Mixed fuel coal water slurry entrained flow bed gasification system

A technology of gasification system and mixed fuel, which is applied in the gasification of granular/pulverized fuel, the production of combustible gas, and the special form of dry distillation. , unfavorable carbon gasification reaction and other problems, to achieve the effect of meeting large-scale utilization, improving carbon conversion rate, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

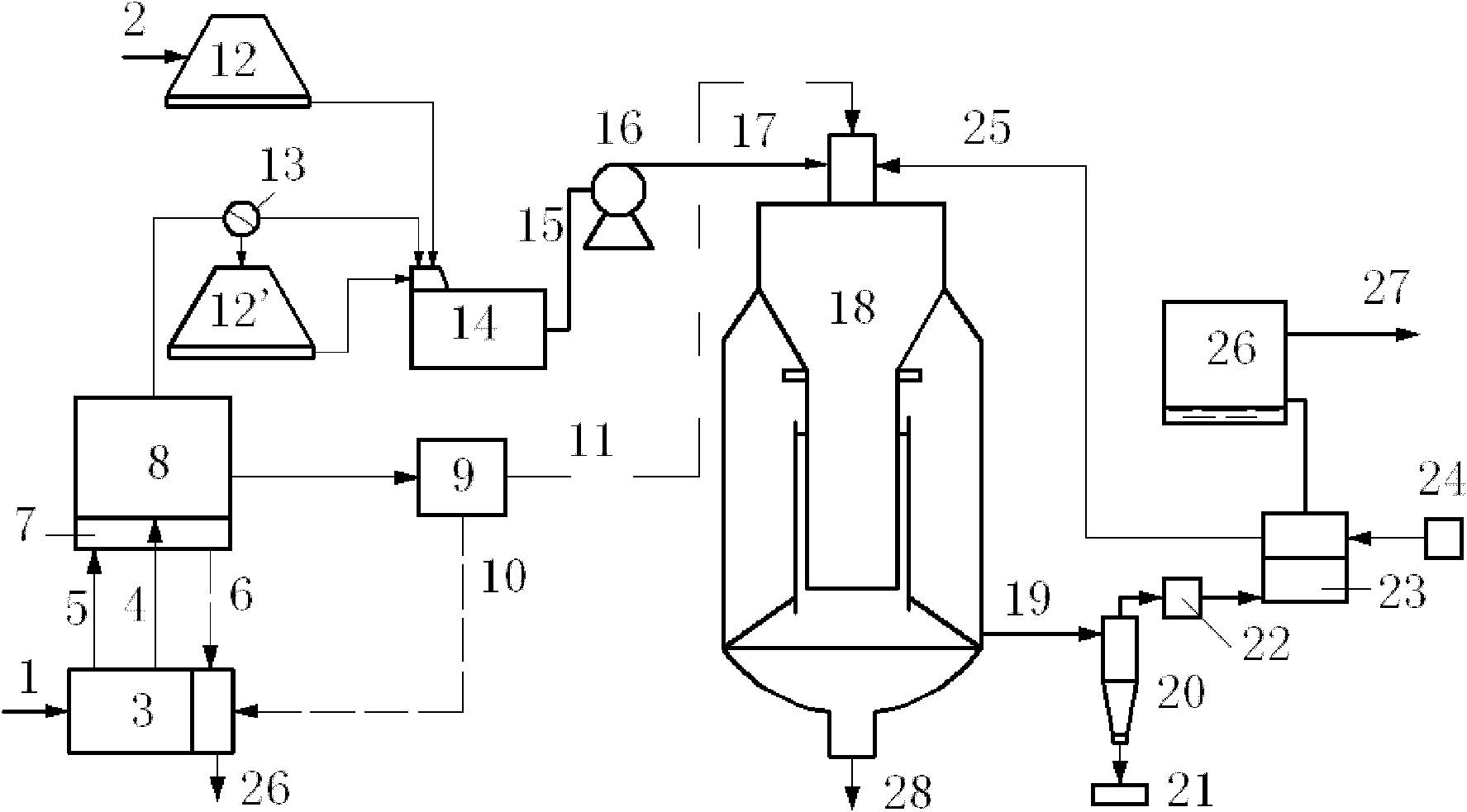

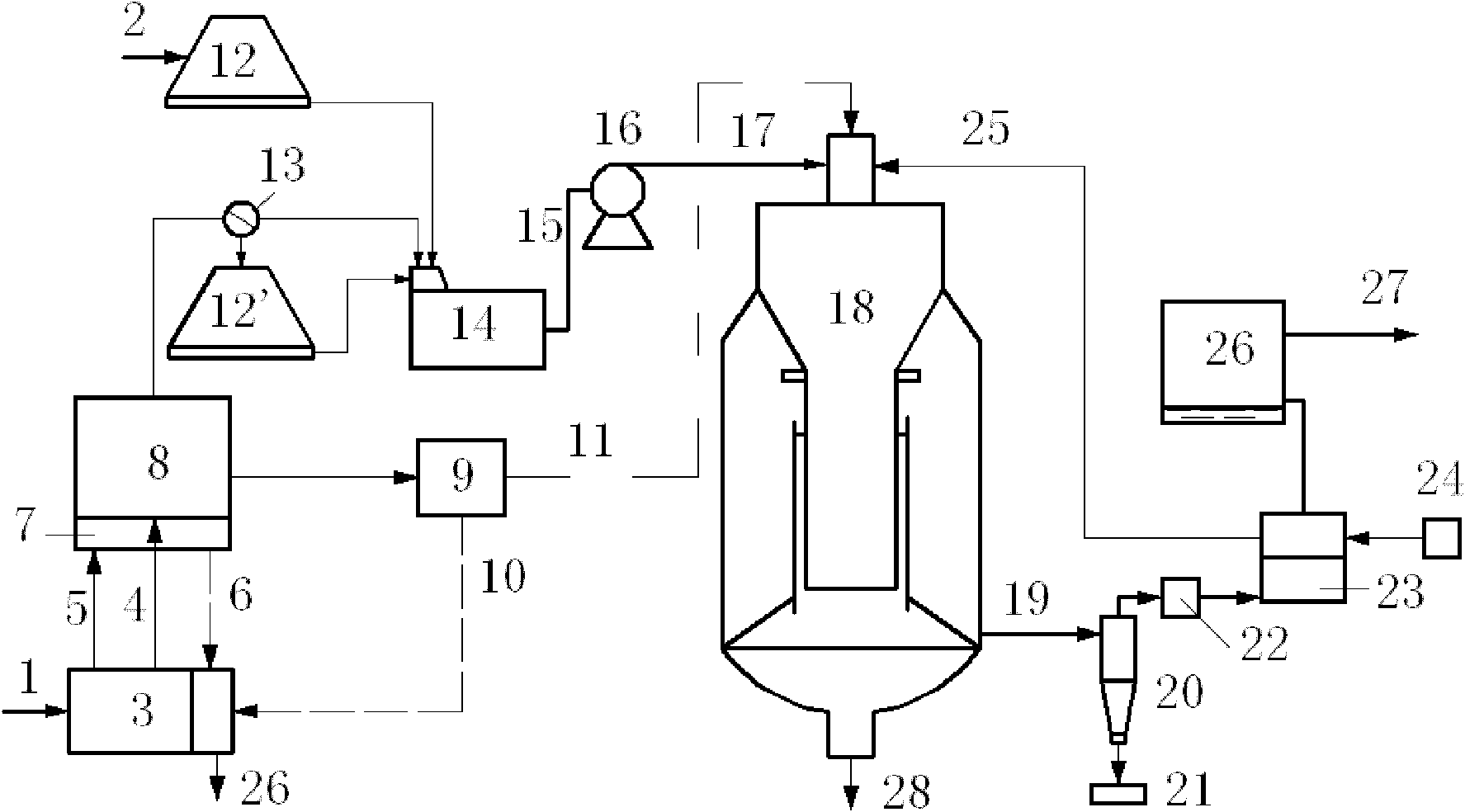

[0020] Such as figure 1 As shown, this embodiment includes: a pretreatment module 1, a coal water slurry preparation module 2, an entrained bed coal water slurry gasifier 3, a purification module 4 and a separate oxygen supply module 5, wherein: the pretreatment module 1 receives the raw material to be treated The material is connected to the input end of the coal-water slurry preparation module 2, the coal-water slurry preparation module 2 receives the biocoke material output from the pretreatment module 1 and performs grinding and pulping treatment, and the output end of the coal-water slurry preparation module 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com