Coke drun with overhead deflector plate and method using this

A deflecting device and coking tower technology, applied in the field of deflection plates, can solve problems such as promoting liquid and solid blowing out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

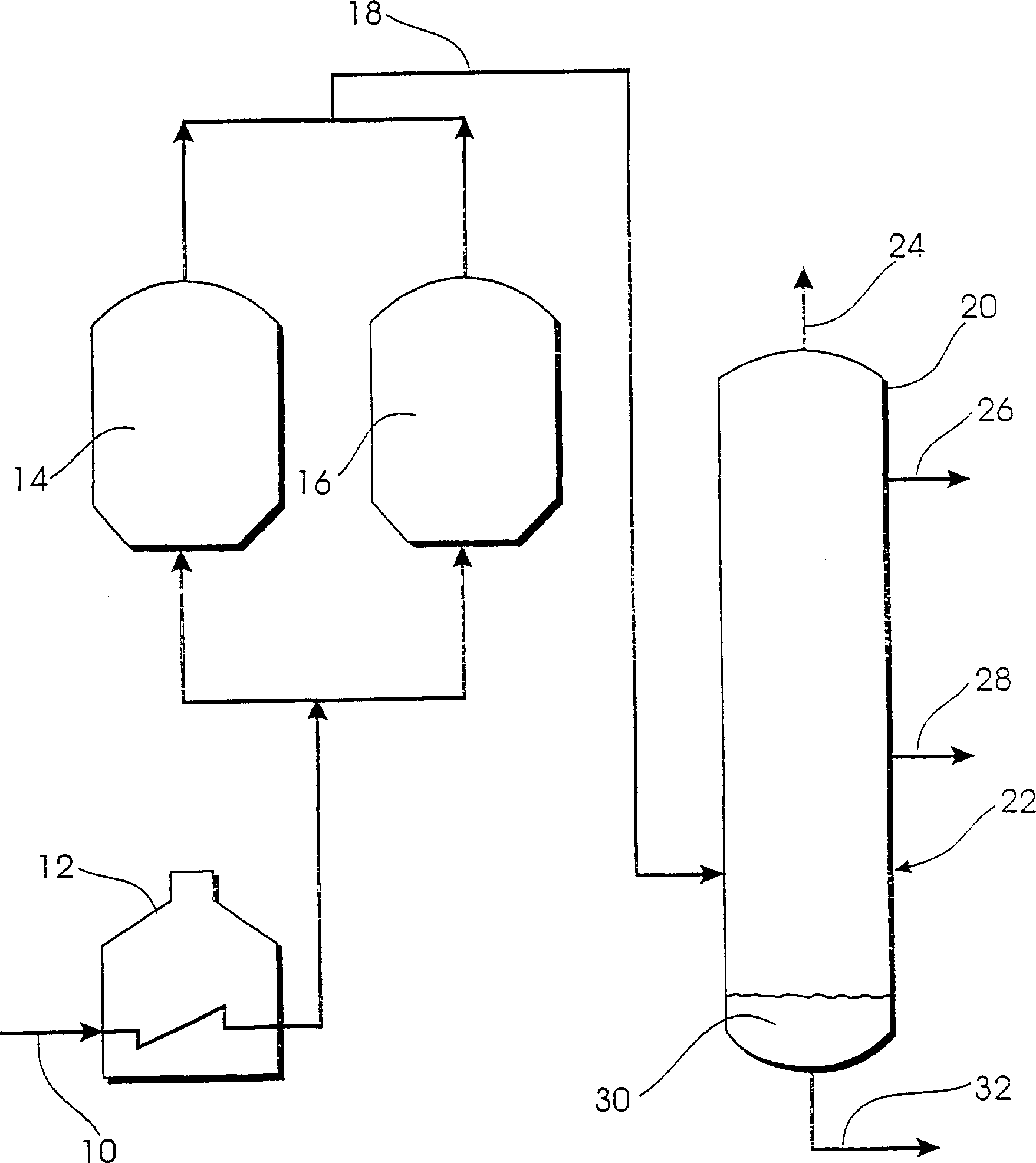

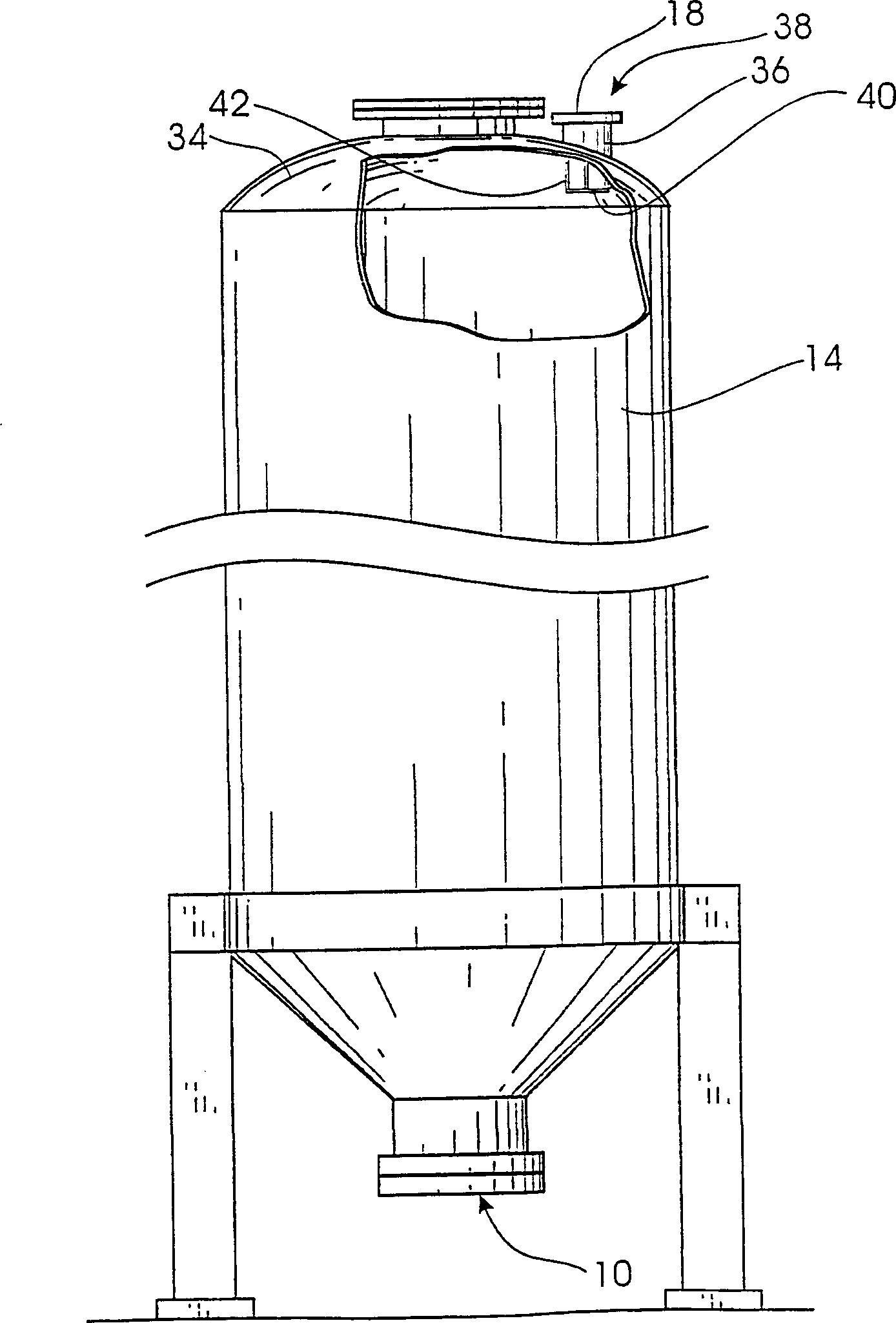

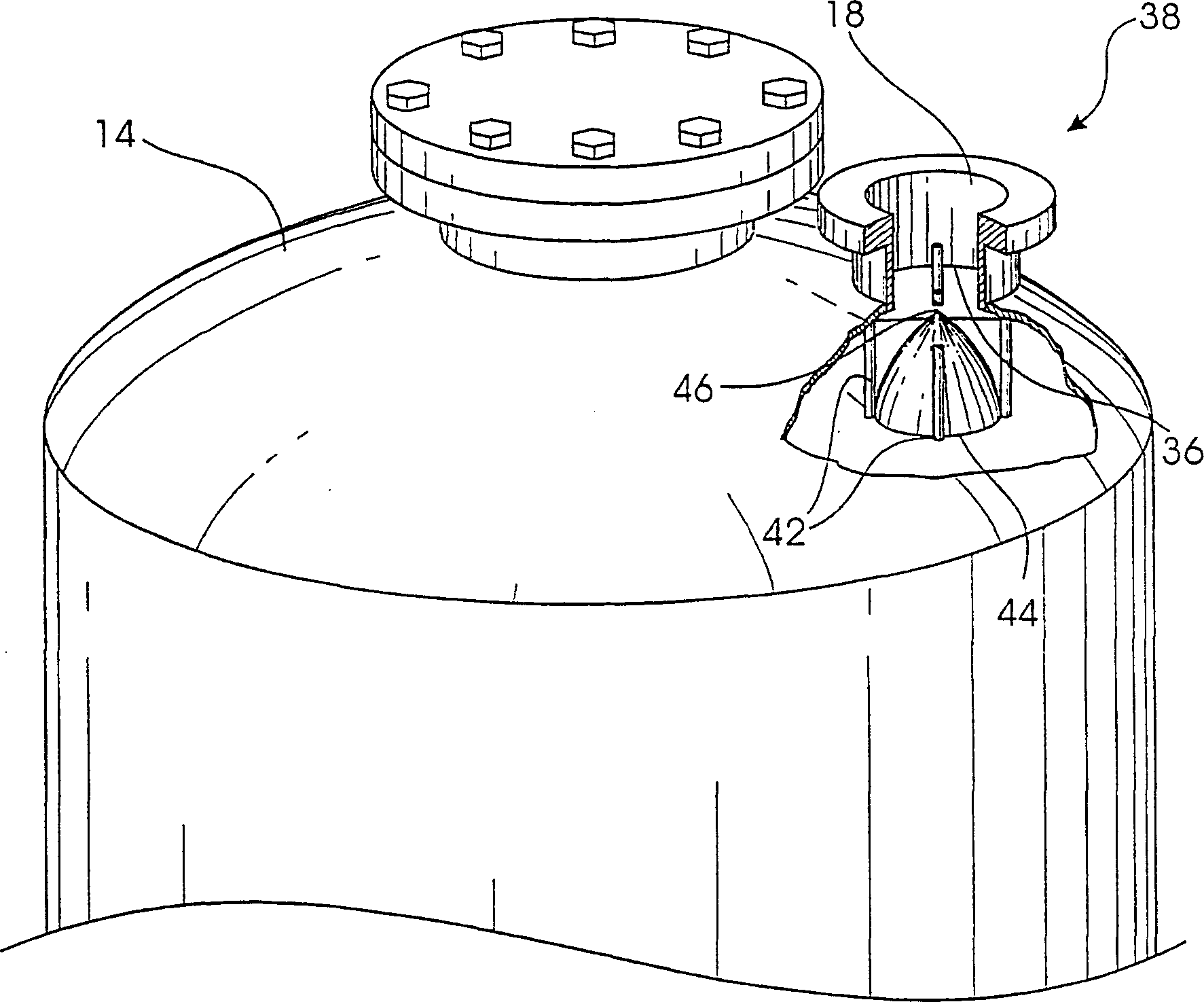

[0018] figure 1 A simplified conventional coker is shown in which coking feedstock is passed from line 10 to furnace 12 where it is heated. figure 1 The layout of the present invention uses a coking tower, but it should be understood that the present invention can be used in single tower or multiple tower situations. Coking drums 14 and 16 are alternately filled and emptied. When a coking drum is full of solid coke, the coke can be withdrawn at least near the bottom (and usually the top).

[0019] Overhead vapor from the packed coker is returned to coker fractionator 20 via line 18 . Recovered liquid, such as coker gas oil or coker feedstock, is sent to fractionator 20 via line 22 . An overhead wet gas stream is withdrawn from fractionator 20 via line 24 and an intermediate liquid fraction is withdrawn via lines 26 and 28 . Unwanted solids and heavy hydrocarbon liquids 30 are withdrawn from the bottom of fractionator 20 via line 32 and directed to the furnace. Other modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com