Battery gas production analysis system

An analysis system and battery technology, applied in the field of electrochemical analysis, can solve the problems such as the decrease in the accuracy of test results, unfavorable battery cycle testing, affecting the service life of the instrument, etc., and achieve the effect of obvious condensation effect, ensuring accuracy, and improving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

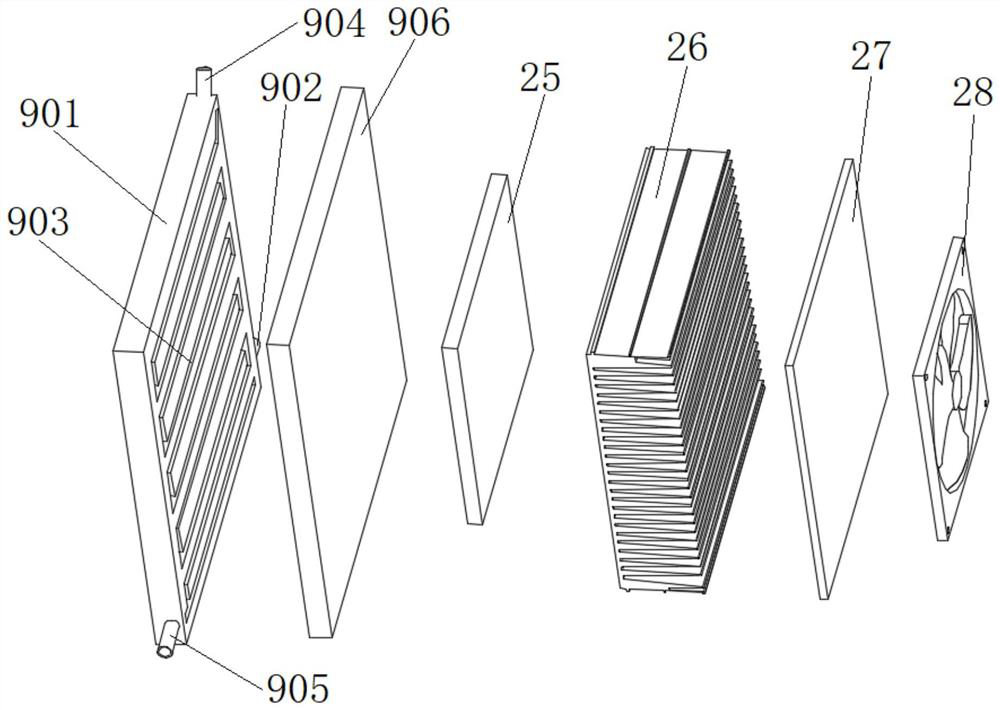

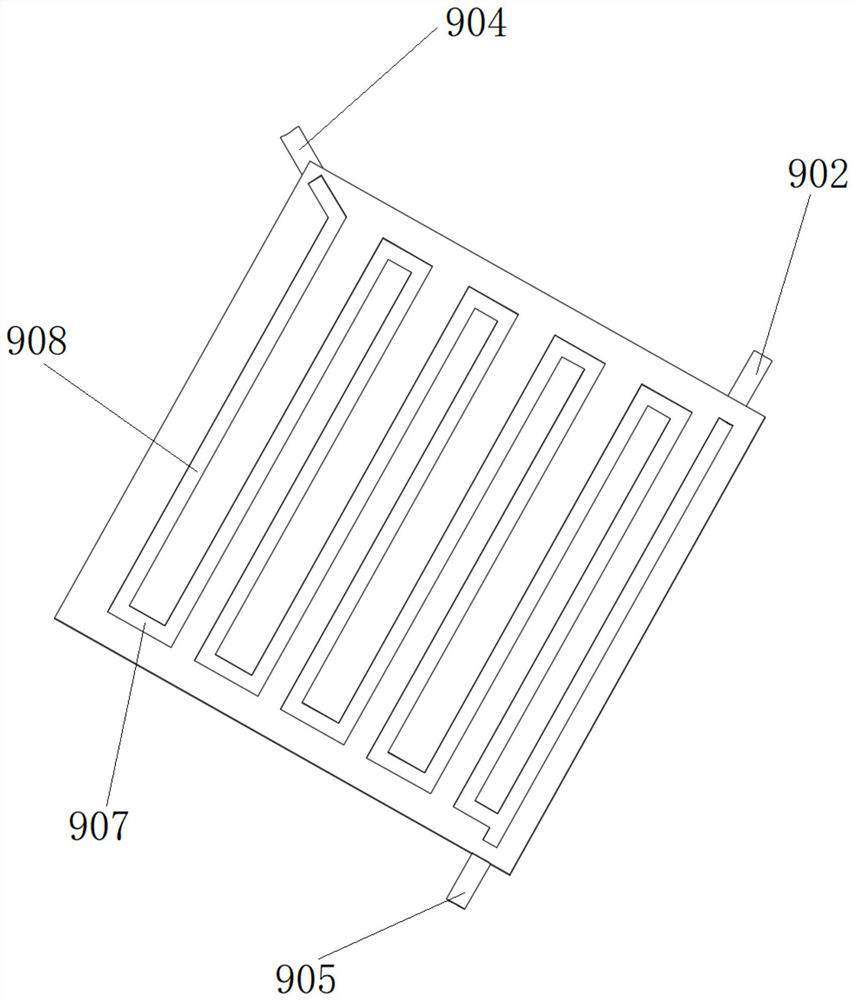

[0071] The technical features in the embodiments of the present invention will be described in detail below with reference to the accompanying drawings of the present invention.

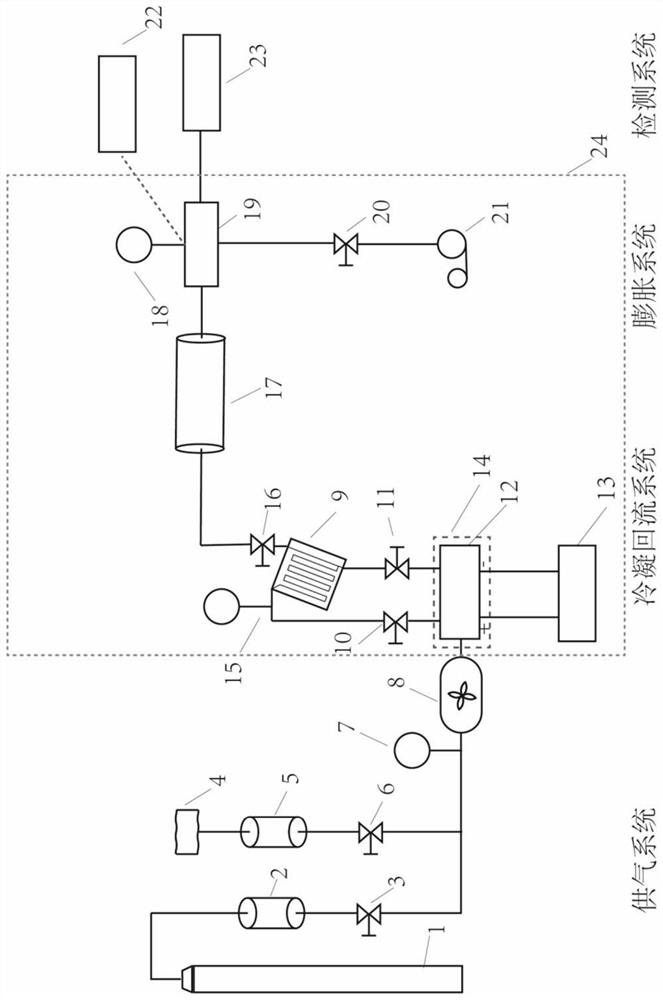

[0072] like figure 1 As shown, a battery gas production analysis system includes a gas supply device, a condensation reflux system, an expansion system and a detection system.

[0073] Among them, the gas supply device mainly includes a high-pressure branch and a low-pressure branch. Among them, the high-pressure gas source 1 is connected in series with the high-pressure branch composed of the adsorption device I2 and the solenoid valve I3, which provides high-voltage test conditions for the battery; the high-pressure gas source 1 is switched on and off through the solenoid valve I3.

[0074] The low-pressure gas source 4 is sequentially connected to the low-pressure branch composed of the adsorption device II5 and the solenoid valve II6 to provide the gas source for commercial batteries containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com