Film-releasing condensation vacuum system

A vacuum system and vacuum pump technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of vacuum pump pumping capacity reduction, pipeline vibration, and increased floor space, so as to improve pumping efficiency and reduce exhaust With water, the effect of intense heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and at the same time, the advantages of the present invention will become clearer and easier to understand.

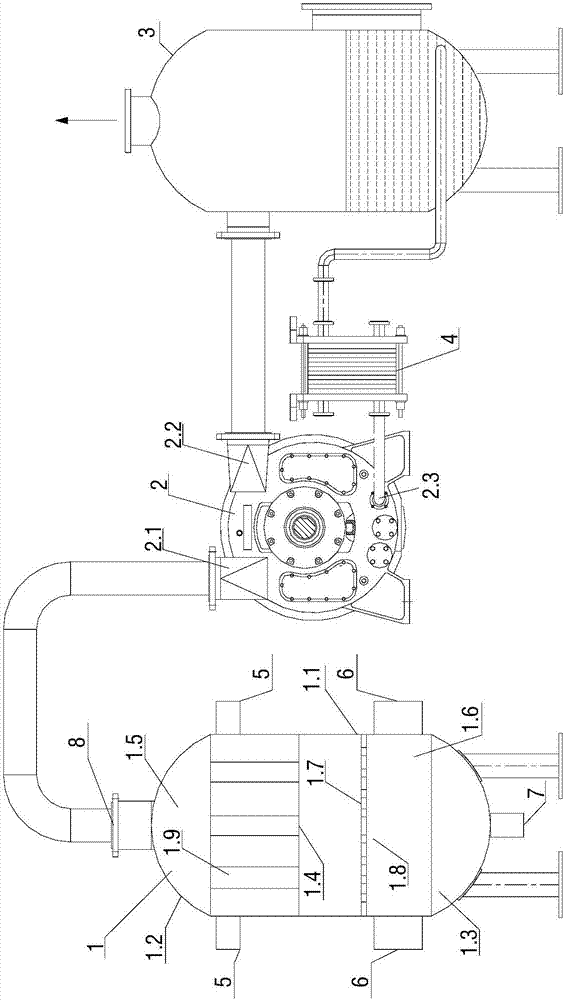

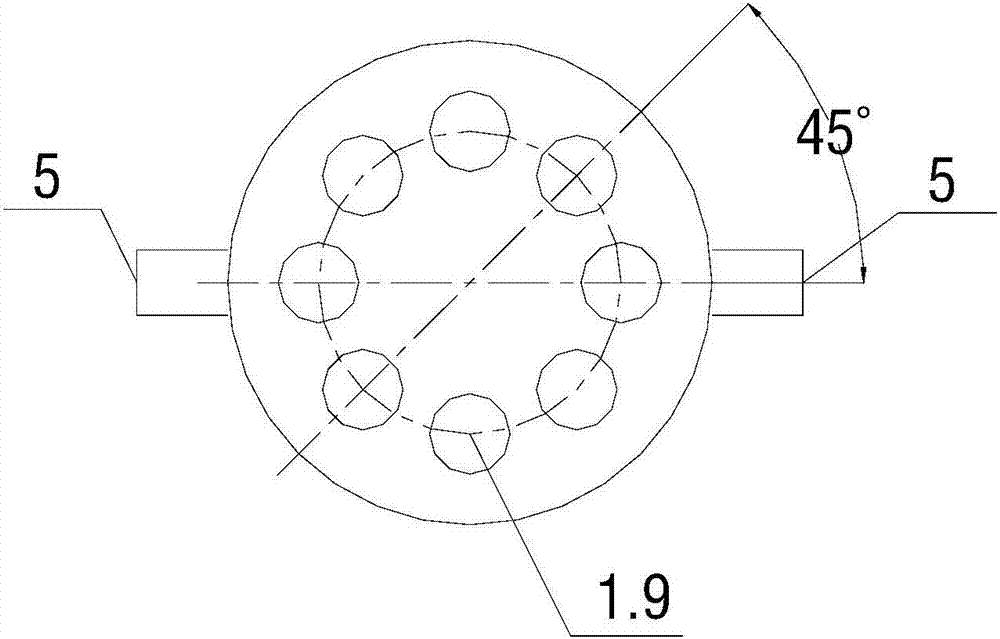

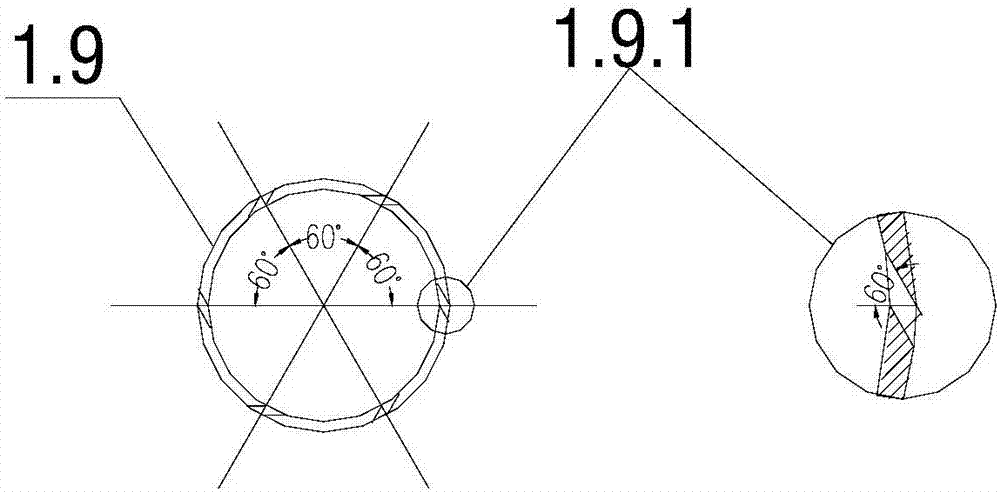

[0025] A kind of film forming condensation vacuum system of the present invention, it comprises film forming condensing device 1, vacuum pump 2, vapor-water separator 3 and heat exchanger 4; The suction port 8 on the top of described film forming condensing device 1 is connected with described film forming condensing device 1 through pipeline The suction port 2.1 of the vacuum pump 2 is connected, and the discharge port 2.2 of the vacuum pump 2 is connected with the steam-water separator inlet 3.1 on the top of the steam-water separator 3 through a pipeline, and the steam-water separator 3.1 is connected with the vacuum pump 2 through the heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com