Feeding and discharging device and detection equipment

A technology for testing equipment and turning materials, applied in lighting and heating equipment, conveyor control devices, transportation and packaging, etc., can solve the problems of large space occupation and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

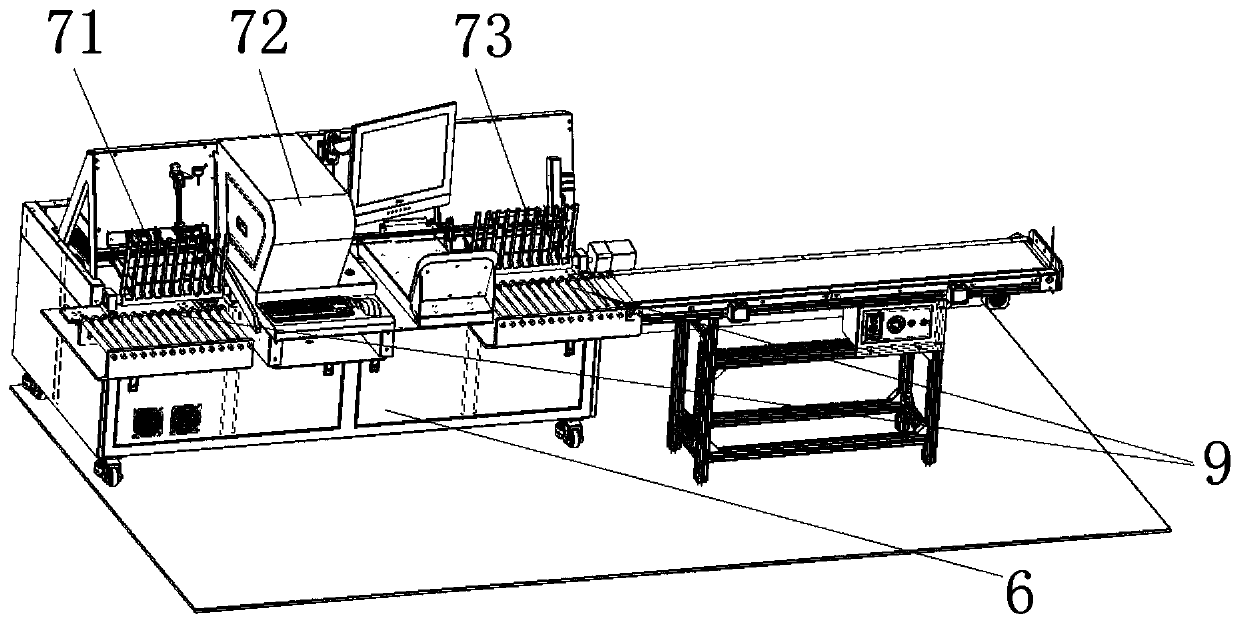

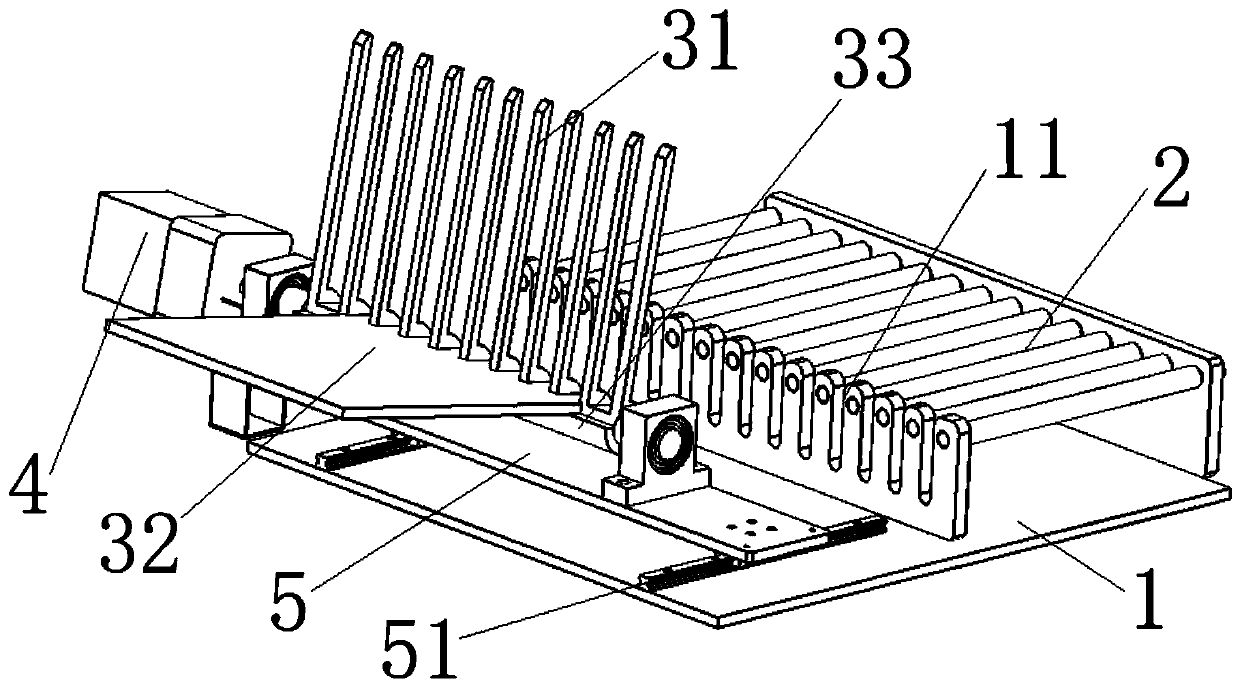

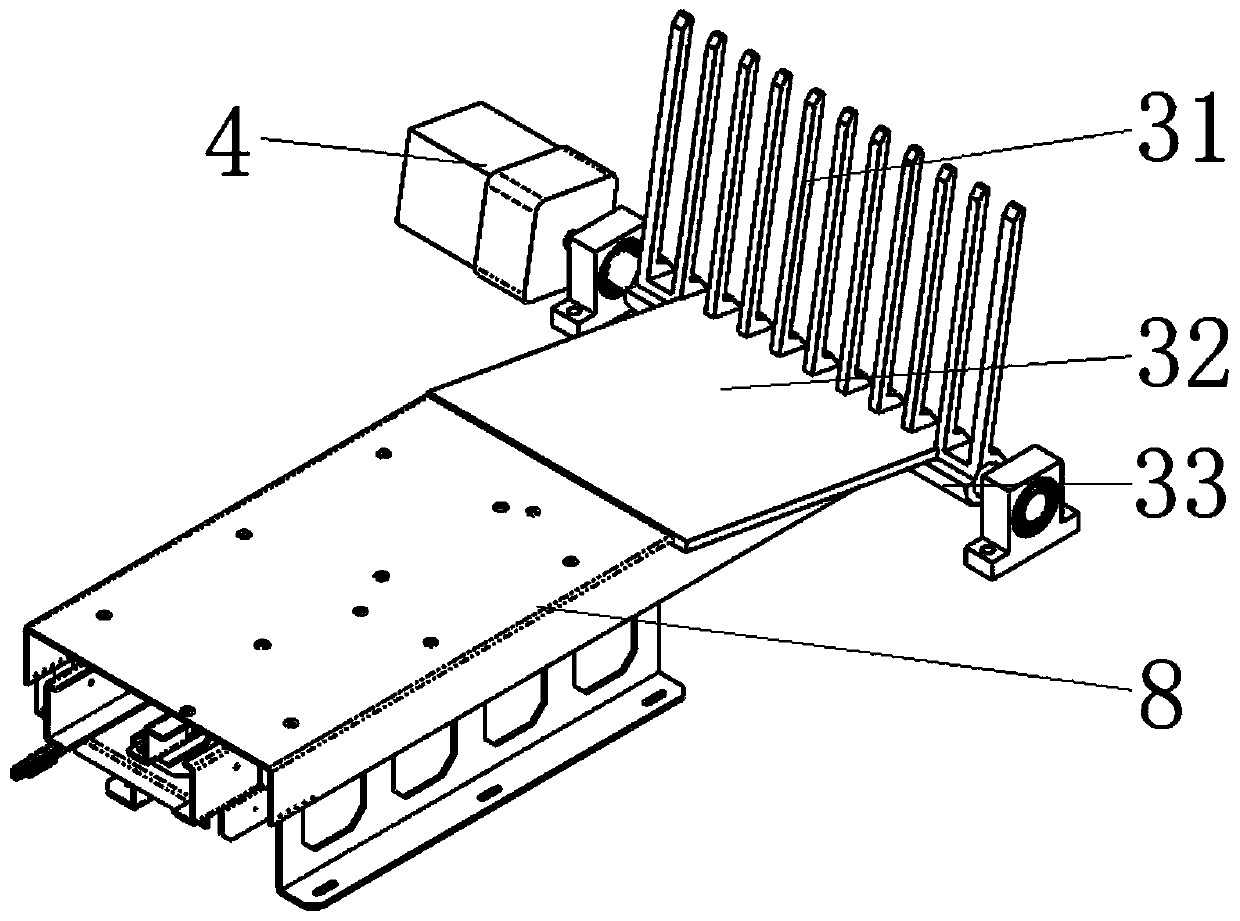

[0049] like figure 1 A detection device shown includes a base frame 6, and fixed on the base frame 6: a loading area 71, a detection area 72, an unloading area 73 and a limit piece 8, and the workpieces to be processed pass through the loading area in sequence 71. Detection area 72 and feeding area 73. Wherein in feeding area 71, and in unloading area 73, be respectively provided with such as Figure 2 to Figure 3 The shown loading and unloading device 9; a detection device is provided in the detection area 72, specifically, the detection device can be a visual detection device; the limit member 8 has an inclined limit surface, and the inclined limit surface is inclined upward along the direction away from the conveying line , the second support member 32 in the loading and unloading device 9 overlaps the inclined limit surface when transferring the workpiece to be processed. Specifically, the workpiece to be processed may be a PCB board or others.

[0050] It should be not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com