Self-packing dual-channel fluid control stepless fracture sliding sleeve device

A fracturing sliding sleeve and dual-channel technology, which is applied in the directions of sealing/isolation, wellbore/well valve device, production fluid, etc., can solve the problems of limited number of stages, low reliability, high operating cost, etc., and achieve reduction The effect of connecting tools, saving construction costs, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

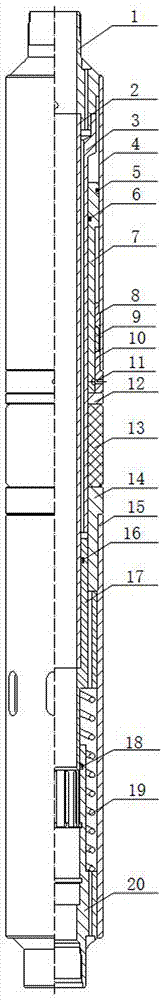

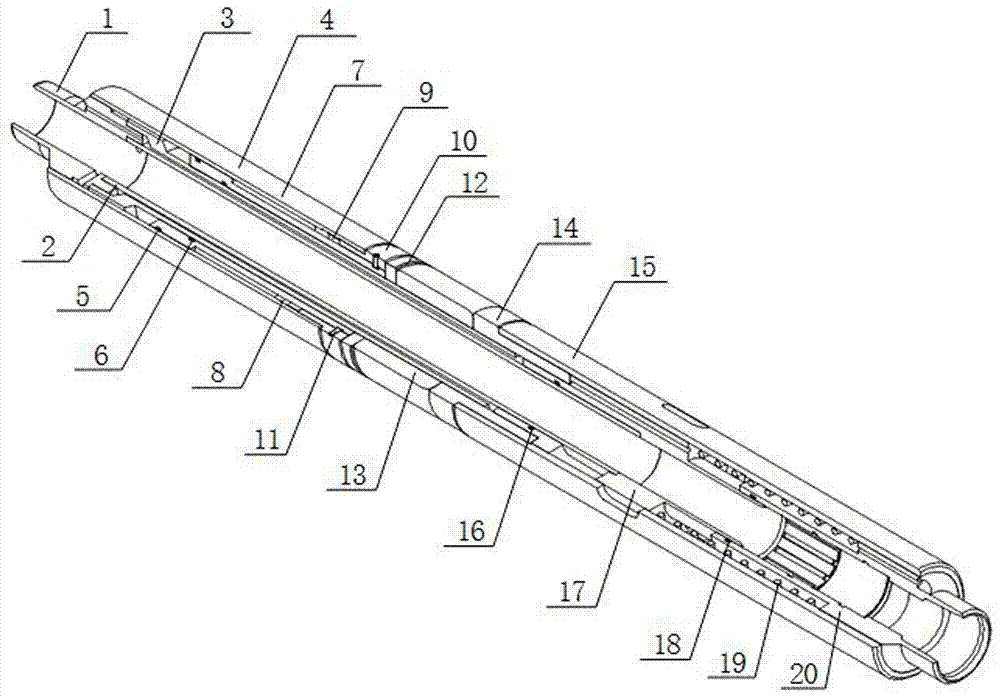

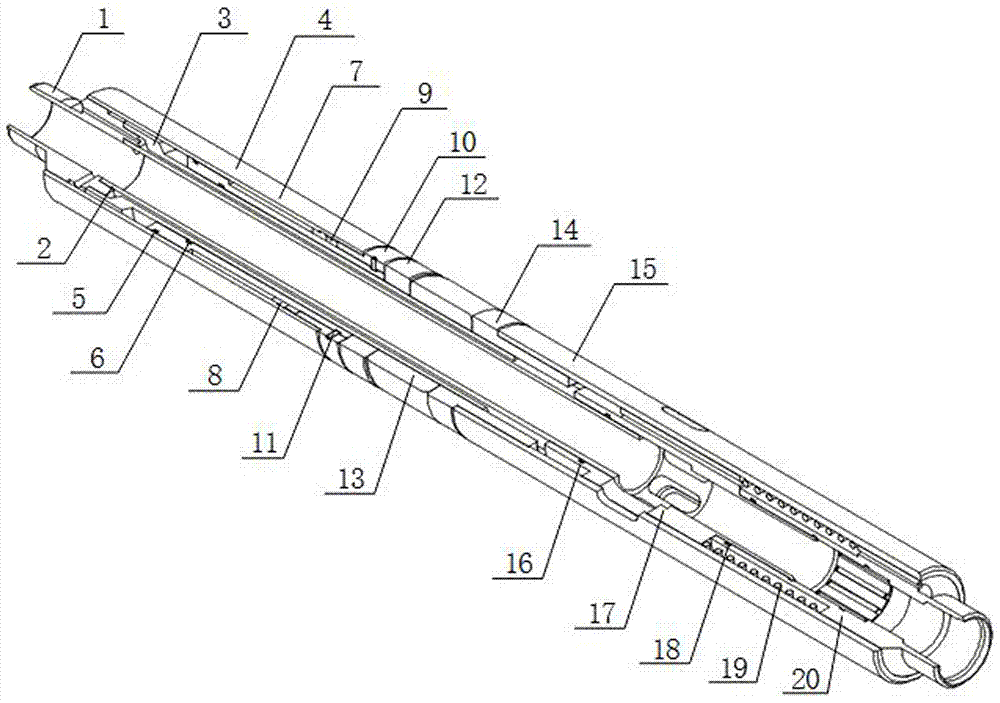

[0024] like Figure 1-9 As shown, the self-sealing double-channel hydraulically controlled stepless fracturing sleeve includes: upper distribution joint 1, inner central tube 2, outer central tube 3, outer sleeve 4, sealing ring 1 5, sealing ring 2 6, and piston 7 , Lock ring retaining ring 8, lock ring 9, upper pressure ring 10, shear nail 11, spacer ring 12, rubber tube 13, lower pressure ring 14, distribution sleeve 15, sealing ring 3 16, sliding sleeve 17, sealing ring 4 18. Pre-tension spring 19, lower joint 20; upper distribution joint 1 is provided with an outer oil pipe buckle 101 at the upper end, and upper distribution joint 1 is provided with an upper hydraulic control channel 102 in the axial direction between the inner and outer walls, and the upper distribution joint 101 is inside A setting hole 103 that does not interfere with the upper hydraulic control channel 102 is arranged radially between the outer walls. The inner thread at the lower end of the upper flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com