Filter

A technology of filters and filter components, which is applied in the direction of filtration separation, dispersed particle filtration, chemical instruments and methods, etc., and can solve problems such as dust generation and particle introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] (the whole frame)

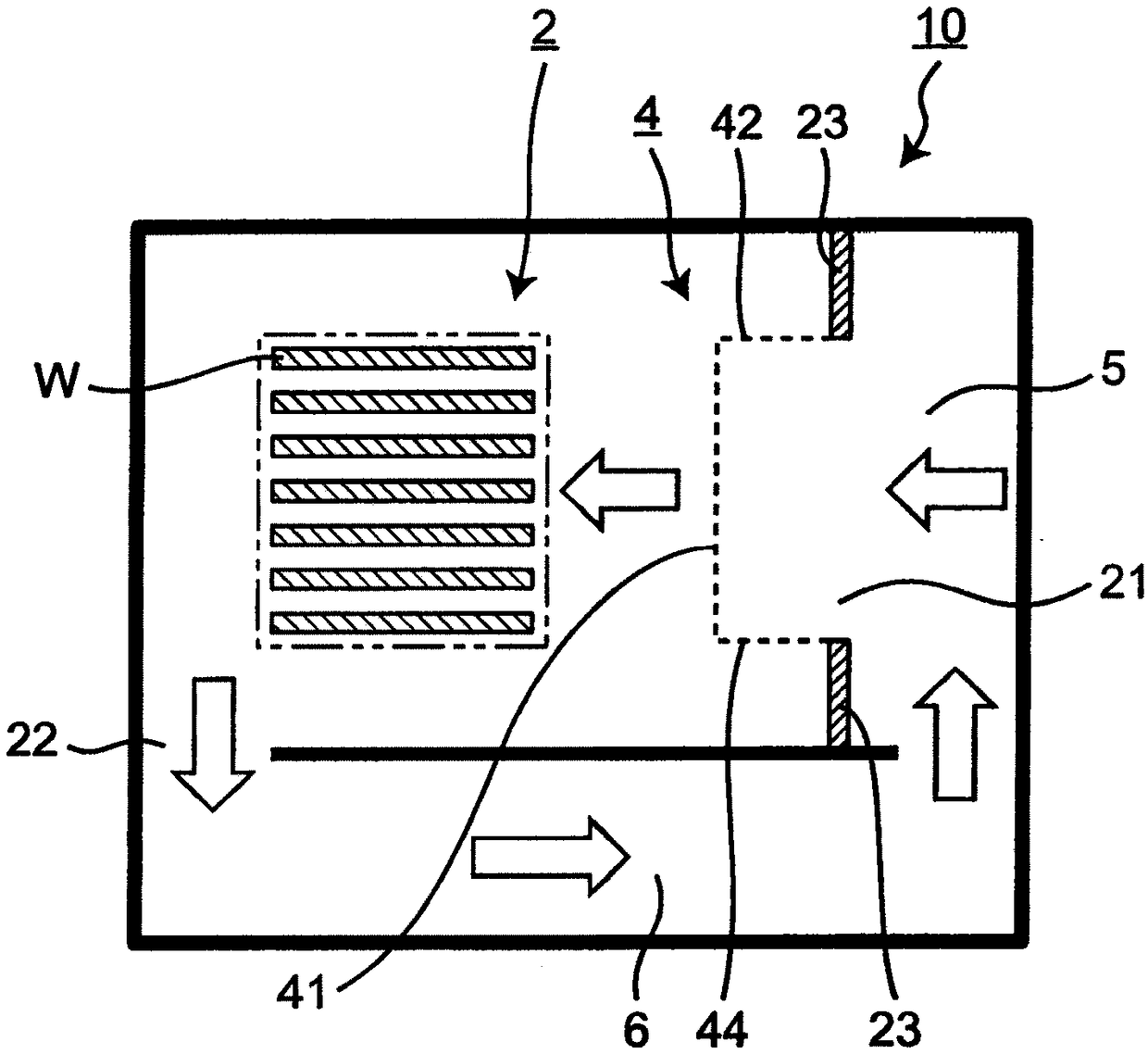

[0042] figure 1 It is a schematic structural diagram of the cleaning oven 10 which concerns on embodiment of this invention. Such as figure 1 As shown, the cleaning oven 10 includes: a heat treatment chamber 2, the heat treatment chamber 2 is configured for heat-treated workpieces W, and has a gas inlet 21 for gas inflow and a gas outlet 22 for gas flow out; filter 4, the above filter 4 passes through Welding is installed on the inner frame 23 forming the gas inlet 21; the space before the filter 5, the space before the filter 5 is used for gas storage before passing through the filter 4; The outgoing gas is sent to the pre-filter space 5. exist figure 1 , the flow of gas is shown by hollow arrows.

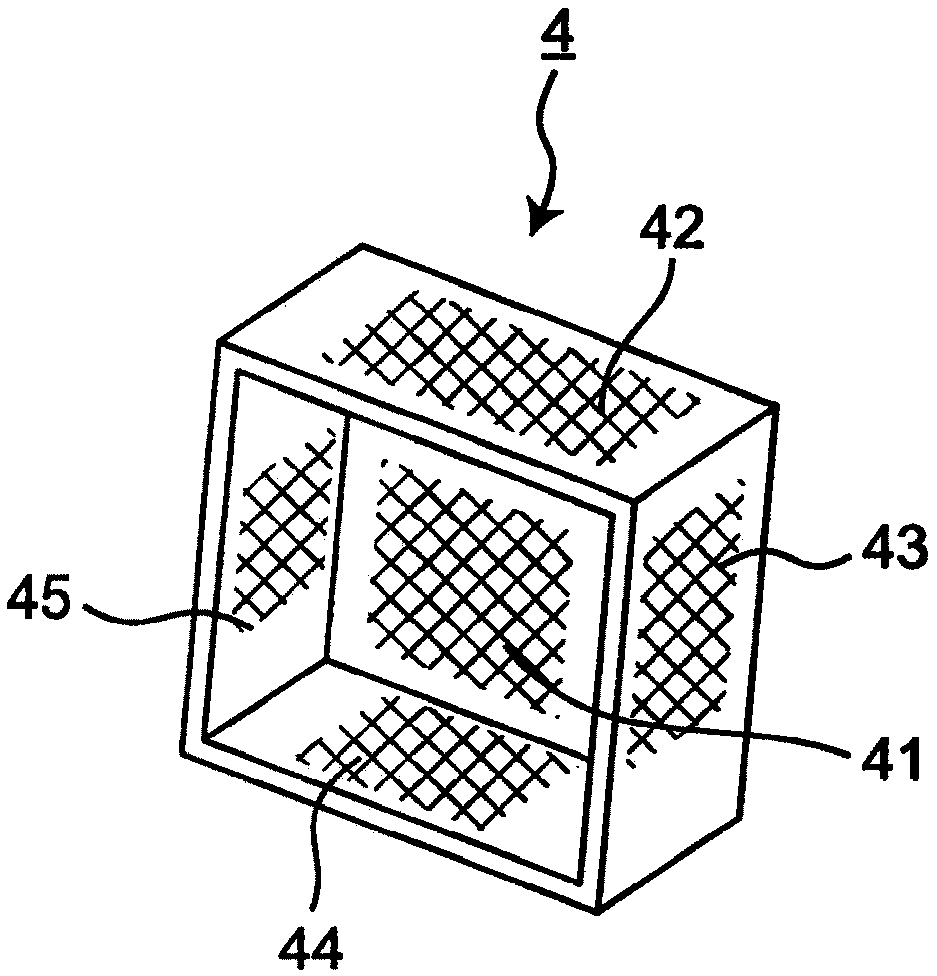

[0043] figure 2 is a schematic perspective view of the filter 4 . Such as figure 1 and figure 2 As shown, the filter 4 includes: a top portion 41 protruding toward the heat treatment chamber 2 side;

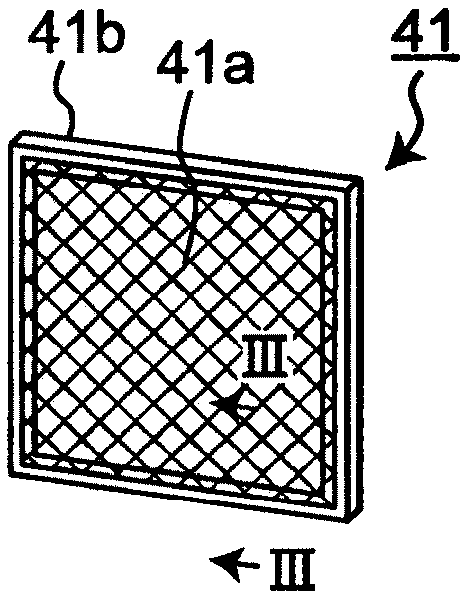

[0044] Figure 3A is a schematic diagram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com