Metal plate rust removal and paint spraying machining equipment and using method

A technology for sheet metal and processing equipment, applied in spray booths, spray devices, pre-treated surfaces, etc., can solve the problems of unsatisfactory paint adhesion, low processing efficiency, and affecting the use of sheets, so as to improve the effect of sheet painting and improve processing Efficiency, particle reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

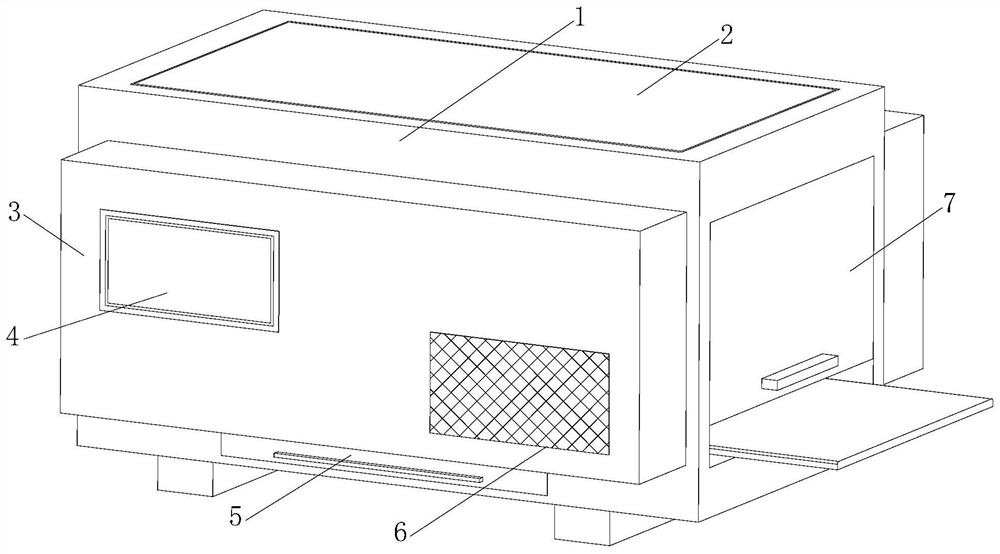

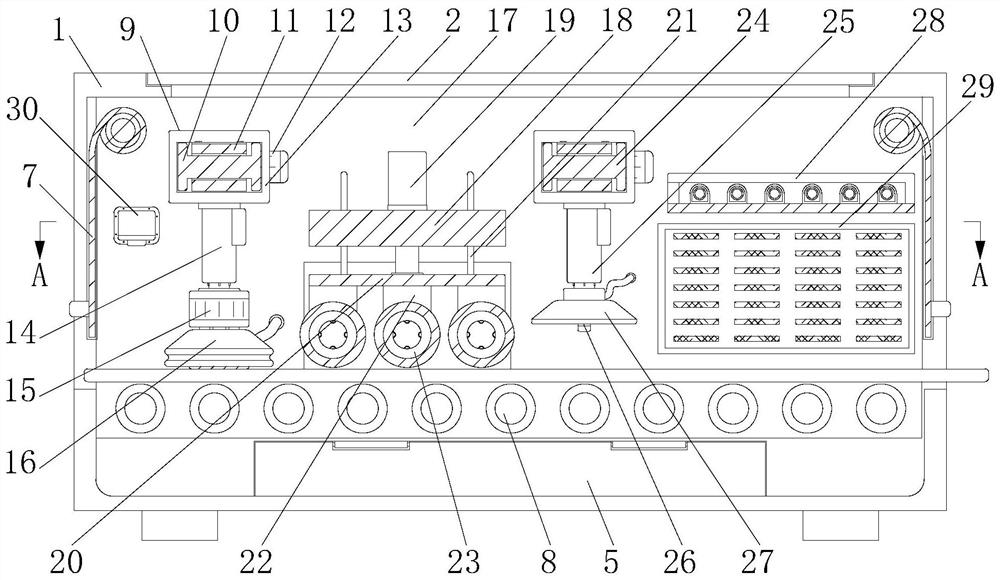

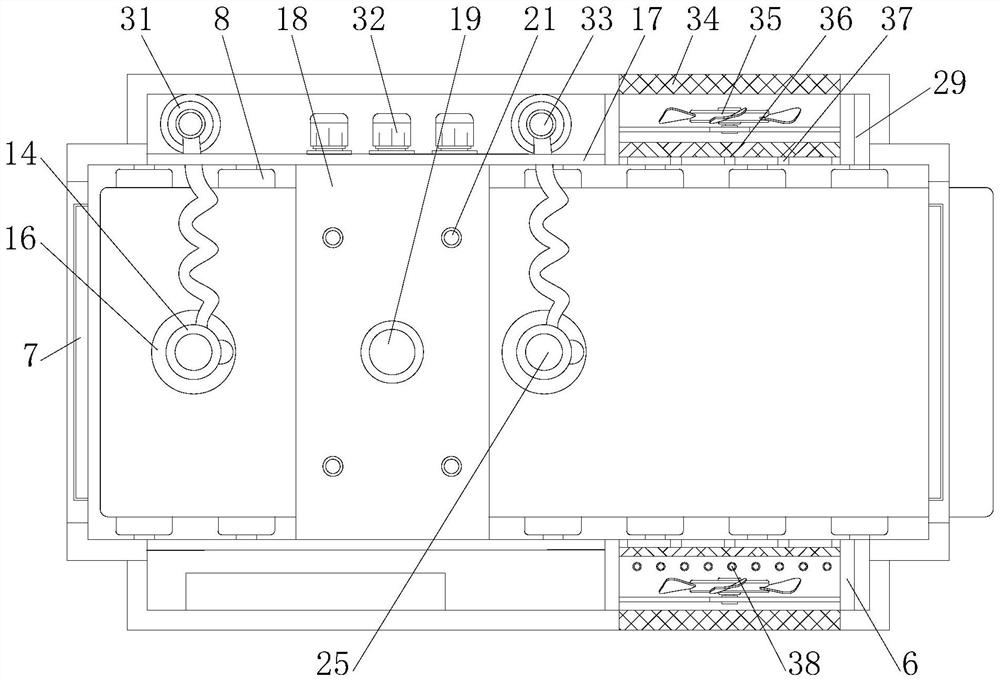

[0034] Such as Figure 1-Figure 4 As shown, a metal plate rust removal and painting processing equipment disclosed in the present invention includes a device body 1 and a plurality of horizontal and evenly arranged conveying rollers 8 located inside the device body 1 and perpendicular to the moving direction of the metal plate. The embodiment of the present invention One end of the same side of a plurality of conveying rollers 8 can be sleeved with a transmission belt, and the output shaft of the transmission motor drives the transmission action of the transmission belt, and then drives a plurality of conveying rollers 8 to run together, thereby causing the metal components on the upper surface to displace ;

[0035] The entrance end of the device body 1 is provided with a grinding assembly, which moves along the direction perpendicular to the movement of the metal sheet to grind the metal sheet. A cleaning component, the other side of the cleaning component is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com