Semiconductor on insulator and methods of forming same using temperature gradient in an anodic bonding process

An anode connection, semiconductor technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as the limitations of semiconductor materials and insulating substrate characteristics, to simplify equipment, reduce investment and maintenance costs, and increase production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

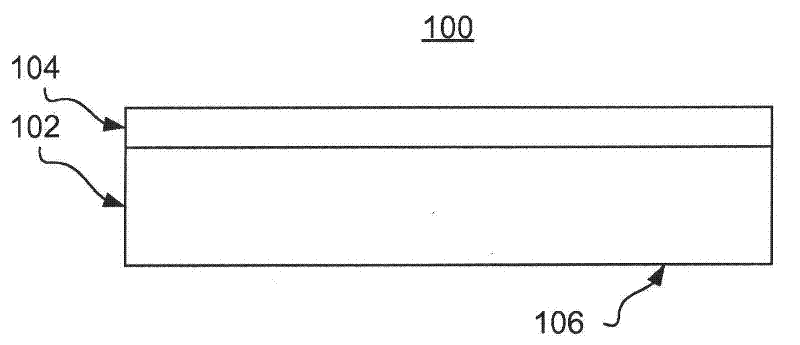

[0025] Referring to the drawings, wherein like reference numerals denote like elements, figure 1 An SOG structure 100 according to one or more embodiments disclosed herein is shown in FIG. The SOG structure 100 may include a glass substrate 102 and a semiconductor layer 104 . The SOG structure 100 has suitable use in the processing of thin film transistors (TFTs), for example, in display applications including organic light emitting diode (OLED) displays and liquid crystal displays (LCD), integrated circuits, photovoltaic devices, and the like.

[0026] The semiconductor material of semiconductor layer 104 may be substantially in the form of a single crystal silicon material. The term "substantially" is used to describe the semiconductor layer 104 in consideration of the fact that semiconductor materials generally contain at least some internal or surface defects, either inherent or intentionally added, e.g., lattice defects or a small amount of grain boundaries. The term ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com