Cylinder device using optimal placement of fine protrusion for improved wear resistance

A technology of fine concavo-convex and cylinder device, applied in the direction of cylinder, cylinder head, engine components, etc., can solve the problems of increased engine oil consumption and increased wear and tear, and achieve the effect of reducing wear and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Next, an air cylinder device having optimum fine unevenness arrangement and surface roughness according to the present invention will be described with reference to the drawings.

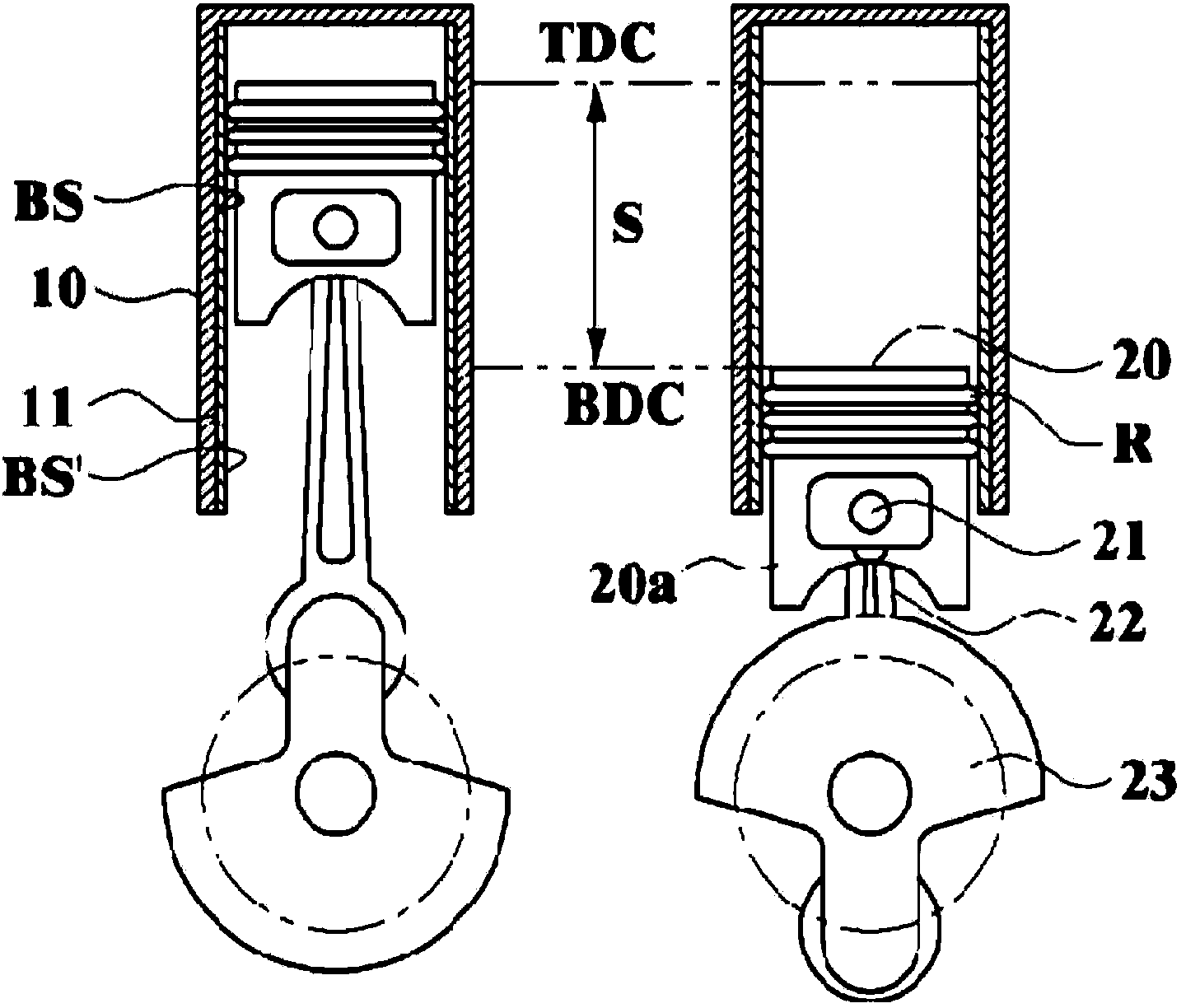

[0060] However, the cylinder bore side walls BS, BS' described below mean the surfaces that directly contact the piston 20 that performs linear reciprocating motion, such as figure 1 As shown, in the case of the type in which the cylinder liner 11 is not additionally inserted, the inner peripheral surface of the cylinder block 10 becomes the bore side wall BS.

[0061] On the contrary, in the case of the type in which the cylinder liner 11 is additionally inserted, the inner peripheral surface of the above-mentioned cylinder liner 11 becomes the cylinder bore side wall BS′, and various coatings ( In the case of not shown), the coating becomes the cylinder bore side wall.

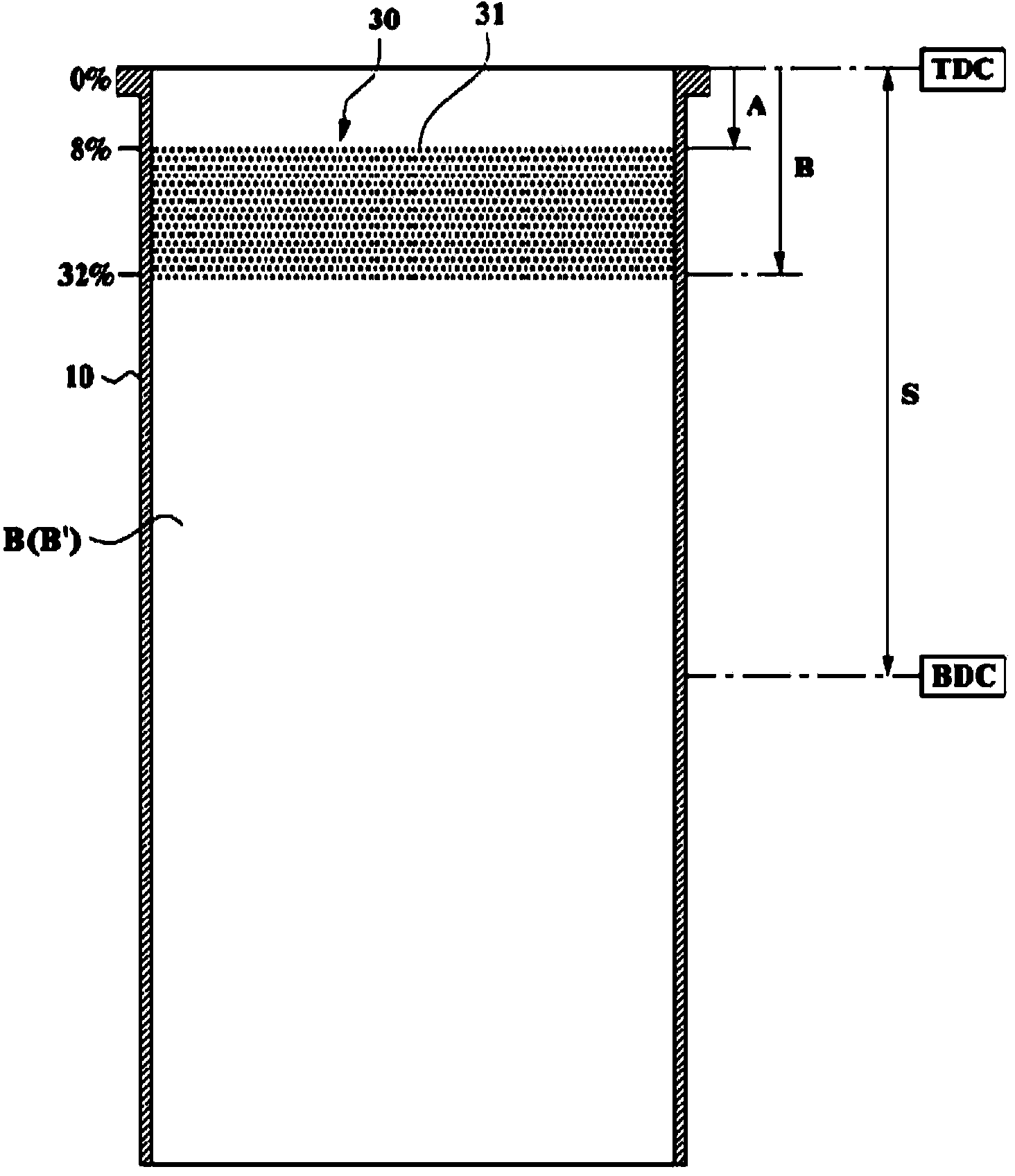

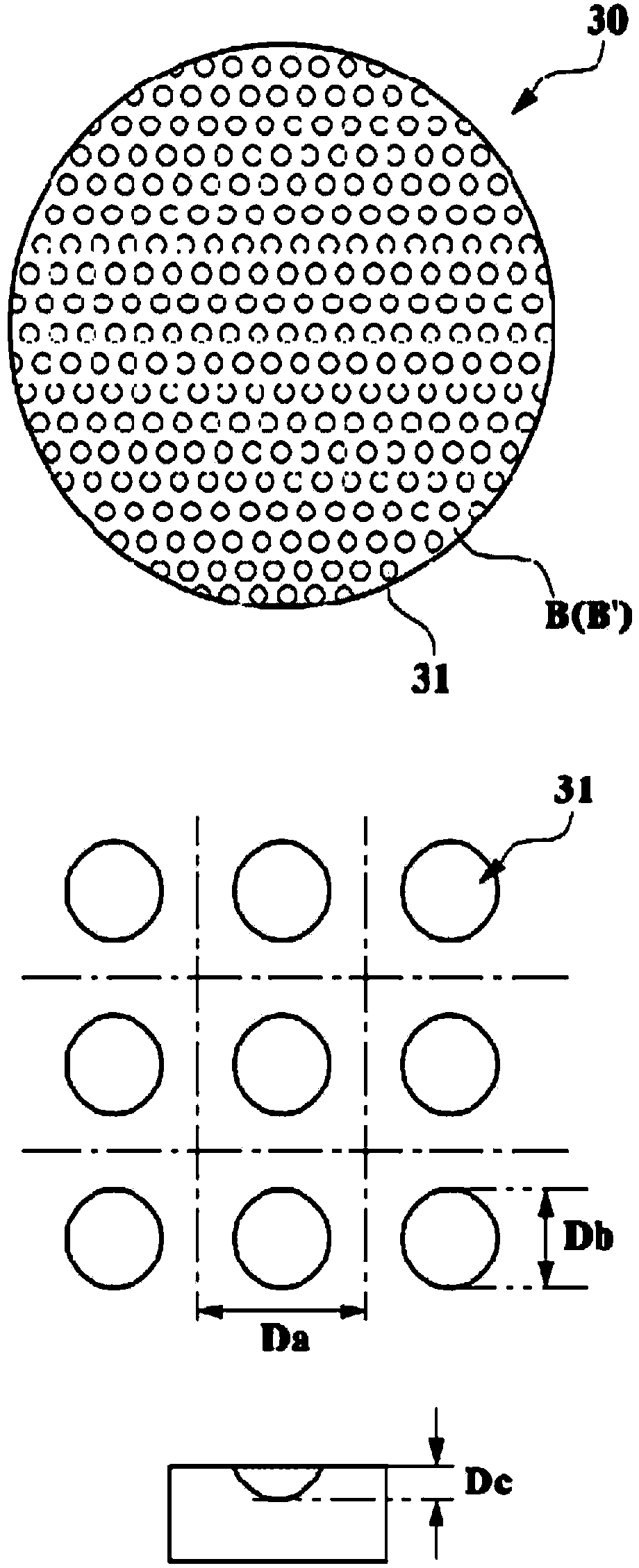

[0062] Such as figure 2 As shown, the cylinder device of the present invention having the optimal micro-concave-convex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com