Method for preparing fuel gas by utilizing municipal waste

A technology for municipal waste and gas, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of low gas production rate, high gasification temperature and high tar content, and achieve the effect of high gas production rate and low gasification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

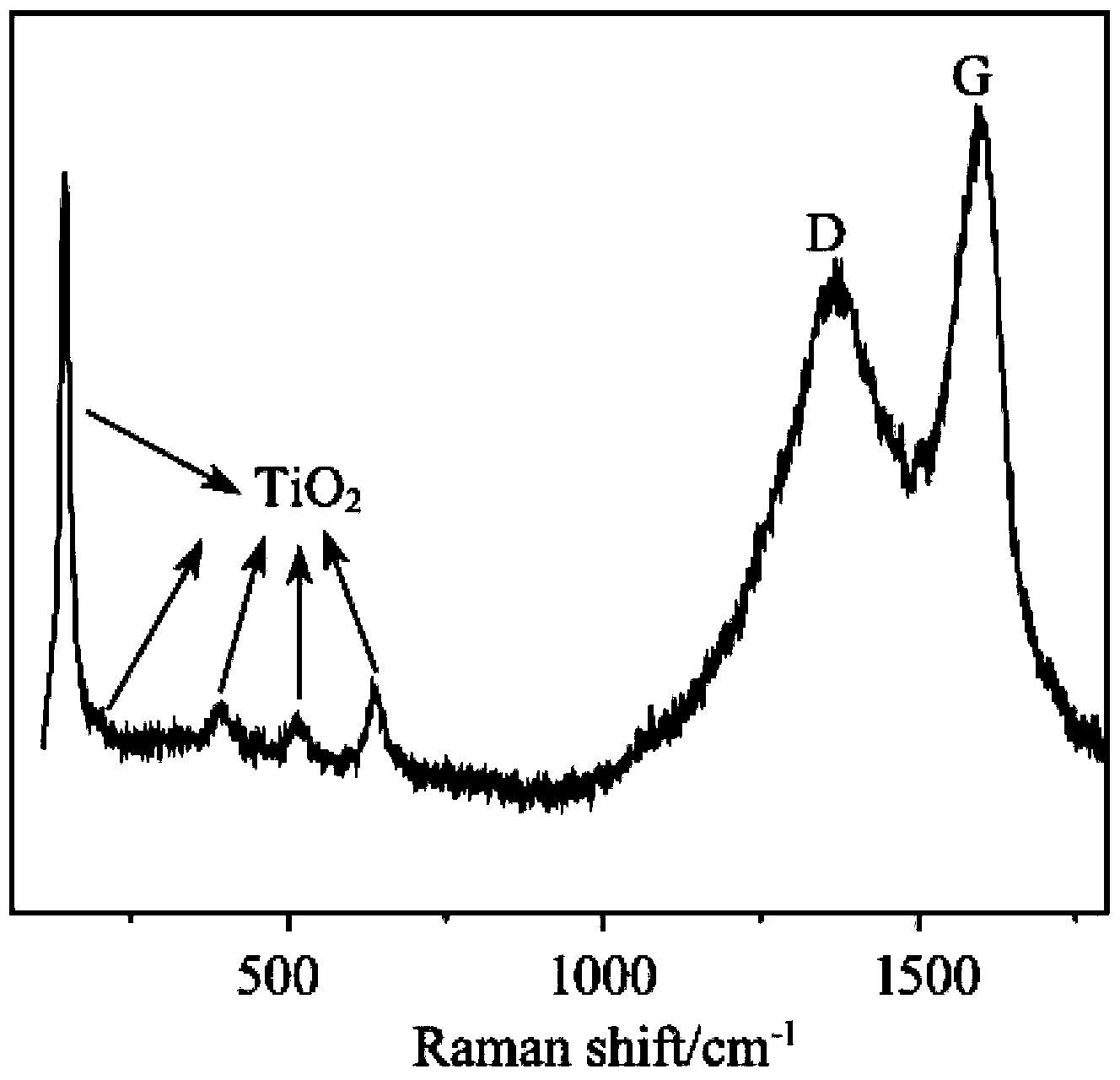

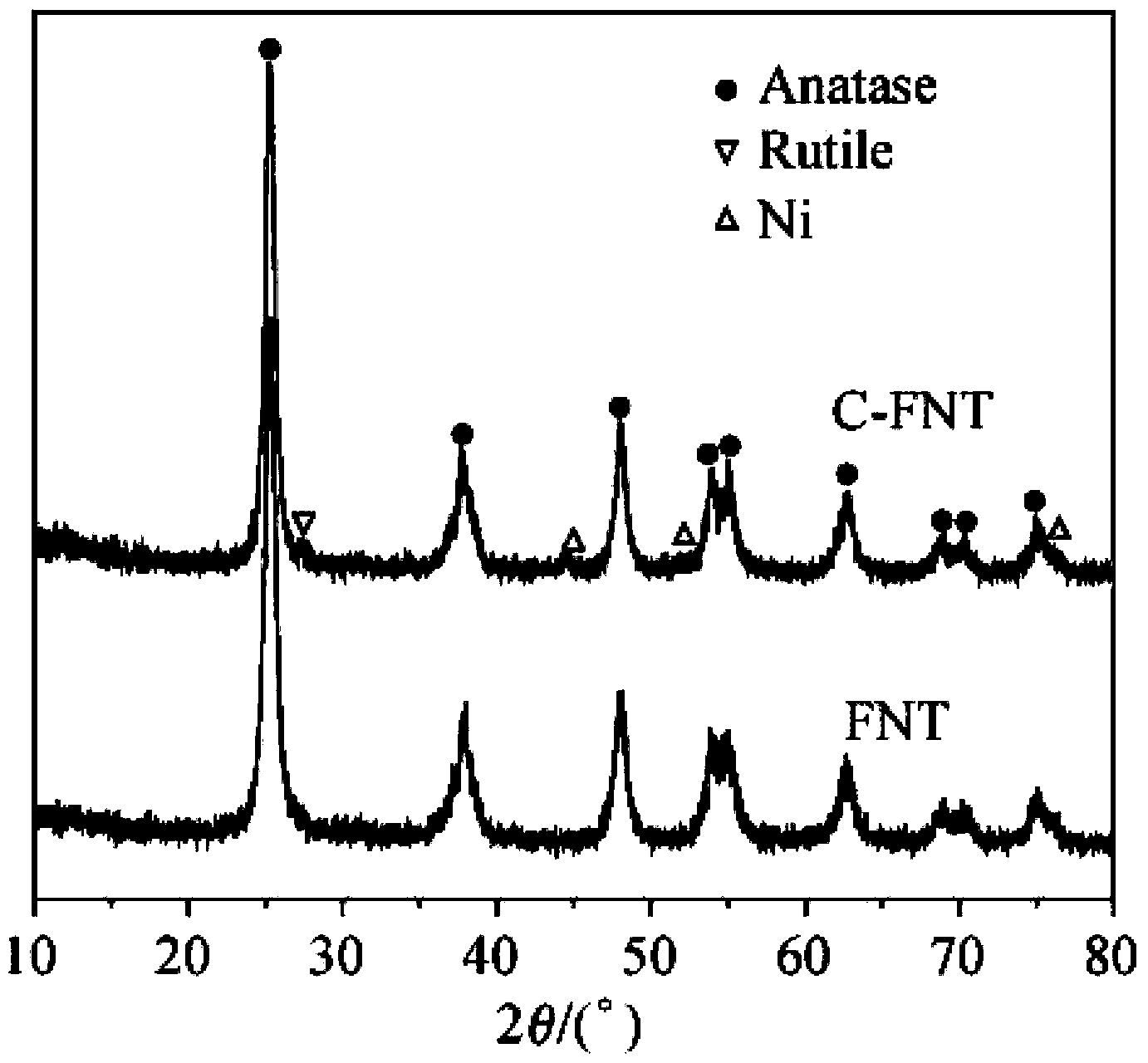

[0049] Preparation and characterization of embodiment 1 catalyst

[0050] The surface characteristics of the catalyst were analyzed using ASAP2010 specific surface and pore size analyzer (Micrometrics).

[0051] Weigh 68g tetrabutyl titanate solution, add 377mL absolute ethanol and 26.75g nitric acid, stir to obtain solution A; 0.404gFe(NO 3 ) 3 9H 2 O,2.619g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 215mL deionized water to obtain solution B. Add solution B dropwise to solution A, stir for 2h, let stand for 20h, and dry at 120°C. Raise the temperature to 500°C at a rate of 3°C / min, and roast for 3h. Preparation Fe-NiO / TiO 2 , the prepared Fe-Ni / TiO 2 The comparative area is 63.0m 2 / g, take the prepared Fe-NiO / TiO 2 Put 10g of catalyst in a fluidized bed reactor, adjust the flow rate of nitrogen gas to 5L / min to fluidize the catalyst. Raise the temperature to 500°C, and after the temperature in the reactor is stabilized, feed acetylene gas into the reactor at a flow rate ...

Embodiment 2

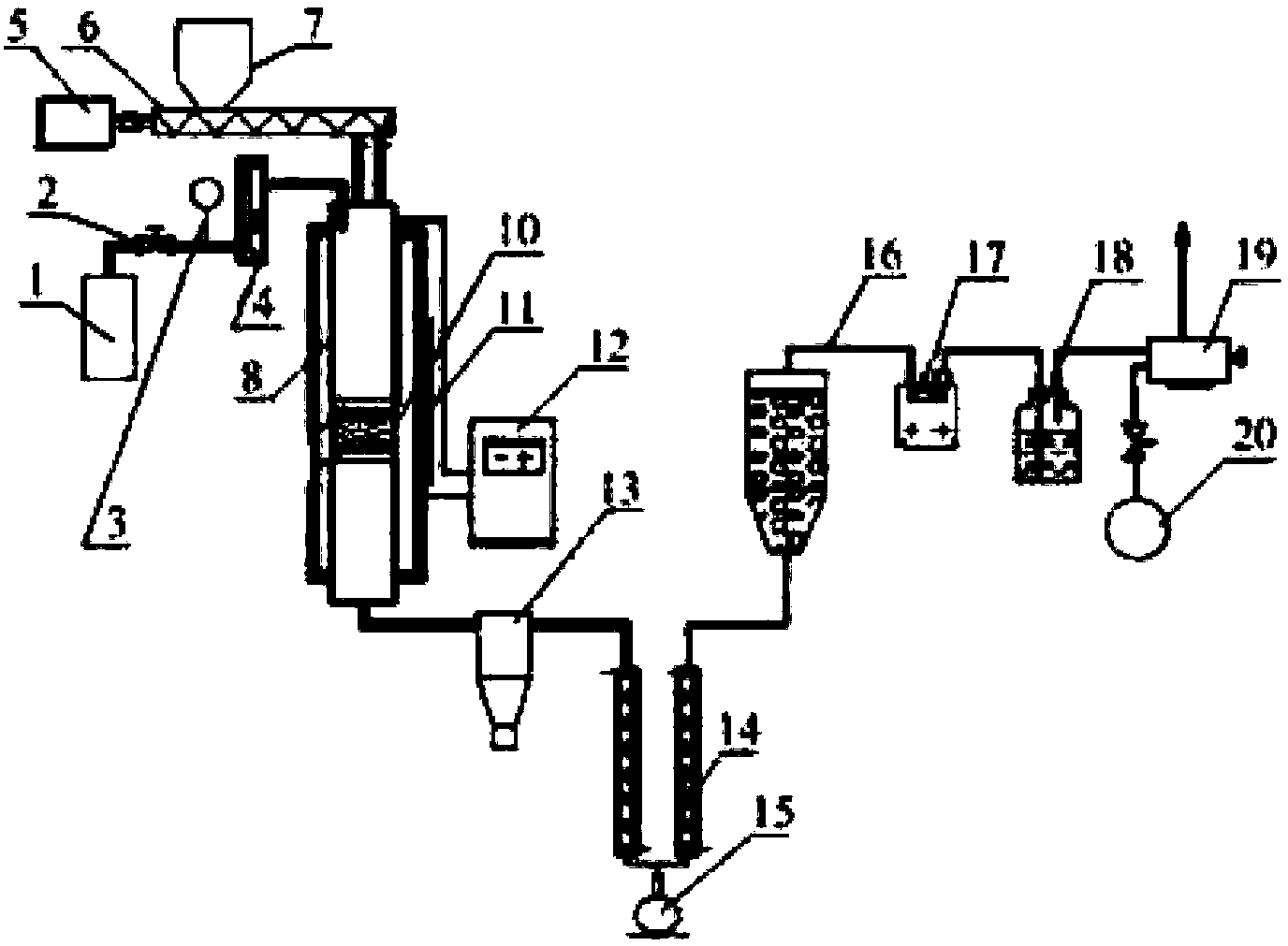

[0056] The processing of embodiment 2 municipal refuse

[0057] The rubbish that waste paper, plastic rubber, fabric, wood and bamboo are mixed is pulverized into 5mm, is placed in the rotary feeder 6 and sealed, and the catalyst prepared in Example 1 is added in the fixed-bed pyrolysis gasifier 8, and the The electric furnace is energized, and the temperature is raised to preheat the fixed-bed pyrolysis-gasifier. When the temperature of the fixed-bed pyrolysis-gasifier reaches 700°C, the waste material is sent into the fixed-bed pyrolysis-gasifier 8 at a rate of 0.8kg / h, and the Water vapor is fed into the fixed bed pyrolysis gasification furnace 8 at a rate of 0.8kg / h for pyrolysis gasification reaction. The reaction time is 20 minutes, and the gasification products obtained after the reaction are exported from the fixed bed pyrolysis gasification furnace After the cyclone separator 13 removes the carried particulate matter, it is then cooled by the condensing device 14, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com