Patents

Literature

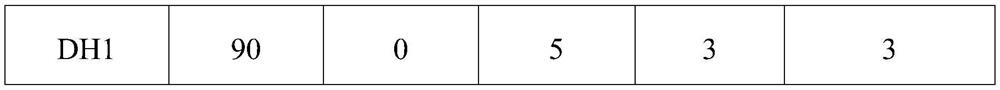

71results about How to "Lower gasification temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

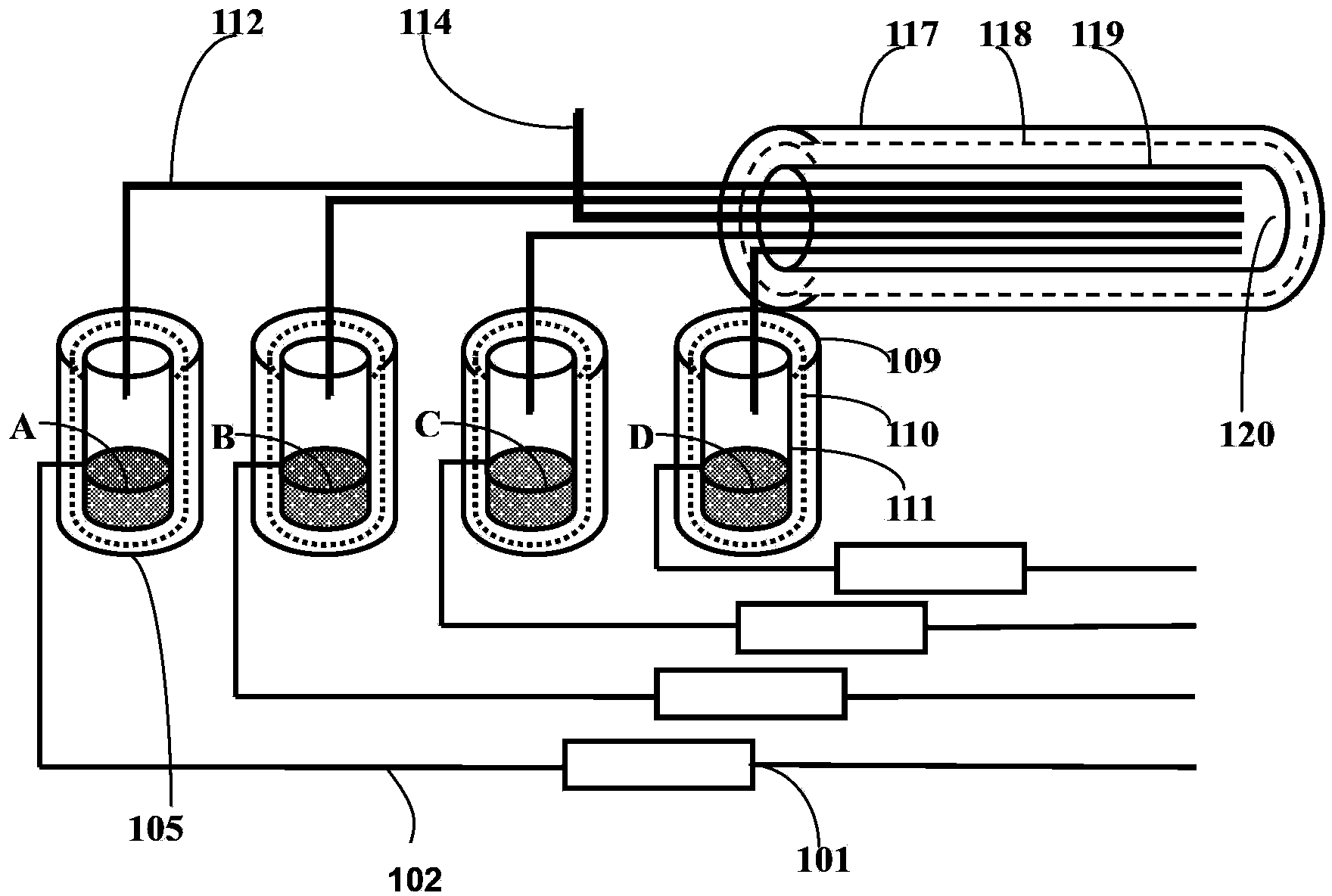

Optical fiber perform doper and doping method

InactiveCN103359927AImprove consistencyImprove uniformityGlass making apparatusHeating systemMetal chelate

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

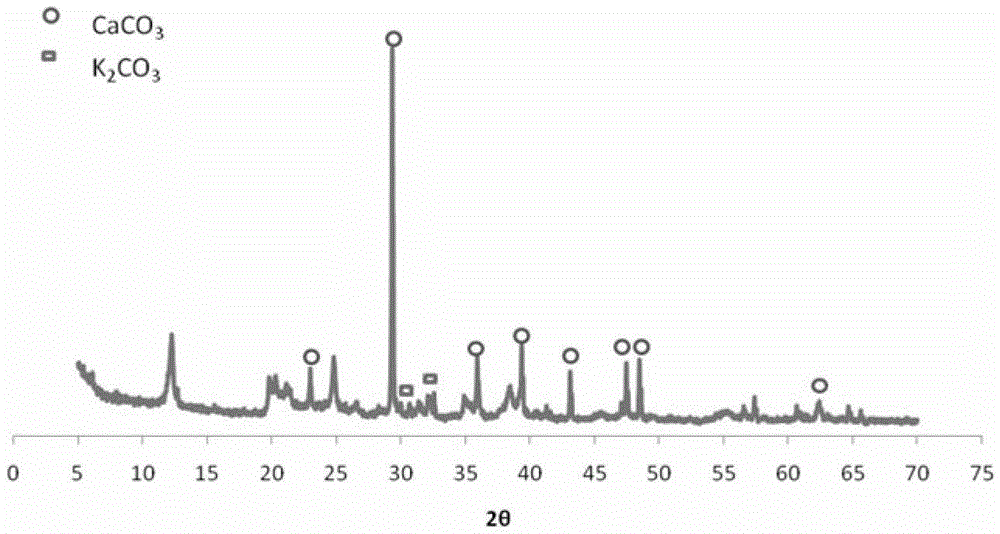

Multifunctional catalysis composition

ActiveCN103566962AGood catalytic coke gasification abilityLower gasification temperatureCatalytic crackingMolecular sieve catalystsBoehmiteOxide

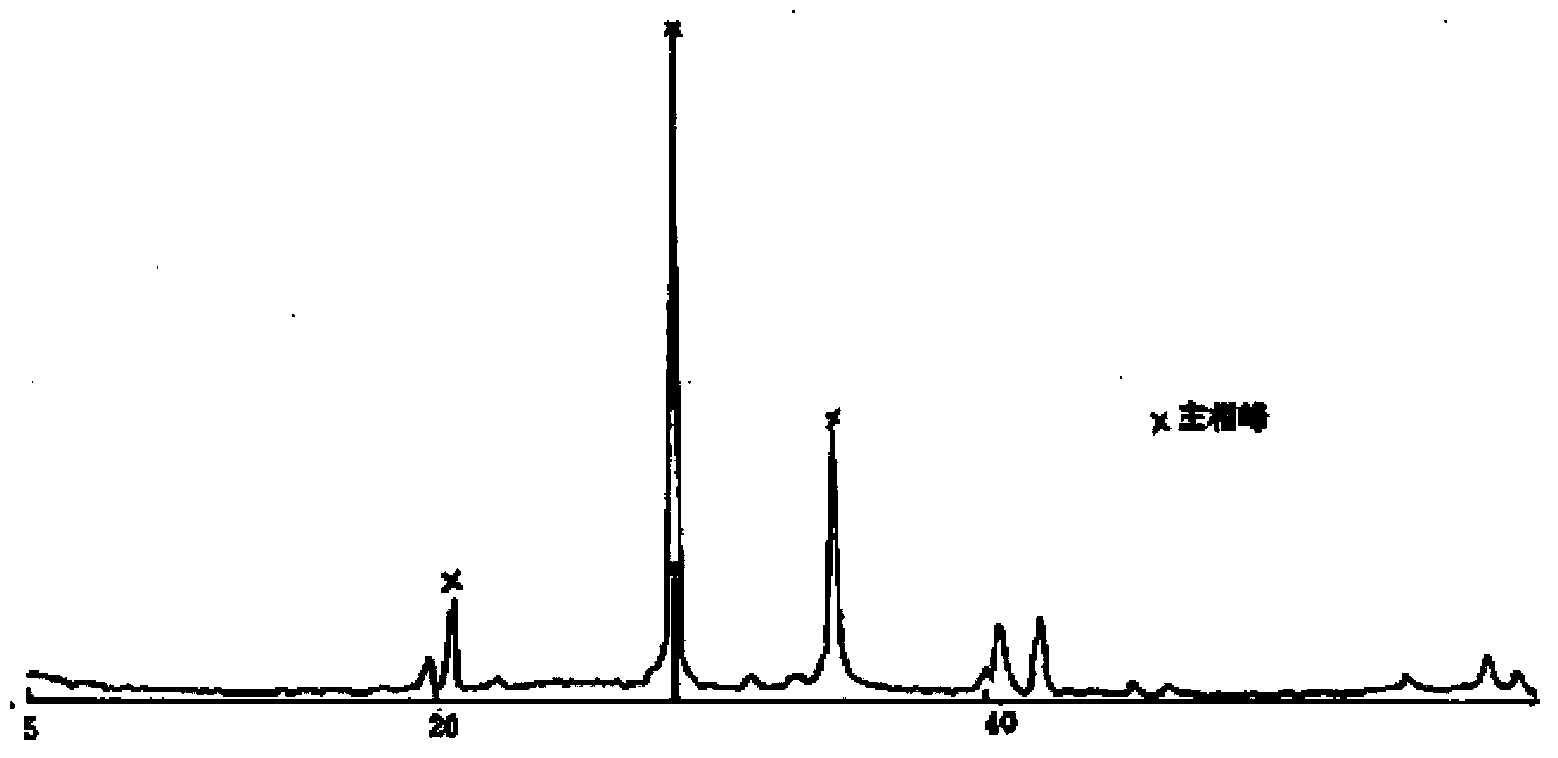

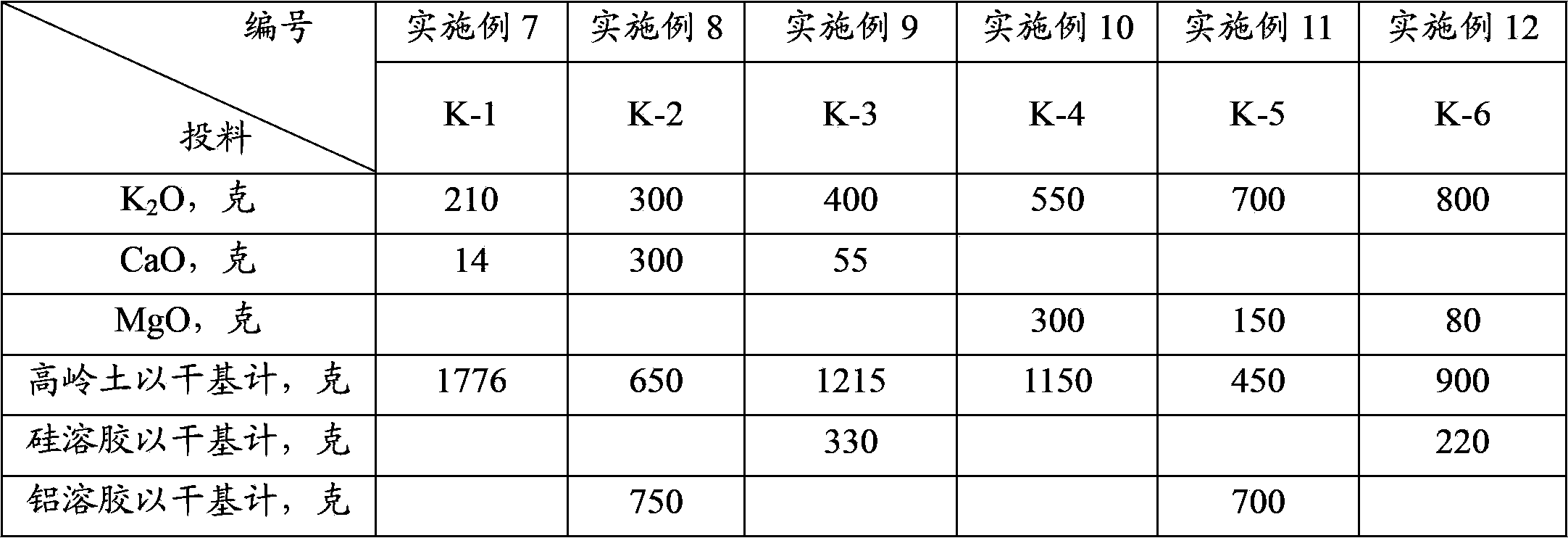

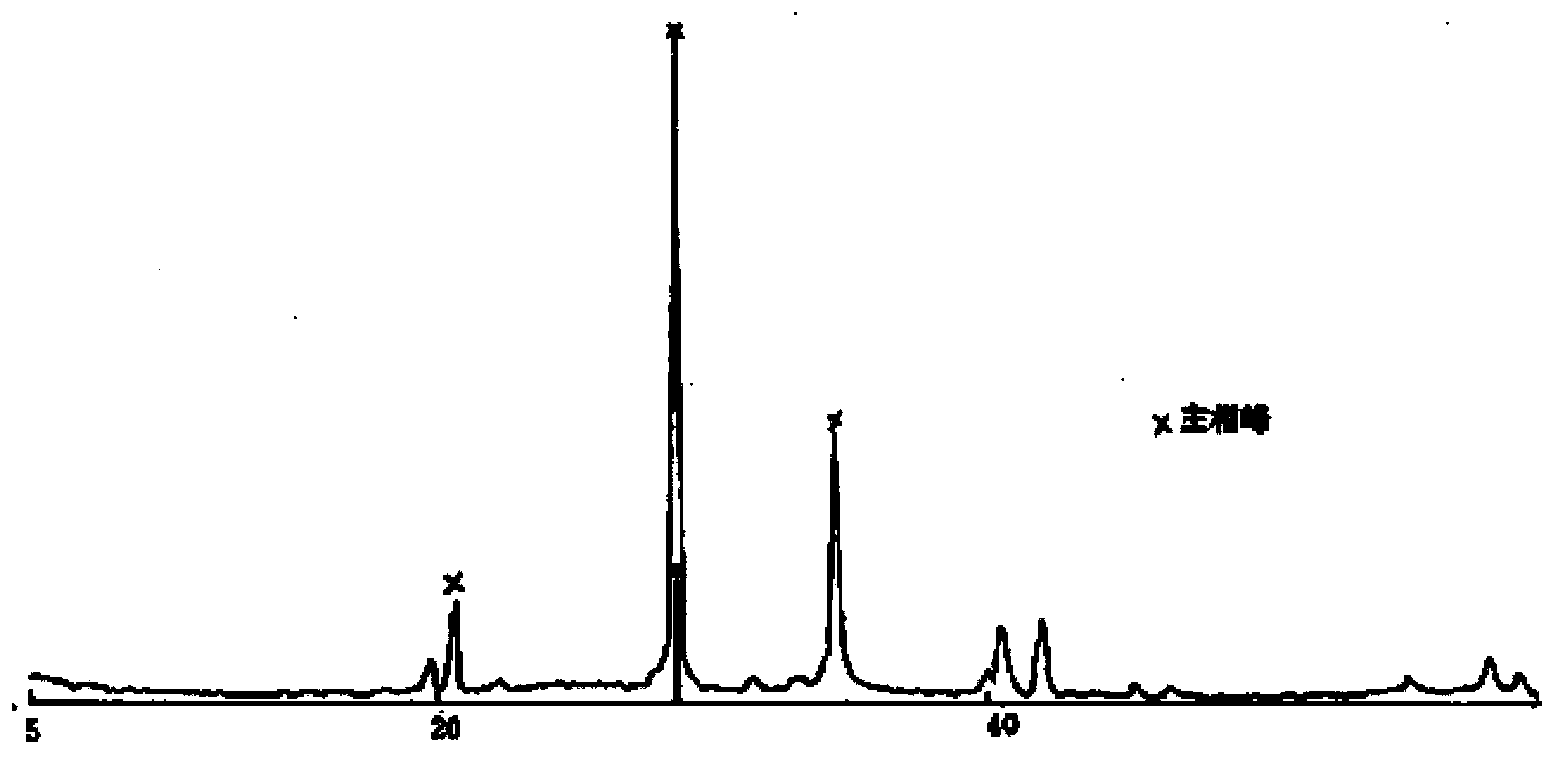

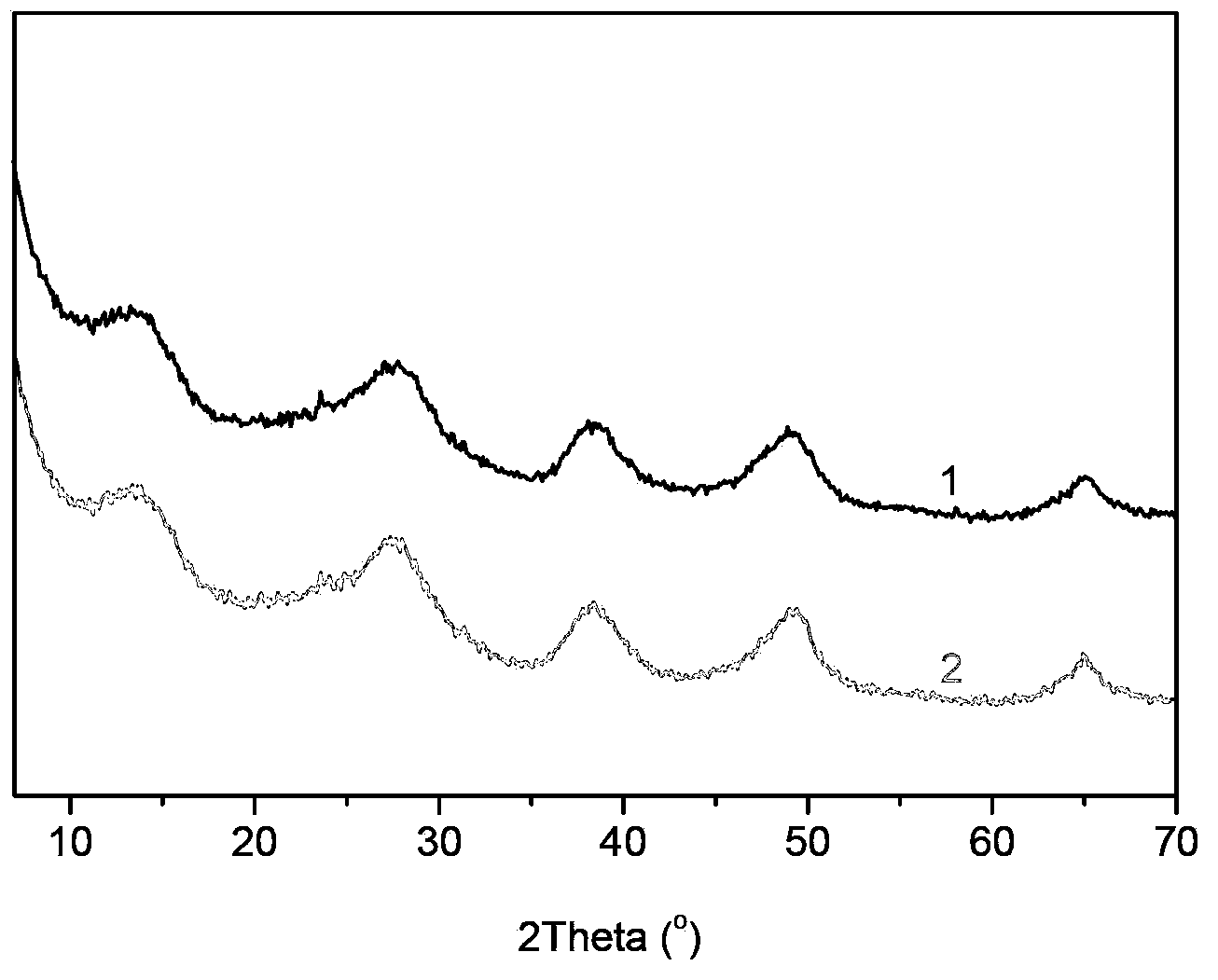

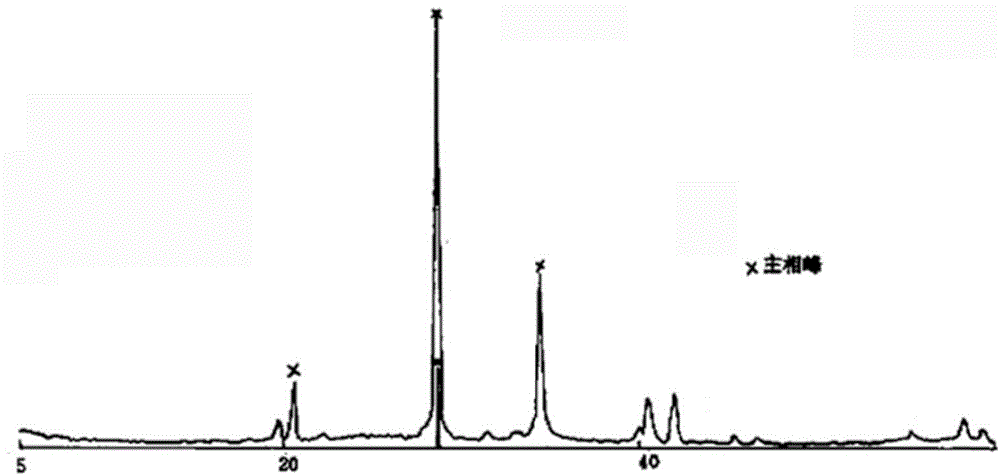

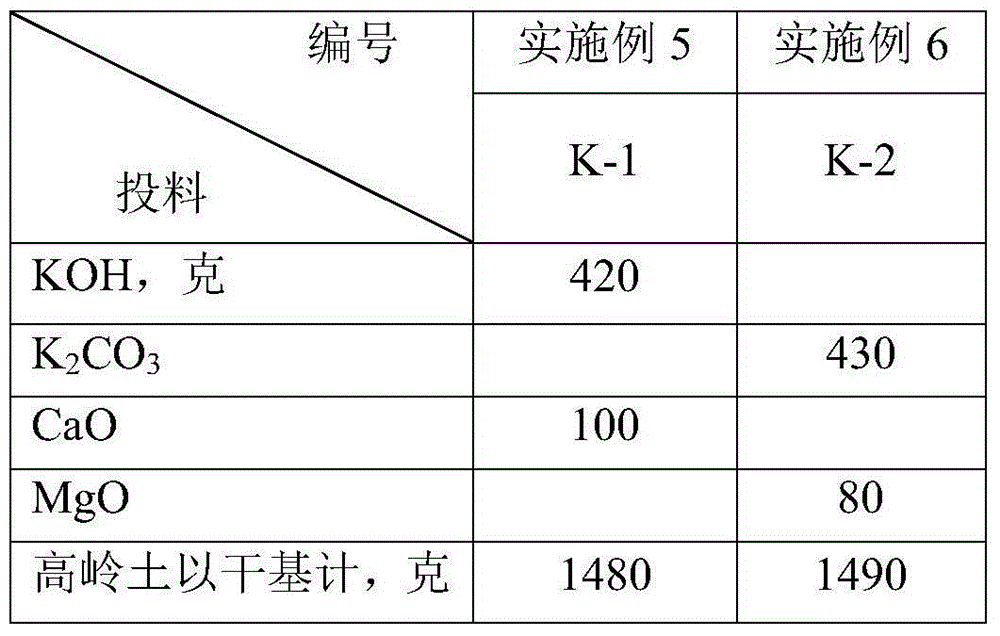

A multifunctional catalysis composition comprises 1-50wt% of a mesoporous aluminosilicate material, 1-40wt% of a gasification active component, 1-60wt% of a cracking active component, 0-70wt% of clay and 5-97wt% of a heatproof inorganic oxide matrix, wherein the mesoporous aluminosilicate material has a phase structure of pseudo-boehmite, has an anhydrous chemical expression formula of (0-0.3)Na2O.(40-90)Al2O3.(10-60)SiO2 by weight of oxide, and has a specific surface area of 200-400m<2> / g, a pore volume of 0.5-2.0mL / g, an average aperture of 8-20nm and a most probable aperture of 5-15nm The catalysis composition can reduce the gasification temperature of the cracking gasification conversion of hydrocarbon oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multifunctional catalysis composition

ActiveCN103566918AGood catalytic coke gasification abilityLower gasification temperatureCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsActive componentPetroleum

A multifunctional catalysis composition comprises 1-70wt% of a mesoporous aluminosilicate material, 1-60wt% of a gasification active component, 0-70wt% of clay and 5-98wt% of a heatproof inorganic oxide by oxide, wherein the mesoporous aluminosilicate material has a phase structure of pseudo-boehmite, has an anhydrous chemical expression formula of (0-0.3)Na2O.(40-90)Al2O3.(10-60)SiO2 by weight of oxide, and has a specific surface area of 200-400m<2> / g, a pore volume of 0.5-2.0mL / g, an average aperture of 8-20nm and a most probable aperture of 5-15nm. The catalysis composition is used for the cracking gasification of heavy petroleum hydrocarbons, and realizes a low gasification temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of heavy oil

ActiveCN103773425ALower gasification temperatureEmission reductionHydrogenCatalytic crackingChemistryFuel oil

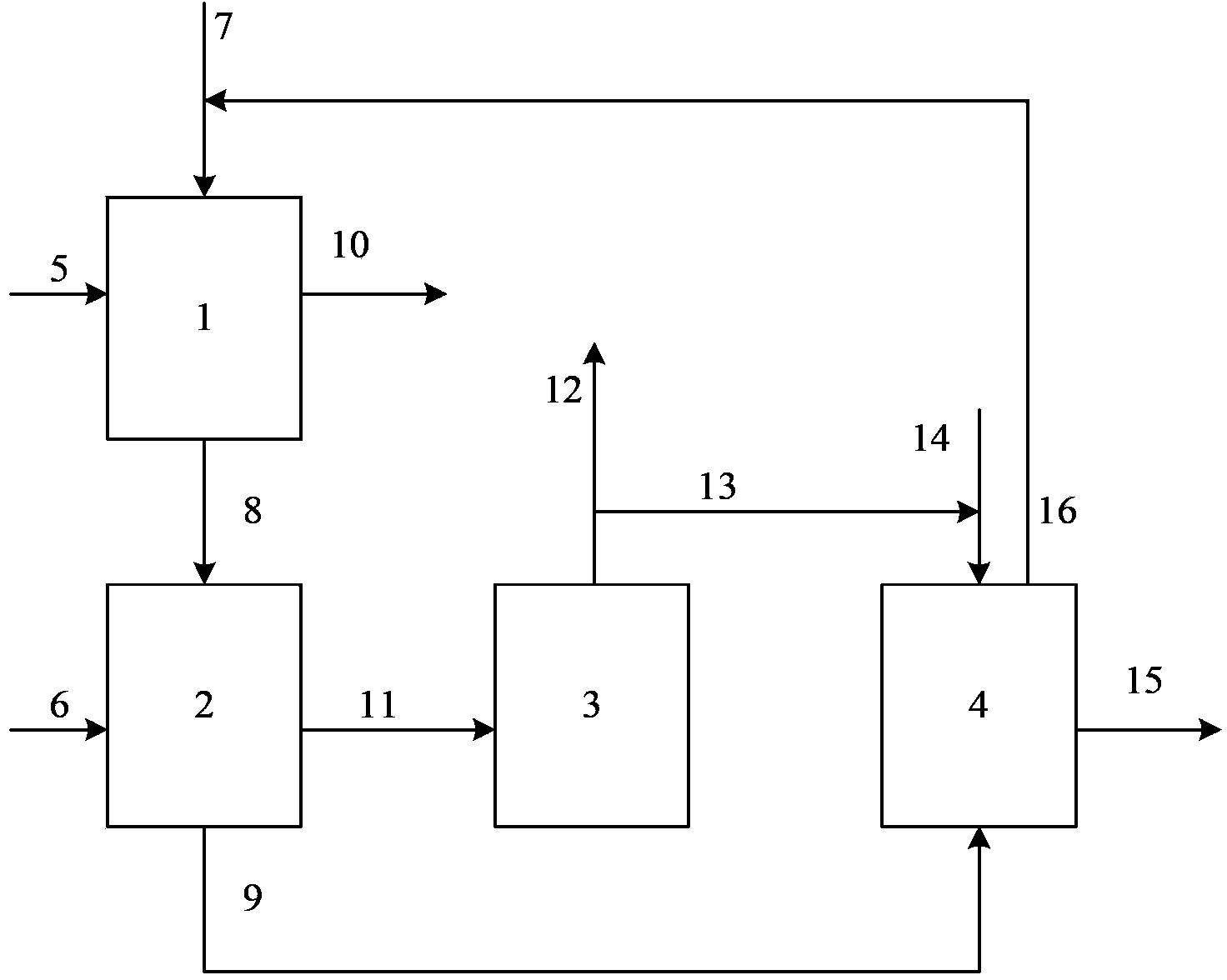

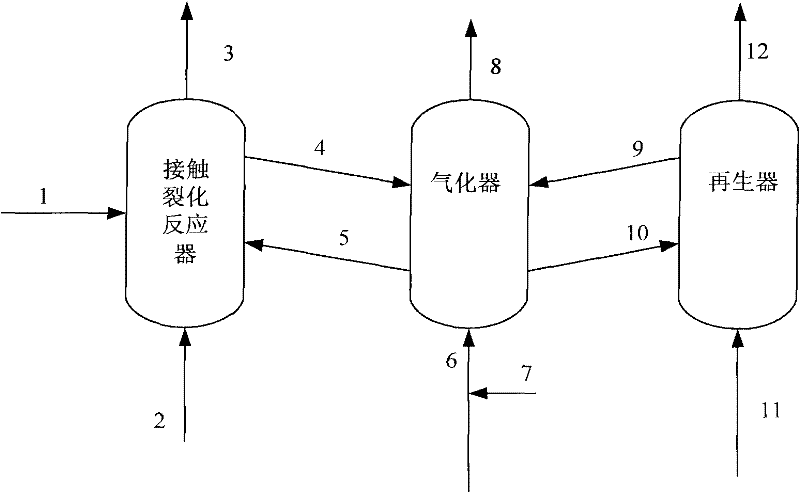

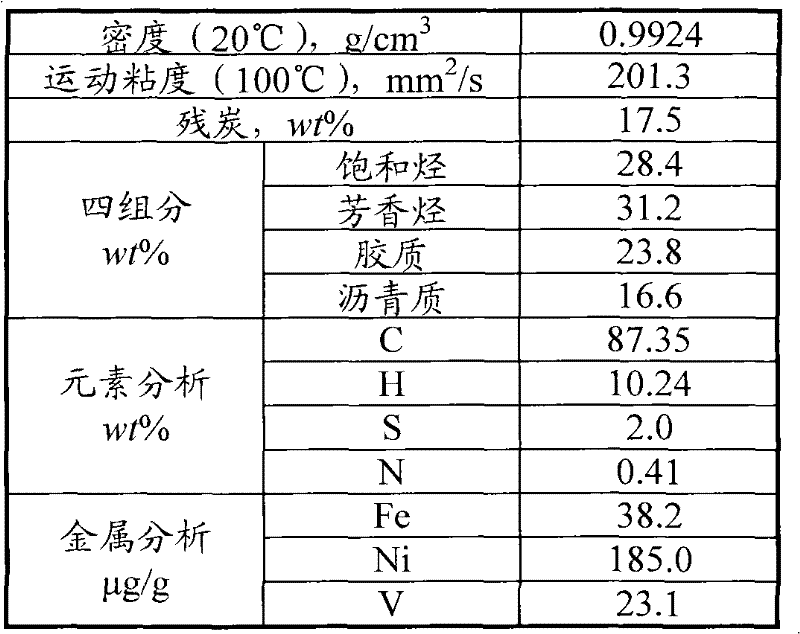

A processing method of heavy oil comprises the following steps: carrying out a contact cracking treatment on inferior heavy oil, making cokes deposited on a contact agent carry out a gasification reaction at a low temperature in a gasification unit to convert the cokes into gasified gas which is rich in carbon monoxide and hydrogen gas, transporting the gasified gas rich in carbon monoxide and hydrogen gas into a converting unit to generate hydrogen gas and CO2, separating the hydrogen gas and CO2, and transporting CO2 to a dry reforming unit to carry out reaction with gas rich in methane in the presence of a regeneration contact agent so as to generate CO and hydrogen gas; wherein the contact agent can be recycled and returned to the contact cracking reactor after the contact agent has exerted a catalyzing function and then is discharged out from the dry reforming reactor. The processing method reasonably utilizes residues and metals of heavy oil processing to produce products with a high economic value, and is economic and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

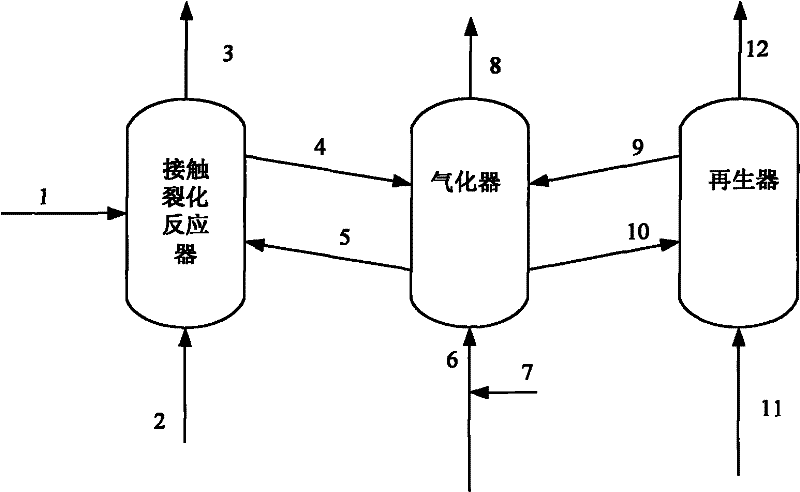

Inferior heavy oil contact cracking-gasification combined treatment method

ActiveCN102453518AEconomic routeEffective WaysHydrogenTreatment with plural serial stages onlySyngasReaction temperature

The invention discloses an inferior heavy oil contact cracking-gasification combined treatment method. The inferior heavy oil contact cracking-gasification combined treatment method comprises the following steps that 1, inferior heavy oil is fed into a contact cracking reactor, undergoes a contact cracking reaction with a contact agent to produce reaction oil gas and a carbon-containing contact agent; and after gas-solid separation, the reaction oil gas is fed into a follow-up separation system and the carbon-containing contact agent is fed into a gasifier; 2, in the gasifier, carbon of the carbon-containing contact agent obtained by the step 1 and a gasification agent undergo a binding reaction at a low gasification temperature to produce synthesis gas rich in CO and H2; simultaneously a CO2 capture material of the carbon-containing contact agent absorbs CO2 produced by the binding reaction; and the reacted carbon-containing contact agent enters into a regenerator; and 3, oxygen-containing gas is fed into the regenerator; residual carbon of the reacted carbon-containing contact agent and oxygen undergo a reaction at a high reaction temperature and burn completely; the CO2 capture material binding with CO2 releases CO2 so that the reacted carbon-containing contact agent recovers activity; and the regenerated carbon-containing contact agent returns back to the contact cracking reactor. Through the inferior heavy oil contact cracking-gasification combined treatment method, a light oil yield of a cracking reaction is improved; a gasification reaction temperature is reduced; and contact agent hydro-thermal inactivation and structure damage are avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

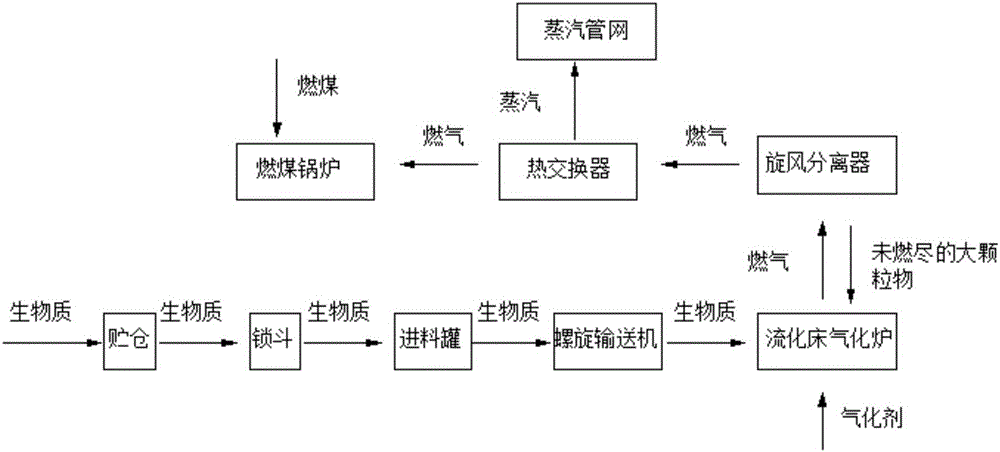

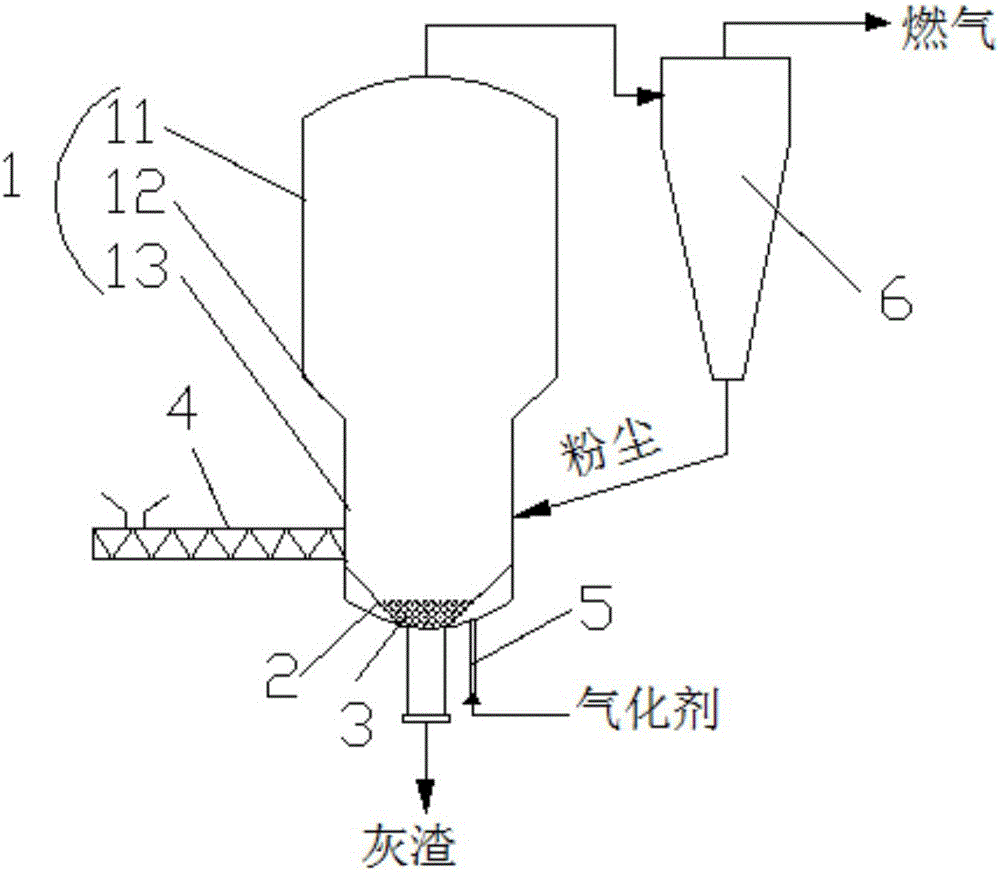

Biomass gasification power-generation process

InactiveCN106244246AHigh strengthImprove gasification efficiencyGasifier feeding meansGasification processes detailsParticulatesFood consumption

The invention discloses a biomass gasification power-generation process. The biomass gasification power-generation process comprises the following steps of step (I), pressurizing biomass granules until the gauge pressure is 0.1-4.0Mpa, then discharging materials to a charging tank, then conveying the discharged materials to a fluidized-bed gasifier, and performing a gasification reaction with a gasification agent so as to obtain fuel gas for standby application; step II, performing cyclone dust removal on the fuel gas prepared in step (I) through a cyclone separator, performing separation to obtain large particles which are not burn-out, and returning the large particles to the fluidized-bed gasifier for gasifying once again; and step (III), cooling the flue gas which is subjected to dust removal by the cyclone separator to 300-700 DEG C through a heat exchanger, and enabling the cooled flue gas to be led into a coal boiler to be subjected to mixed combustion with the coal for power generation. According to the biomass gasification power-generation process disclosed by the invention, the biomass granules are sent to a large-scale coal boiler through the fuel gas generated by gasification to be subjected to combined combustion with the coal for power generation, so that the coal consumption required for power generation is reduced, the amount of CO2 generated during combustion is reduced, greenhouse effects caused by CO2 can be alleviated, and emission of NOX by power plants is reduced.

Owner:武汉高斯生态能源技术有限公司

Clean synthesis gas and preparation method thereof

The invention relates to a preparation method of clean synthesis gas. The method comprises the following steps of: mixing dried biomass particles and dried coal powder uniformly to obtain the mixed particles; and feeding the mixed particles into an entrained flow gasifier by dense phase pneumatic transmission mode, and performing co-gasification on the mixed particles and a gasification agent to generate the clean synthesis gas. The invention also relates to the clean synthesis gas prepared by the method. In the preparation method of the clean synthesis gas, the co-gasification temperature of the entrained flow gasifier is high, the obtained synthesis gas dose not contain harmful ingredients, such as tar, phenol and the like, so the problem that the volatile content of the biomass is high and energy density is low, so secondary pollution is caused by decoking due to high the tar content of the synthesis gas which is gasified independently is solved; meanwhile, the use ratio of the biomass is increased, CO2 emission reduction is facilitated, large-scale, high-efficiency, clean and economic use of the biomass can be realized.

Owner:EAST CHINA UNIV OF SCI & TECH

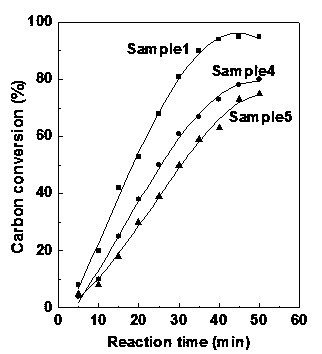

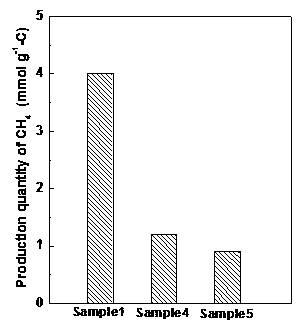

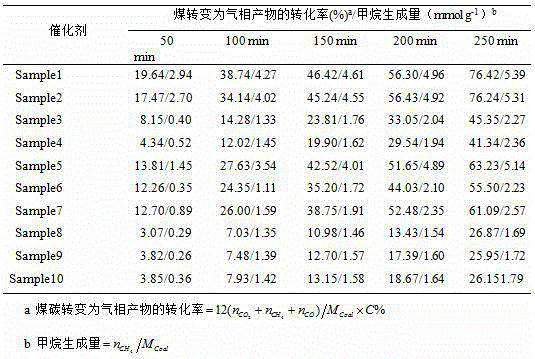

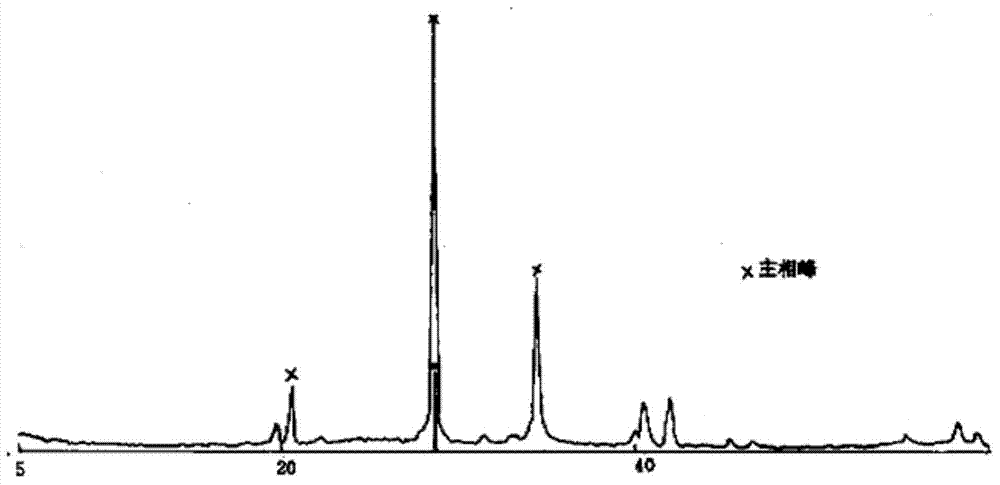

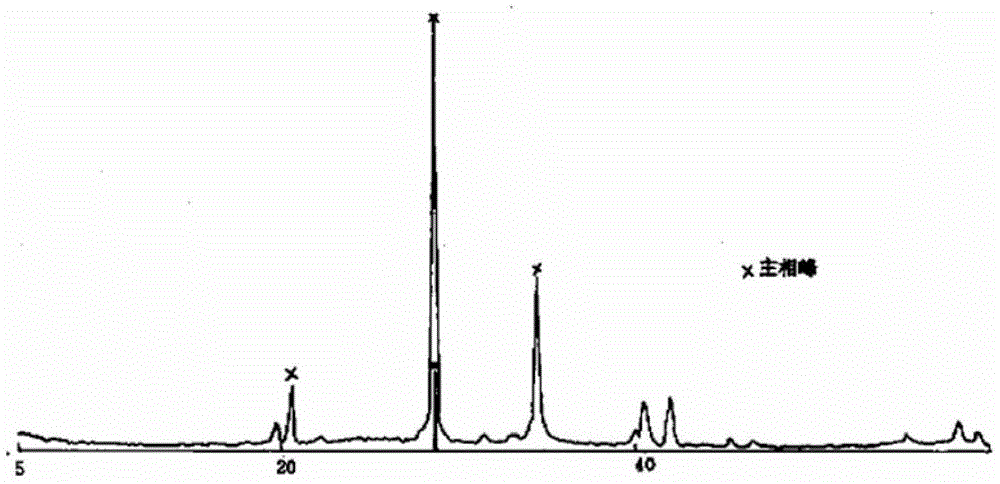

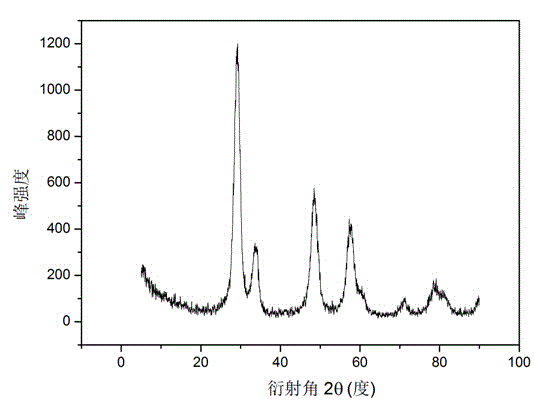

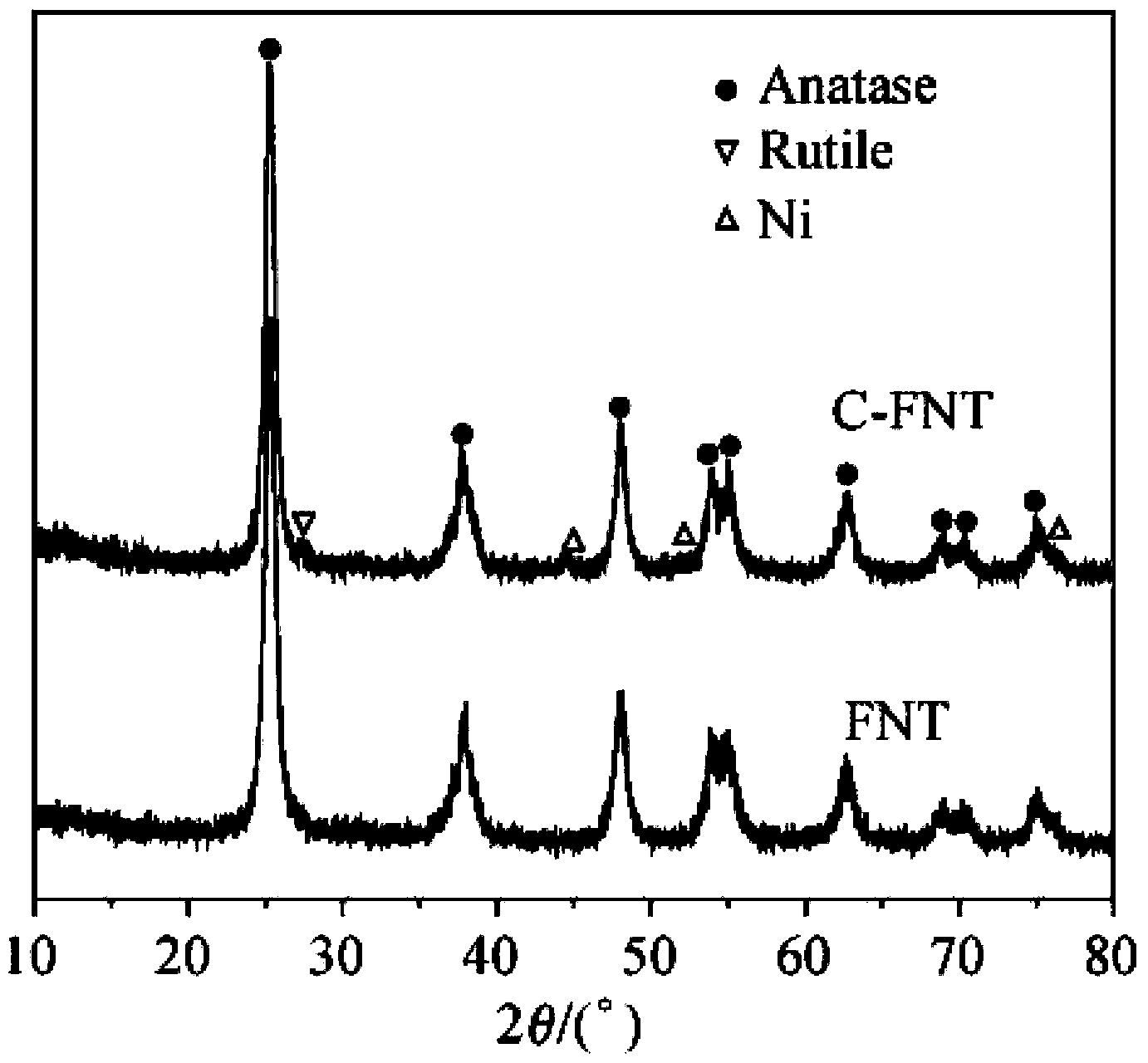

Catalytic coal gasification catalyst and preparation method thereof

InactiveCN103566937AEffective anchoringExcellent methanation abilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFixed bed

The invention belongs to the technical field of catalytic coal gasification catalysts and provides a high-efficiency catalytic coal gasification catalyst and a preparation method thereof. The high-efficiency catalytic coal gasification catalyst takes a complex Ni(NH3)6CO3 as a catalyst precursor, active ingredients are uniformly dispersed on a coal base by adopting an ion exchange technique, and loading capacity of the active ingredients is 2-8%. When the prepared catalytic coal gasification catalyst is applied in a catalytic coal gasification fixed bed reactor, rate of gasification of coal can be effectively improved, and components of coal gas can be improved, so that methane content is increased and utilization rate of the coal is greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

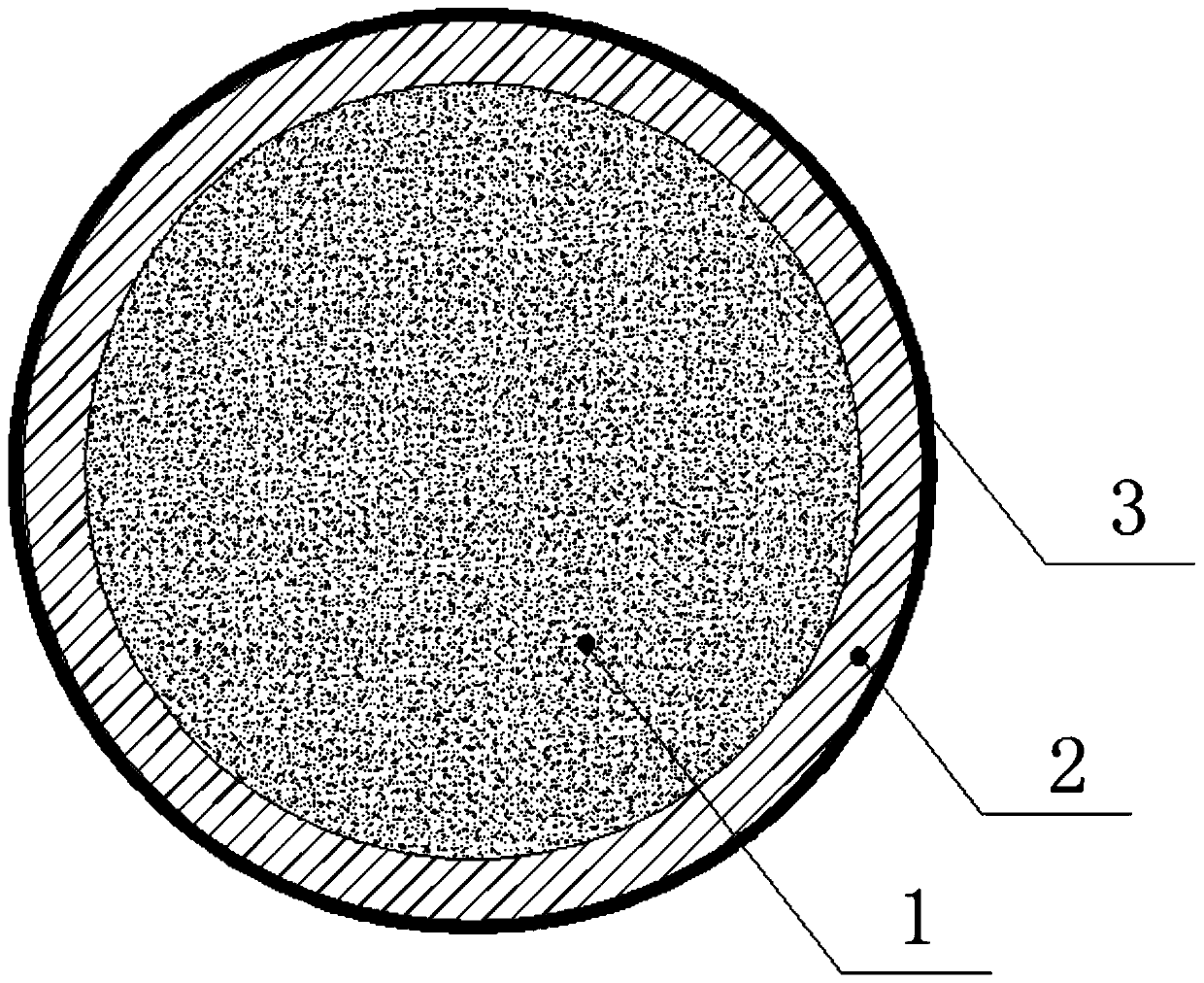

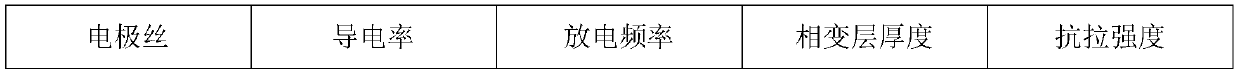

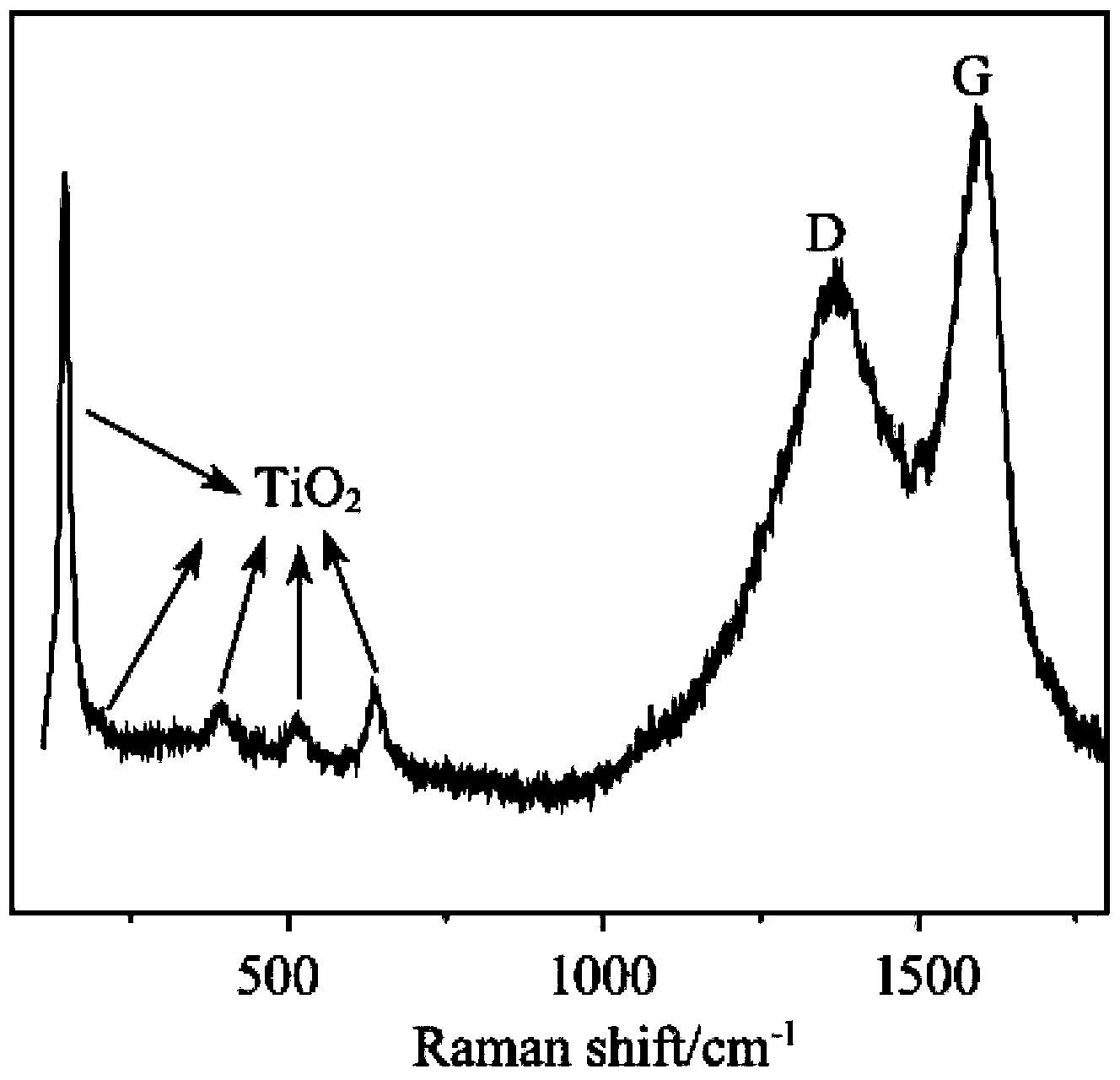

Electrode wire containing carton on surface layer for low-speed wire-cutting electrical discharge machining and preparation method thereof

ActiveCN110125499AImprove conductivityHigh positioning accuracyElectrical-based machining electrodesLow speedSurface layer

The invention discloses an electrode wire containing carton on the surface layer for low-speed wire-cutting electrical discharge machining and a preparation method thereof. The electrode wire is characterized by comprising a core material (1), a carbide layer (3) on the outermost layer, and a phase change layer (2) positioned between the core material (1) and the carbide layer (3). The electrode wire with the special structure can improve the machining speed by above 15% compared with a plating wire, and is higher in machining precision compared with the plating wire. The electrode wire is simple in machining process, greatly improves the performances, and achieves higher market competitiveness compared with the plating wire.

Owner:NINGBO BODE HIGHTECH CO LTD

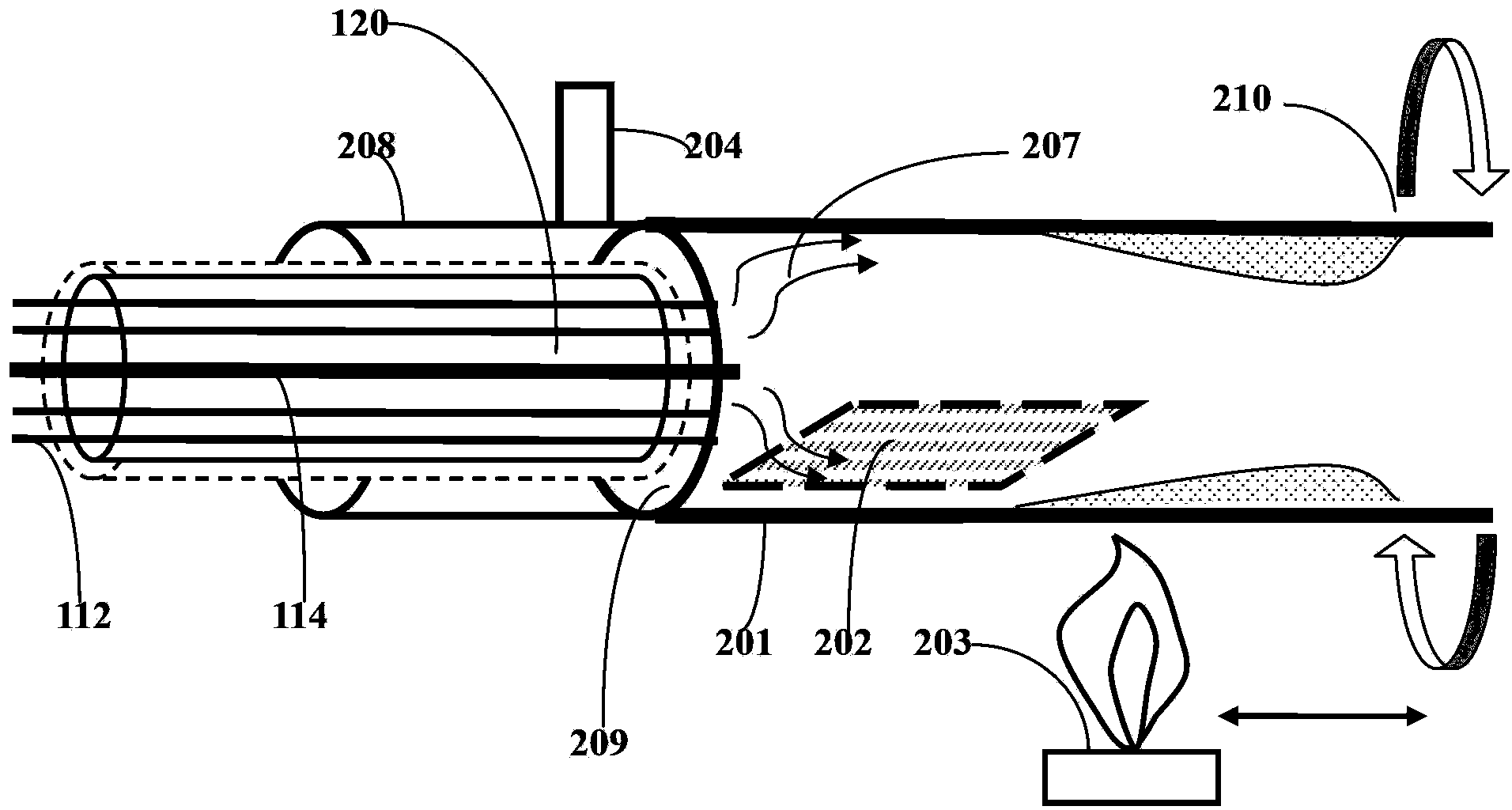

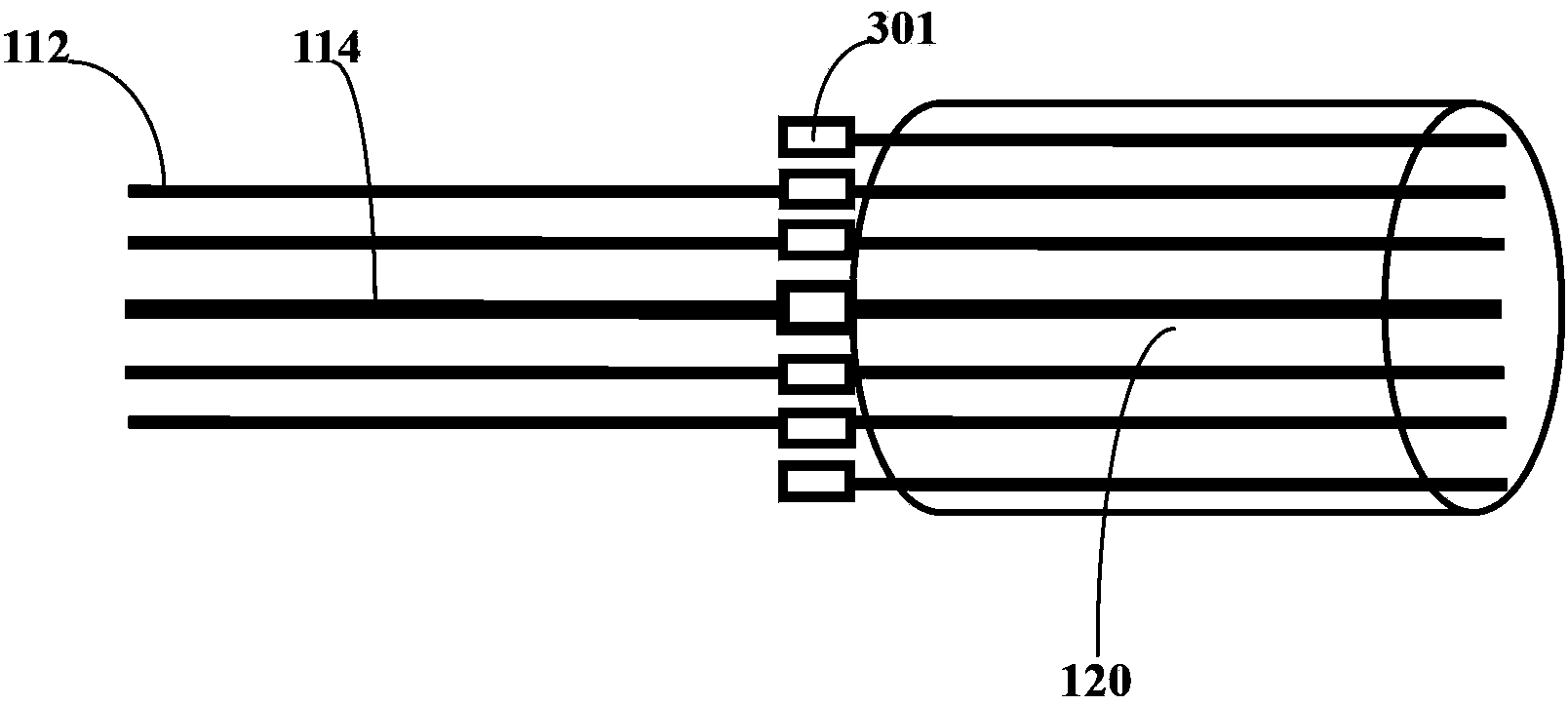

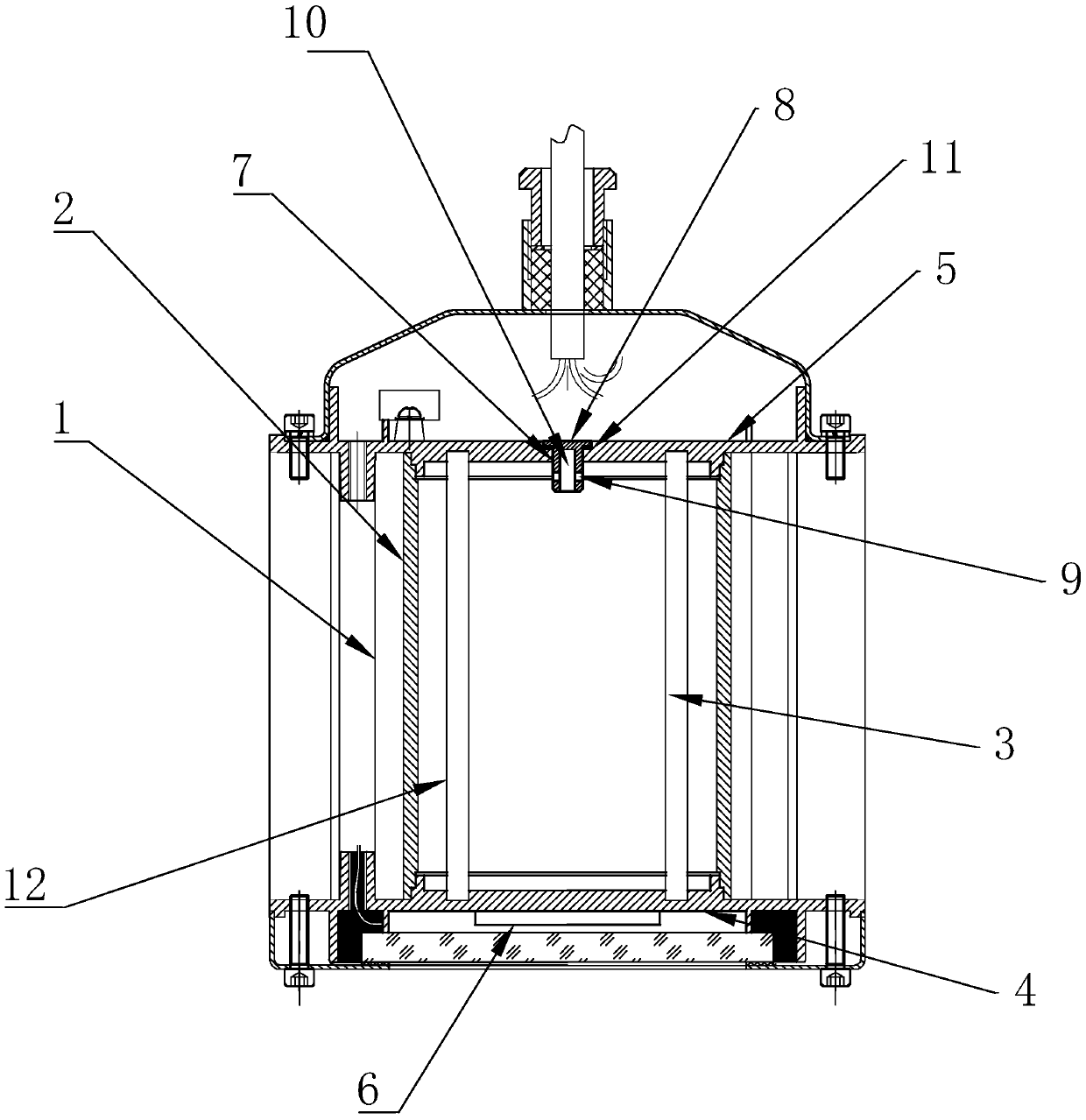

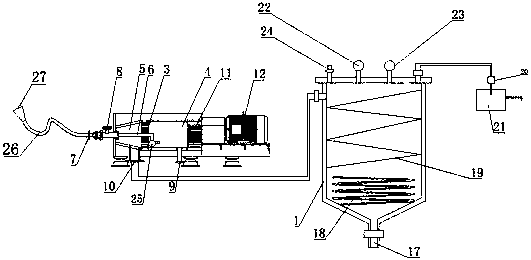

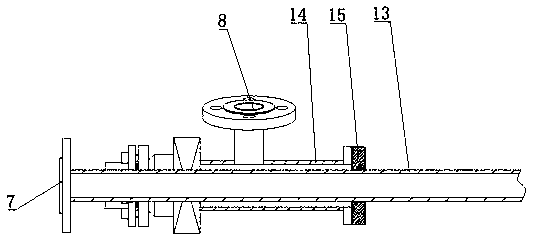

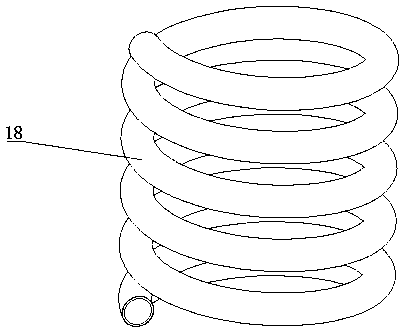

Process and device for producing myrcene by thermal cracking of beta-pinene

PendingCN107602322ALower gasification temperatureNot easy to cokeHydrocarbon by isomerisationSmall dropletEngineering

The invention discloses a process and device for producing myrcene by thermal cracking of beta-pinene. According to the flowing direction of material, the device is mainly composed of a raw material storage tank, a metering and feeding pump, an ultrasonic atomization gasification device, an inductive coupling thermal cracking tube, a condenser and a product collector which are sequentially connected in series, wherein an ultrasonic atomization nozzle is arranged at the top of the ultrasonic atomization gasification device; and the ultrasonic atomization nozzle is connected with an ultrasonic atomizer controller. At ordinary pressure or low pressure, beta-pinene is subjected to ultrasonic atomization treatment and becomes uniformly dispersed micron-scale small droplets, complete atomizationgasification is realized at relatively low temperature, and a gasified material rapidly enters the inductive coupling thermal cracking tube and carries out rapid thermal cracking reaction, thus generating myrcene.

Owner:广东松林香料有限公司

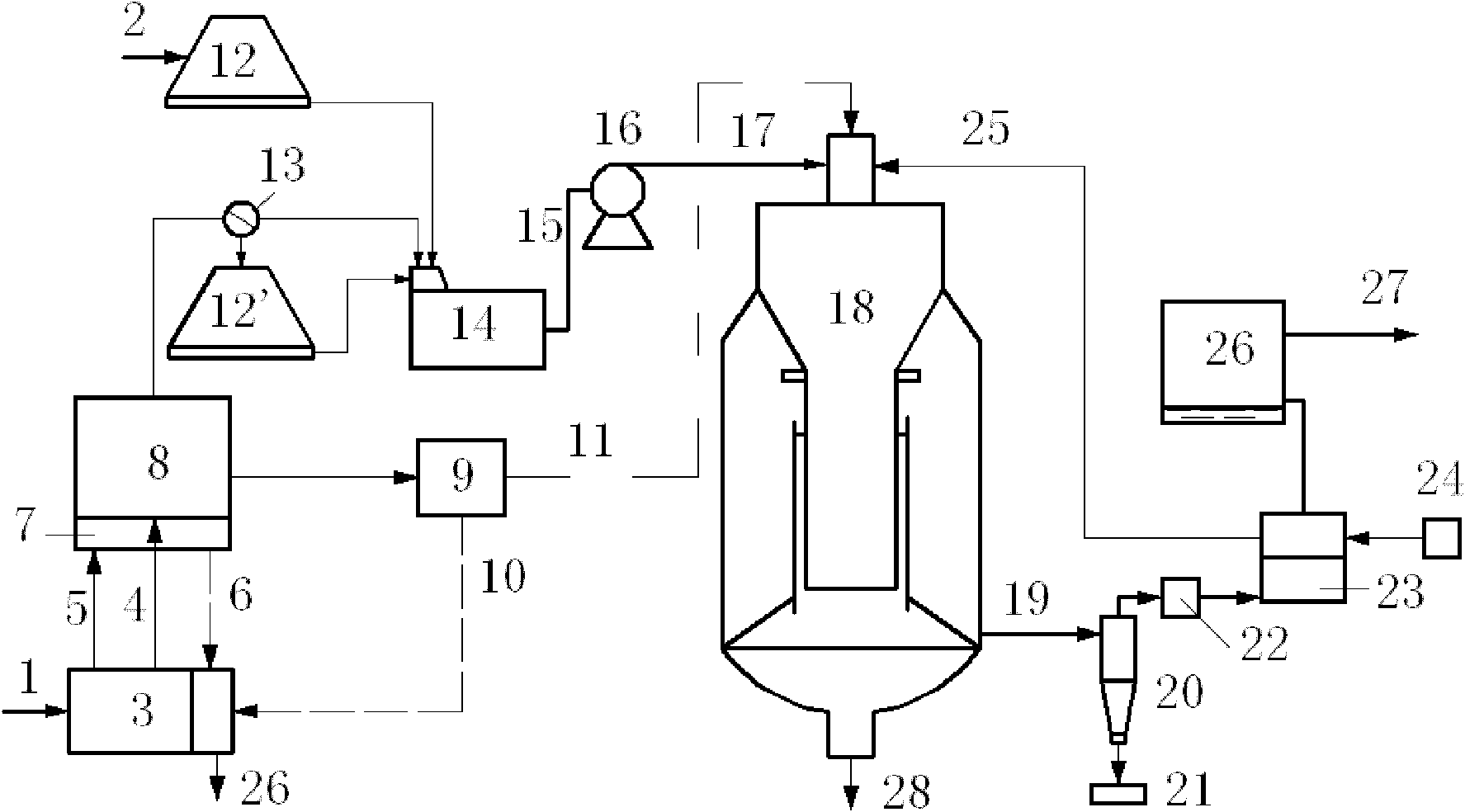

Mixed fuel coal water slurry entrained flow bed gasification system

InactiveCN101838558ASuitable for large-scale useImprove conversion rateSpecial form destructive distillationGranular/pulverulent flues gasificationCoal waterPulp treatment

The invention belongs to the technical field of biological energy and discloses a mixed fuel coal water slurry entrained flow bed gasification system. The mixed fuel coal water slurry entrained flow bed gasification system comprises an entrained flow bed coal water slurry gasifier, a pretreatment module, a coal water slurry preparation module, a purification module and a separation oxygen supply module, wherein the pretreatment module receives biomass to be treated and is connected with the input end of the coal water slurry preparation module, the coal water slurry preparation module receives biological coke charges output by the pretreatment module and carries out milling and pulping treatment, the output end of the coal water slurry preparation module is connected with the entrained flow bed coal water slurry gasifier and outputs coal water slurry, the entrained flow bed coal water slurry gasifier is connected with the separation oxygen supply module to receive combustion-supporting gas and is also connected with the purification module to output combustion gas, and the purification module is connected with an air separator and outputs the combustion-supporting gas. The invention can realize large-scale utilization of the biomass, does not generate gasification tars and enhances the carbon conversion rate of coal gasification.

Owner:SHANGHAI JIAO TONG UNIV

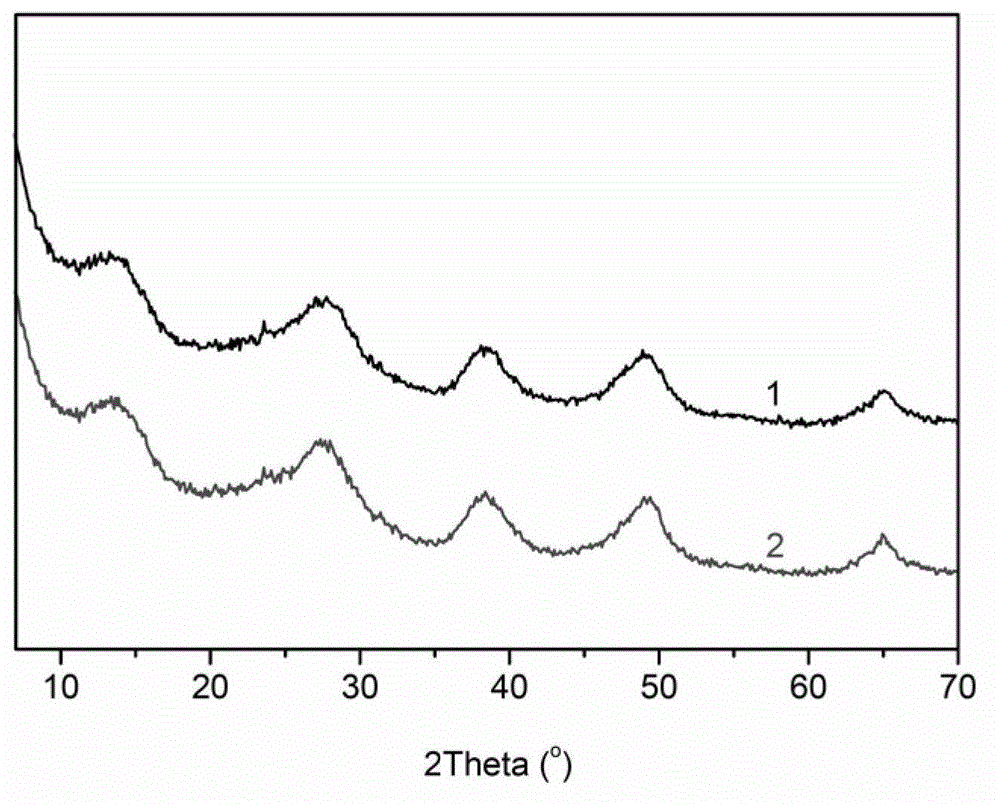

Cracking gasification catalytic composition, preparation method thereof, and cracking gasification method of petroleum hydrocarbons

ActiveCN106179478AImprove conversion abilityGood conversion effectCatalytic crackingMolecular sieve catalystsRare-earth elementLanthanide

The invention discloses a cracking gasification catalytic composition, a preparation method thereof and a petroleum hydrocarbon cracking gasification method. In weight percentage, the catalytic composition comprises: 1% to 50% of mesoporous active materials, wherein, The anhydrous chemical expression of the active mesoporous material in terms of oxide weight is (0-0.2) Na 2 O·(40-85)Al 2 o 3 ·(10-55)SiO2 2 ·(0.5-10)P 2 o 5 ·(0.5-10)M x o y , wherein the metal M is selected from Mg, one or more of the periodic table IIB, IIIB, IVB, VIIB group elements, and lanthanide rare earth elements, y is the highest valence state when the metal M forms an oxide, and x and The value of y is such that the valences of M and O are balanced. It has better cracking activity and gasification conversion performance when applied in heavy oil catalytic cracking-gasification combined process, and can obtain higher yield of liquefied gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

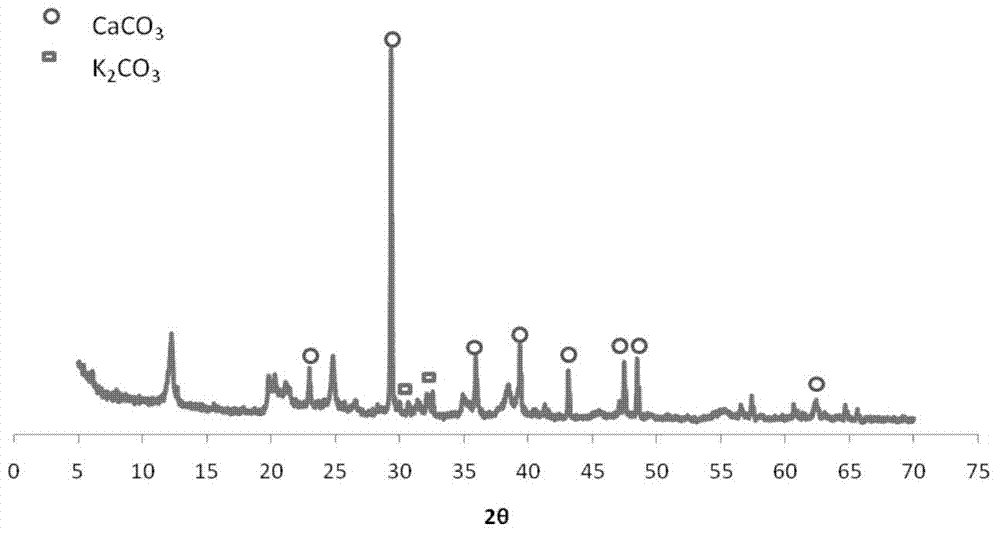

Catalyst for preparation of natural gas from coal and preparation method thereof

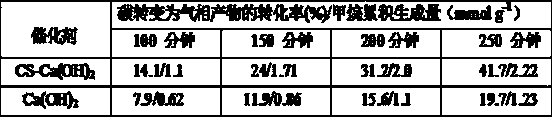

InactiveCN106540730AImprove wettabilityImprove gasification efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsGaseous fuelsGas phaseHydrophilic hydrophobic

The invention belongs to the technical field of a coal catalytic gasification catalyst and provides a method for preparing an alkali metal salt into an efficient coal catalytic gasification catalyst and an application thereof. According to the catalyst, the wetting property of a coal particle surface is improved by taking the alkali metal salt as a precursor of the catalyst, adding a surfactant and utilizing hydrophilic-hydrophobic structure characteristics of the surfactant component; effective metal components are uniformly supported on a coal base through a conventional soaking method; and the effective components are dispersed in an atomic scale. The catalyst prepared by the invention is applied to a fixed bed reactor for preparation of natural gas from coal through catalytic gasification, not only can a rate of converting coal into a gas phase product be enhanced, but also compositions of coal gas can be adjusted, the methane content is increased and the utilization rate of the coal is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

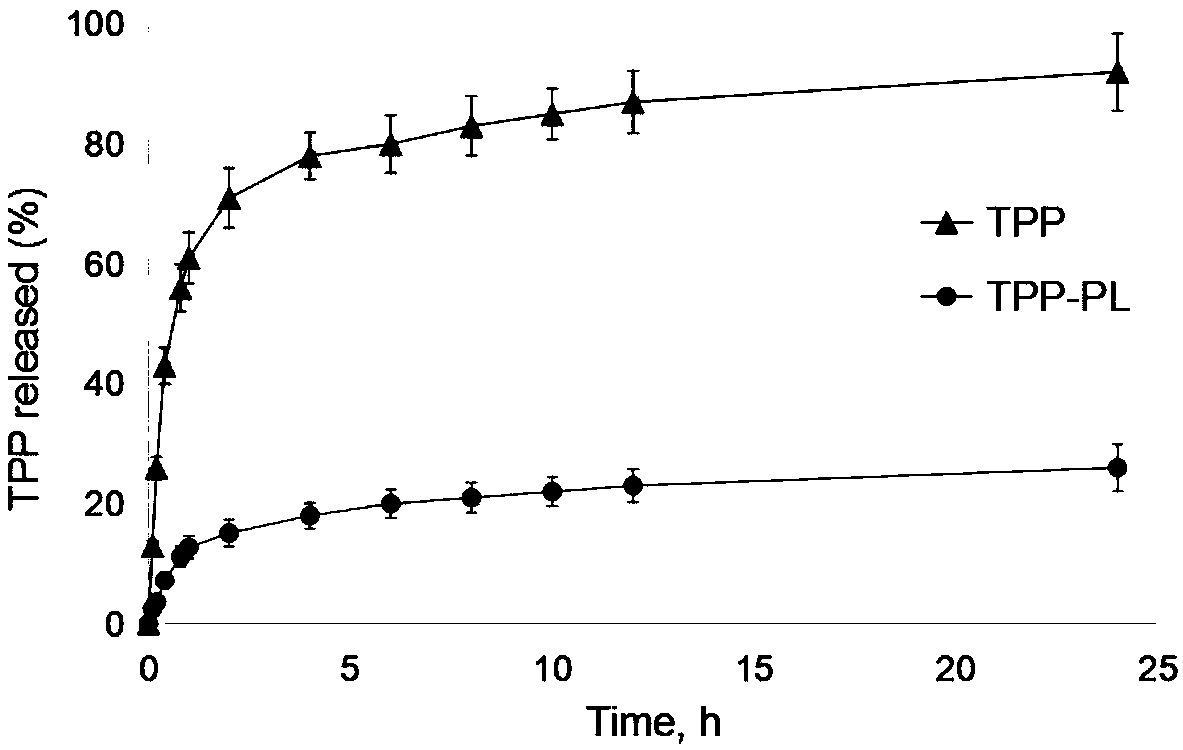

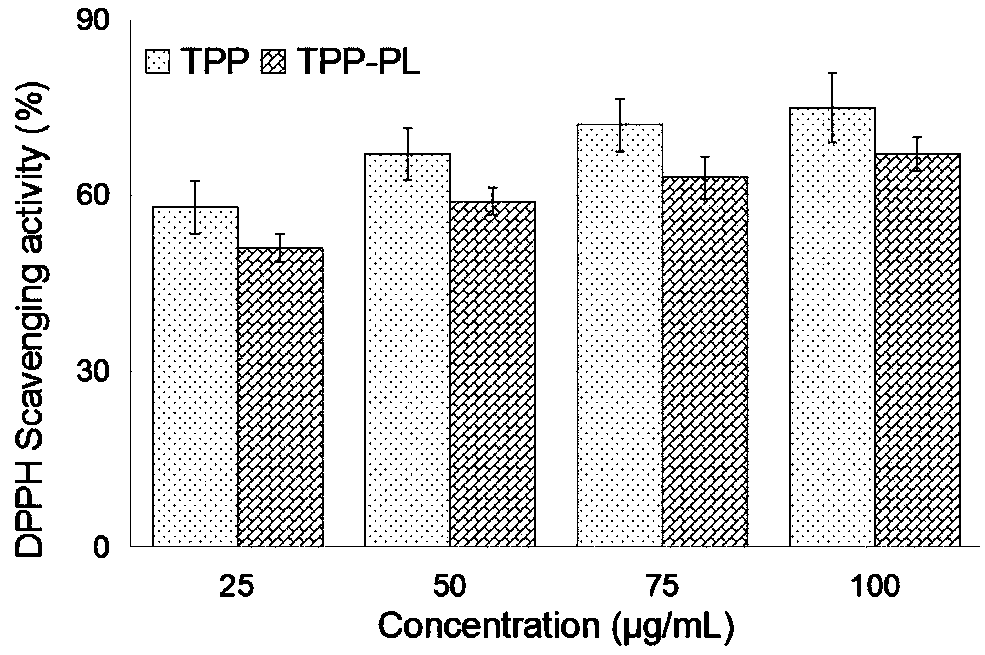

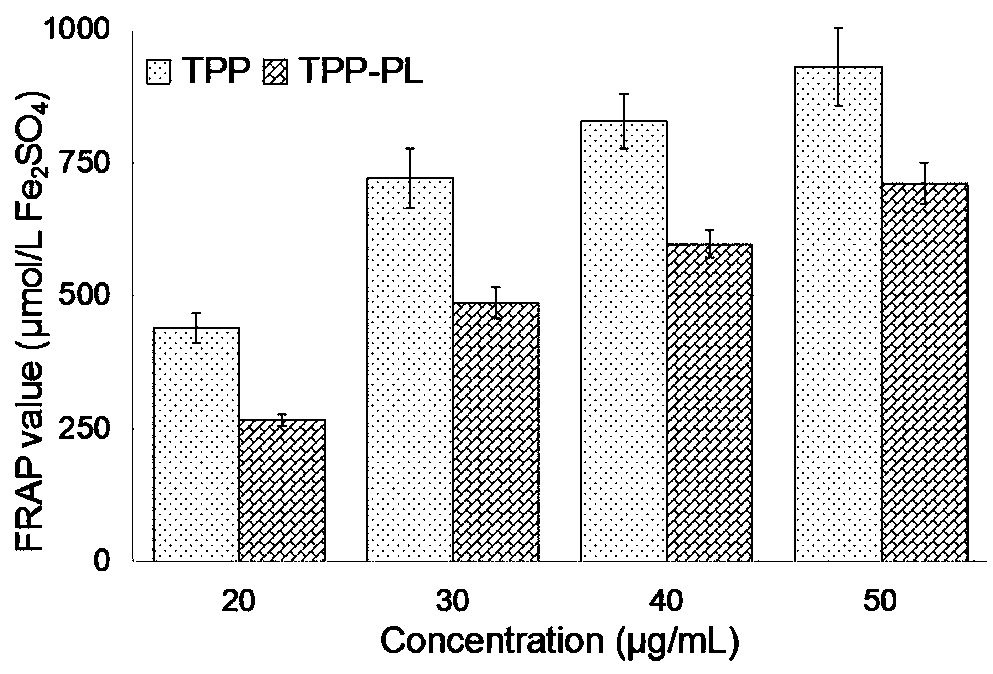

Preparation method and detection method of phospholipid tea polyphenol dried fish floss

ActiveCN107927630ASustained antioxidant activityExtended shelf lifeFood freezingComponent separationDried fishPhospholipid

The present invention discloses a preparation method and a detection method of phospholipid tea polyphenol dried fish floss. The preparation method comprises the following steps: firstly, washing fish; secondly cooking the fish; thirdly, cooling the fish and removing fish skin, fat and fish bones; fourthly, deodorizing; fifthly, squeezing; sixthly, adding a phospholipid tea polyphenol compound; seventhly, rubbing the floss and continuously adding edible salt, white granulated sugar and pea powder; eighthly, stir-frying the floss using low heat until a water content is about 12%; and ninthly, stir-frying the floss to be crisp, and conducting cooling, canning and storing. The prepared phospholipid polyphenol dried fish floss by the preparation method can release tea polyphenols slowly, thusa long-term anti-oxidation effect is played, and a storage period of the dried crucian floss is improved. Besides, the detection method can quickly and accurately detect a fatty acid content in the dried fish floss and further determines an oxidation situation of meat quality of the dried fish floss.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Efficient cooling LED floodlight

InactiveCN105509013AEasy to usePlay the effect of indirect heat transferLighting heating/cooling arrangementsSemiconductor devices for light sourcesCooling effectEngineering

The invention discloses an efficient cooling LED floodlight which comprises a shell. An LED lamp is arranged in the shell. A cooler is further arranged in the shell. The LED lamp is attached to the cooler. A containing cavity is formed in the cooler and filled with phase change liquid. Heat conduction pipes are arranged at the two ends in the containing cavity of the cooler. When the efficient heat dissipation LED floodlight is obliquely used, the phase change liquid can leave the position, wherein the LED lamp is attached, on the cooler, the LED lamp emits heat in the use process at the moment, the heat conduction pipes are arranged on the cooler and play a role in indirect heat conduction, heat of the LED lamp is transmitted into the phase change liquid through the heat conduction pipes, and therefore phase changes happen to the phase change liquid, a good cooling effect can be achieved even in the oblique use process, the overall cooling performance is improved, and long-time use of the LED lamp is ensured.

Owner:HAOXIONG ELECTRICAL CO LTD

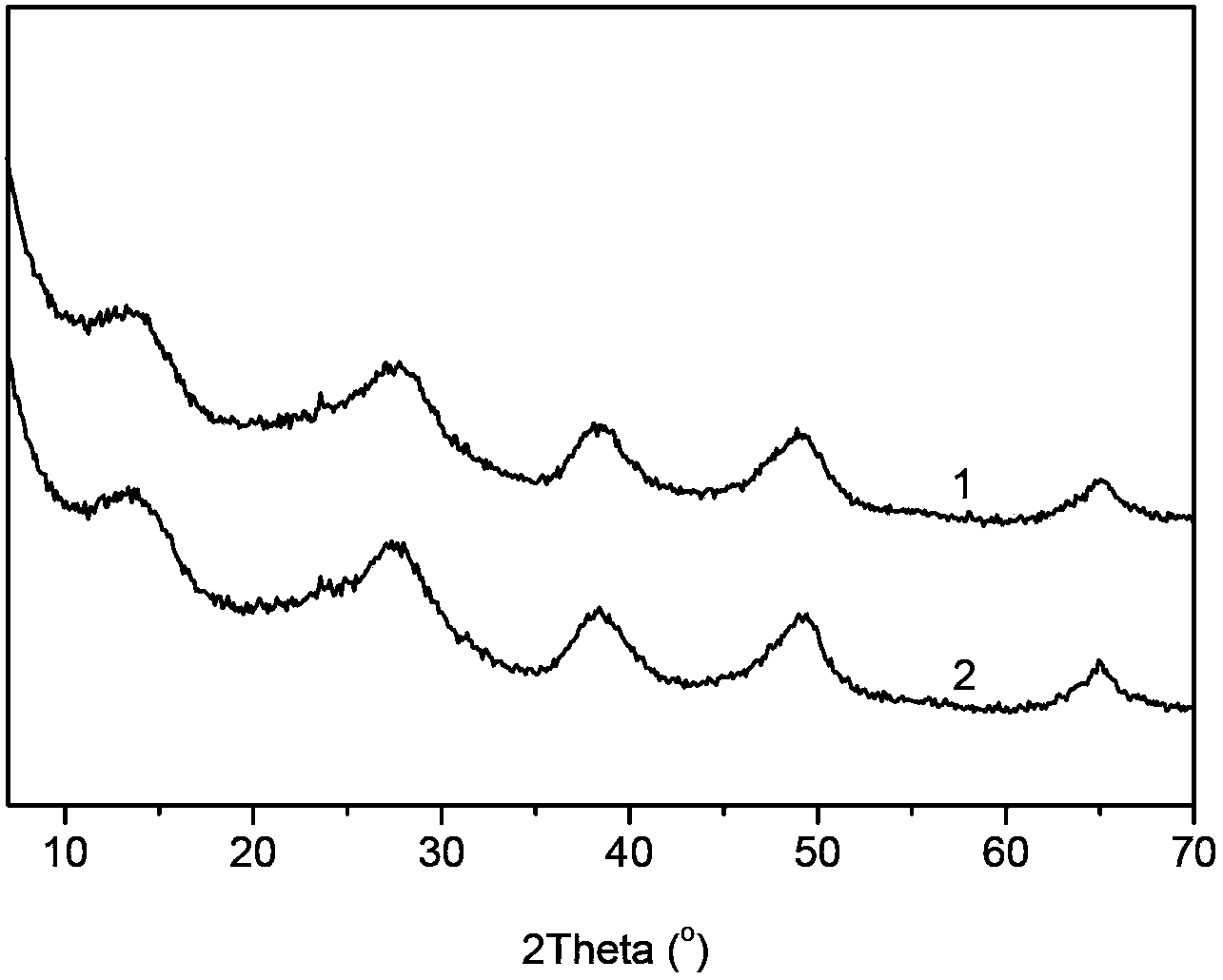

Multifunctional catalysis composition

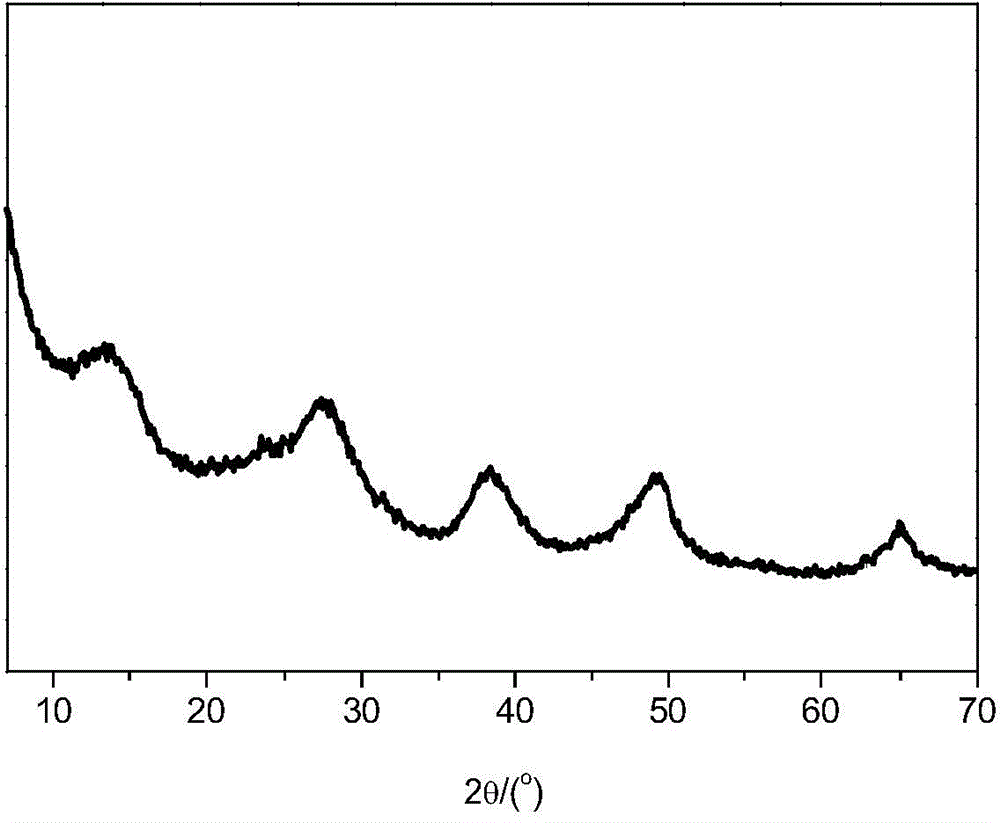

ActiveCN104741138AImprove gasification effectReduce churnPhysical/chemical process catalystsCatalytic crackingActive componentPetroleum

The invention discloses a multifunctional catalysis composition, which comprises the following raw materials in percentage by weight: 1%-80% of a mesopore active phosphorus-silicon-aluminum material, 1%-60% of a gasified active component, 0%-70% of clay and 2%-98% of heat-resistant inorganic oxide, wherein the mesopore active phosphorus-silicon-aluminum material has a phase structure of pseudo-boehmite, an anhydrous chemical expression based on the weight of oxides is (0-0.2)Na2O.(50-86)Al2O3.(12-50)SiO2.(0.5-10)P2O5, the specific surface area is 200-600m<2> / g, the pore volume is 0.5-1.8mL / g, and the mean pore size is 8-18nm. The catalysis composition can be applied to cracking gasification of heavy petroleum hydrocarbon, and is good in cracking property and low in gasification temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

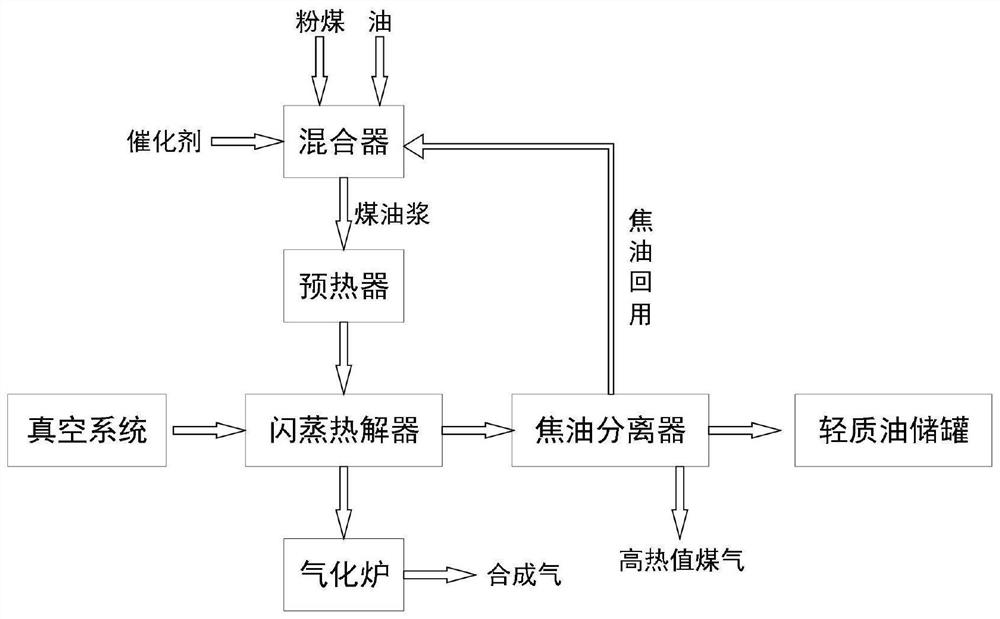

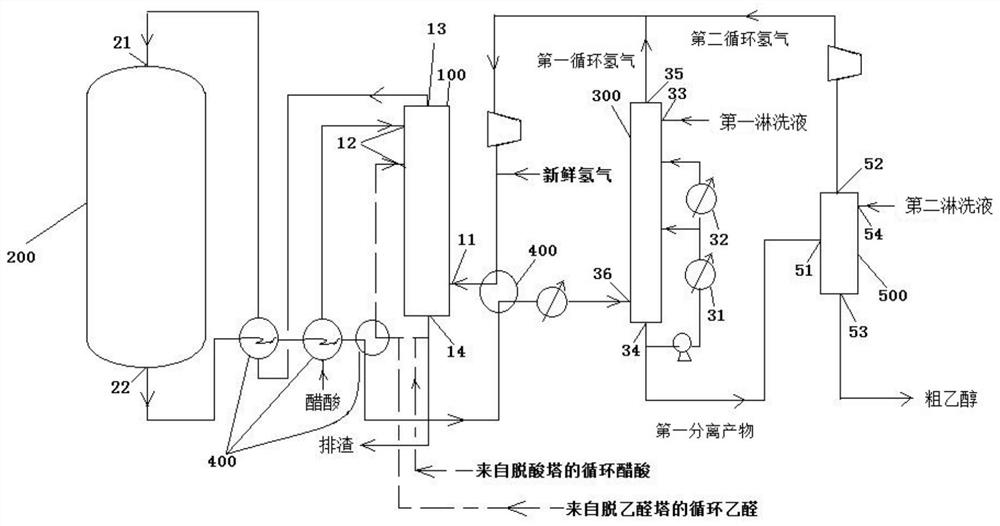

Kerosene co-catalytic pyrolysis-semicoke catalytic gasification method

PendingCN113214874ALower gasification temperatureImprove gasification efficiencyGasification processes detailsCombustible gas productionCatalytic pyrolysisSyngas

The invention discloses a kerosene co-catalytic pyrolysis-semicoke catalytic gasification method which comprises the following steps: mixing low-rank coal, oil and a catalyst to obtain kerosene slurry, preheating the kerosene slurry to 300-500 DEG C, feeding the preheated kerosene slurry into a flash pyrolysis device, maintaining the pressure of the flash pyrolysis device at 0.5-60kPa, and feeding volatile components generated by flash pyrolysis of the kerosene slurry into a tar separator; after volatile components obtained by flash evaporation and pyrolysis of the kerosene slurry escape, carrying out condensation polymerization on residual components through a flash evaporation and pyrolysis device to obtain solid semi-coke, crushing the solid semi-coke to 1-200 meshes, feeding the crushed solid semi-coke to a gasification furnace, heating the crushed solid semi-coke to 900-1200 DEG C at a speed of 10 DEG C / min in the gasification furnace, and taking CO2 as a gasification agent to obtain synthesis gas CO and H2; and condensing and separating volatile components obtained by flash evaporation and pyrolysis of the kerosene slurry through a tar separator to obtain light tar and high-calorific-value coal gas. According to the method disclosed by the invention, the yield and the quality of the pyrolysis tar are improved, meanwhile, the gasification temperature of the semicoke is reduced, and the gasification efficiency of the semicoke is improved.

Owner:XIJING UNIV

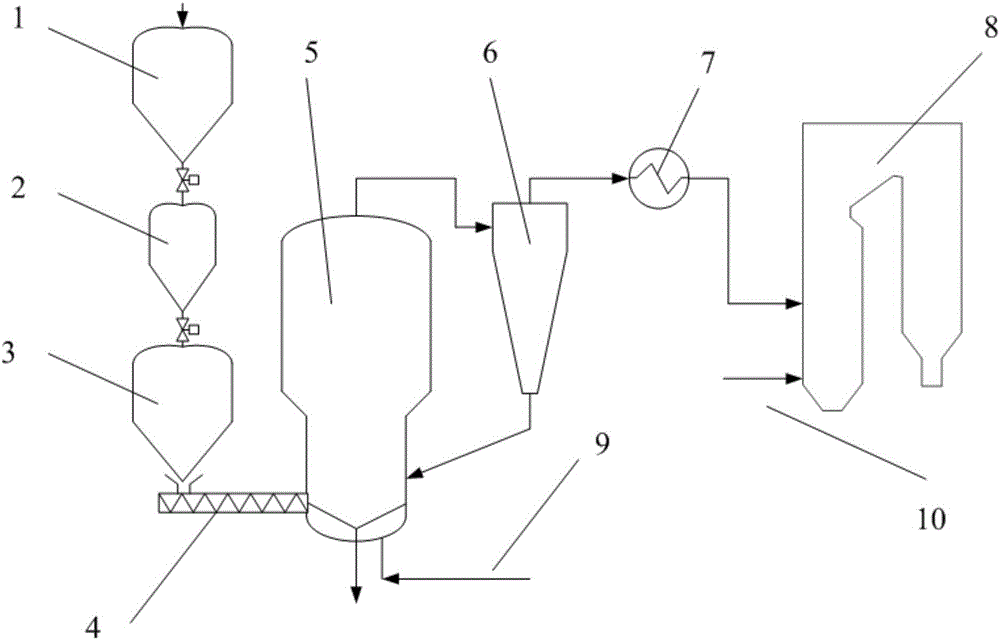

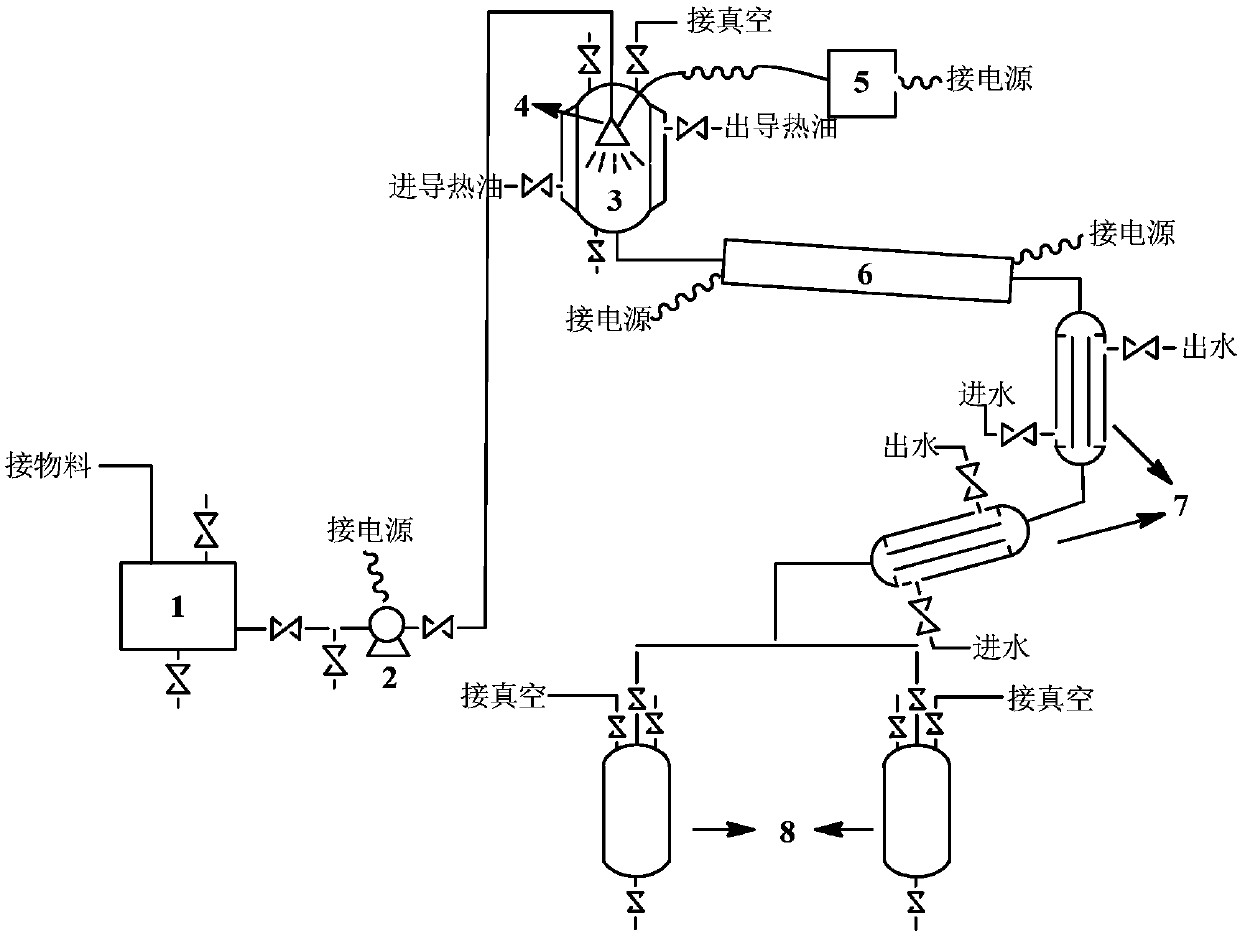

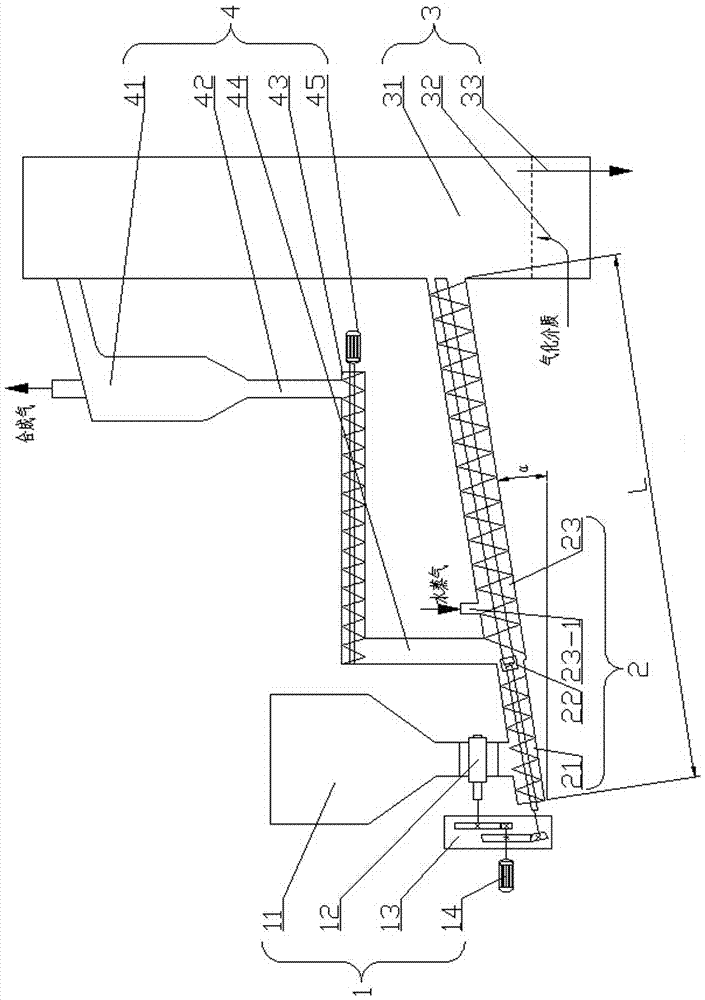

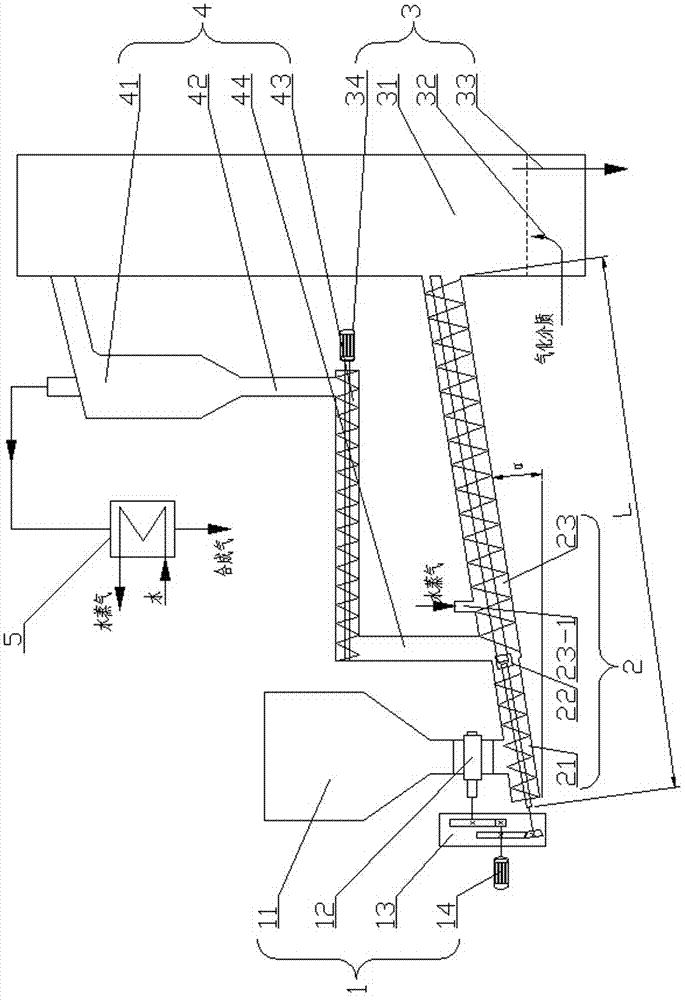

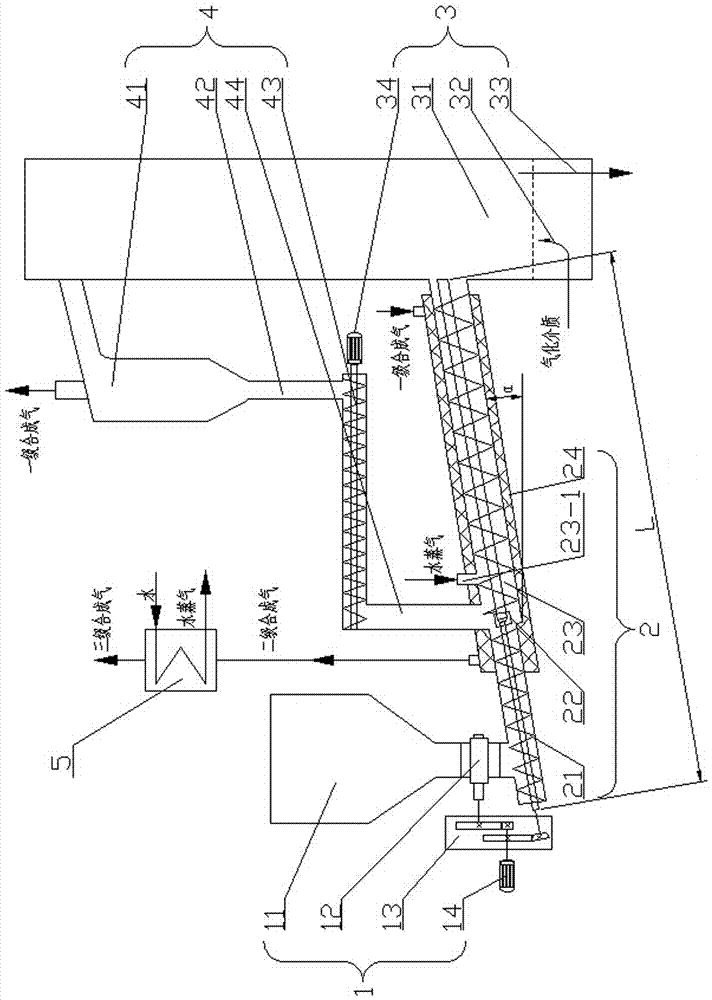

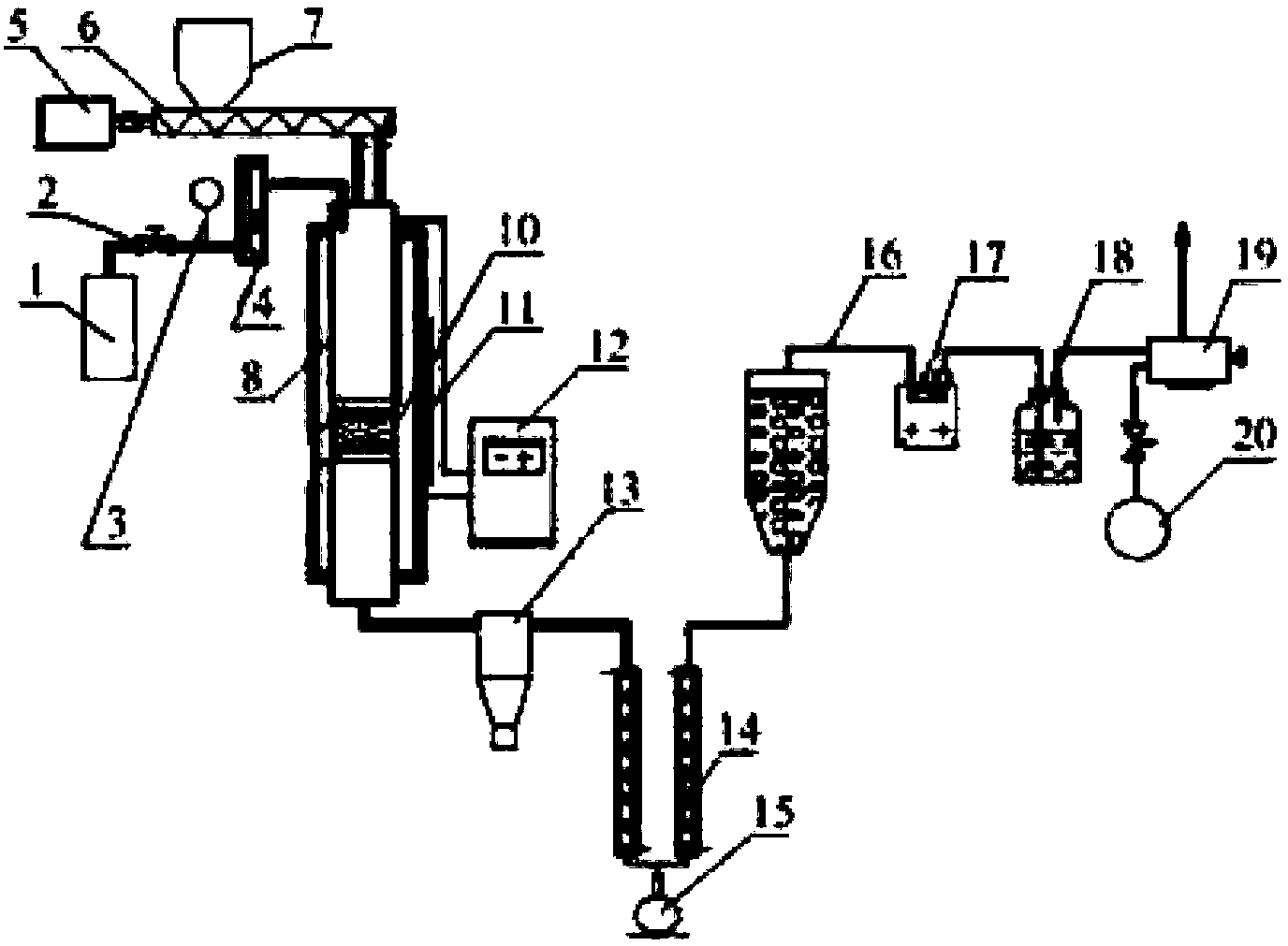

Low-rank fuel low-temperature gasification device based on screw pyrolyzers and fluidized bed gasifier

ActiveCN107400539AReduce contentFacilitated catalytic crackingGasification processes detailsGasification apparatus detailsFluidized bed gasifierWater vapor

A low-rank fuel low-temperature gasification device based on screw pyrolyzers and a fluidized bed gasifier belongs to the field of gasification of low-rank fuels. The power output shaft of a motor 1 is connected with the power input shaft of a transmission gearbox in a transmission mode, a first-order screw pyrolyzer is mutually coupled with a gas lock device through a transmission gearbox, the screw shaft of the first-order screw pyrolyzer is connected with the screw shaft of a second-order screw pyrolyzer through a shaft coupling, and the second-order screw pyrolyzer communicates with the fluidized bed gasifier; the upper part of the second-order screw pyrolyzer is provided with a water vapor inlet; the fluidized bed gasifier communicates with a cyclone separator, the fluidized bed gasifier communicates with a gas inlet system, and a residue discharging tube communicates with the bottom of the fluidized bed gasifier; and the cyclone separator communicates with a first-stage return tube, the first-order return tube communicates with a screw return device, the screw return device communicates with a second-order return tube, and the second-order return tube communicates with the second-order screw pyrolyzer. The in-situ catalytic cracking of parts of tar by pyrolytic coke and the re-adsorbed alkali metal and alkali earth metal catalyzed low-temperature gasification of coal coke are used to realize the high-efficiency low-temperature gasification of the low-rank fuel.

Owner:哈尔滨丰瀛投资有限公司

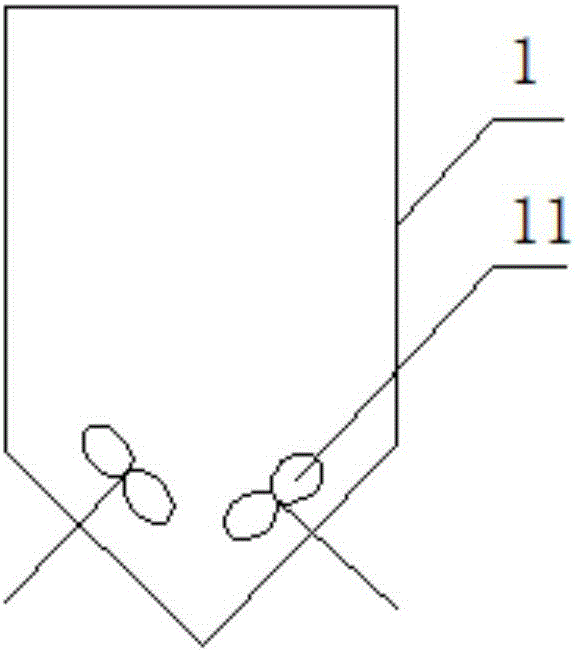

Fluidized-bed gasification furnace for treating biomass

InactiveCN106336905ALight weightSmall specific surface areaGasifier feeding meansGasifier mechanical detailsFluidized bed gasifierRound table

The present invention discloses a fluidized-bed gasification furnace for treating biomass. According to the fluidized-bed gasification furnace, the fluidized-bed gasification furnace body comprises an upper cylinder having a cylindrical structure, a lower cylinder having a cylindrical structure, and a connection section for connecting the upper cylinder and the lower cylinder; and the fluidized-bed gasification furnace is characterized in that the diameter ratio of the upper cylinder to the lower cylinder is 1.5-2:1, the connection section has a top-removing cone structure, the inclination angle of the connection section is 45-75 DEG, the bottom portion of the lower cylinder is provided with a wind distribution plate, the wind distribution plate has a hollow round table structure having the large upper portion and the small lower portion, and the included angle between the wind distribution plate and the bottom portion of the lower cylinder is 20-55 DEG. According to the present invention, the biomass raw material can be subjected to the large-scale treatment with the fluidized-bed gasification furnace, the fluidized-bed gasification furnace has the high energy conversion rate, the tar content in the produced fuel gas is low, and the secondary pollution cannot be generated.

Owner:武汉高斯生态能源技术有限公司

A multifunctional catalytic composition

ActiveCN103566918BGood catalytic coke gasification abilityLower gasification temperatureCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsActive componentPetroleum

A multifunctional catalysis composition comprises 1-70wt% of a mesoporous aluminosilicate material, 1-60wt% of a gasification active component, 0-70wt% of clay and 5-98wt% of a heatproof inorganic oxide by oxide, wherein the mesoporous aluminosilicate material has a phase structure of pseudo-boehmite, has an anhydrous chemical expression formula of (0-0.3)Na2O.(40-90)Al2O3.(10-60)SiO2 by weight of oxide, and has a specific surface area of 200-400m<2> / g, a pore volume of 0.5-2.0mL / g, an average aperture of 8-20nm and a most probable aperture of 5-15nm. The catalysis composition is used for the cracking gasification of heavy petroleum hydrocarbons, and realizes a low gasification temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waste oil treatment device and method thereof

PendingCN111137940ALower gasification temperatureProduce pollutionFatty/oily/floating substances removal devicesGeneral water supply conservationSlagDistillation

The invention provides a waste oil treatment device and a treatment method. The device comprises a separation cavity and a distillation cavity; a partition plate is arranged in the middle of the separation cavity and divides the separation cavity into a slag cavity and an oil cavity; and a chemical pump is arranged in the slag cavity. According to the method, oil floating in a water body is firstly adsorbed by using an adsorbate, followed by treatment, thus not polluting the water body; compared with the wind power treatment, efficiency is high and manpower is saved; most of slag and water inthe waste oil entering the distillation cavity are separated out in advance through the separation cavity, so that the content of waste slag and water in the distillation cavity can be effectively reduced, the opening frequency of a waste discharge port of the distillation cavity is greatly increased, and the production efficiency is improved; slag discharge in the separation cavity is carried outat the normal temperature, so that the probability of safety accidents can be effectively reduced; the distillation cavity is heated and vacuumized in advance, so that the gasification temperature ofwaste oil in the distillation cavity can be effectively reduced, and energy is saved.

Owner:广东联芯智能科技有限公司

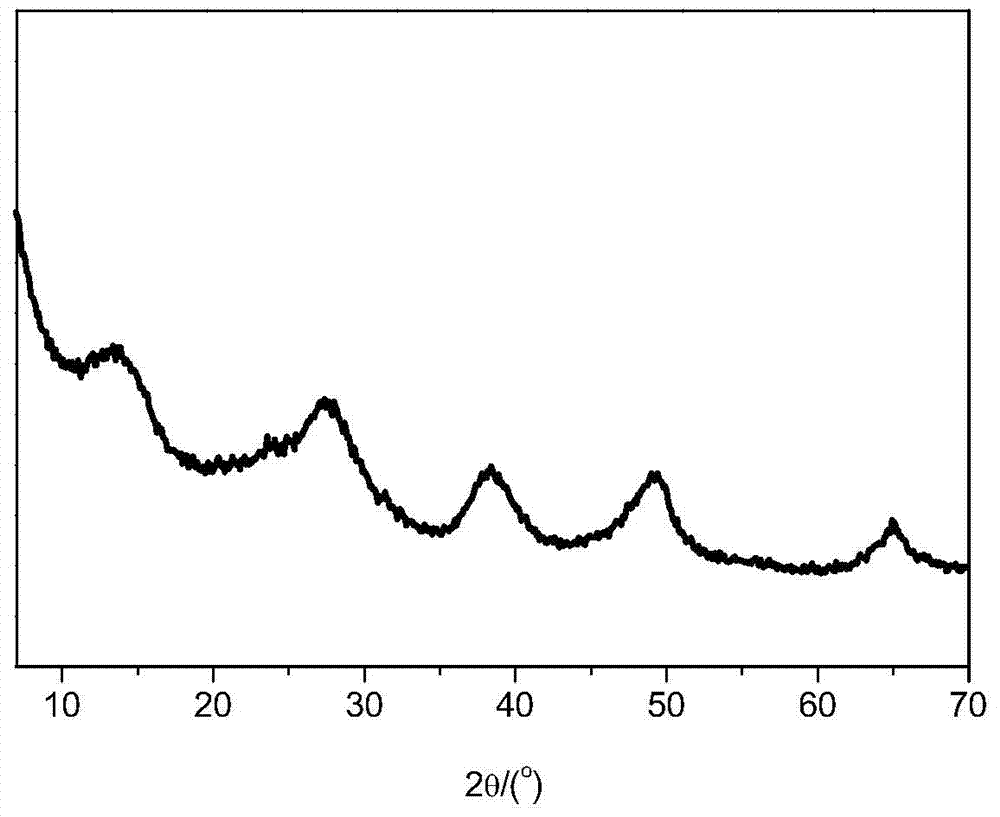

Catalyst and application thereof

InactiveCN104959139AGood catalytic activity at low temperatureLower gasification temperatureMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionSludgeCerium

The invention relates to a catalyst and application of the catalyst to manufacturing combustible gas from low-order fuel in supercritical water by means of catalytic gasification, and particularly discloses application of a catalyst to manufacturing high-quality combustible gas such as methane and hydrogen from low-order fuel in supercritical water by means of catalytic gasification. The catalyst and the application have the advantages that the catalyst is a supported catalyst (Ru / Ce<x>Zr<1-x>O<2>), cerium-zirconium solid liquid is mainly used as a catalyst carrier of the supported catalyst (Ru / Ce<x>Zr<1-x>O<2>), metallic ruthenium is used as an active component of the supported catalyst (Ru / Ce<x>Zr<1-x>O<2>), accordingly, the catalyst is excellent in low-temperature catalytic activity when high-moisture low-order brown coal is catalytically gasified in the supercritical water by the aid of the catalyst, and volumetric components of the combustible gas in obtained gas products can be higher than 60%; the catalyst is applicable to manufacturing the combustible gas from the low-order fuel such as the high-moisture low-order brown coal, wet biomass, municipal sludge and bottom sludge in lakes.

Owner:KUNMING UNIV OF SCI & TECH

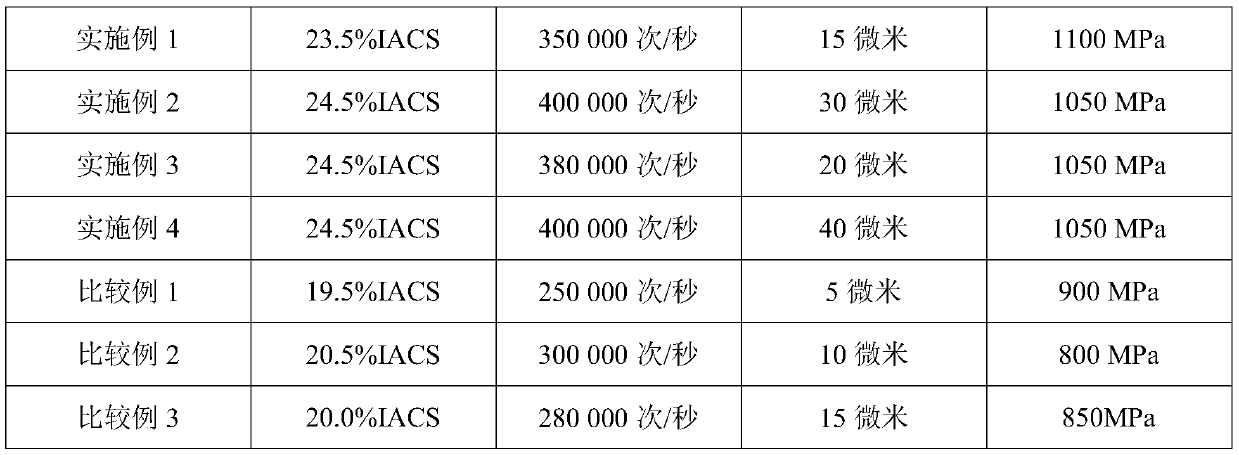

Method and apparatus for preparing high-content polyenoic ethy lester

ActiveCN1814580AHigh purityReduced thermal deteriorationOrganic compound preparationCarboxylic acid esters preparationPolymer scienceEthyl ester

The invention discloses high content polyenoic acid ethyl ester manufacturing method. It is did vacuum filming volatilizing for the material in volatilizing kettle by sweeping bottom and liquid material vacuum volatilizing device and formed high content product with over 80% purity after rectifying in filling rectifying tower. The sweeping bottom and liquid material vacuum volatilizing device are worked continuously to form polyenoic acid ethyl ester with high EPA-E and DHA-E content. The invention offers the volatilizing kettle and its rectifying device to ensure perfect effect.

Owner:北京百慧生化制药有限责任公司

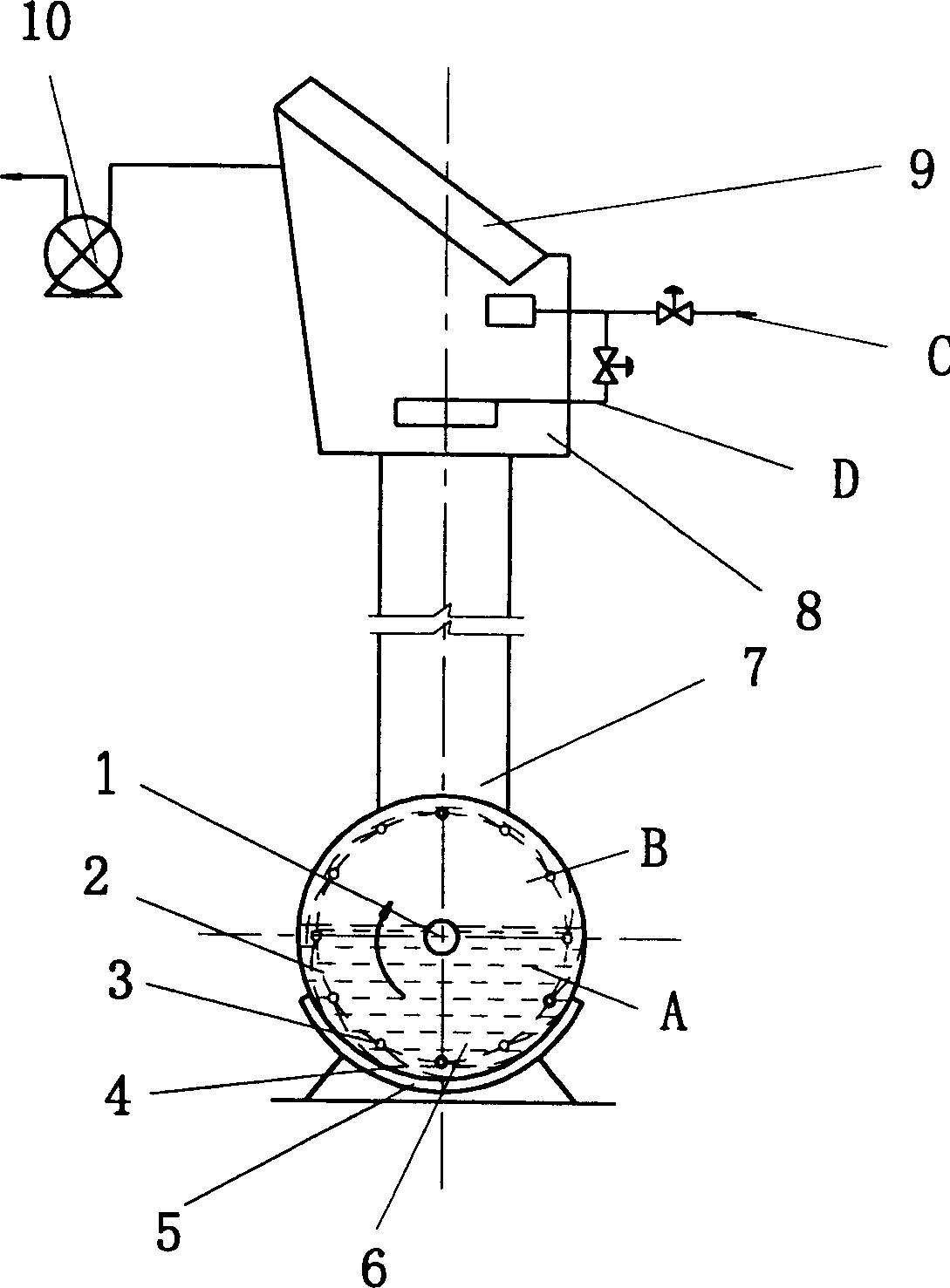

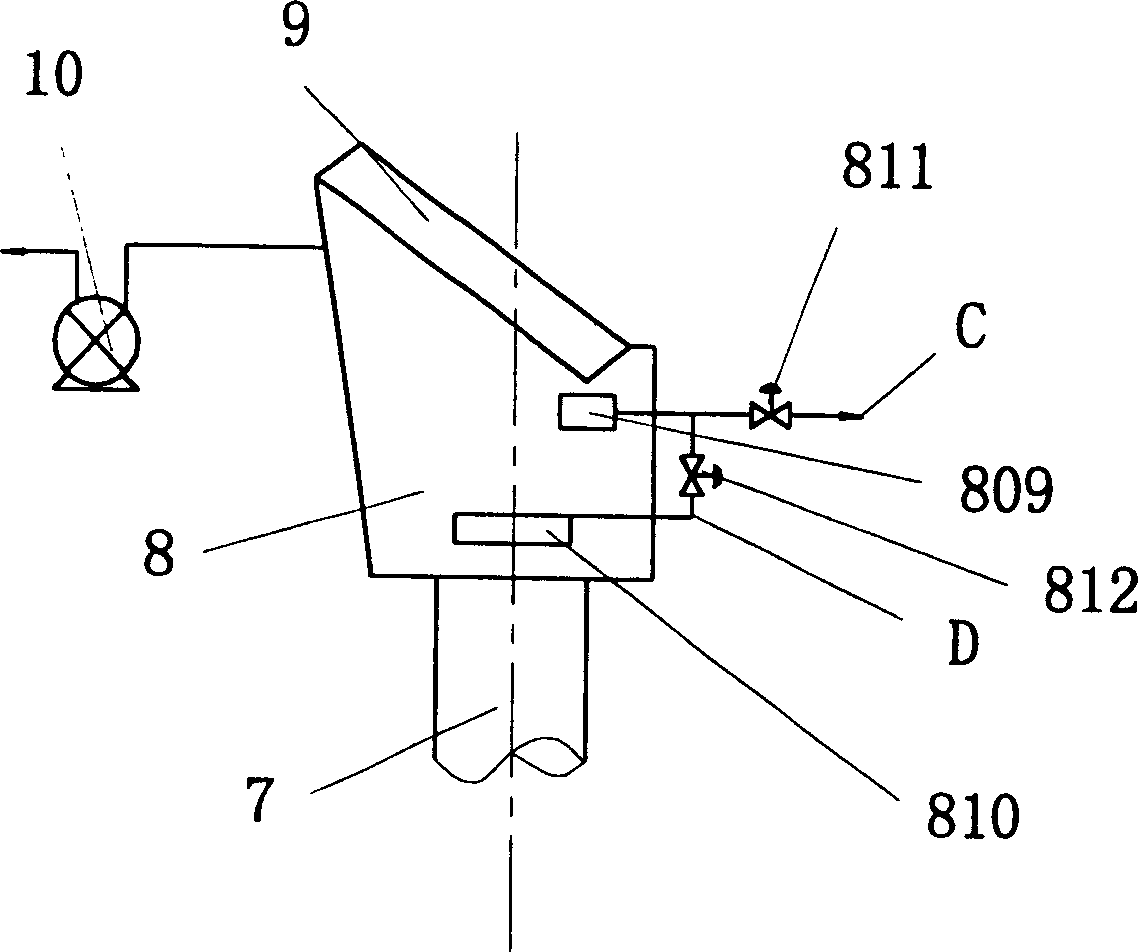

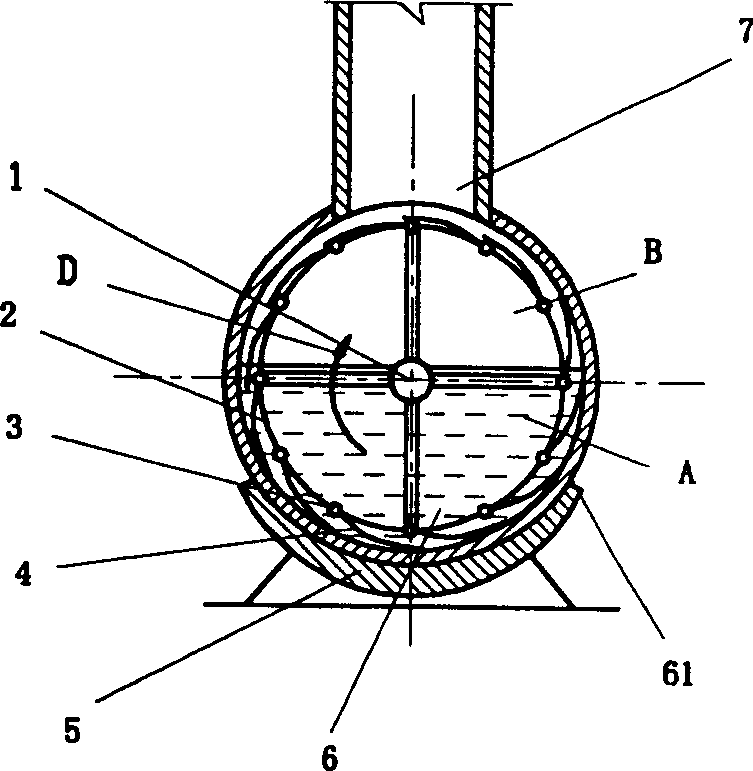

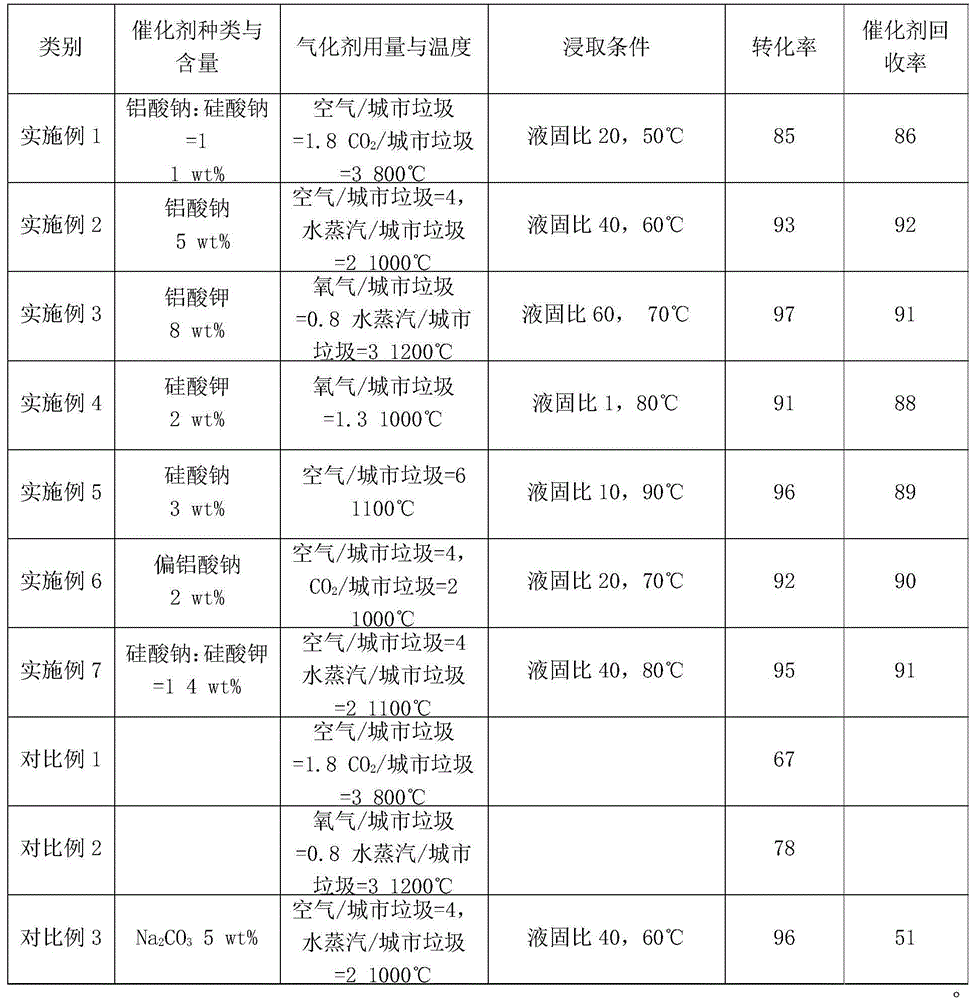

Catalytic pyrolysis gasification method of urban garbage

ActiveCN106590747ALower gasification temperatureIncrease reaction rateGasification processes detailsChemical recyclingCatalytic pyrolysisLitter

The invention relates to a garbage treatment method which comprises the following specific steps: loading urban garbage with the aluminate and silicate of an alkali metal with a high melting point and low volatility at a certain loading capacity; pyrolyzing at 300-900 DEG C; gasifying at 800-1,200 DEG C to obtain catalyst-containing gasified residues; and washing to realize catalyst recycling. The aluminate and silicate of the alkali metal are applied to the catalytic gasification treatment of urban garbage; and the catalyst has the advantages of good catalysis property, low volatility at high temperature, little equipment corrosion, high ash melting temperature and simplicity in recycling.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

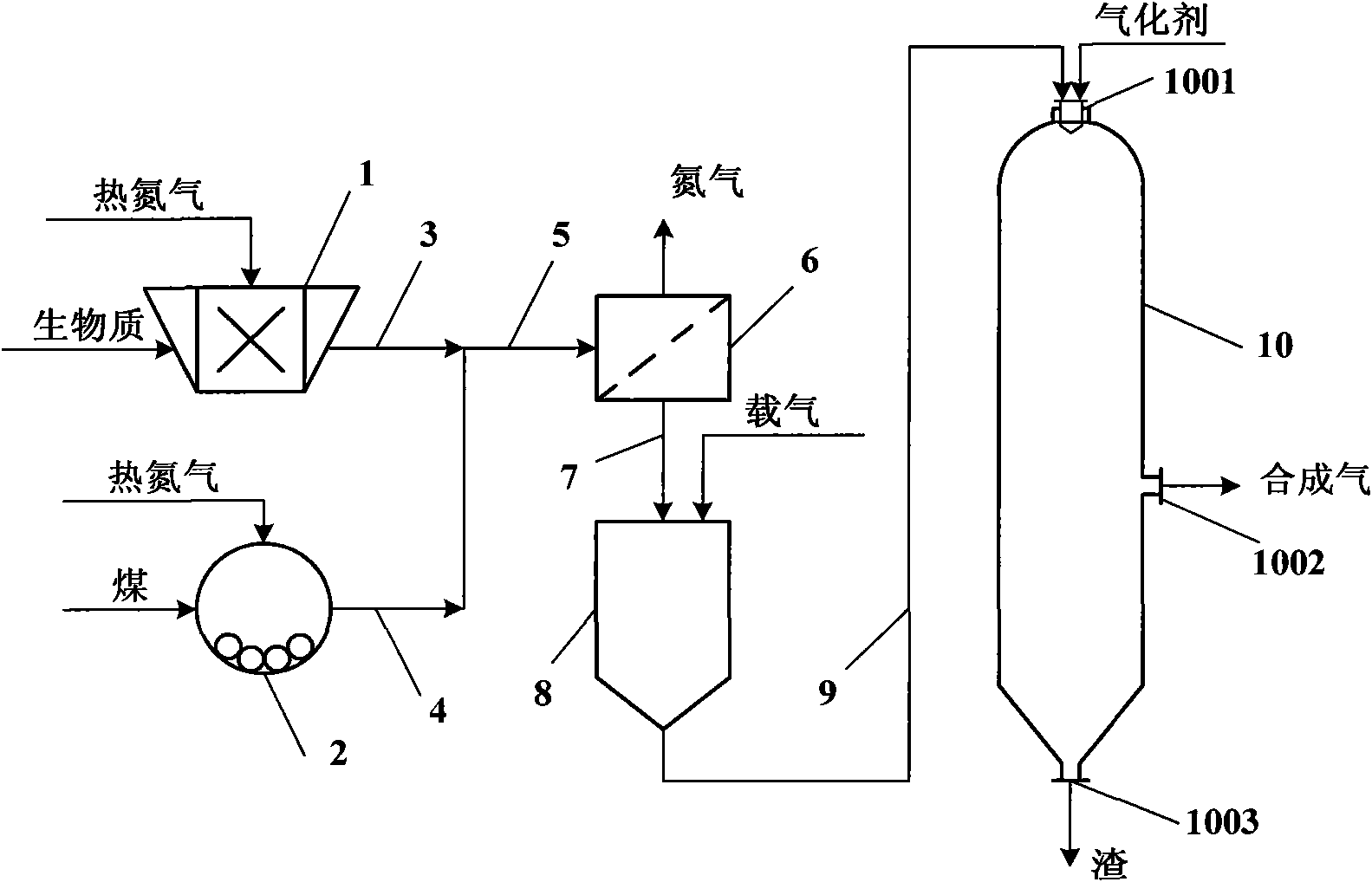

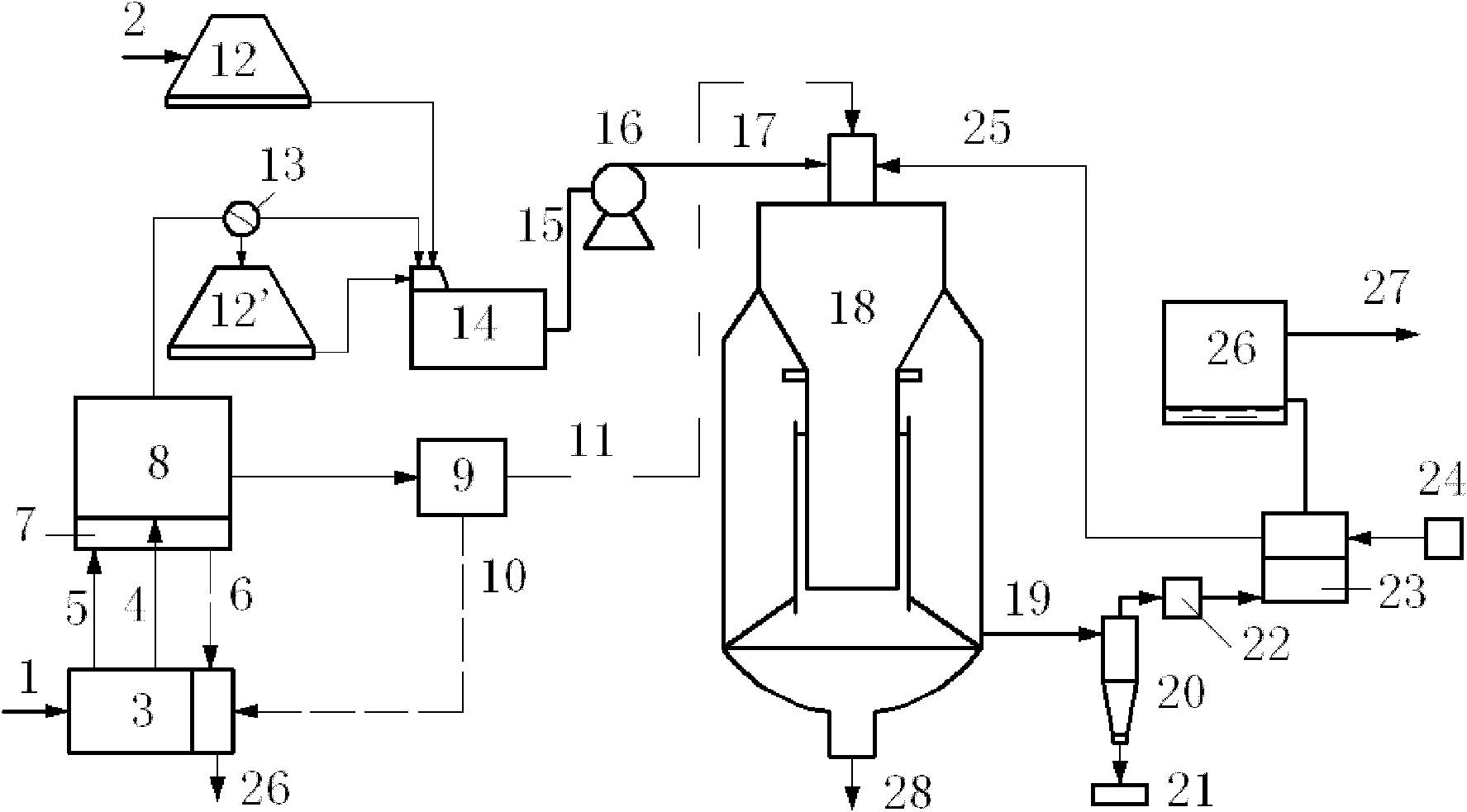

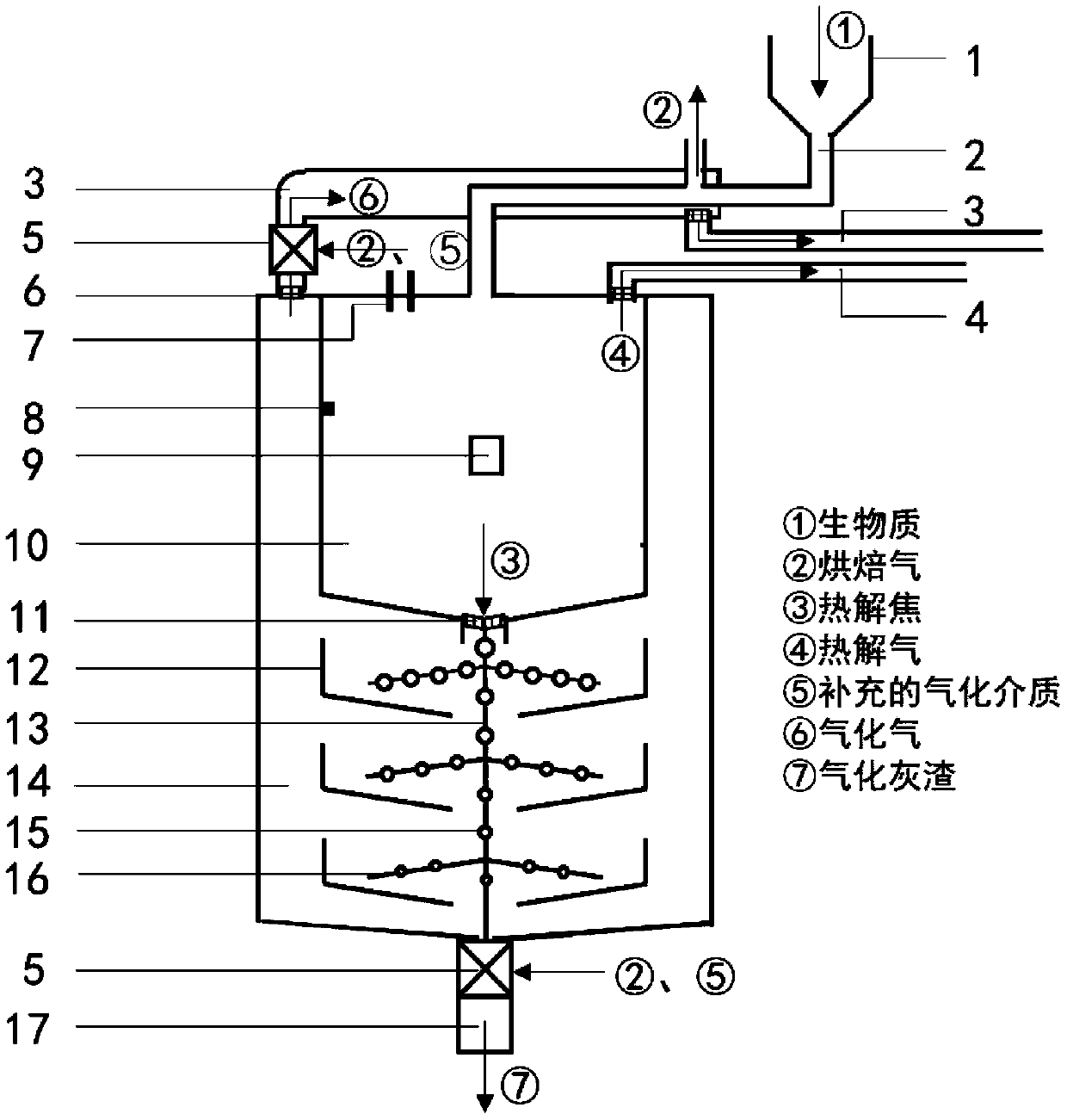

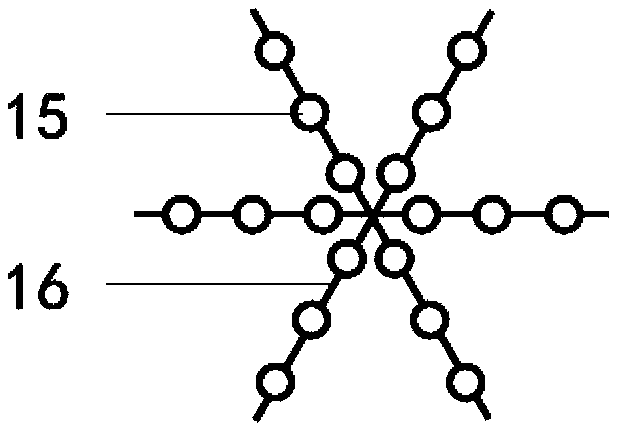

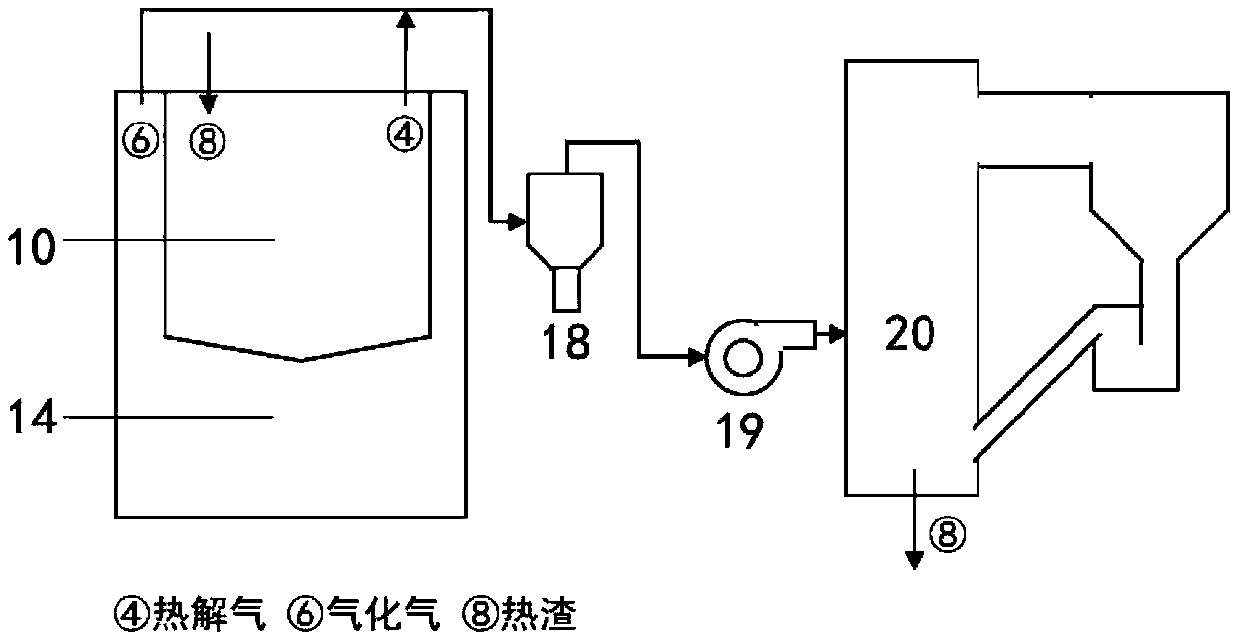

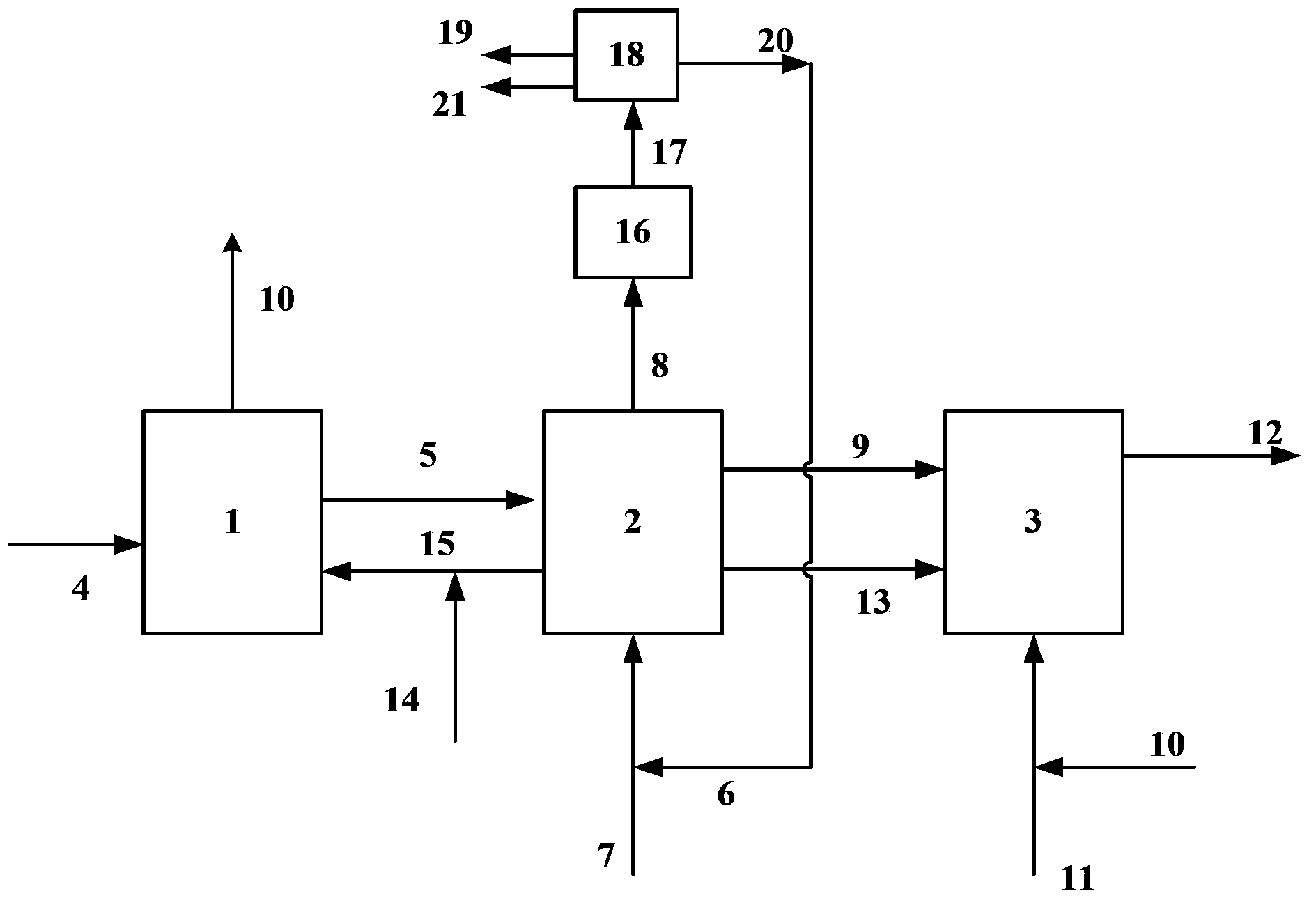

A biomass pyrolysis gasification system and its application

ActiveCN109628156BEfficient use ofEmission reductionGasification processes detailsCombustible gas productionThermodynamicsCoke

The invention belongs to the technical field of biomass energy sources and particularly discloses a biomass pyrolysis gasification system and application thereof. The system comprises a feeding device, a pyrolysis chamber and a gasification chamber, wherein the feeding device is connected with the pyrolysis chamber and used for feeding biomass raw materials into the pyrolysis chamber; the top of the pyrolysis chamber is connected with a pyrolysis gas conveying pipe for conveying pyrolysis gas outwards, and the bottom of the pyrolysis chamber is provided with a pyrolysis coke outlet for conveying pyrolysis coke into the gasification chamber. The gasification chamber sleeves the pyrolysis chamber to form a sleeve structure, the top of the gasification chamber is connected with a gasifying gas conveying pipe for conveying gasifying gas outwards, the gasifying gas conveying pipe sleeves the feeding device to utilize the gasifying gas to bake and preheat the biomass raw materials, and baking gas generated by baking and preheating is conveyed into the gasification chamber; the bottom of the gasification chamber is provided with a gasified ash outlet which is used for conveying gasified ash generated by gasification into an ash collector. The system can be deeply coupled with a coal-fired boiler and has the advantages that the gasification efficiency is high, the comprehensive heat value of fuel gas is high, and pyrolysis gas can be used as reburning fuel.

Owner:HUAZHONG UNIV OF SCI & TECH

Heavy oil upgrading method capable of preparing methane

ActiveCN103571529ALower gasification temperatureEmission reductionTreatment with plural serial stages onlyHydrocarbonsMethanationSulfur

The invention discloses a heavy oil upgrading method capable of preparing methane. The heavy oil upgrading method comprises following steps: light oil is obtained after contact cracking of low-quality heavy oil, and at the same time, an obtained coked catalyst is delivered into a gasification unit; in the gasification unit, coke on the coked catalyst and a gasification agent are subjected to gasification and methanation reaction so as to obtain a gasification gas containing CH4, CO, H2 and CO2, wherein sulfur in the gasification gas mainly comes from H2S; the gasification gas is delivered into desulphurizing equipment for desulphuration, and then the gasification gas is further separated, obtained CH4 is removed, and obtained CO and H2 are delivered back to the gasification unit; an obtained a semi-regenerative contact agent is delivered into a regeneration unit, and in the presence of oxygen, complete combustion of carbon residue on the semi-regenerative contact agent is realized so as to obtain a complete-regenerative contact agent and smoke, wherein sulfur in the smoke mainly comes from SOx; the smoke is delivered through a alkali washing device, or is processed using a sulfur transferring agent so as to achieve emission standards, and then is discharged, and the complete-regenerative contact agent is delivered back to a contact cracking reactor. The heavy oil upgrading method is capable of realizing utilization of petroleum resources with high efficient and little pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing fuel gas by utilizing municipal waste

ActiveCN103382403AAvoid it happening againLower gasification temperatureCombustible gas productionProduction rateWater vapor

The invention provides a fuel gas generation device. The fuel gas generation device comprises a vapor generator, a rotary feeder, a fixed bed pyrolysis gasifier, a heating electric furnace, a cyclone separator and a condensing device; the vapor generator is connected with the inlet of the fixed bed pyrolysis gasifier; the rotary feeder is connected with the inlet of the fixed bed pyrolysis gasifier; the fixed bed pyrolysis gasifier wraps the heating electric furnace; the cyclone separator is connected with the outlet of the fixed bed pyrolysis gasifier; the condensing device is connected with the cyclone separator. According to the fuel gas generation device, a large amount of tar which is generated from gasification of municipal solid waste is avoided, the gasification temperature is low, and the gas production rate is high.

Owner:杭州并联世纪科技有限公司

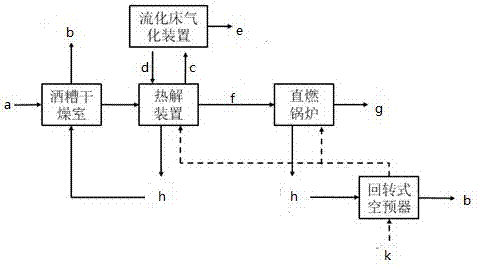

Grain stillage treatment system

PendingCN107033933AAvoid bringing out phenomenaDry fastEnergy inputGasification processes detailsAir preheaterOperating point

The invention relates to a distiller's grains processing system, comprising: a distiller's grains drying chamber, a pyrolysis device, a direct-fired boiler, a fluidized bed device, and a rotary air preheater. The melting point threat treatment system of distiller's grain incineration improves the safety factor and stability of the treatment process; solves the steam source of the brewing enterprise and reduces the operating cost of the enterprise; improves the energy utilization rate of the treatment system; reduces the operating load of the process flue gas purification system.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

Catalytic coal gasification catalyst dispersion method

InactiveCN104178221AGood dispersionAvoid uniformityGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystUltrasonic assisted

The invention discloses a preparation process for rapid dispersion of a catalyst on a coal based material, and provides a simple and efficient method for the preparation of a catalytic coal gasification catalyst. According to the method, rapid distribution of the catalytic coal gasification catalyst on the coal based material by ultrasonic assisted technology. The preparation process is applied in a catalytic coal gasification fixed bed reactor, and compared with a routine method for production of the catalytic coal gasification catalyst, the preparation process can not only shorten the time of preparing the catalyst, but also can greatly improve the gasification efficiency of the coal based material and increase the methane production, and can improve the clean and efficient use of the coal based material.

Owner:CHINA PETROLEUM & CHEM CORP +1

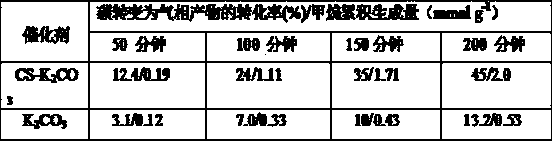

System and method for preparing crude ethanol through hydrogenation of hydrogenation raw materials and application

ActiveCN113461485AImprove the effect of gas-liquid separationReduce corrosionOrganic compound preparationHydroxy compound separation/purificationAcetic acidPhysical chemistry

The invention relates to the field of ethanol preparation, in particular to a system and method for preparing crude ethanol through hydrogenation of hydrogenation raw materials and application. The system comprises gasification equipment (100), heating equipment (400), reaction equipment (200), first gas-liquid separation equipment (300) and second gas-liquid separation equipment (500), wherein the heating equipment (400) is used for respectively heating a hydrogenation raw material, hydrogen and a mixed raw material gas obtained by gasification by utilizing heat of a reaction product; and the first gas-liquid separation equipment (300) is sequentially provided with a first separation section, a second separation section and a third separation section from bottom to top and is used for carrying out first gas-liquid separation on a reaction product in a direct cooling manner. The low-temperature gasification of acetic acid can be realized, the gas-liquid separation effect of the reaction product in the process of preparing crude ethanol by hydrogenation of the hydrogenation raw material is remarkably improved, and the reaction heat is fully utilized.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com