In-mill screening and lifting device and vertical roller mill

A vertical roller mill and screening technology, applied in the direction of sieve, solid separation, chemical instruments and methods, etc., can solve the problems of increasing the load of the powder separation fan, increasing the consumption of mechanical energy, etc., to save mechanical energy, save energy, Easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It is easy to understand that, according to the technical solution of the present invention, those skilled in the art can propose multiple structural modes and implementation modes that can be replaced without changing the essence and spirit of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or restriction on the technical solution of the present invention.

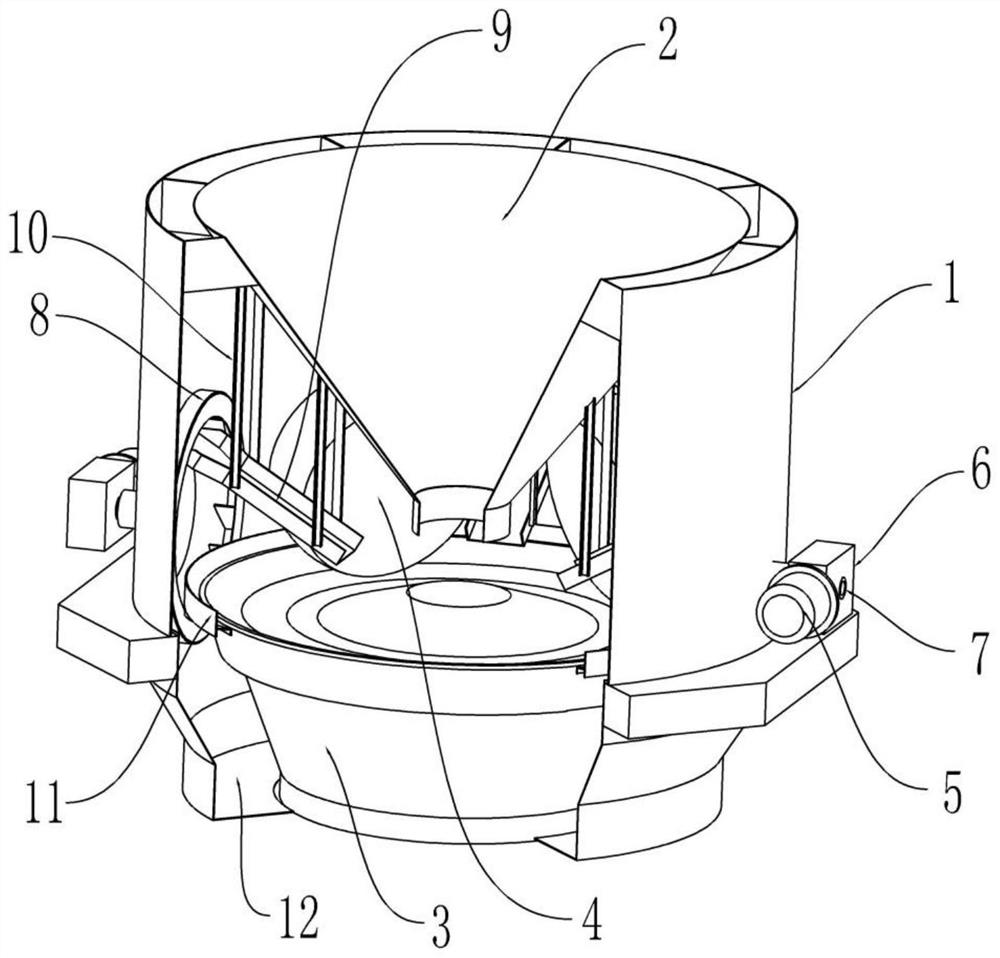

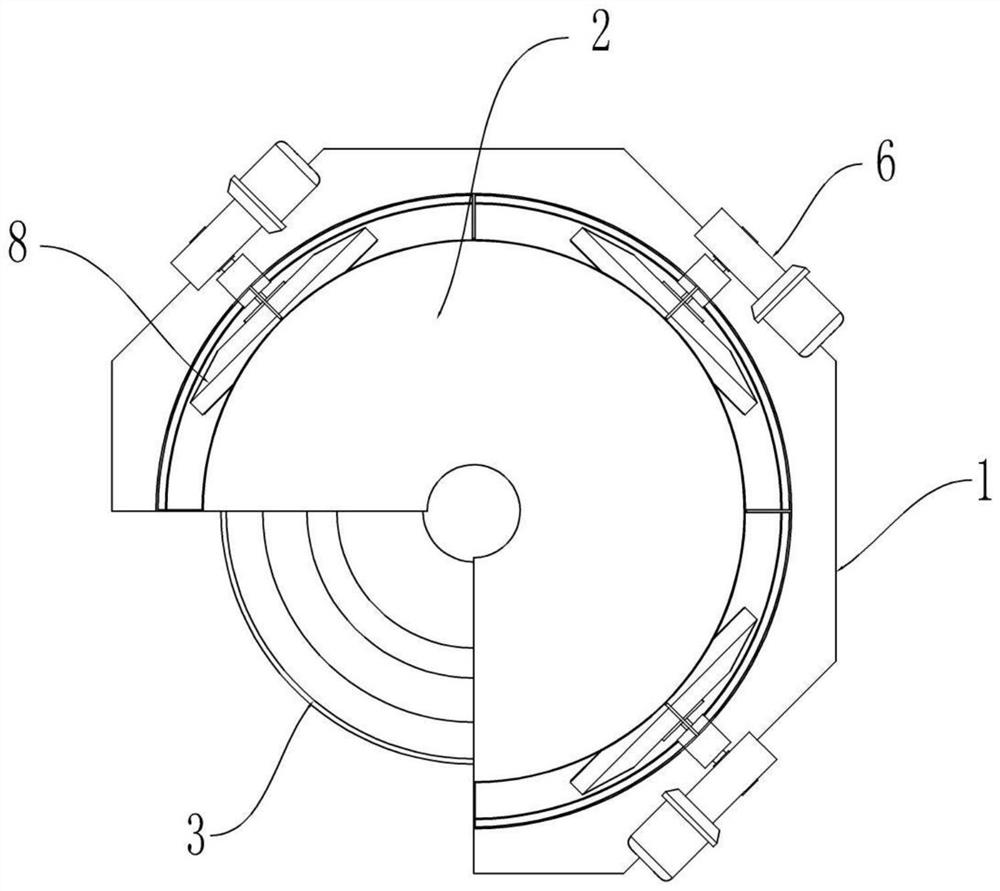

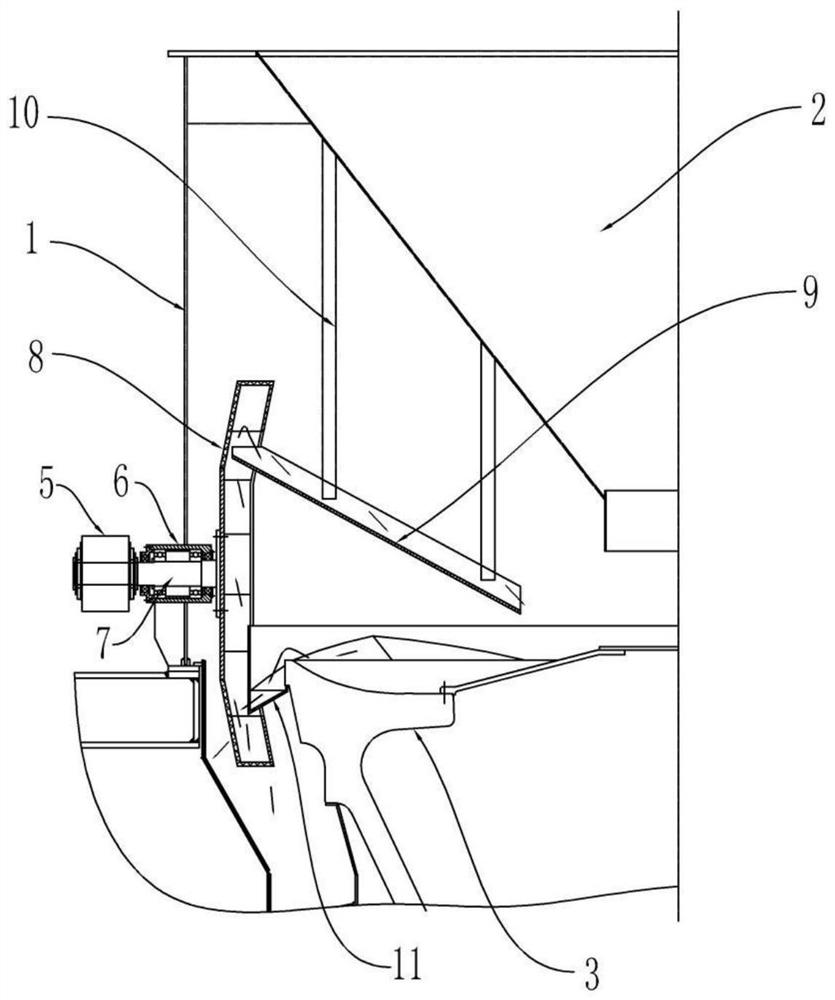

[0025] According to an embodiment of the present invention combined with Figures 1 to 8 show. A vertical roller mill, comprising a shell 1, a feeding cone 2, a grinding disc 3, a grinding roller 4, a mill hopper 12 and a screening and lifting device inside the mill. The blanking cone 2 is arranged inside the housing 1 to guide the inflow of materials; the millstone 3 is located below the outlet of the blanking c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com