A preparation method of needle-punched regenerated leather for automotive interior skin

A technology for automotive interiors and regenerated leather, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, and textile/flexible product manufacturing. Excellent, enhanced texture, optimized raw material ratio and production process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Prepare kraft fiber and 4080 fiber, accurately weigh 60Kg and 12Kg respectively, mix them and send them to the opener for rough opening and fine opening respectively.

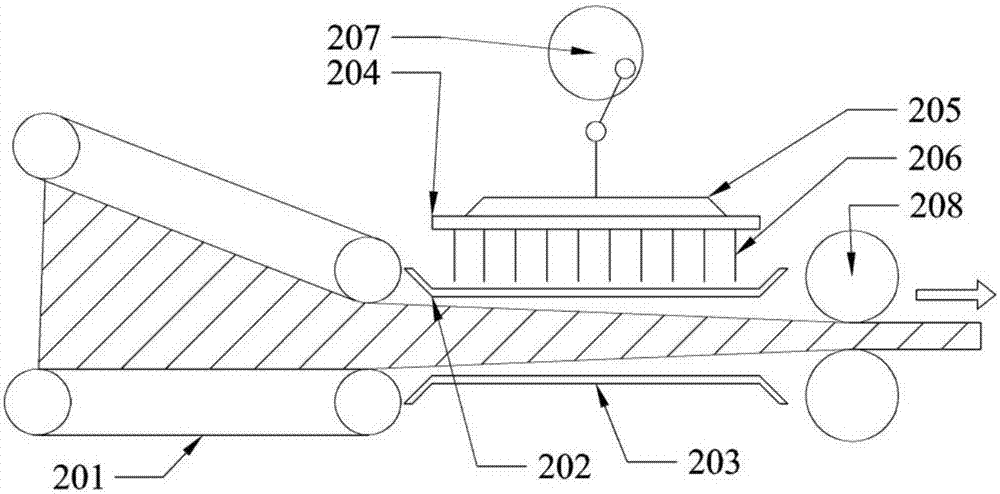

[0044] (2) Feed mixed fibers for air-forming. A 4080 fiber mat with a thickness of 50 μm is pre-laid on the output curtain, and then cross-folded and laid on the fiber mat. Divide the one-way trip of the net-laying trolley into five sections, the length ratio is 1:2:4:2:1, and the corresponding speed ratio of the net-laying trolley is 1.12:1.06:1:1.06:1.12.

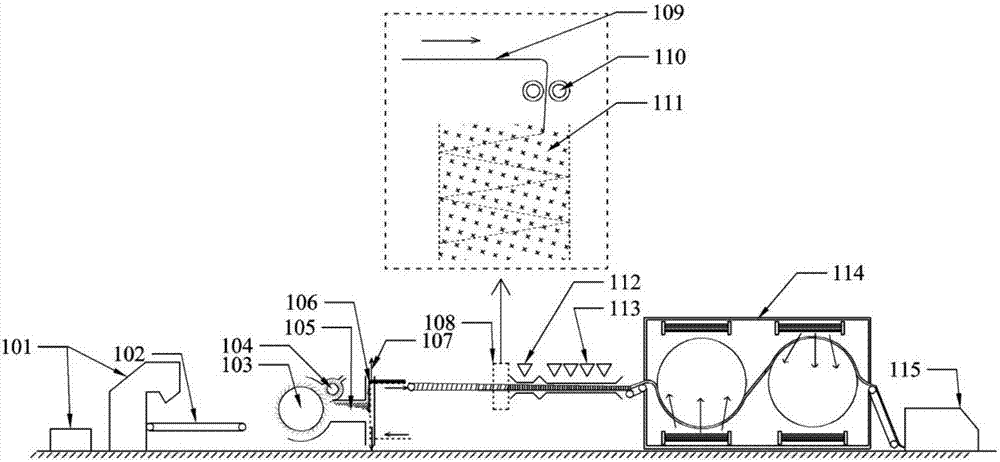

[0045] (3) if figure 1 As shown in 112, pre-acupuncture is carried out on the laid fiber web, the needle density is about 4000 pieces / m, the needle frequency is 500 punches / min, and the needle depth is 12mm. In order to fully reinforce the fiber mesh, the figure 1 In the position of 113 in the middle, 3 to 4 double-plate lower stab machines are used. The first acupuncture density is 350 pricks / cm 2 , the needling depth is 9mm; the second ne...

Embodiment 2

[0050] (1) Prepare the kraft fiber and N720 fiber, respectively accurately weigh 80kg and 12kg, mix them and send them to the opener for rough opening and fine opening respectively.

[0051] (2) Feed mixed fibers for air-forming. A 4080 fiber mat with a thickness of 100 μm is pre-laid on the output curtain, and then cross-folded and laid on the fiber mat. Divide the one-way trip of the net-laying trolley into five sections, the length ratio is 1:2:4:2:1, and the corresponding speed ratio of the net-laying trolley is 1.12:1.06:1:1.06:1.12.

[0052] (3) if figure 1 As shown in 112, pre-acupuncture is carried out on the laid fiber web, the needle density is about 3000 pieces / m, the needle frequency is 600 punches / min, and the needle depth is 9mm. In order to fully reinforce the fiber mesh, the figure 1 In the position of 113 in the middle, 3 to 4 double-plate lower stab machines are used. The first acupuncture density is 400 pricks / cm 2 , the needling depth is 9mm; the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com