Novel cigarette quality detecting device used for putuo 70/90 cigarette making machine

A detection device and cigarette machine technology, which are applied in the fields of tobacco, cigarette manufacturing, and application, can solve the problems of inconvenient on-site maintenance, high use and maintenance costs, unstable detection values, etc., so as to improve rejection accuracy, facilitate use and maintenance, The effect of reducing inflows into the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and example the present invention is described in further detail:

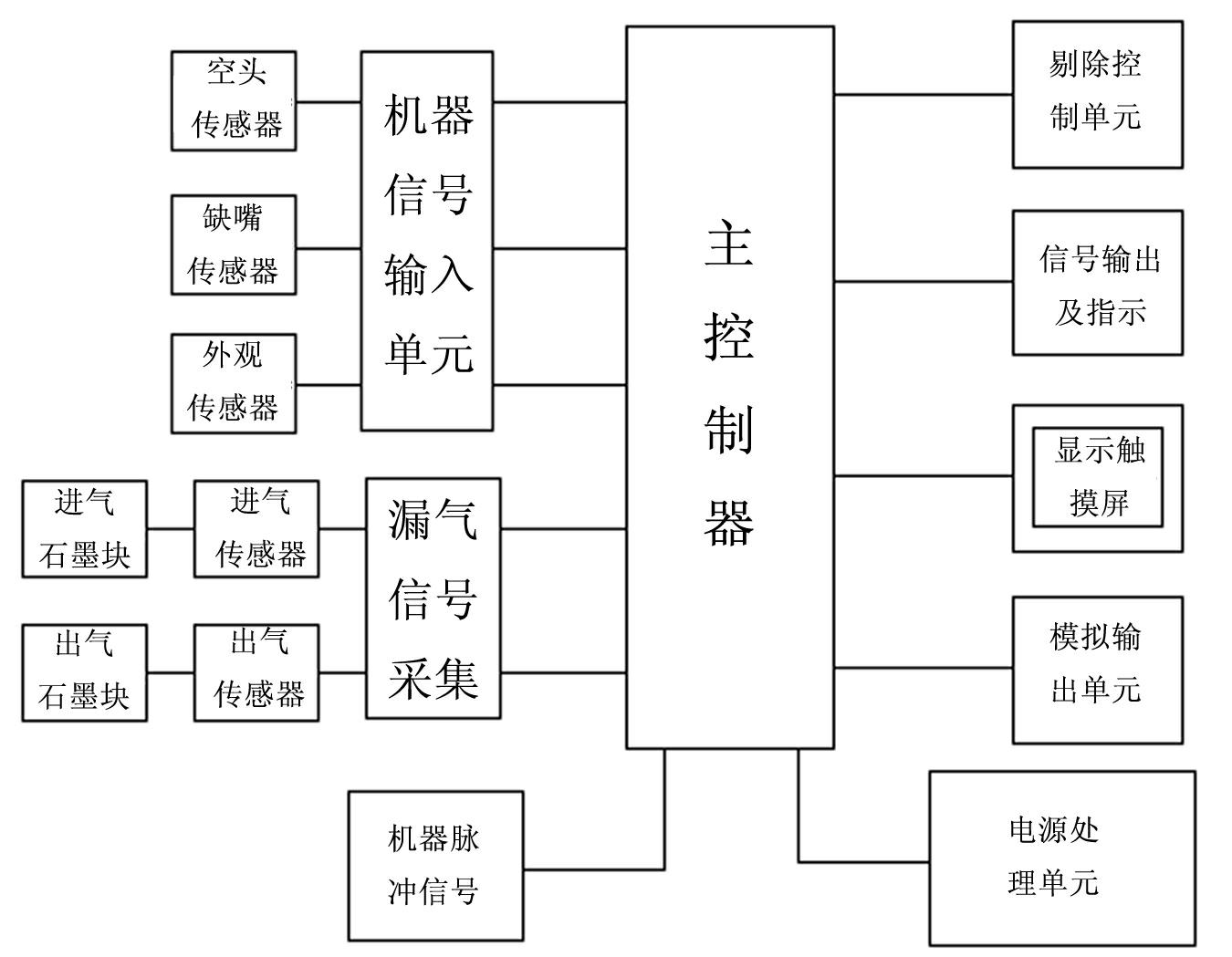

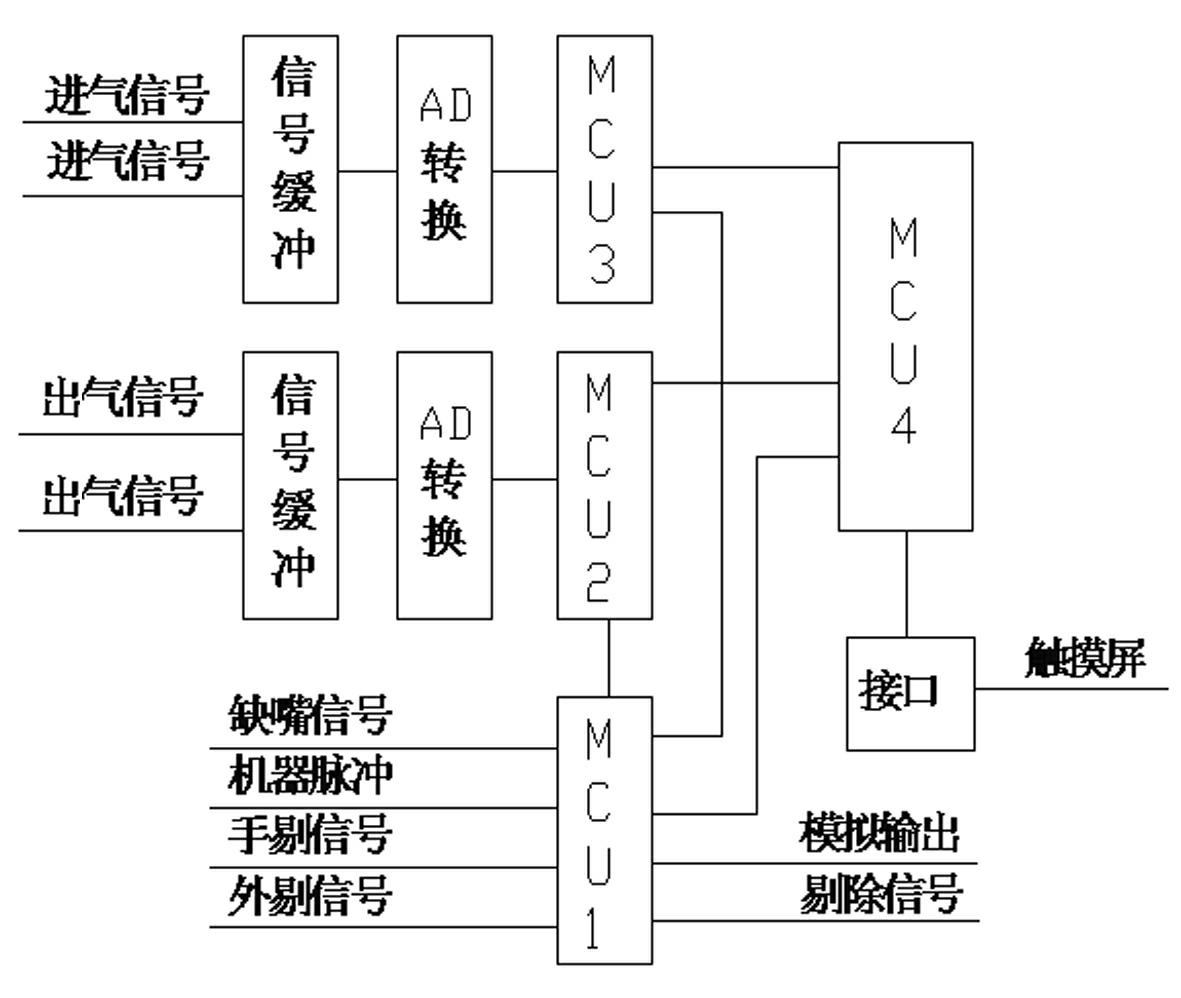

[0037] Such as Figure 1-11As shown, the new cigarette quality detection device used in Putuo 70 / 90 cigarette machine is based on air leakage signal acquisition and main controller, and also includes machine signal input unit, rejection control unit, power processing unit, analog output unit and display unit.

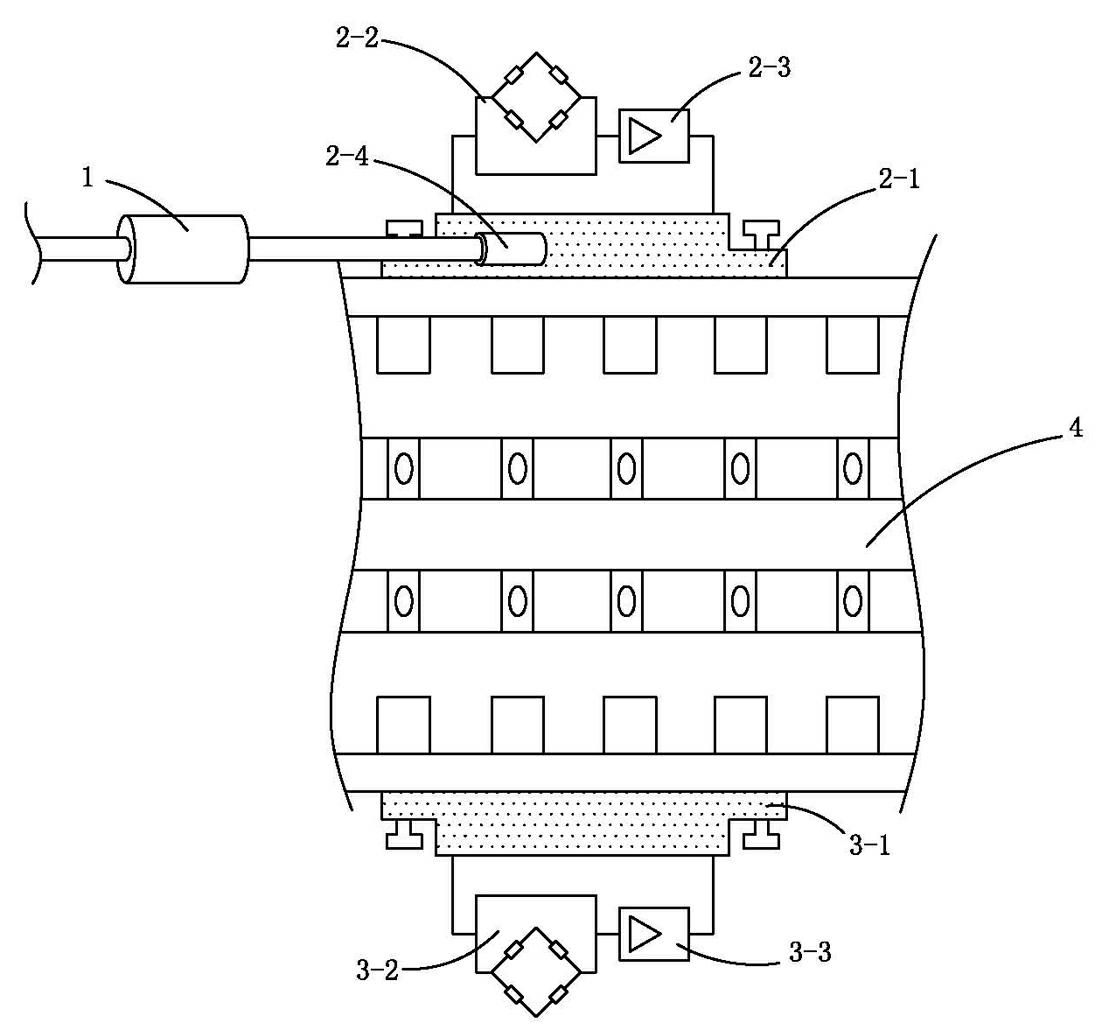

[0038] The air leakage signal acquisition unit consists of an air intake tank 1, an intake graphite block 2-1, an intake pressure sensor 2-2, an intake pressure signal amplifier 2-3, an air outlet graphite block 3-1, and an air outlet pressure sensor 3- 2. The outlet pressure signal amplifier 3-3 is composed of the air leakage signal acquisition part, which sends the compressed air depressurized by the pressure regulating valve to the intake graphite block 2-1 through the intake air storage tank 1, and the intake pressure sensor 2-2, Install the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com