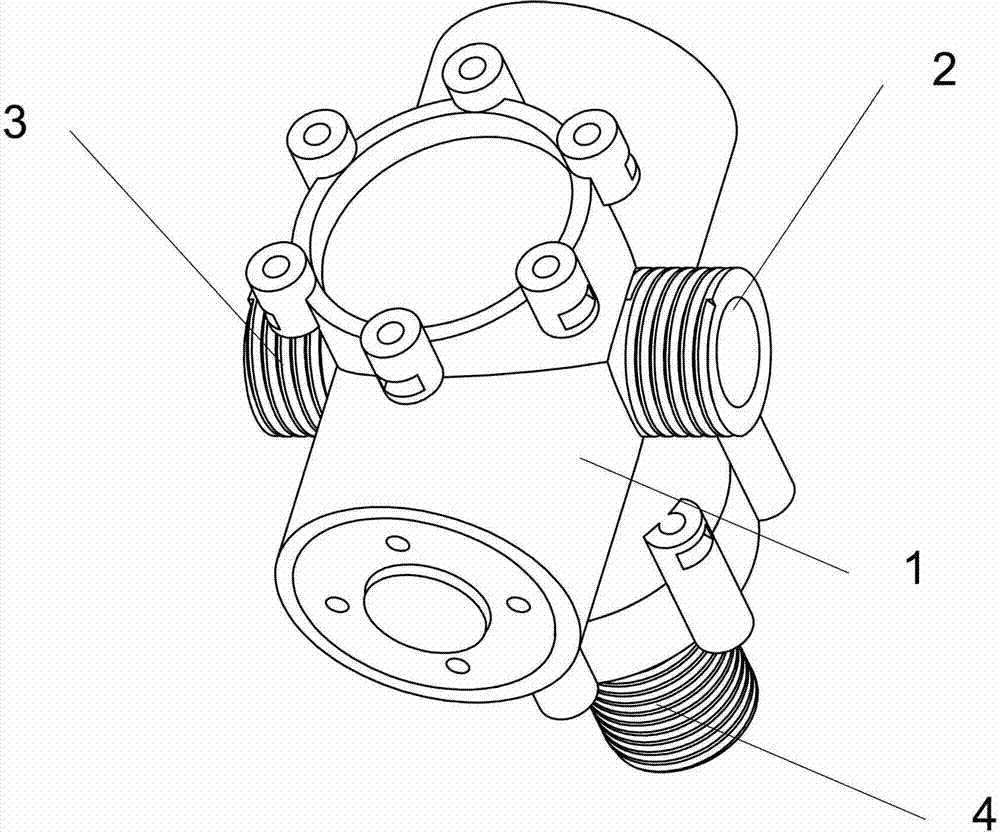

Valve core structure of water heater

A water heater and valve core technology, which is applied to multi-port valves, valve devices, engine components, etc., can solve the problems of unsatisfactory sealing performance, affecting bathing comfort, and large overall structure, and achieves simple and compact structure design and flow path design. Scientific and reasonable effect that meets comfort requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and specific embodiments.

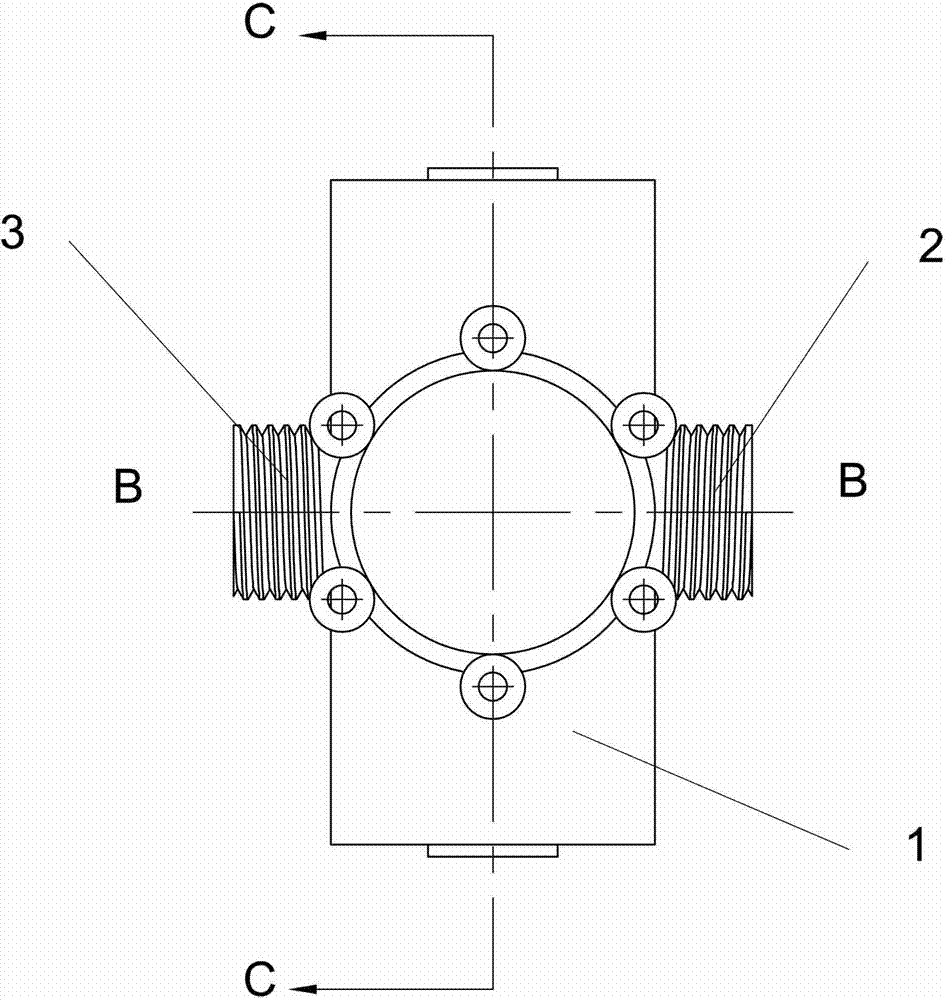

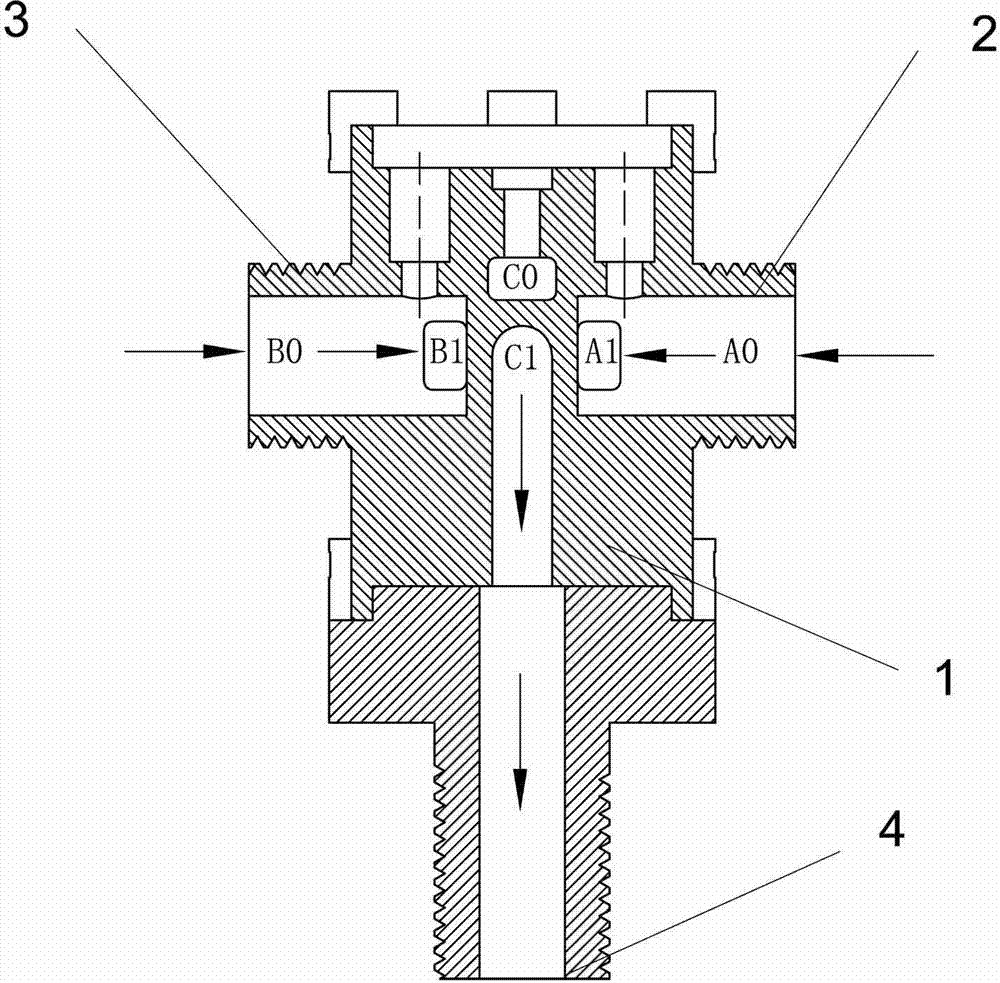

[0028] See figure 1 —6. A water heater valve core structure, including an integral valve body, which are respectively arranged in the automatic valve cavity 5 and manual valve cavity 6 of the valve body and the automatic valve core and the movable valve core. The valve body is also provided with a cold water pipe port 2. Hot water pipe port 3, water outlet pipe port 4, cold water pipe port 2 is the cold water flow channel A0 connected to tap water, and hot water pipe port 3 is the hot water flow channel B0 and water outlet pipe port connected to the inner tank of the water heater 4 is the outlet flow channel C1 leaving the valve body. The valve body 1 is provided with an automatic valve chamber 5 and a manual valve chamber 6; an automatic valve core is provided in the automatic valve chamber, and a manual valve core is provided in the manual valve chamber; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com