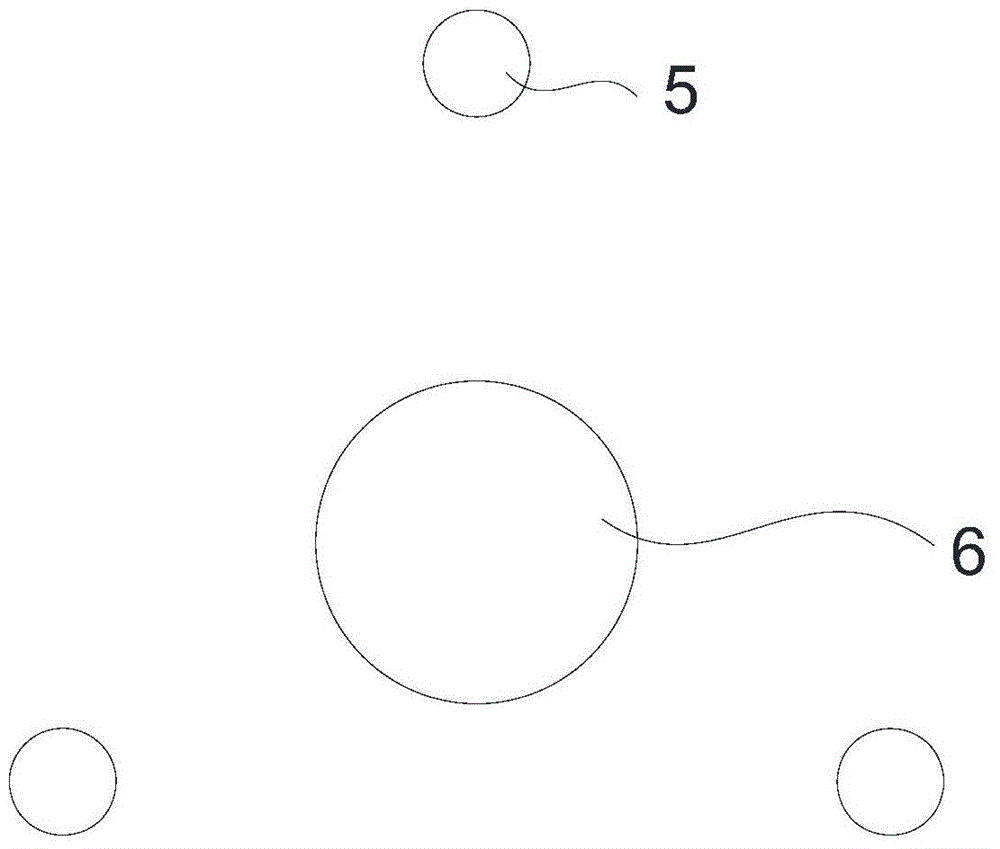

[0023] Drill holes at the positions where blind holes 2 need to be drilled on the laminated first core board 41 to the third PP layer 33, and then drill a series of equal-sized marked holes at the four corners of the laminated board without wiring 5. The diameter of the marking hole is 0.5mm; the marking holes 5 are arranged in a circular pattern of inspection modules (such as figure 2 ), the distance from hole to hole is 0.4mm.

[0024] After pressing the above-mentioned laminated board and the first PP layer 31 into a PCB board, reposition the position of the PCB board on the drilling machine; adjust the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com