Cooling water circulating device for non-woven fabric production

A technology of cooling water circulation and non-woven fabrics, which is applied in the direction of cleaning device for processing textile materials, equipment configuration for processing textile materials, spraying/spraying textile material processing, etc. It can solve the problem of long cooling time, achieve fast water cooling efficiency and improve efficiency , Improve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

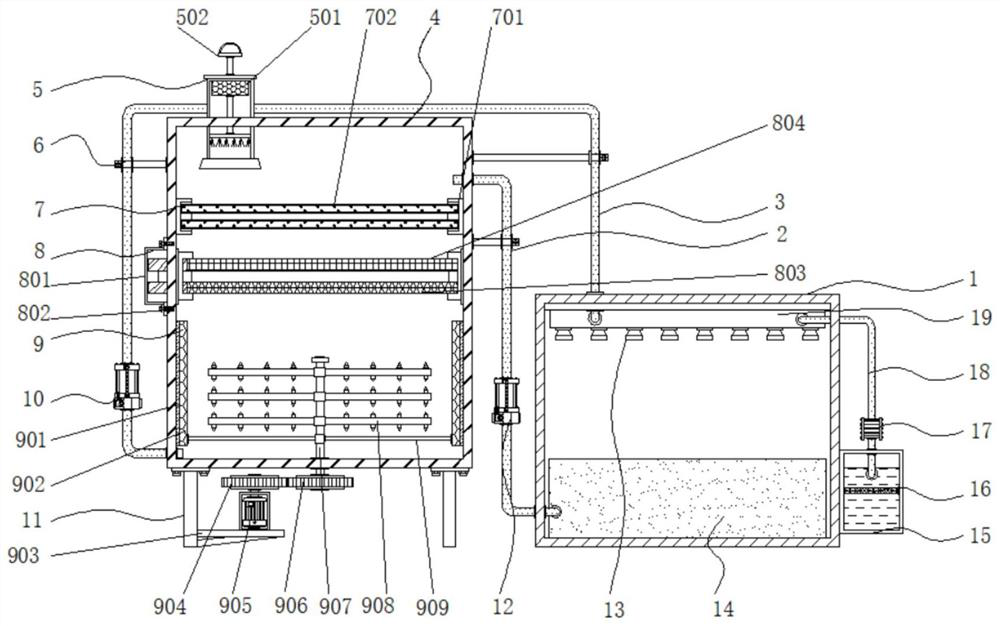

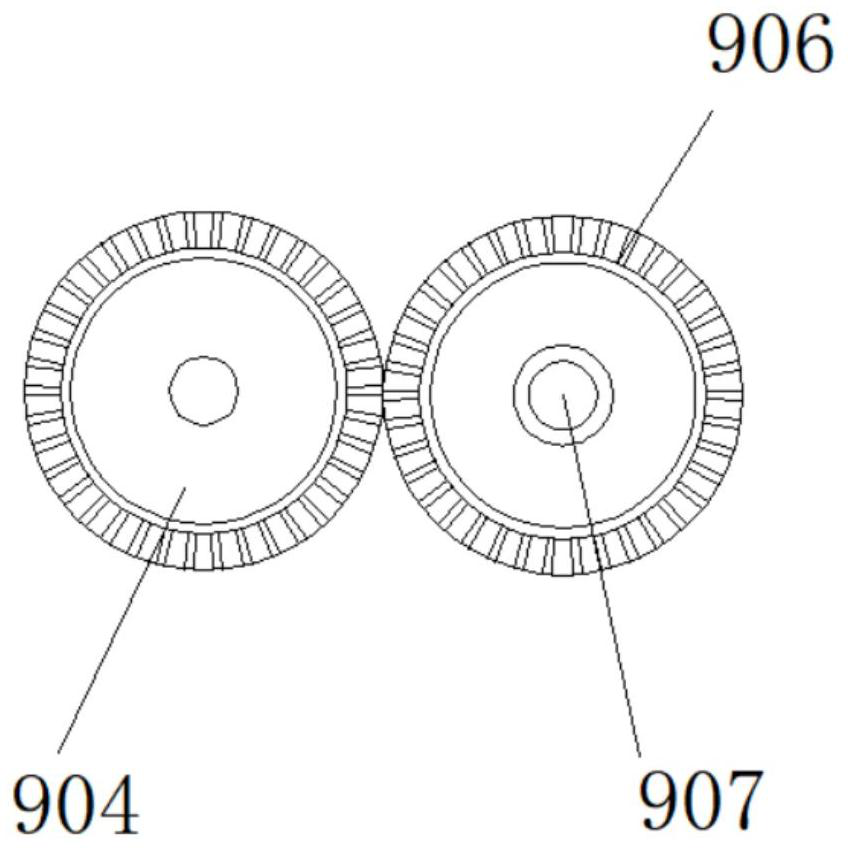

[0035] Example 1: See Figure 1-6 , a cooling water circulation device for non-woven fabric production, comprising a box body 4, a color removing structure 5 is arranged on one side of the top of the box body 4, legs 11 are fixedly connected to both sides of the bottom end of the box body 4, and the top of the box body 4 is provided with There is a purification structure 7, a filter structure 8 is arranged under the purification structure 7, a stirring mechanism 9 is arranged at the bottom end inside the box body 4, a cooling chamber 1 is arranged on one side of the box body 4, and a cooling chamber 1 is arranged at the bottom end inside the cooling chamber 1 A cooling pool 14, a cooling water circulation mechanism is arranged on one side of the cooling chamber 1;

[0036] see Figure 1-6 , a cooling water circulation device for non-woven fabric production also includes a cooling water circulation mechanism, the cooling water circulation mechanism includes a distribution pipe...

Embodiment 2

[0038] Embodiment 2: The color removal structure 5 is made up of a blocking block 501, a handle 502, a movable rod 503, a feed pipe 504, a material leakage port 505 and a cleaning plate 506, and the feed pipe 504 is fixedly connected to one side of the top of the box body 4, And the bottom end of the feed pipe 504 runs through the inside of the casing 4, the bottom end of the feed pipe 504 is fixedly connected with a material leakage port 505, and the top inside the feed pipe 504 is provided with a blocking block 501, and the internal movement of the blocking block 501 A movable rod 503 is connected, the top of the movable rod 503 is fixedly connected with a handle 502, and the bottom end of the movable rod 503 is fixedly connected with a cleaning plate 506, and the outer diameter of the cleaning plate 506 and the blocking block 501 is smaller than the inner diameter of the feed pipe 504;

[0039] Specifically, as figure 1 and Figure 6 As shown, after the blocking block 501 ...

Embodiment 3

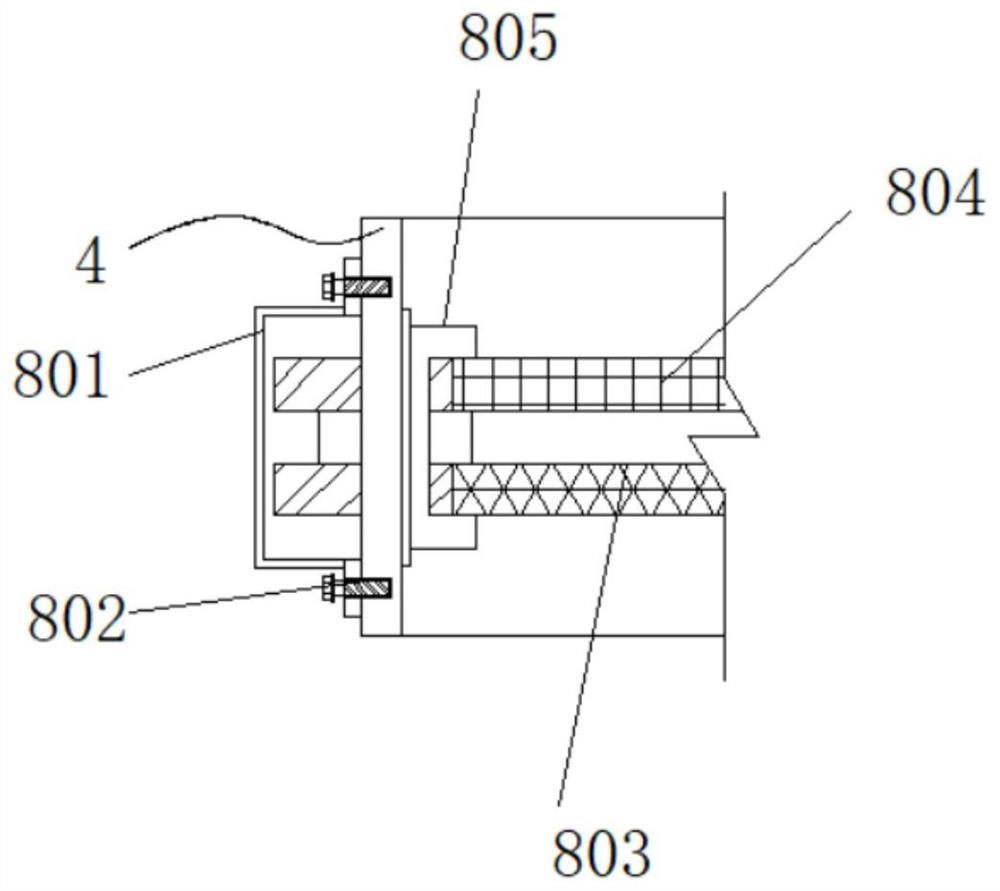

[0040] Embodiment 3: Purification structure 7 is made up of fixing seat 701, placing seat 702, water leakage port 703, placing groove 704 and activated carbon 705, and fixing seat 701 is provided with two groups and is respectively fixedly connected to one side of the inner top of box body 4 and the other side. On one side, the inside of the fixed seat 701 is provided with two groups of placement seats 702, the top and bottom ends of the placement seats 702 are fixedly connected with multiple groups of water leakage ports 703, the interior of the placement seat 702 is fixedly connected with a placement groove 704, and the placement groove 704 is provided with Multiple groups are arranged in a staggered manner inside the placement seat 702, and the interior of the placement groove 704 is filled with activated carbon 705;

[0041] Specifically, as figure 1 and Figure 4 As shown, two sets of placement seats 702 are arranged between the fixing seats 701, and the top and bottom e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com