Peculiar smell isolator and using method thereof

An isolator and odor technology, which is applied to indoor sanitary piping devices, water supply devices, buildings, etc., can solve the problems of poor odor isolation effect and poor adaptability, and achieve the effect of odor isolation and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

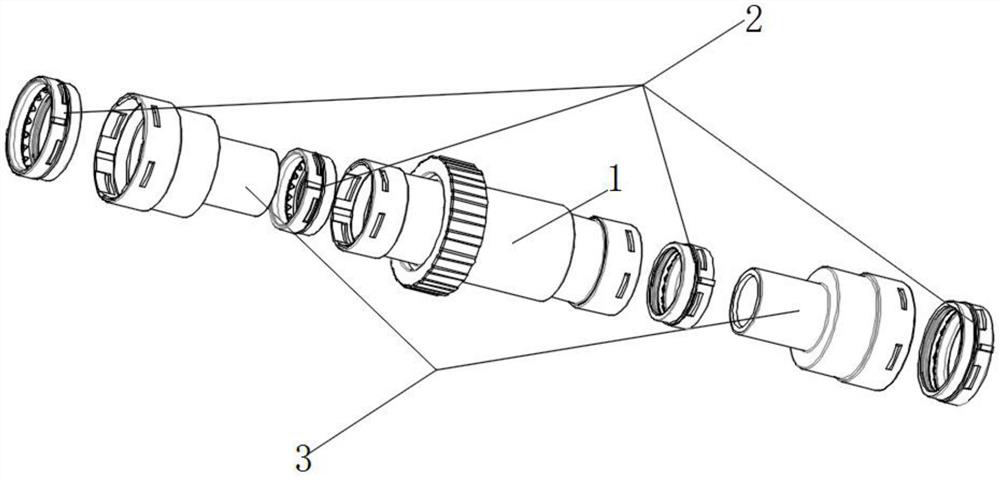

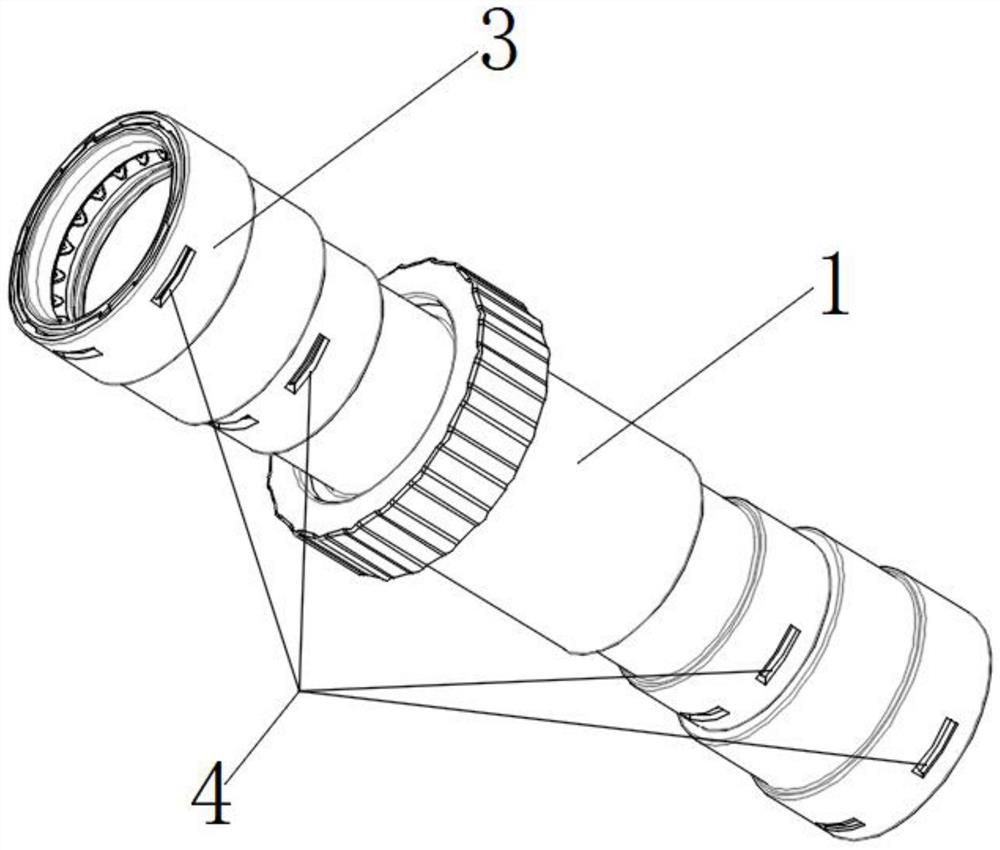

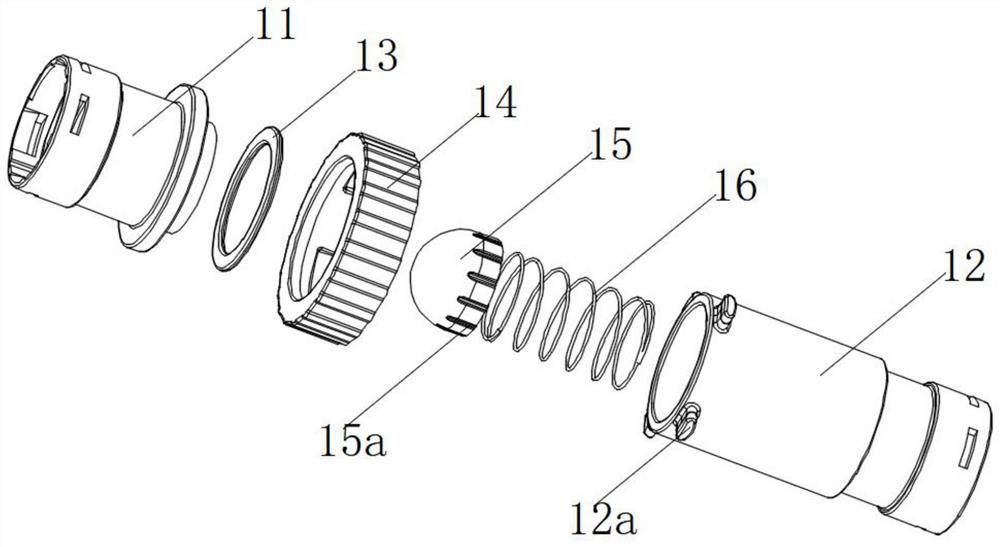

[0043] Combine below Figure 1 to Figure 7 As shown, the embodiment of the present invention provides an odor isolator, which includes an odor isolator body 1, a spring 16 is embedded in the odor isolator body 1, a ball cap 15 is fixed at the top of the spring 16, and the ball cap 15 The odor isolator main body 1 slides freely, the water inlet end and the water outlet end of the odor isolator main body 1 are both engaged with the adapter 3, and the odor isolator main body 1 and the adapter 3 are detachably connected, and the odor isolator main body 1 and the adapter 3 are detachably connected. The joint of the adapter 3 and the interior of one end of the adapter 3 away from the main body 1 of the odor isolator are provided with a sealing component 2 , and the main body 1 of the odor isolator and the adapter 3 are connected through the sealing component 2 .

[0044] Specifically, the odor isolator main body 1 includes an upper cover body 11, a lower body 12, a fixing sleeve 14,...

Embodiment 1

[0052] against Figure 1-7 The working principle of the specific embodiment 1 shown:

[0053] In this embodiment, when installing the product, ensure that the water flow is from the upper cover 11 to the lower main body 12. During horizontal installation, the water flows through the junction of the upper cover 11 and the lower main body 12 due to the pressure of the water flow itself. When there is no water flow in the pipe, the length of the spring 16 is greater than that of the lower body 12 because the length of the spring 16 is greater than that of the lower body 12. length, the spring 16 will make the ball cap 15 close to the outlet of the upper cover body 11, seal the upper cover body 11, and prevent the backflow of peculiar smell in the pipeline and the sewer; during vertical installation, due to the spring of the spring 16 The force is 60g, which is greater than the self-weight of the ball head cap 15, which can ensure that the ball head cap 15 can fit with the water ...

specific Embodiment 2

[0056] When using this odor isolator, its use steps are:

[0057] Sp1: When using this odor isolator, select a different adapter 3 according to the nominal diameter of the pipeline to be connected, and the main body 1 of the odor isolator can be directly connected to a DN25 pipeline;

[0058] Sp2: When using the adapter 3, sleeve the sealing assembly 2 on the adapter end of the adapter 3, and then insert the two sets of adapters 3 together with the sealing assembly 2 into the two ends of the main body 1 of the odor isolator, respectively. its connection is fixed;

[0059] Sp3: According to the nominal diameter of the pipeline, select the suitable sealing component 2 to be sleeved on one end of the pipeline, and then insert the pipeline together with the sealing component 2 into the adapter 3, and the sealing component 2 is connected to fix it;

[0060] Sp4: This product is suitable for all kinds of horizontally placed pipes and vertically placed pipes.

[0061] This product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com