An internal-external heating type pyrolysis device

A double-heating, pyrolysis technology, applied in special forms of dry distillation, direct and indirect heating combined dry distillation, petroleum industry, etc., can solve problems such as increasing application value, shortening reaction cycle, and low efficiency of biomass pyrolysis, achieving Effect of increasing application value, reducing energy consumption, improving pyrolysis efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The beneficial effects of the present invention will be further described below in combination with the specific examples given by the inventor.

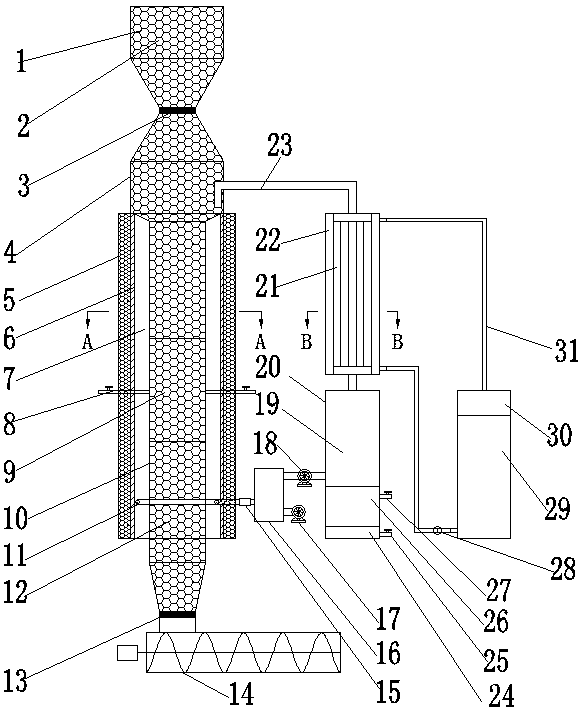

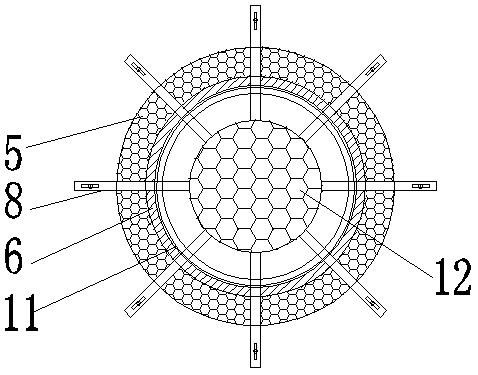

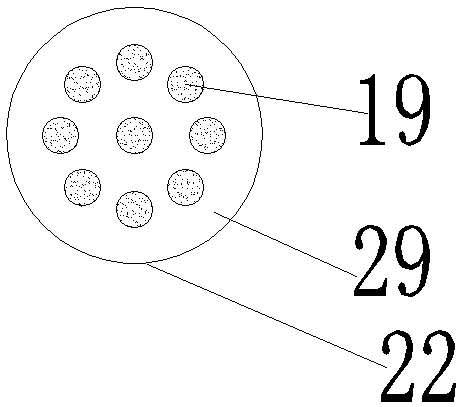

[0016] figure 1 A schematic diagram of the structure of the internal and external double-heating pyrolysis device of the present invention is given, including a furnace body. The upper part of the furnace body is an upper hopper 1 and a raw material settling chamber 4. The lower end of the upper hopper 1 and the upper end of the raw material settling chamber 4 pass through the No. 1 gate valve. 3 connections; figure 2 It is an enlarged view of the A-A view of the furnace body, the outermost layer of the middle section of the furnace body is an insulating layer 5, and the inside thereof is a refractory layer 6, and the upper end of the pyrolysis reaction tube 10 located in the center of the furnace body is connected to the lower end of the raw material settling chamber 4; The lower end of the pyrolysis reaction tube 10 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com