Clutch release bearing device and motor vehicle equipped with such bearing

一种分离轴承、离合器的技术,应用在离合器、机械驱动离合器、轴承等方向,能够解决增加源自摩擦、减少使用寿命等问题,达到减小摩擦、减少污染、灰尘和颗粒量减少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

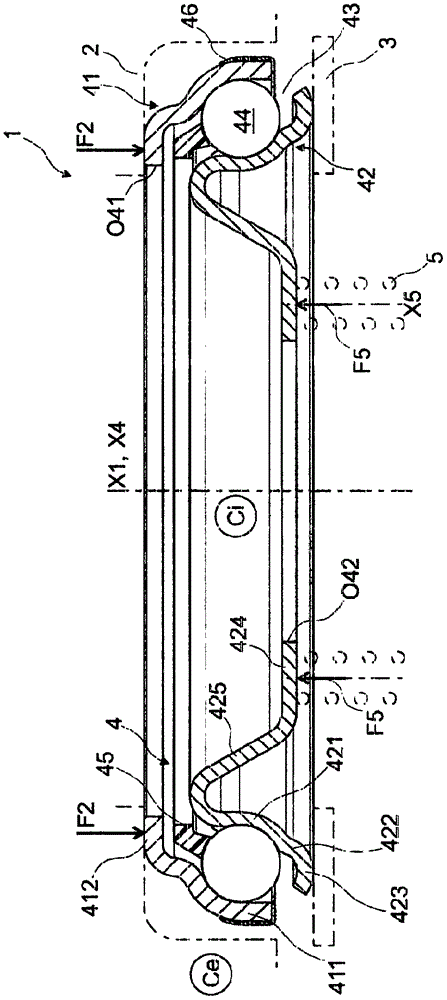

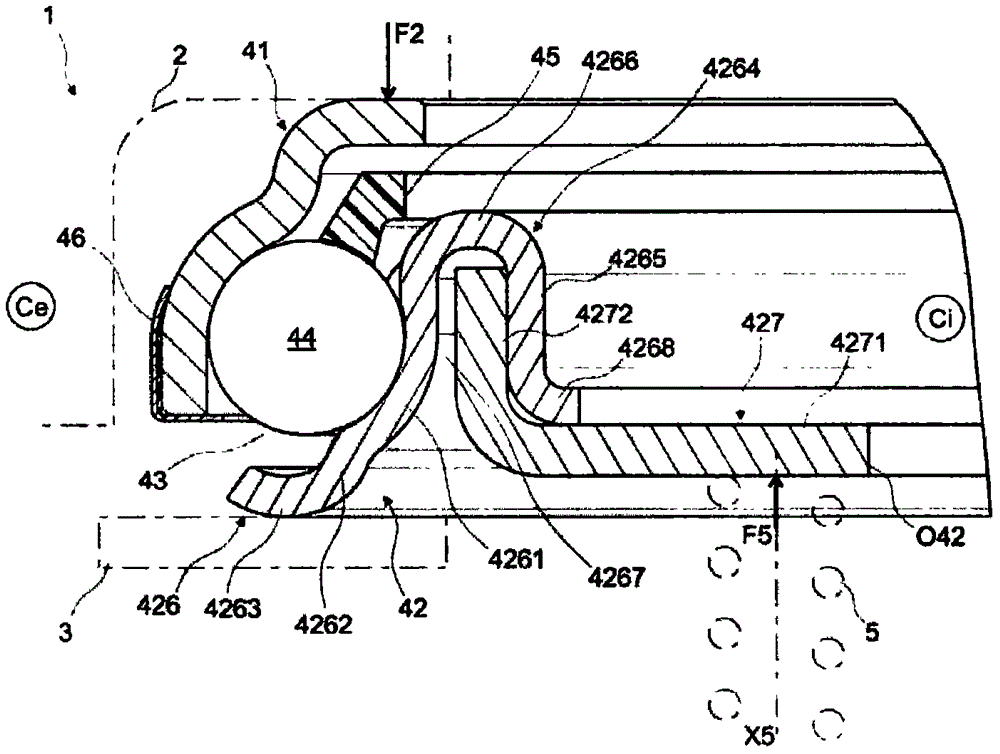

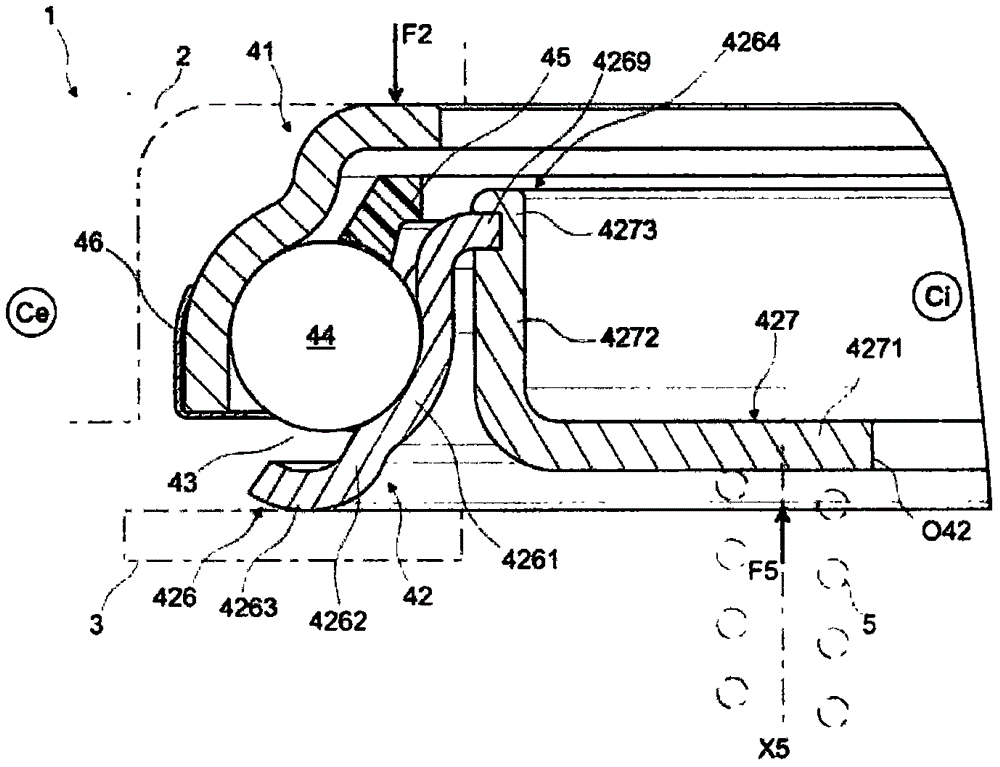

[0047] Figure 1-6 The clutch release bearing device 1 shown in is intended to be mounted on a motor vehicle in order to transmit an axial force F2 to a drive member 3 such as a pressure plate, which is exerted by a member 2 capable of translational movement, in figure 1 are shown only by dotted lines.

[0048] X1 represents the central axis of the clutch release bearing device 1 , and the rotation axis of the pressure plate coincides with X1 during normal operation of the device 1 .

[0049] In the following, for easier positioning of the bearing 1 in space, an inner side Ci corresponding to the main axis X1 is defined, which is the outer side Ce away from the axis X1 via the device 1 .

[0050] Furthermore, for the present and subsequent embodiments, the adjectives “axial” and “radial” and the adverb “axially” are defined with respect to the central axis X1 of the device 1 . The axial part or part is thus parallel to the axis X1, while the radial part or part is perpendicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com