A filter and solid-liquid reaction system for solid-liquid reaction

A solid-liquid reaction and filter technology, which is applied in the direction of filtration separation, filtration circuit, chemical instruments and methods, etc., can solve problems such as pipeline blockage, inability to discharge materials, poor fluidity, etc., and achieve easy replacement, easy reuse, and guaranteed The effect of recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] as attached figure 1 to attach Figure 8 Shown:

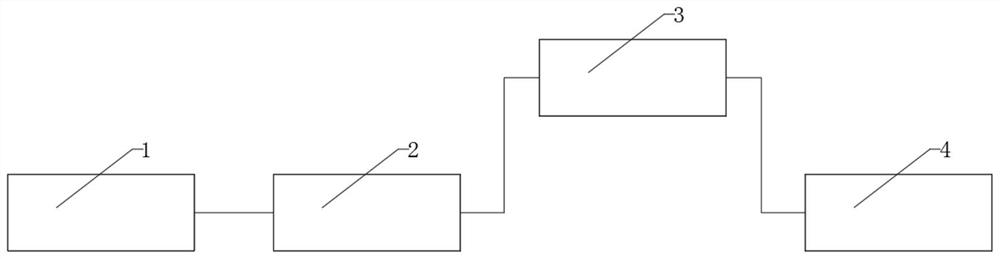

[0041] The present invention provides a solid-liquid reaction system, which includes a reaction kettle 1 , a settling tank 2 , a filter 3 and a filtrate tank 4 . The downstream of the reaction kettle 1 is connected to the settling tank 2, and the downstream of the settling tank 2 is connected to the filter 3; the downstream of the filter 3 is connected to the filtrate tank 4.

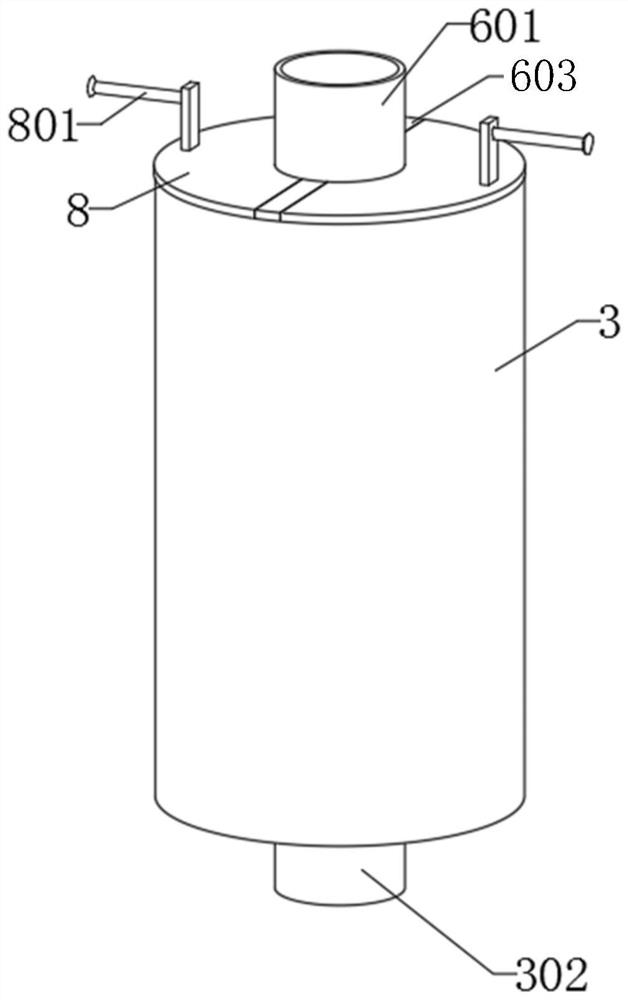

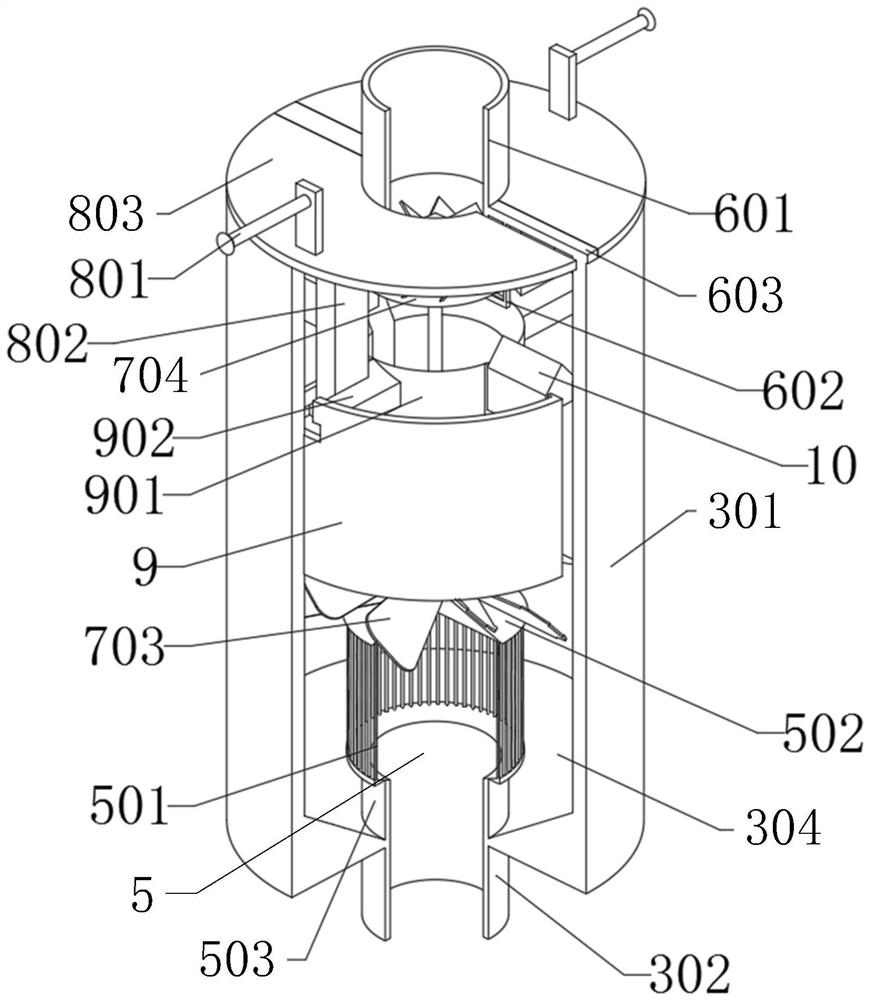

[0042] The filter 3 is a cylindrical structure, which includes a filter cylinder 301 , a feeding part 6 , a rotating part 7 , a primary filter part 9 , a secondary filter part 5 and a sealing plate 8 .

[0043]The filter cylinder 301 is a cylindrical structure, the top surface of the cylinder is open, and the bottom surface of the cylinder is provided with a discharge port. The discharge port is externally connected to a discharge connector 302 , and the discharge port is internally connected to a secondary filter element 5 . The feeding part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com