Solar cell sheet processing hydraulic condensation circulation system

A technology of solar cells and circulation systems, applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve problems such as freezing and affecting gasification, and achieve the effects of improving processing efficiency, saving resources, and using safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

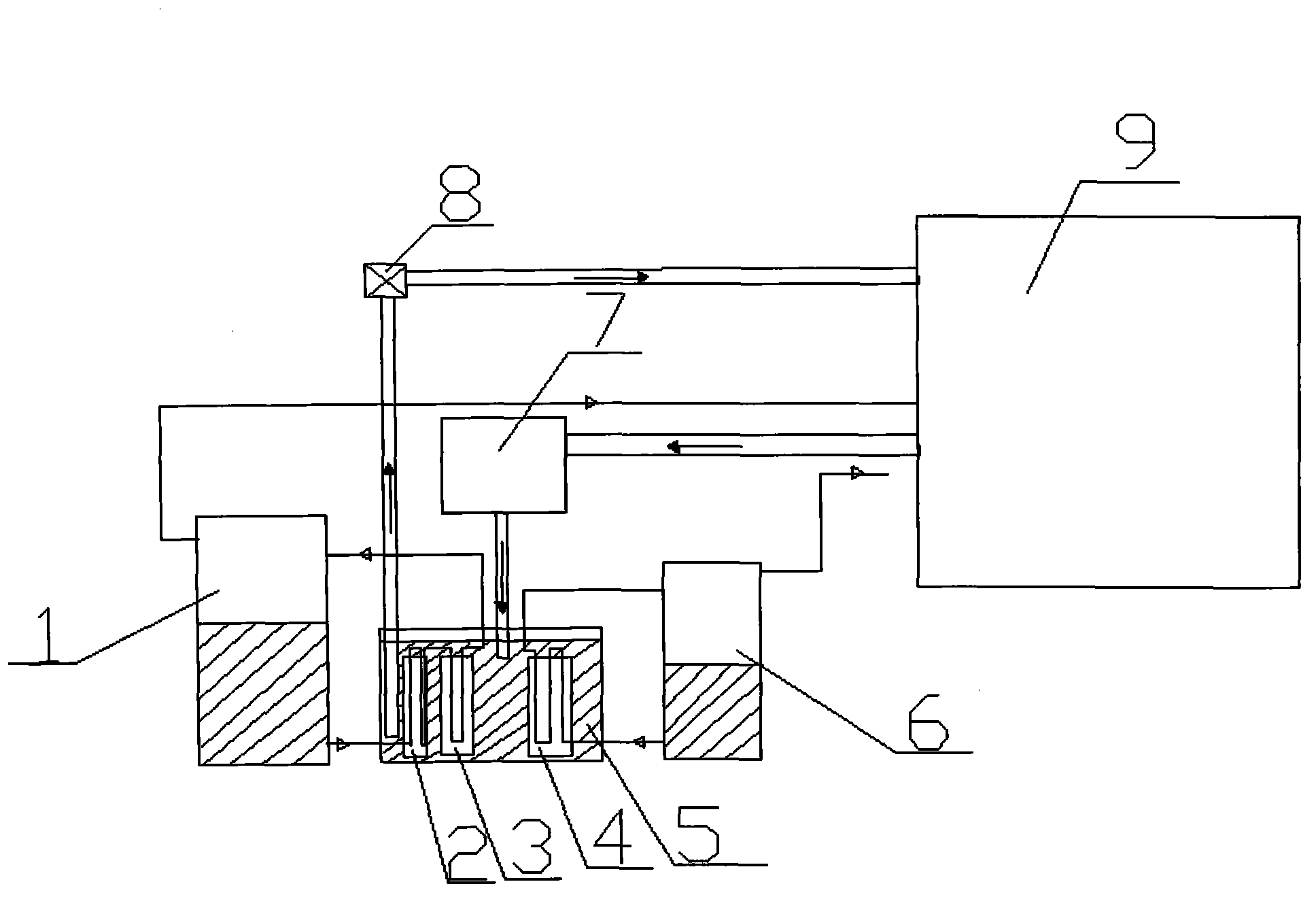

[0015] The temperature of nitrogen or oxygen required for solar cell processing is 0-25°C and the pressure is 0.5-7kg / cm 2 , when liquid nitrogen or oxygen enters the vaporization device from the storage tank, the temperature is -190°C and the pressure is 2-3kg / cm 2 , The temperature of the cooling water coming out of the workshop is 30-40°C, and it enters the cooling tower for preliminary cooling and enters the reservoir. The liquid nitrogen or oxygen absorbs the temperature of the cooling water in the reservoir to normal temperature through the vaporization device, and the cooling water absorbs heat through the vaporization device in the reservoir to reduce the temperature and play a cooling role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com