Novel bulkhead gate device capable of eliminating gate front vortex

A flat gate and vortex technology, which is applied in the field of new flat gate devices, can solve the problems of large size, great difficulty and influence over-current capacity of the vortex elimination frame, and achieves the effects of simple structure, easy maintenance and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

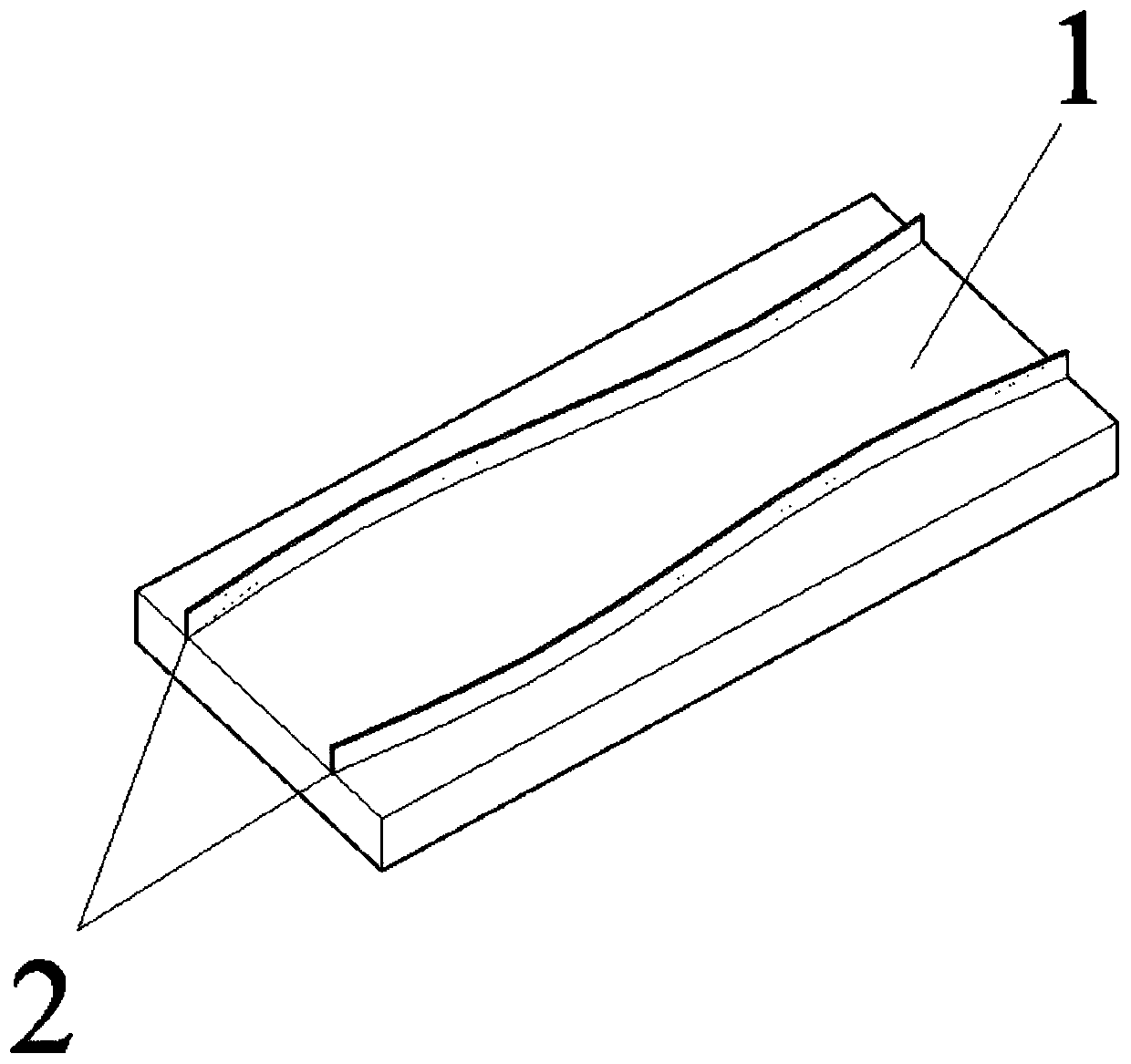

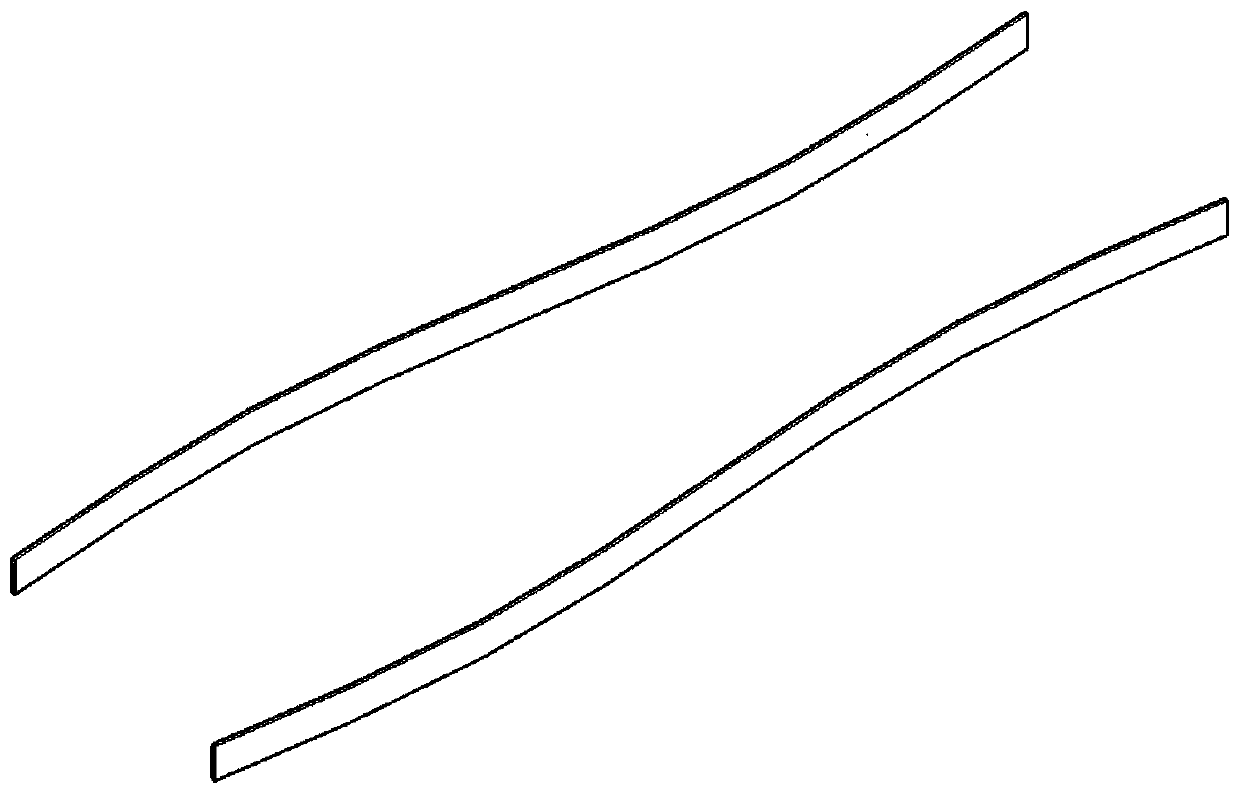

[0020] Such as figure 1 Shown is a new type of flat gate device that can eliminate the vortex in front of the gate, including a flat gate 1 and a curved grille 2 . The structure of the curved grille 2 is as follows: figure 2 , Figure 3(a), Figure 3(b) and Figure 3(c).

[0021] In this example, a flood gate is 16m high and 7m wide. Through model tests, it is found that the vortex in front of the sluice has different openings and different water depths in front of the sluice. The difference in the lateral position of the vortex is small. Move around 1.0m; replace the gate with the flat gate of the present invention that can eliminate the vortex in front of the gate, or install a curved grille 2 on the water facing surface of the gate to form the new flat gate device of the present invention that can elimin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com