Multi-effect spray gasifier chilling device

A gasification furnace, spraying technology, applied in the field of multi-effect spraying gasification furnace chilling device, can solve the problems of ablation deformation, load reduction or shutdown, etc., to reduce the amount of liquid droplets entrained in syngas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

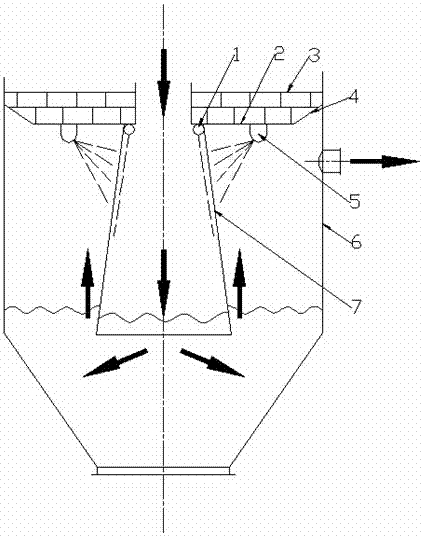

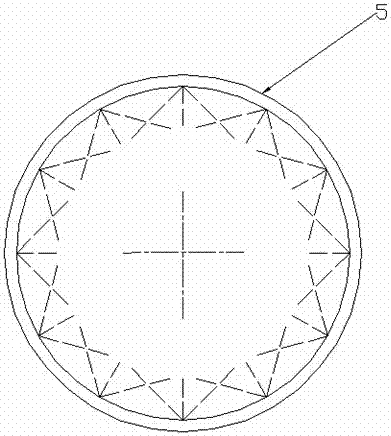

[0034] Such as figure 1 , 2 As shown, the chilling device of the multi-effect spray type gasifier includes the chilling ring 1 in the gasifier, the refractory brick 3, the brick support plate 4, the brick support flange 2 and the downcomer 7, the brick support plate 4 and the The shell 6 of the gasifier is fixed, the brick supporting flange 2 is welded to the supporting brick plate 4, and the refractory brick 3 is built on the supporting brick plate 4 and the supporting brick flange 2; the quenching ring 1 is located at the upper end of the downcomer 7, And it is fixed under the brick supporting flange 2; a circle of spray ring 5 is also fixedly arranged under the supporting brick flange 2, and the outer wall of the spray ring 5 is in direct contact with the supporting brick flange 2.

[0035] The downcomer 7 is in the form of a frustum-shaped structure with a small top and a large bottom, and the gradual expansion angle of the frustum-shaped structure is 5-10°. The water ou...

Embodiment 2

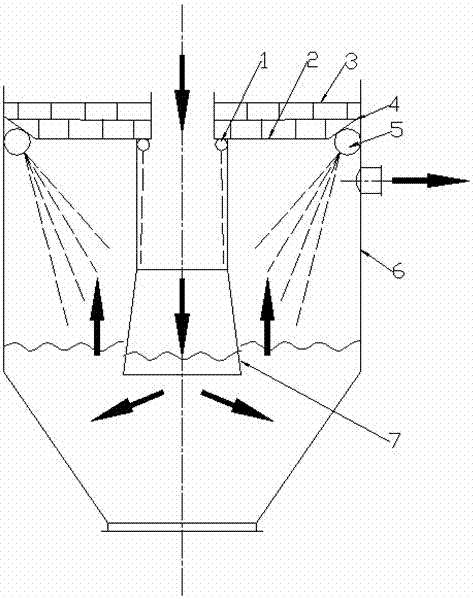

[0038] Such as image 3 , 4 As shown, the chilling device of the multi-effect spray type gasifier includes the chilling ring 1 in the gasifier, the refractory brick 3, the brick support plate 4, the brick support flange 2 and the downcomer 7, the brick support plate 4 and the Gasifier shell 6 is fixed, brick support flange 2 is welded to support brick plate 4, refractory brick 3 is built on support brick plate 4 and brick support flange 2; chilling ring 1 is located at the upper end of downcomer 7 and fixed Below the brick supporting flange 2 and below the brick supporting plate 4, a circle of spray ring 5 is fixedly arranged, and the outer wall of the spray ring 5 is in direct contact with the brick supporting plate 4.

[0039] The downcomer 7 includes an upper cylindrical structure and a lower frustum-shaped structure. The diameter of the upper cylindrical structure is the same as the minimum diameter of the lower frustum-shaped structure, that is, the cross-sectional area ...

Embodiment 3

[0042] Such as Figure 5 , 6As shown, the chilling device of the multi-effect spray type gasifier includes the chilling ring 1 in the gasifier, the refractory brick 3, the brick support plate 4, the brick support flange 2 and the downcomer 7, the brick support plate 4 and the Gasifier shell 6 is fixed, brick support flange 2 is welded to support brick plate 4, refractory brick 3 is built on support brick plate 4 and brick support flange 2; chilling ring 1 is located at the upper end of downcomer 7 and fixed Below the bracket flange 2.

[0043] The downcomer 7 includes an upper frustum-shaped structure, a middle cylindrical structure and a lower frustum-shaped structure. The maximum diameter of the upper frustum-shaped structure is the same as the diameter of the middle cylindrical structure and the minimum diameter of the lower frustum-shaped structure. The cross-sectional area of the bottom of the structure is the same as that of the top of the middle cylindrical structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com