Separating system of a flue-gas desulfurization system of a ship

A separation system and exhaust gas desulfurization technology, applied in the field of separation systems, can solve the problems of plates no longer functioning correctly, pollution, etc., and achieve the effects of reducing oil, shortening the structure height, reducing oil and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

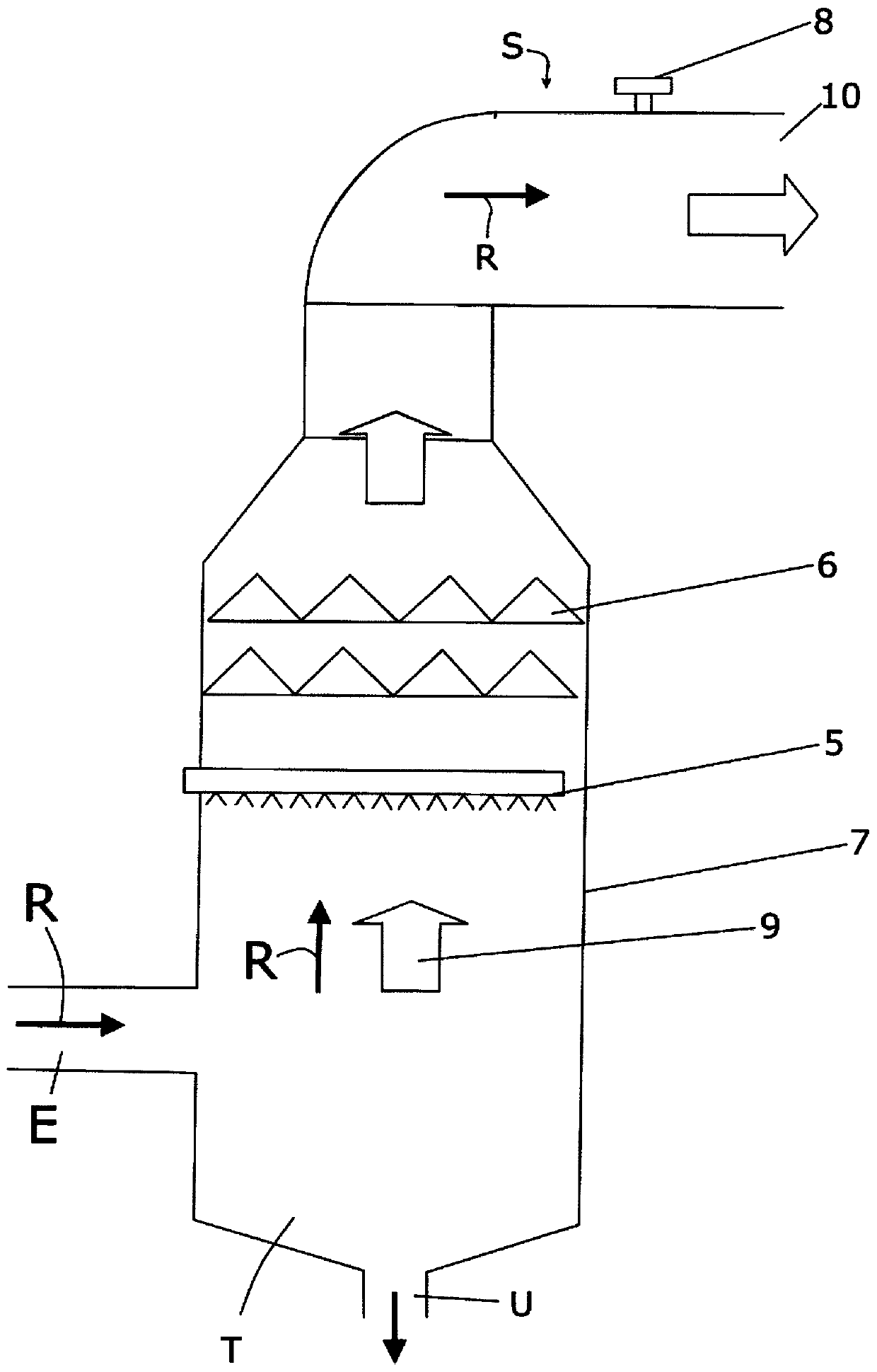

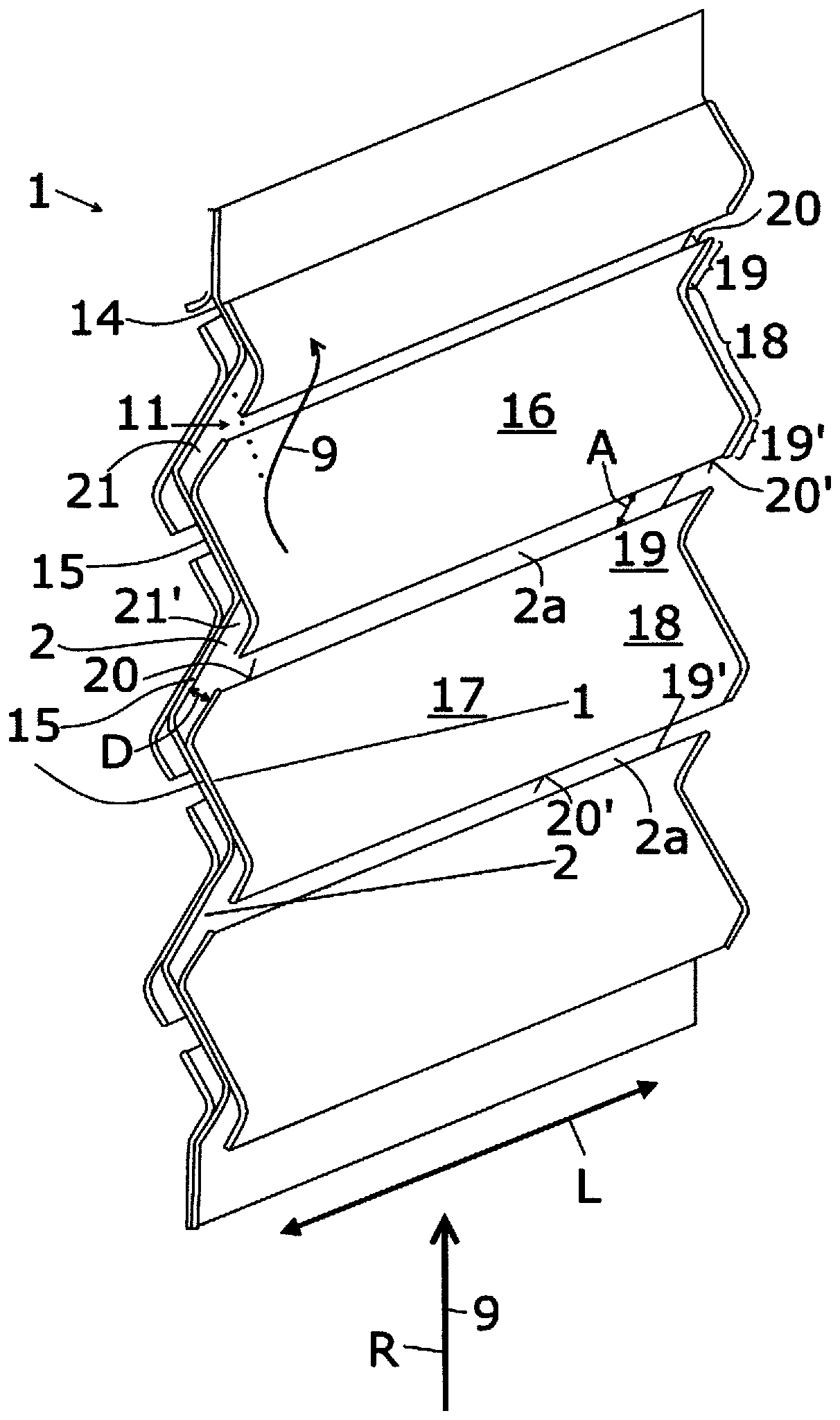

[0062] The prior art separation system shown in FIG. 1 comprises a container 7 through which an exhaust gas flow 9 is guided in flow direction R, that is to say from bottom to top. To this end, the container 7 has a lateral inlet E. Below the lateral inlet E, the container 7 comprises a tank T for collecting liquid. At the deepest point of the tank T there is provided an outlet U through which the collected liquid can be drained off and possibly fed to a further use device or a cleaning device. In the container 7, the exhaust gas flows through the spraying device 5, with which the liquid is delivered in the form of a spray in the exhaust gas for the reaction with SO 2 or SO 3 Combine and wash out the solid. Formed already absorbed SO 2 or SO 3 and droplets of solid components. They are washed out by means of a droplet separator arranged downstream of the spraying device in the flow direction of the exhaust gas. Most of them fall down in the container 7 due to gravity an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com