A material feeding slurry making and classification recovery system for soil leaching and repairing

A recycling system and soil leaching technology, applied in the field of polluted soil leaching and remediation, can solve problems such as screen blockage and secondary pollution, and achieve the effect of avoiding blockage, ensuring normal construction and ensuring cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

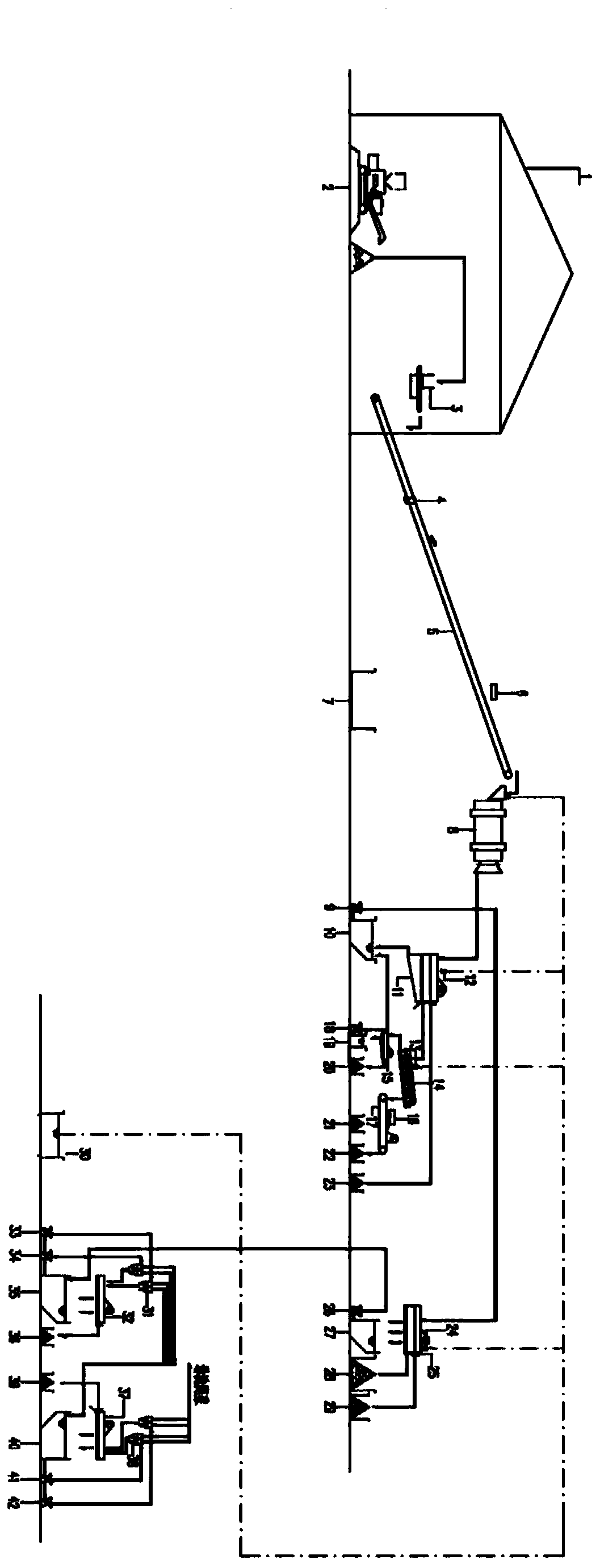

[0055] This embodiment provides a system for feeding slurry and graded recovery for soil leaching repair, such as figure 1 As shown, the system includes in order:

[0056] Crushing and screening module, the crushing and screening module includes a sieve with a screen aperture of 50mm, which is used to pretreat the contaminated soil into materials with a particle size of <50mm, so as to ensure the matching between the particle size of the feed contaminated soil and the system ;

[0057] Feed slurry making module is used for pulp making of feed contaminated soil, which is convenient for subsequent leaching and reduction of contaminated soil;

[0058] The leaching particle size module is used to leaching and recovering clean soil with different particle sizes to reduce the amount of pollution restoration work;

[0059] The washing water system, the crushing and screening module includes a feeding workshop 1 and a crushing and screening equipment 2 located therein; the crushing ...

Embodiment 2

[0091] The working steps of the soil rinsing and repairing system adopting the feeding pulping and classification recovery system of the present invention are as follows:

[0092] 1. Crushing and screening

[0093] Transport the excavated polluted soil to the feeding workshop, and use the crushing and screening machine to crush and screen in turn, and crush and screen the polluted soil containing two particle sizes of 50mm. The rinsing system is used to treat polluted soil with particle diameter<50mm;

[0094] 2. Feed pulp making

[0095] The crushed and screened <50mm particle size polluted soil is fed to the chain conveyor, and the chain conveyor feeds the contaminated soil to the belt conveyor I, and the belt conveyor is equipped with a belt scale to accurately adjust the amount of polluted soil. When the polluted soil goes to the high-level electromagnetic iron remover, the miscellaneous iron in the polluted soil is removed to the temporary storage area I of the miscella...

Embodiment 3

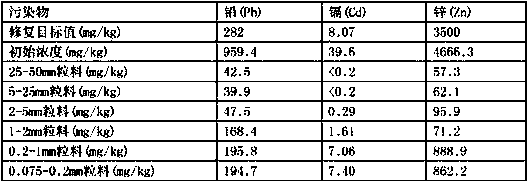

[0101] The feeding pulp making and classification recycling system of the present invention has been successfully applied to the soil leaching and restoration of a steel polluted site project in South China, the details are as follows:

[0102] The amount of soil remediation in this project is 517,591m3, among which heavy metal pollutants include Pb, Cd and Zn, etc.; the feed material for soil leaching is pretreated contaminated soil with a particle size of <50mm after crushing and screening, and the granular material is leached and classified as 25 -50mm, 5-25mm, 2-5mm, 1-2mm, 0.2-1mm, 0.075-0.2mm and <0.075mm, a total of 7 kinds of pellets. Among them, 25-50mm, 5-25mm, 2-5mm, 1-2mm, 0.2-1mm and 0.075-0.2mm, a total of 6 kinds of pellets are recyclable pellets. After soil sampling and testing, all the recyclable pellets after leaching meet the standard , can be recycled directly, the degree of reduction is 75-85%. The relevant data before and after washing treatment are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com