Oceangoing vessel ballast water processing method

A treatment method and technology for ocean-going ships, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of non-use and complicated piping system, and achieve the effects of convenient maintenance, reduced discharge time, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

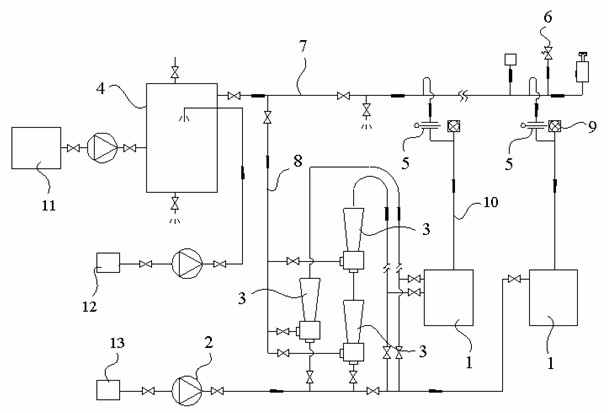

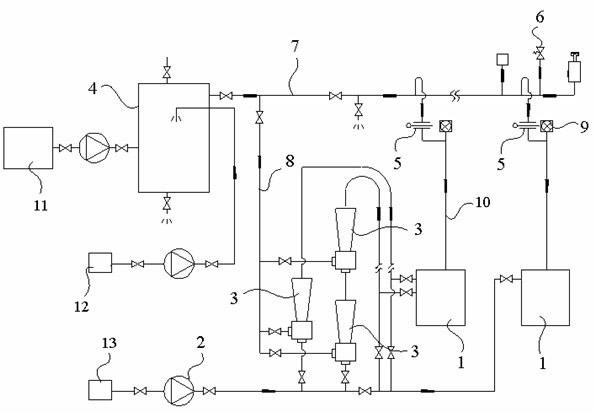

[0015] The present invention will be further explained below in conjunction with specific drawings.

[0016] A method for treating ballast water of an ocean-going ship, which first uses an inert gas to empty the air above the ballast water in the ballast water tank, then pumps the ballast water out of the ballast water tank, and uses the inert gas to treat the ballast water. Blowing off and mixing, a physical reaction occurs, and while sucking out the oxygen in the ballast water, the soluble inert gas is incorporated into the ballast water, and the treated ballast water can be discharged into the ballast water tank. The specific operation of the physical reaction is: mix the inert gas and ballast water in the Venturi injector, the inert gas forms a cavity in the high-pressure water flow, absorbs the oxygen dissolved in the water into the cavity, and then the cavity overflows from the water, Opened to atmosphere, the ballast water remains with dissolved inert gases.

[0017] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com