Steam pressure reduction power generation device

A power generation device and steam technology, applied in the direction of engine components, machines/engines, blade support components, etc., can solve the problems of low operating efficiency, low stand-alone power, high manufacturing cost per kilowatt, etc., to achieve small operation and maintenance workload, Improve the running stability and buffer the effect of steam pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

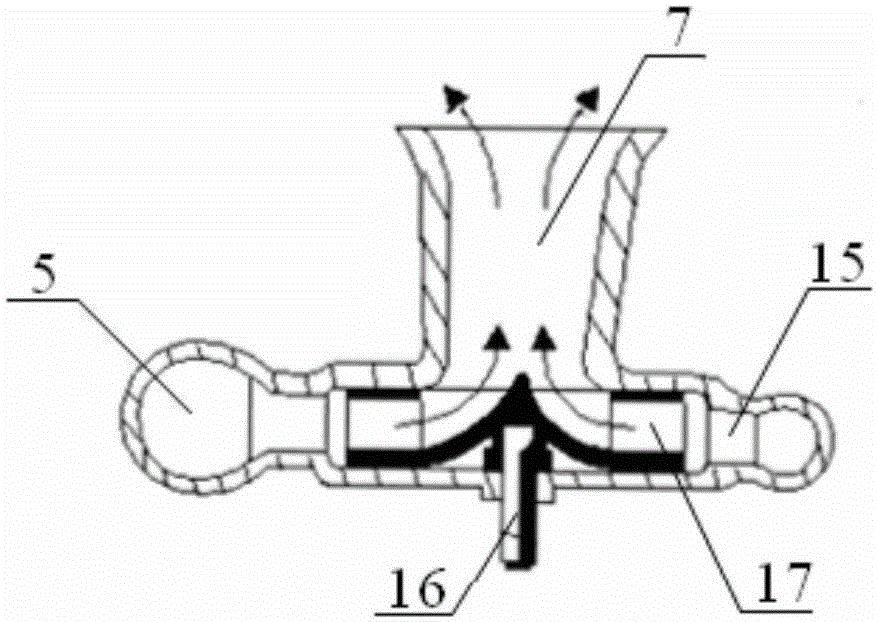

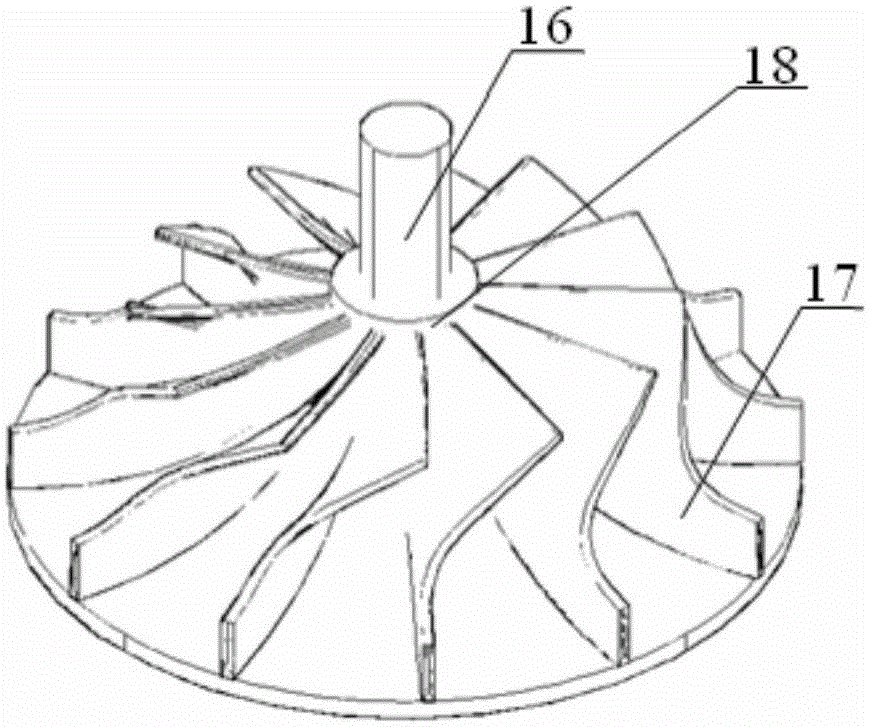

[0058] The rotating shaft 16 inside the radial steam turbine 6 drives the generator to generate electricity through the rotating shaft 7, and can also drive the fan and water pump power-consuming equipment. The speed of the steam turbine is converted into the speed required by the driven equipment.

Embodiment 2

[0060] A chemical plant needs to heat water vapor during the process, and the steam consumption is 70 tons per hour. The source steam pressure of the production process is 1.1 MPa, and the actual steam pressure is 0.42 MPa, which requires decompression of the steam. The radial steam turbine can be used to depressurize the steam, and at the same time output electric energy to avoid the waste of steam quality caused by direct throttling and depressurization.

[0061] After calculation, it can be seen that:

[0062] Steam enthalpy at the inlet of the steam turbine: 3166.8kJ / kg; enthalpy after steam turbine work: 3003.4kJ / kg; steam flow: 70000 / 3600=19.4kg / s;

[0063] Generating power: 2944kW; annual generating capacity: 20.61 million kWh.

Embodiment 3

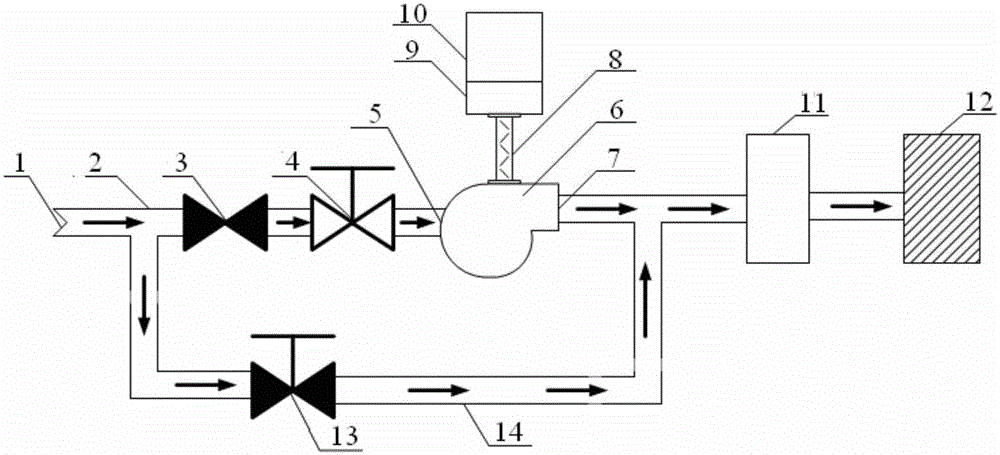

[0065] Such as figure 1 In the steam decompression power generation device shown, in order to meet the different steam consumption requirements of the lower-level steam equipment, the steam pipeline 2 is also provided with a steam branch pipeline 14 to avoid the consumption of the steam source through the radial steam turbine. Regulating valve 13 adjusts and directly transports to the steam storage tank 11 for storage, meeting the requirements of lower-level steam consuming equipment for high-pressure steam.

[0066] The operation and maintenance workload of the system is small. The system is equipped with a normally closed bypass line. When the generator set is overhauled, the bypass steam pipe is opened, which does not affect the normal steam delivery of the factory. The generator set requires no energy and other operating costs other than steam. When downstream steam users intermittently use steam, causing steam pulsation in the pipe, as a preference, a steam storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com