Synchronous opening/closing device for horizontal gate in hydraulic model test

A technology of opening and closing devices and hydraulic models, applied in the direction of hydraulic models, etc., can solve the problems of inability to affect the flow state, low precision, and easy damage of the structure, and achieve the effect of synchronous opening and closing with high synchronization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

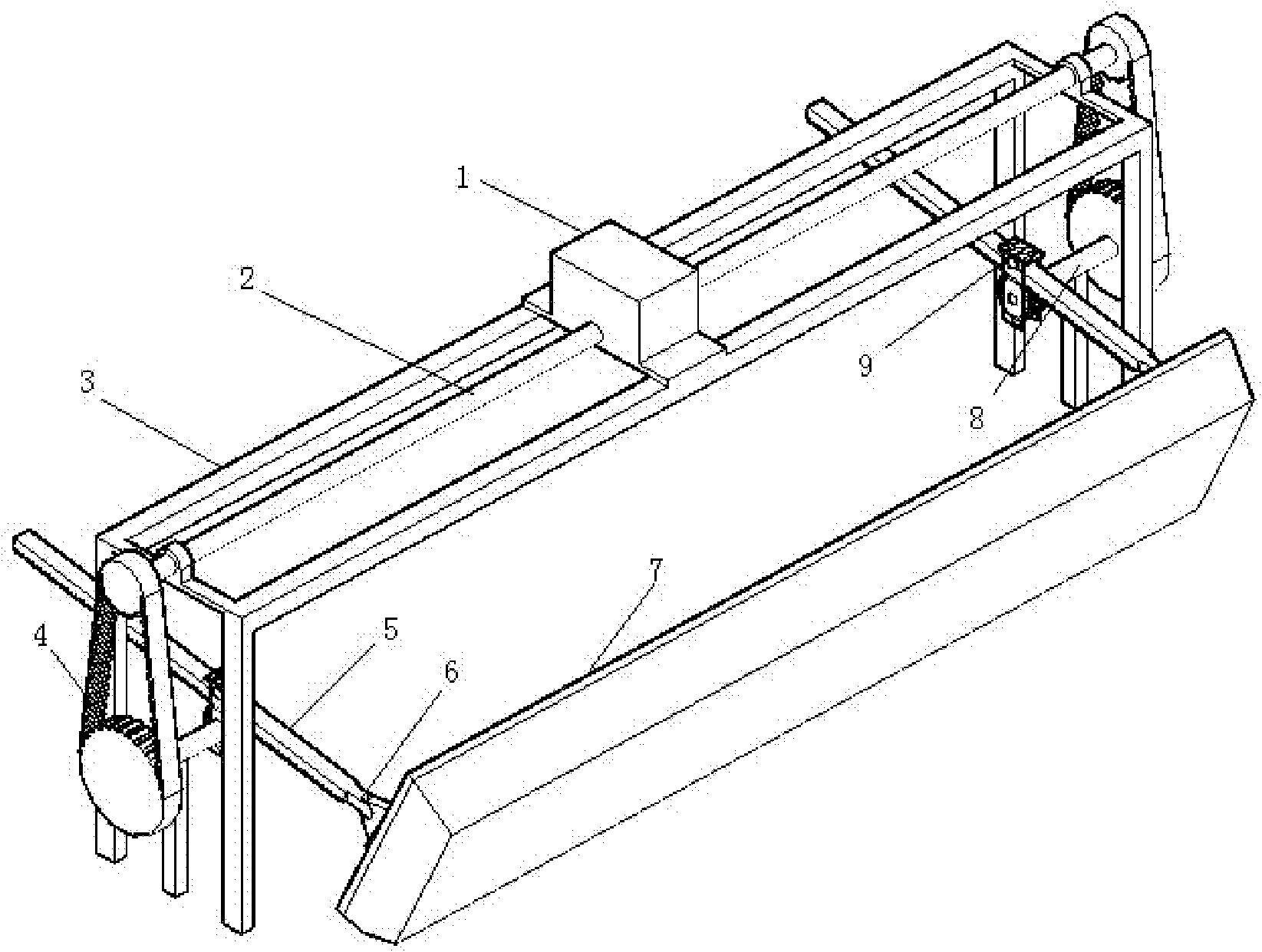

[0013] Due to site constraints and control accuracy, hydraulic model tests are not suitable for the large-scale gate synchronous opening and closing equipment used in actual engineering. The existing synchronous opening and closing equipment either affects the water flow state, or is difficult to maintain accurate synchronization, and cannot meet the demand. testing requirements. Therefore the present invention provides a kind of synchronous opening and closing device of horizontal gate of hydraulic engineering model test, please refer to figure 1 , the device includes a bracket 3, a speed-regulating motor 1, a gearbox, a main drive shaft 2 and two push-pull mechanisms with the same structure; the speed-regulating motor 1 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com