Rigid dry high-voltage cable terminal end

A technology for high-voltage cables and terminals, which is applied in the field of rigid dry-type high-voltage cable terminals, can solve the problems of long construction time, large size of cable terminals, and accidents, and achieve small operation and maintenance workload, excellent explosion-proof performance, The effect of not being easy to pollute the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

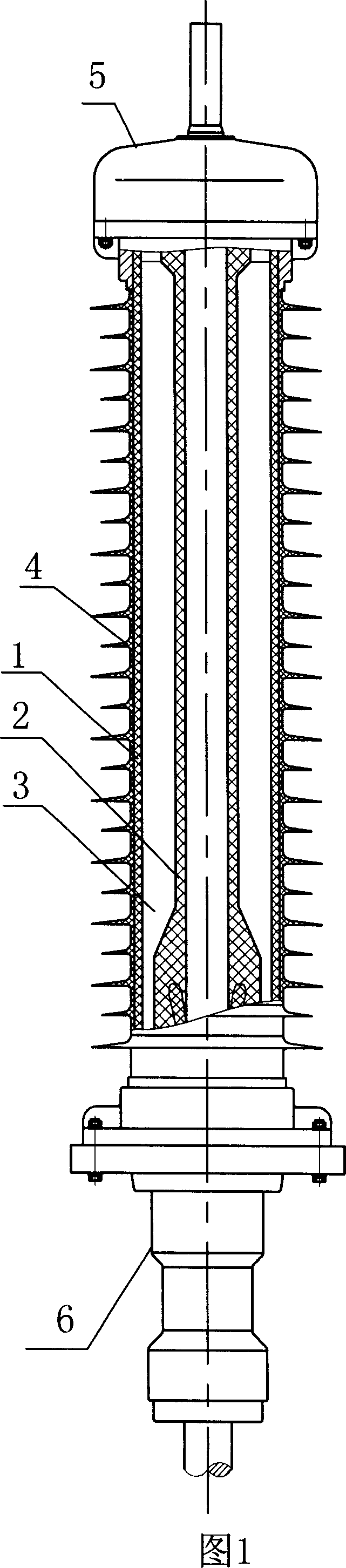

[0008] This embodiment is composed of a silicone rubber composite epoxy sleeve 1, a stress control body 2, a silicone rubber insulating material 3, a silicone rubber shed 4, a sealing cap 5, and a tailpipe 6. The silicone rubber composite epoxy sleeve 1 and the stress Silicone gel insulating material 3 is filled between the control body 2 to form a polymer insulation layer; the upper and lower ends of the silicon rubber composite epoxy sleeve 1 and the stress control body 2 are sealed by sealing caps 5 and tail pipes 6 respectively. The outer wall of the silicone rubber composite epoxy casing 1 is provided with an umbrella skirt 4 with an antifouling effect.

[0009] The overall weight of the terminal is light, and the on-site installation process is simple. The cable insulation surface is treated according to the usual procedures, the cable is stripped and cut, and then the terminal part is inserted into the stripped and cut cable, and the sealing cap and the tail pipe are sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com