Dust and fog removing device

A demister device and demister technology, applied in the field of air purification, can solve problems such as ingress, achieve the effect of reducing the amount of droplets and dust, reducing the amount of droplets and particles, and improving the ability of dust removal and fog removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

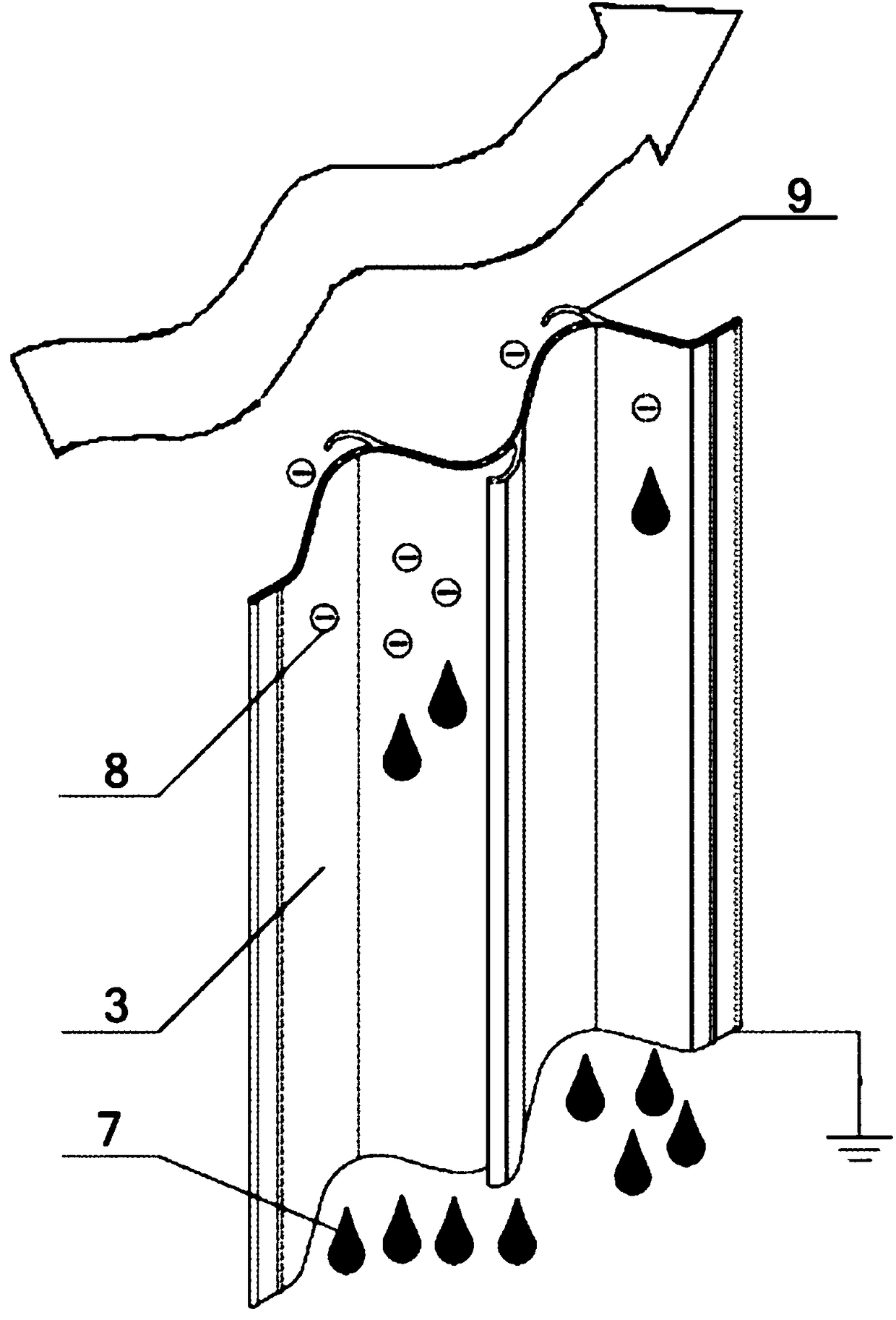

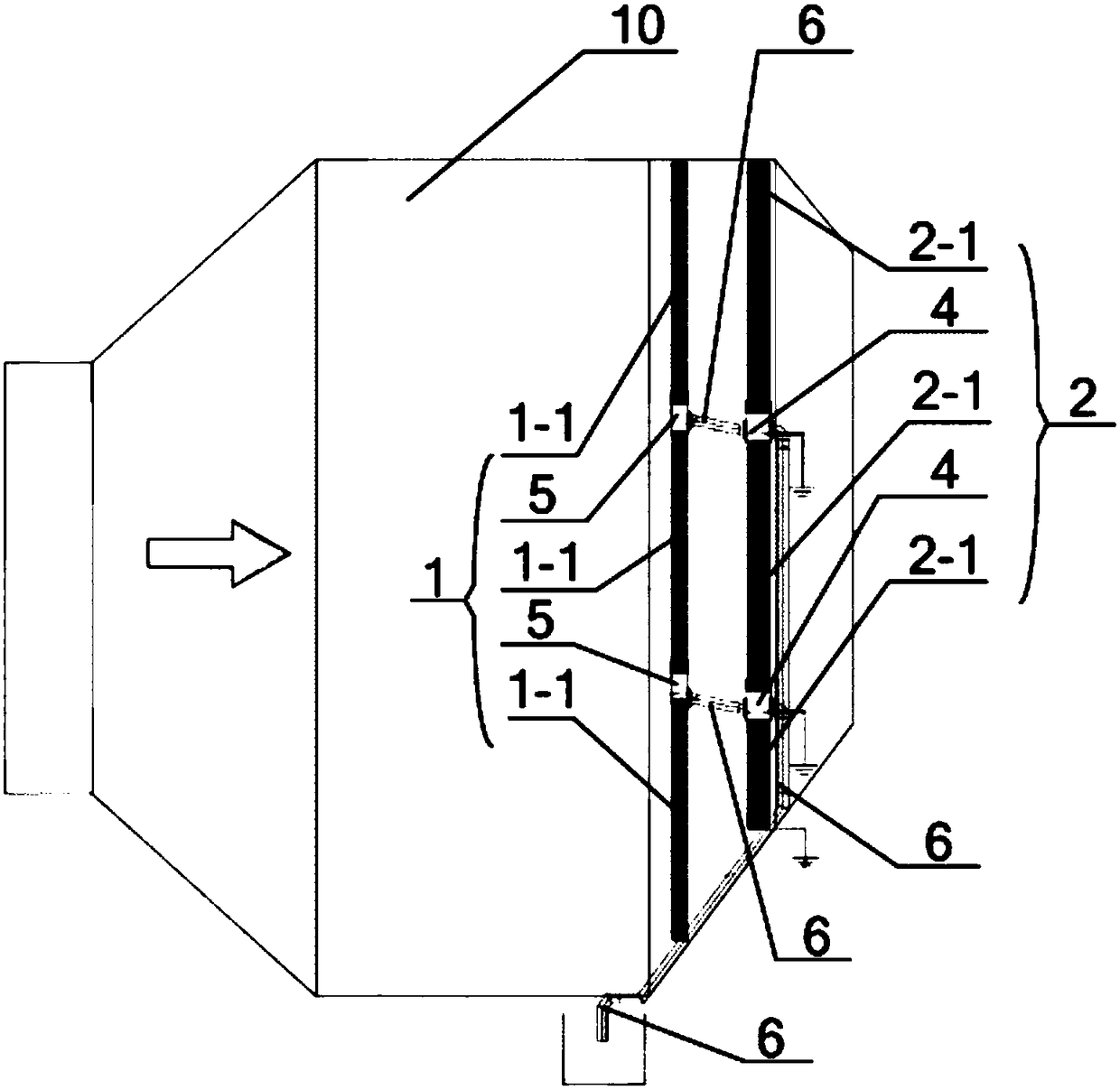

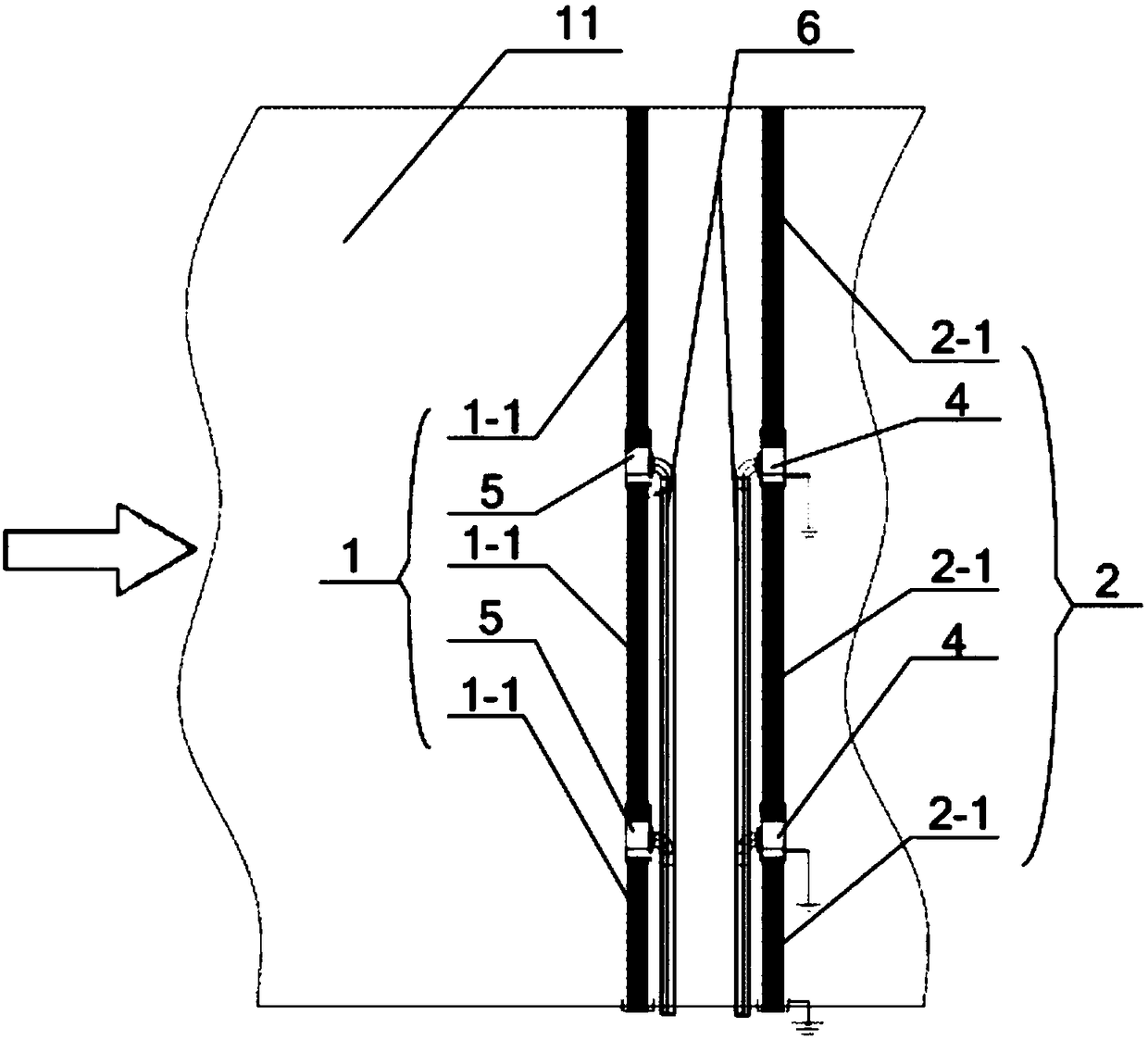

[0024] The reference signs in the drawings of the specification include: primary demister 1, primary demister module 1-1, secondary dust demister 2, secondary demist module 2-1, conductive blade 3, conductive water collection tank 4. Insulating material sink 5, drain pipe 6, liquid drop 7, fine particles 8, hook structure 9, wet electrostatic precipitator 10, flue 11.

[0025] The embodiment is basically as attached Figures 1 to 5 As shown: the dust and mist removal device includes a primary demister 1 and a secondary dust and mist eliminator 2, wherein the blades of the primary demister 1 and the blades of the secondary dust and mist eliminator 2 are arranged parallel to each other, and the primary demist The end of the blade of the device 1 is placed in the corresponding water collection tank, and one end of the blade of the secondary dust and mist eliminator 2 is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com