Material chemical processing grinding device

A chemical processing and abrasive technology, applied in grain processing and other directions, can solve the problems of poor abrasive effect, restricting the probability of direct contact between abrasive devices and material particles, and inability to separate particles in time, so as to improve the effect, improve the abrasive rate, and avoid accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

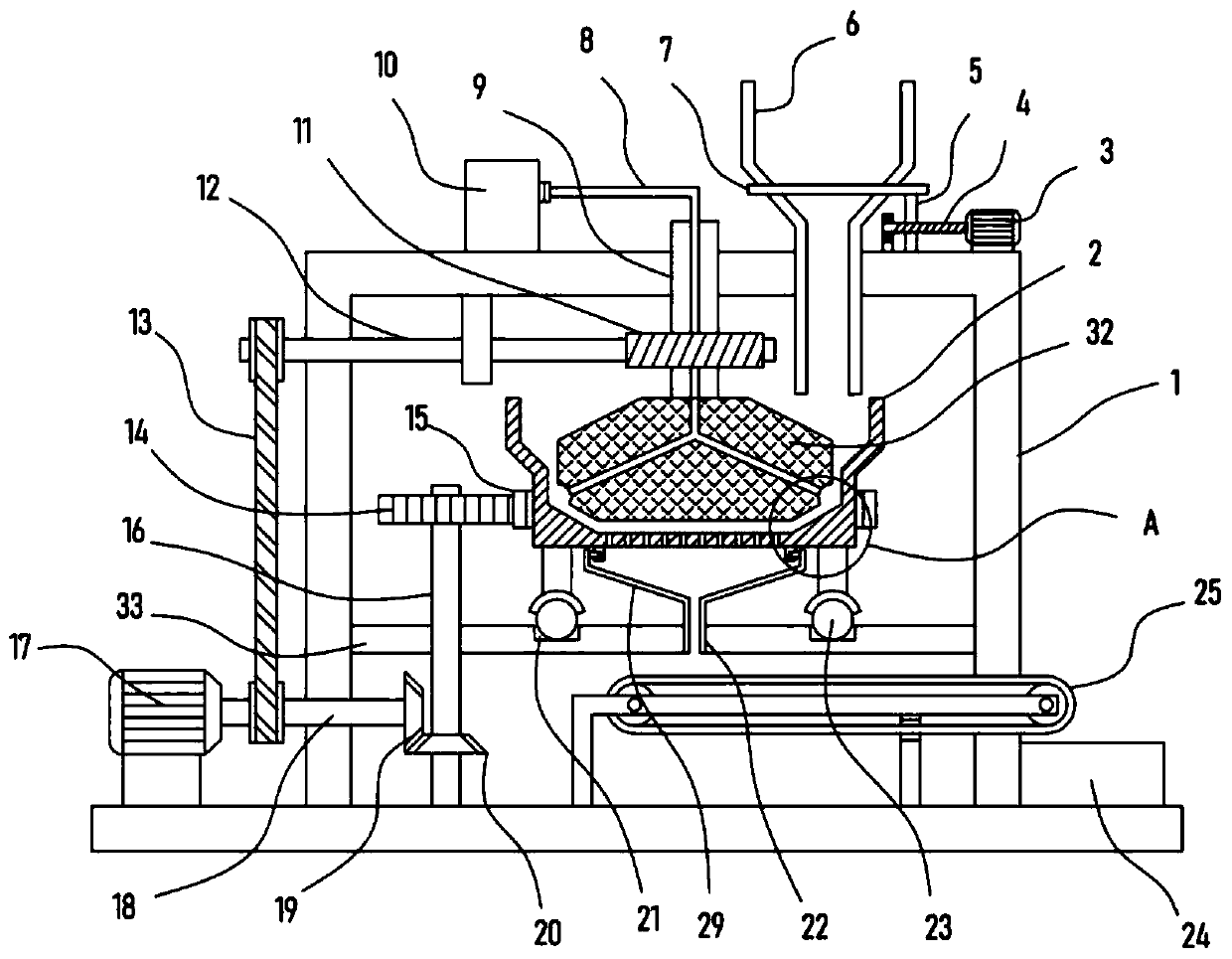

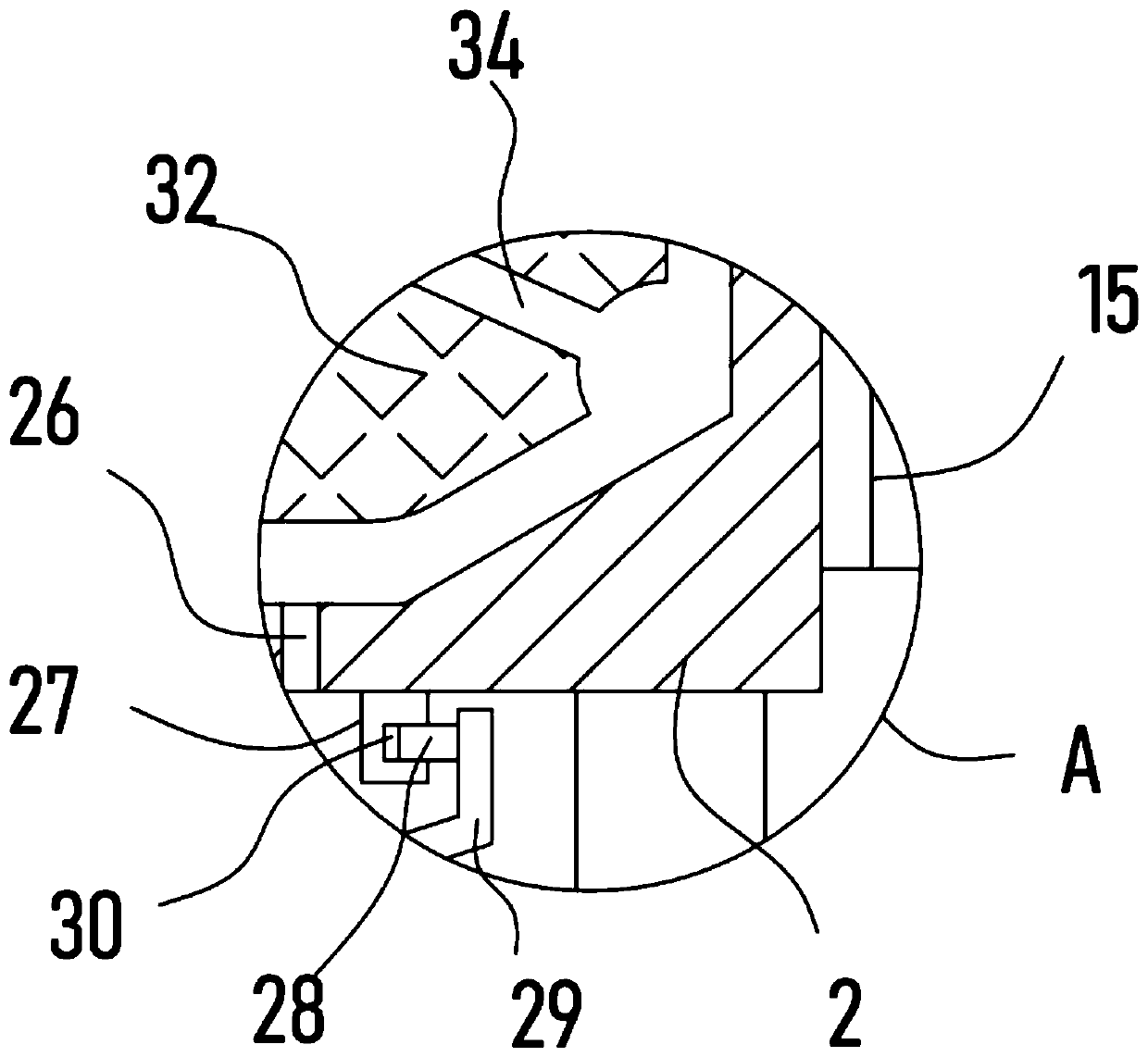

[0024] see Figure 1-4 , a material chemical processing abrasive device, comprising a support frame 1, a fixed plate 33 is horizontally fixed on the support frame 1, an abrasive groove 2 and an abrasive head 32 adapted thereto are arranged on the fixed plate 33, and the bottom of the abrasive groove 2 is evenly opened Several blanking mesh holes 26 are arranged, and a blanking hopper 29 is arranged directly below the abrasive trough 2, and a discharge pipe 22 is vertically connected to the bottom of the blanking hopper 29.

[0025] Before the chemical material is abrasive, the granular chemical material is placed inside the abrasive tank 2, and the abrasive operation of the chemical material is realized through the rotation of the abrasive head 32. Enter the blanking hopper 29 through the blanking mesh 26, and discharge through the discharge pipe 22, and the size of the blanking mesh 26 can be designed according to actual needs, so that the size of the blanking mesh 26 is cons...

Embodiment 2

[0032] In order to improve the abrasive effect of the chemical material and ensure the drying of the chemical material during the abrasive, on the basis of Embodiment 1, an air compressor 10 is provided on the top of the support frame 1, and the outlet end of the air compressor 10 is connected with a penetrating rotating shaft 9 and Extending to the air pipe 8 inside the abrasive head 32 , the air pipe 8 communicates with an air guide channel 34 extending to the side wall of the abrasive head 32 , and the end of the air guide channel 34 away from the air pipe 8 communicates with the inside of the abrasive tank 2 .

[0033] The airflow produced by the air compressor 10 enters the inside of the abrasive head 32 along the air delivery pipe 8, and the airflow flows to the inside of the abrasive groove 2 along the air guide passage 34 provided inside the abrasive head 32 to realize drying of the chemical material particles in the abrasive groove 2, avoiding Bonding occurs between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com