Design method of built-in steam condensation removal device

A technology of exclusion device and design method, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve the problems of damaging optical sensors, affecting detection accuracy, and large volume, and achieves broad application prospects, good condensation effect, The effect of simple and applicable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

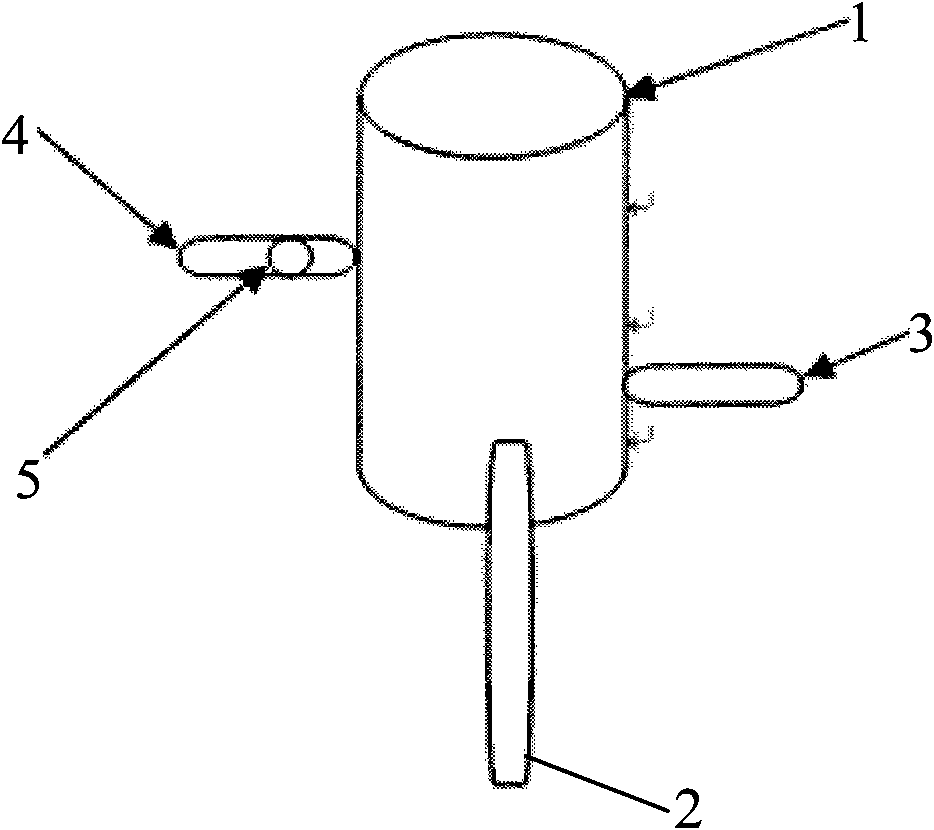

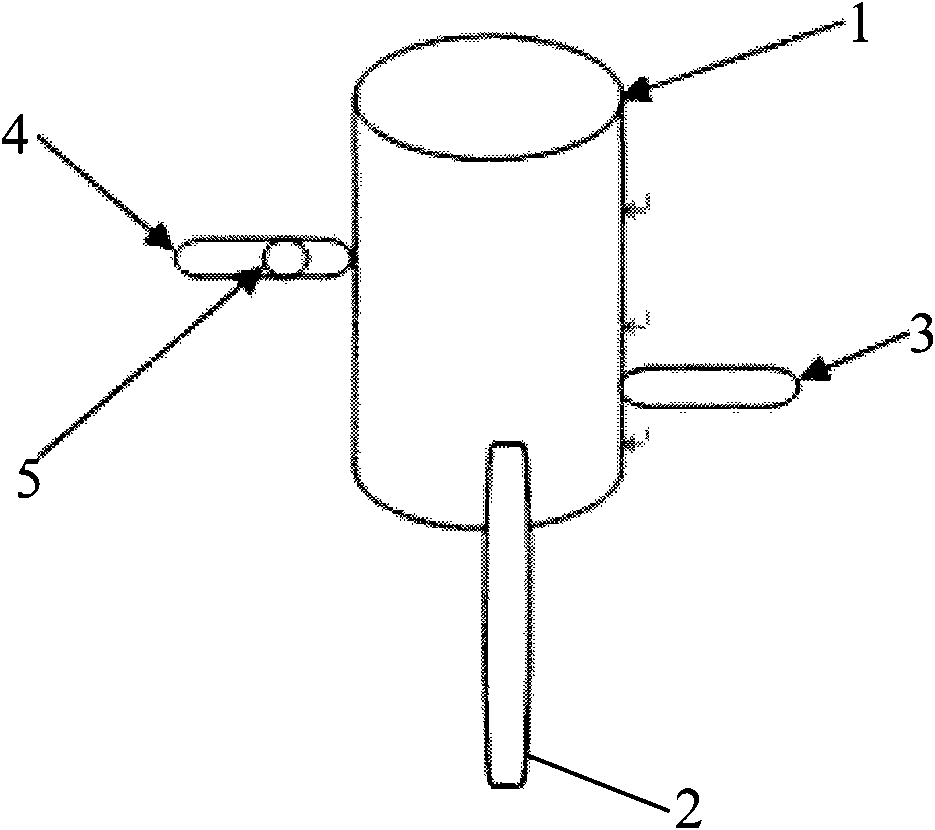

[0012] The principle of flow mechanics is used to optimize the design of a device for removing water vapor, which can condense water vapor in time and automatically remove it, so as to ensure that water vapor does not enter the optical sensor.

[0013] Such as figure 1 As shown, the device for removing water vapor in the automobile exhaust gas analyzer includes an air chamber 1 and a drain pipe 2, the air chamber 1 is cylindrical, the bottom of the air chamber 1 is connected to the drain pipe 2, and a side wall of the air chamber 1 is provided The air inlet 3 is provided with an air outlet 4 at the position opposite to the air inlet 3 on the side wall of the air chamber. 5. The gas flow rate entering the gas chamber is particularly large, while the gas flow rate at the gas outlet suddenly decreases, causing the water vapor in the gas to be retained, condensed, and quickly discharged from the instrument.

[0014] In application, the gas flow rate of the gas outlet 4 is change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com