A biomass pyrolysis gasification system and its application

A technology of pyrolysis gasification and biomass, applied in gasification process, manufacture of combustible gas, petroleum industry, etc. The effect of reducing the gasification temperature, simplifying the raw material pretreatment process, and improving the gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

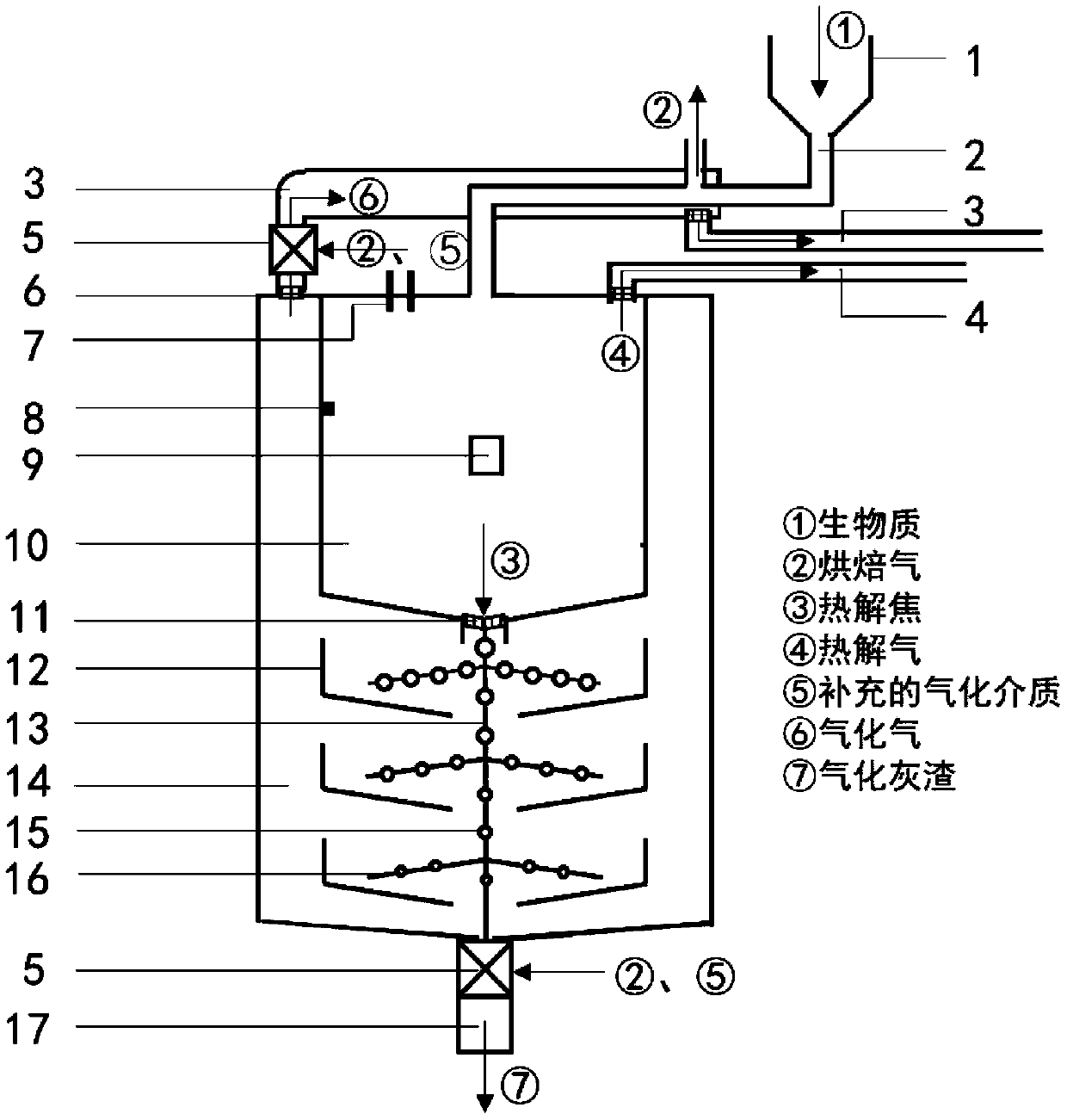

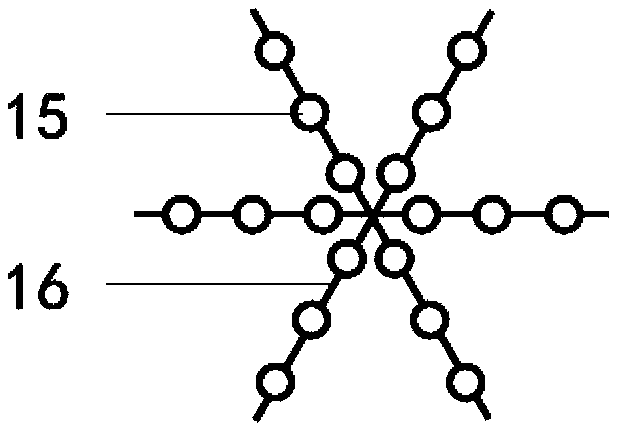

[0039] Under the guidance of the screw feeding device, the preliminarily treated biomass raw material reaches the feed inlet at the upper end of the pyrolysis chamber from the silo, during which the biomass raw material undergoes low-temperature roasting and releases H 2 O.CO 2 small molecule gas; the torrefied biomass raw material is decomposed into pyrolysis coke and pyrolysis gas with higher comprehensive calorific value in the pyrolysis chamber; pyrolysis coke exits from the lower end of the pyrolysis chamber and slowly passes through the gasification chamber , the gasification reaction is carried out under the action of the gasification medium; the gasification gas and pyrolysis gas enter the coal-fired boiler under the guidance of their own dedicated pipelines; the gasification ash enters the ash collector after exchanging heat with the gasification medium.

[0040] When the coupled coal-fired boiler is a fluidized bed boiler 20, the pyrolysis gas and gasification gas ar...

Embodiment 2

[0042] In the biomass pyrolysis gasification system, the operation mode is consistent with that of Example 1.

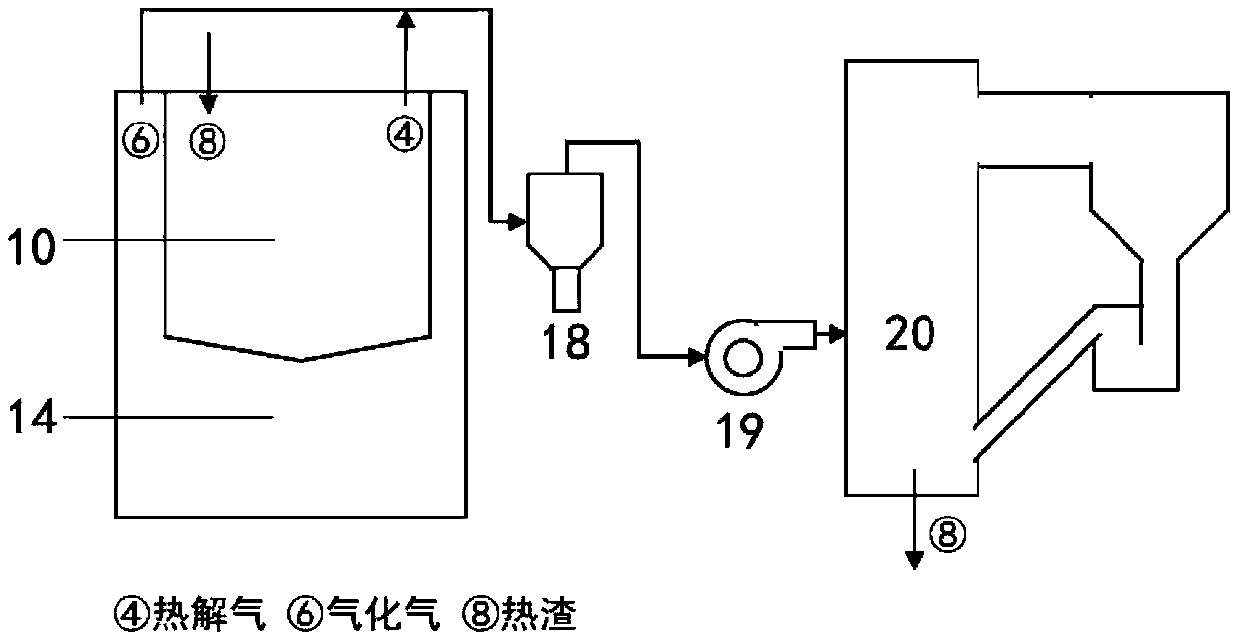

[0043] The pyrolysis gas sent from the pyrolysis gas delivery pipeline 4 of the biomass pyrolysis gasification system is sent to the upper part of the coal-fired boiler 21 through the booster fan 19, so as to promote the reburning of the coal-fired boiler and reduce the NOx emission of the coal-fired boiler; The gasification gas sent from the gasification gas delivery pipeline 3 of the biomass pyrolysis gasification system is separately sent to the lower part of the coal-fired boiler through the gas-solid separator 18 to promote coal combustion. In the case of heat transfer, the gas-solid separator returns part of the separated gasification gas to the burner in the pyrolysis chamber to burn supplementary heat, such as Figure 4 shown.

Embodiment 3

[0045] In the biomass pyrolysis gasification system, the operation mode is consistent with that of Example 1.

[0046] When the pyrolysis gasification system operates under slightly positive pressure (200-400Pa higher than atmospheric pressure), the gasification gas sent by the biomass gasification gas pipeline 3 and the pyrolysis gas sent by the pyrolysis gas pipeline 4 are exchanged Heater 5 performs heat exchange, gasification gas is sent to the lower part of the boiler to promote coal combustion, and pyrolysis gas is sent to the upper part of the boiler to promote reburning of the coal-fired boiler and reduce NOx. During this period, there is no booster fan, which can simplify the system, such as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com